How and with what to tie the reinforcement? At first glance, it seems that the answer to this question is simple. We take a soft annealed knitting wire, a hook and get to work. But the experience of users of our portal suggests that even in such a simple matter there are a lot of nuances, starting from the choice of wire diameter and ending with the method of binding. However, these “little things” directly affect the speed of work and final costs. So, from this article you will learn:

- Is it profitable to tie a reinforcement cage with a battery-powered knitting gun?

- How to make a homemade hook for tying reinforcement.

- How to learn to crochet reinforcement.

Strip foundation in private construction: features and limitations

The basis of the strip foundation is concrete. This material was widely used as a basis for the construction of buildings back in Ancient Rome. And only 200 years ago they figured out how to increase its strength using a frame made of steel rods. A new building material, reinforced concrete, combined the advantageous characteristics of metal and concrete and made it possible to build impressive structures. The process of placing a metal frame in concrete began to be called reinforcement.

When a country house is being designed, a strip foundation is most often chosen as the basis for it. The preparation of a strip base (like any other) takes 25-30% of the construction cost; the reason for its demand