Whatever finishing floor covering is planned for the flooring, it is necessary to create a reliable foundation for it. An excellent solution is a concrete screed, characterized by durability, high strength, relatively low costs and, in principle, simple installation technology. At the same time, it is possible to carefully level the base horizontally or, if necessary, give it the necessary slope, raise the level to the required height, hide communications, carry out insulation and waterproofing.

Light floor screed

But a conventional screed also has a very significant drawback - the significantly higher density of concrete, which leads to a serious increase in the load on the base. There is no big problem if the floor is laid on the ground. But if the work is carried out on the ceiling, and a considerable thickness of fill is required for leveling, then the massiveness of the material can significantly limit the use of such technology, or even make it completely impossible. But this is if we talk about ordinary concrete. In such situations, one solution is a lightweight floor screed. This concept covers several different materials and technologies for their installation.

Features of lightweight screed

The principle of a light screed is to use a filler with a lower density than traditional sand or fine gravel. The usual composition belongs to the group of heavy concrete, where the weight of a cubic meter of solution exceeds 2200 kg. other options may refer to:

- lightweight – 1800-2200 kg/cub.m;

- light – 500-1800 kg/cub.m;

- especially light - within 500 kg/cub.m.

If you still choose a traditional composition, then a cement-sand mixture with grade strength M150 falls into the group of lightweight concrete. Here the density of the screed will be in the range from 1900 to 2000 kg/cubic meter. m. In other words, with a thickness of 500 mm, the coating will exert a load of 100 kg/sq.m. on the base. Test pressure for load-bearing structures and floors is not always appropriate.

Gas-saturated concrete has a lower density. These are porous materials for floor screeds, prime examples of which are block products for the construction of walls with partitions. But due to the cellular structure of the dry residue and the peculiarities of the technological process, such a solution is unacceptable in the case of a screed device.

Structure of porous concrete Source kladka-penoblokov.ru

As a result, the optimal way out of the situation is to partially or completely replace the traditional mineral filler with materials with a lower specific gravity. Thus, with the help of most factory mixtures, it is possible to prepare a working mixture, the mass of which will be almost 2 times less than the cement-sand mortar. There are samples with an indicator that achieves a 4-fold reduction in the weight of the screed.

Specifications

In most cases, factory-made light screed mixtures produce a leveling coating with a compressive strength ranging from 1 to 15 MPa. With such indicators, in the future it will be necessary to form a more reliable finishing layer. It is needed to distribute the localized load across the entire floor to avoid destructive processes.

Consequences of violation of floor screed technology Source recn.ru

Reducing the density of the screed entails an improvement in the properties of the screed regarding acoustics and thermal conductivity. There is also a positive effect of the lightening filler on:

- water absorption, and therefore frost resistance;

- consumption of materials due to volume, for example, expanded clay gravel;

- productivity (the limit on the thickness of the layer is 300 mm, which allows, as a rule, to level the rough base in one go).

In the thickness of the coating, you can freely extend pipe utilities and electrical wiring, and lay “warm floor” systems of any type. In the case of the latter, there is an additional advantage. Unlike traditional concrete, lightweight floor screed has a greater heat capacity, which means the level of heat loss through the floors is reduced.

General recommendations

High-quality self-leveling floor.

Experienced builders advise:

- in the room where the foundation will be poured there should be no drafts, moisture and temperatures below +15 for about two weeks;

- Do not try to mix dry powder with water by hand, be sure to use a drill;

- It is not advisable to paint the self-leveling surface or leave it uncoated for a long time, so after grinding the surface is covered.

Selection of materials

Craftsmen have different opinions regarding the optimal choice of materials. Some believe that it would be more practical to make floor screed from factory mixtures. The main justification is the technical calculations and laboratory studies carried out by the manufacturer regarding the composition and proportions of the ingredients used.

Example of a mixture for a lightweight floor with reinforcement Source prom.st

From such solutions it is known what indicators can be expected in the end. Other builders prefer to independently select components, which allows them to control cost estimates and the safety of materials. It is also easy to find information about recommended recipes that have already been tested by time. In any case, the final choice is the decision of the home owner.

Ready-made mixtures for pouring screed

On the construction market, ready-made screed mixtures are presented in a wide range. They differ in composition, quality and technical characteristics. Let's consider the properties of the most popular samples that are used to install lightweight types of floor screeds using “wet” technology.

Vetonit Light floor

The basic components of the material are cement and expanded clay filler after crushing (the average fraction is 8 mm). The material exhibits good adhesion and strength when leveling concrete and wooden floors. The density of the screed declared by the manufacturer after drying is 700-900 kg/cubic m, which depends on the degree of compaction of the working mass. The compressive strength of the coating is in the range from 3 to 5 MPa.

Working version of a solution with expanded clay filler Source prom.st

When working with such a composition, it is important to comply with a number of technical requirements:

- operation is permissible only indoors, regardless of its type;

- You can fill the screed when the thermometer readings are above +10 degrees Celsius, but +15-+20 degrees are considered optimal (this applies to the air condition in the room and the base);

- For uniform drying of the formed coating, the subfloor must have a humidity of at least 90%.

Among the technical properties of “Vetonit Light Floor” the following stand out:

- shrinkage of the solution as water is drained does not exceed 0.5 per meter;

- thermal conductivity indicators allow the material to be used for insulating flat roofs;

- the thickness of the formed screed can range from 30 to 300 mm.

To prepare a solution for a mixture from a package weighing 12.5 kg, you will need 3-3.5 liters of clean water. Its temperature should not exceed + 35 degrees Celsius. The working time of the mixture, during which the evenness of the screed can be adjusted, is 30 minutes. It is permissible to walk on the floor after 12 hours. The consumption of dry mixture at a minimum thickness is approximately 24 kg 1 sq.m. The shelf life of floor screed material after packaging is limited to 6 months.

Founds Innoline T-34

A mixture based on cement and gravel expanded clay is characterized as a good thermal insulator with high strength.

Light screed from Osnovit Source teplosnab.su

See also: Catalog of companies that specialize in finishing materials and related work

This material differs slightly in its characteristics from its analogue such as Vetonit Light Floor. A layer 30-300 mm thick is also formed here. Only here it is allowed to lay laminate, solid and parquet boards, and facing tiles on top of the screed without reinforcing the floors. This is justified by the higher compressive strength (15 MPa).

Other characteristics of the Osnovit Innoline T-34 mixture are as follows:

- the mixture consumption per square meter of floor with a layer of 10 mm is 10-12 kg;

- the temperature of the base and air during operation should be between +5 and 30 degrees Celsius;

- the working time of the solution is limited to 30-40 minutes;

- for a bag of mixture weighing 30 kg, 9.6-10.8 liters of clean water at room temperature are required to prepare the solution;

- The shelf life of the packaged material is 6 months.

You can walk on a light screed 24 hours after pouring. The material is used to level the floor, soundproof it, and insulate it. Since the composition is resistant to high humidity, work can be carried out indoors, outdoors and on a flat roof.

Prospectors Ecolight

Eco-friendly material for interior and exterior work is also made on the basis of cement and expanded clay.

Prospectors Ecolight Source cloudinary.com

But thanks to a complex of modifying additives, it differs in basic characteristics. It looks like this:

- dry mixture consumption for a minimum layer of 30 mm is 30-33 kg/sq.m;

- A 30 kg bag of mixture requires 5.4-6 liters of water;

- the working time of the solution reaches 90 minutes;

- the compressive strength of the screed after hardening approaches 10 MPa;

- The shelf life of the mixture in sealed original packaging is 12 months.

After complete drying (28 days), the lightweight floor screed must be additionally covered with self-leveling adhesives with high compressive strength. Floors made of concrete, reinforced concrete and cement mortars can serve as a rough foundation. Walking on the surface is allowed after 1 day.

What is perlite in plaster and why is it added?

Perlite plaster is classified as a special composition - it is used to simultaneously finish and insulate walls. The mixture is porous, which reduces heat conductivity. The binding component is cement, lime, gypsum or a combination thereof. Perlite is of natural origin, so compositions based on it are safe for health.

- Features and properties of the material

- Scope of application

- Types of perlite plaster

- Cement based

- Gypsum based

- Selection criteria for external and internal work

- Making your own mixture

- Recommendations for application

- Surface preparation

- Calculation of the amount of solution

- Application technology

- Errors when working with material

Video description

This video shows how to make a screed using a ready-made mixture with expanded clay filler:

Glims LS

Here, polystyrene foam granules are used as filler.

Granulated polystyrene foam Source prom.st

That is, the material has good soundproofing properties and low thermal conductivity (when compared with traditional screed). The mixture is intended for leveling floors with cement-sand, gypsum, concrete indoors with low and high humidity. Operating temperature conditions range from -50 to +70 degrees Celsius.

The thickness of the leveler can be 40-300 mm. When leveling large areas, expansion joints are not required. Walking on this type of screed is allowed after 36-48 hours. Compressive strength is close to 4.5 MPa (concrete grade M50).

The material is sold in 28 kg bags. Consumption of dry mixture per sq. a meter of screed with a minimum layer averages 32 kg. About 8 liters of water are required for packaging the composition. The working time of the solution does not exceed 120 minutes.

Light screed Knauf UBO

The modified cement mixture is filled with granulated polystyrene foam.

Ready-made leveling mixture from Knauf Source bavariaplus.ru

Preparatory work

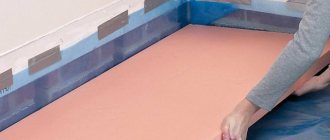

Before making a warm floor screed, you need to select suitable materials and prepare the base. To do this, the remnants of the old finish are removed from the floor covering, so that only concrete remains as a result of cleaning. After this, channels for communications are laid in the base - electrical wiring and pipelines (if necessary, cable channels are used for this).

The next stage is treating the concrete slab with waterproofing mastic or laying a special moisture-protecting membrane. Now you can stick a damper tape to the lower part of the wall, which can protect the screed from cracks and increase the soundproofing parameters of the floor.

At the time of carrying out the preparatory work, suitable polystyrene foam and all the necessary components for preparing the screed must have already been selected and purchased. The base material is usually sold in 170 or 420 liter bags, and the special air-entraining additive SDO (saponified wood resin) is sold in the form of a powder or solution. The presence of SDO allows you to make the insulated floor screed even warmer and easier to work with.

Video description

This video shows the process of preparing a solution for polystyrene concrete screed:

Ivsil Termolite

This composition differs from those listed above in the type of filler. Here the manufacturer uses granulated foam glass. In this way, a cement leveler density of almost 500 kg/cubic meter is achieved. Therefore, the material is positioned as a type of ultra-light floor screed.

The compressive strength of the sample reaches 7 MPa. In this case, the minimum permissible layer is only 7 mm. But when using elastic finishing materials, the limit must be increased by at least 3 mm.

The scope of application of the material extends to both mineral and wooden subfloors. Regarding operating conditions, premises with any level of humidity are considered. It is allowed to carry out work on covered balconies and loggias, verandas and terraces.

Granulated foam glass Source granulin.ru

Paladium Palafloor-307

A mixture of modified cement and granulated foam glass with a fraction of up to 4 mm is distinguished by the minimum density of the screed compared to the samples under consideration. The thickness of the leveling coating can range from 20 to 300 mm. With a minimum layer, the dry mixture consumption is 8-9 kg. The compressive strength of the screed is 7 MPa. The working time of the solution is 4 hours. To prepare the mass, 5.4-6 liters of water are required (12 kg bag).

DIY options

One of the reasons for abandoning factory mixtures in favor of “homemade” ones is the high cost of the former. It is also often necessary to choose the second option due to the lack of the necessary mixtures on trading floors in a particular area and expensive delivery. Let's consider what solutions may be relevant and practical when installing lightweight floor screeds in the house.

Expanded clay

The material is used in fractions up to 5 mm. You can use a dry screed mixture as an alternative. Fired clay has a porous structure, therefore it has good sound insulation and thermal conductivity properties.

Ready-made expanded clay backfill for dry screeding Source pinimg.com

The material is characterized by resistance to changes in humidity, but the granules are destroyed by prolonged contact with water. Resistance to many chemicals and mold and fungi is also observed. As the solution dries, it shrinks slightly when forming any layer.

DIY solutions for light screeds

The use of ready-made building mixtures for light screeds may seem like an “expensive pleasure” to some. Another case is that the necessary compounds are simply not available for sale in your region of residence, and ordering delivery costs a considerable amount.

Well, you can prepare a solution for such a screed yourself. The same cement will be used as a binder, but the filler may be different, depending on which one will be easier and cheaper to obtain. For this the following can be used:

— expanded clay of various fractions;

- expanded perlite sand or vermiculite;

— expanded polystyrene granules;

- sawdust.

Expanded clay as a filler

Expanded clay is granules obtained by firing special types of clay. As a result of this processing, a porous, air-filled structure of the material is obtained, which ensures its low density and insulating qualities.

Expanded clay is a fairly inexpensive material and is very widely used in construction.

Expanded clay is very widely used for the manufacture of finished building parts and structures, for mixing insulation and structural insulation solutions. Its fraction may be different, but the higher it is, the lower the strength indicators of the final structure.

In order for a lightweight screed to play not only a thermal insulating role, but also be able to withstand loads, it is recommended to use expanded clay with a fraction of up to 5 mm for mixing the solution. In principle, expanded clay gravel, which is sold as backfill for “dry screed,” is very suitable for this.

We will not dwell on this material in more detail here - it is comprehensively discussed in another publication.

Expanded clay as a material for coated floor screed

There are several different technologies for insulating and leveling floors using this material. They are discussed with all the details in a special publication on our portal “Do-it-yourself floor screed with expanded clay .

Vermiculite and perlite

Vermiculite is a very unusual insulating material obtained by firing special mica rocks. Under the influence of high temperatures (but without bringing it to the melting stage), the water contained in mica leads to delamination of the crystalline structure, resulting in the formation of a layered air-filled structure with a very low density - only from 60 to 130 kg/m³.

Vermiculite is difficult to confuse with other materials due to its characteristic structure

Vermiculite is very widely used for insulating building structures. It is also quite suitable for mixing solutions under light floor screed. Cement is used as a binder, and the filling is certain proportions of ordinary quartz sand and vermiculite (best with a fraction of 0.6 to 2 mm).

The result is screeds with very good heat transfer resistance, with a total density after full strength gain - from 1000 to 1500 kg/m³ (depending on the proportion of components). It is clear that the higher the density of the screed, the greater its strength characteristics.

“Formulations” of vermiculite concrete of varying degrees of density and strength are shown in the table below.

| Mortar proportions (cement sand vermiculite) | Proportion of components per 1 m³ of solution | Density of the solution, kg/m³ | Strength, kg/cm² | Coef. thermal conductivity, W/m×°С | |||

| Cement | Sand | Vermiculite | Compression | Bend | |||

| 1 / 0,5 / 2 | 495 kg | 247 kg | 865 l. | 1000÷1100 | 45 | 24,5 | 0,25 |

| 1 / 0,75 / 2,25 | 430 kg | 320 kg | 895 l. | 1120÷1180 | 35,5 | 30 | 0,28 |

| 1 / 0,75 / 1,75 | 410 kg | 307 kg | 800 l. | 1210÷1275 | 58,5 | 30 | 0,33 |

| 1 / 1 / 2 | 380 kg | 380 kg | 785 l. | 1300÷1350 | 47 | 30,5 | 0,35 |

| 1 / 1,25 / 1,75 | 365 kg | 455 kg | 740 l. | 1400÷1425 | 66 | 32 | 0,41 |

| 1 / 1,65 / 2,5 | 365 kg | 685 kg | 640 l. | 1450-1550 | 72 | 35 | 0,44 |

The disadvantage of such screeds is that vermiculite has a very high absorbency (it is even often used as a sorbent). That is, such coatings cannot be used in rooms with high humidity, or additionally very reliable waterproofing will have to be provided.

Expanded perlite sand is another material that can be used for lightweight screed filler.

Perlite is a material with similar characteristics, also obtained by firing rock. But only volcanic glass acts as a raw material.

It usually goes on sale in the form of sand, with a fraction rarely exceeding 0.5 mm. The density is markedly low, up to 150 kg/m³. Widely used, for example, for the manufacture of warm plasters. It can also be used for light screeding, but it has not gained much popularity in this “field”. Apparently, because perlite sand is quite inconvenient to work with due to its extremely pronounced “volatility”. It is very dusty, and if there is even a slight breeze, then this turns into a very serious problem. When working with it, be sure to use eye and respiratory protection.

Expanded polystyrene granules

This material, on the contrary, can be classified as the most popular for creating lightweight screed mortars. It is inexpensive, sold in bulk bags, and very light. It goes on sale under different names (“Politerm”, “Polyston” and others) or without its own name at all. This doesn't change the essence. In any case, these are granules, that is, light, 90% air-saturated balls with a diameter of 3–5 mm.

Packages of polystyrene foam granules of 0.5 m³ each. And the weight of such a bag is only 5–6 kilograms.

Ready-made self-prepared solutions after hardening can be either purely insulating (with a density of 200÷300 kg/m³) or insulating-structural (400÷500 kg/m³). This is quite enough for a screed, which will either be covered with ceramic tiles on top, or will be covered with a strong leveling filler 25÷30 mm thick.

To mix polystyrene concrete with the indicated density indicators, you can do without sand. The ingredients used are:

- Portland cement PC-400 as a binder.

- Expanded polystyrene granules.

- Water. Its balanced amount in this case is extremely important, otherwise the resulting polystyrene concrete simply will not show the expected strength values.

- An obligatory component is a special air-entraining foaming additive - saponified wood resin (abbreviated as SDO). Its proportions, including taking into account the concentration, must be strictly observed.

Saponified tree resin can be ready for use or sold in the form of more concentrated solutions.

In this case, before use, it is brought to the required 50% by diluting it with water. Preparation of the solution presents some difficulties. The fact is that an ordinary gravity concrete mixer will not be a good assistant in this matter - due to the excessive lightness of the filler, which will constantly strive to float to the surface. This means you will have to either use a forced-action mortar mixer, or mix it in a separate capacious container using a hand-held construction mixer.

Below is a calculator that will help you correctly calculate the proportions of ingredients for preparing polystyrene concrete of various densities. When working with a calculator, you should correctly understand one important nuance:

One of the initial parameters for calculations is the area of the room. When you enter it, the result of the calculation will show how much materials you need to purchase to fill a light screed in the room.

But it is hardly possible to prepare such a quantity of solution at once, due to the reasons already mentioned above. Therefore, it is advisable, after the general calculation, to also carry out a “local” one, corresponding to one batch, based on the available capabilities. For example, this could be a one-time preparation of polystyrene concrete for an area of, say, 2÷3 m². That is, based on the planned thickness of the screed and the available containers for preparing the solution, it is easy to determine the “golden mean” that will suit you from all points of view. And based on this area, which the one-time prepared mixture will cover, it will not be difficult to obtain the exact “dosage” of all the necessary components - cement, polystyrene, water and SDO.

Briefly about the main thing

A light floor screed is a layer of cement-containing leveler, which contains fillers with a lower density than sand or traditional gravel.

Among the advantages of lightweight screed are light weight, good sound insulation and low thermal conductivity.

As an alternative to sand and gravel, expanded clay, expanded polystyrene and foam glass granules are used for the production of factory mixtures.

To partially or completely replace sand and gravel when preparing solutions for light screed yourself, you can also use vermiculite, perlite and sawdust.

When using any material, it is important to take into account the low mechanical strength of the screed.

Ratings 0

Floor preparation

First of all, the floor is checked for the presence of cracks and cracks that formed during construction work. The cracks are first sealed with a special solution. It comes with instructions for dilution and preparation, apply to the floor and spread the solution with an iron spatula.

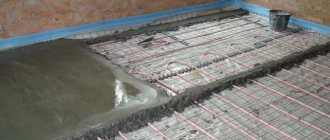

Performing a screed

Next, they check with a level, since in many cases the floor surface is not ideal. To ensure that the solution does not change when it dries, a specialized self-adhesive damper tape is laid along the perimeter of the walls, and the surface is naturally primed.

Advantages of expanded polystyrene concrete

In the production of polystyrene concrete, various additional components can be used, but it is the combination of concrete and polystyrene granules that gives the material valuable qualities for construction - strength, resistance to rotting, fire safety. Advantages of expanded polystyrene concrete:

- good heat and sound insulation properties;

- belongs to the group of low-flammable materials G1;

- plasticity sufficient for the manufacture of window and door lintels;

- high structural strength;

- light weight and ease of handling;

- frost resistance;

- wide scope of application.

An important advantage is the ability to independently prepare polystyrene concrete, for example, for insulating floors and roofs.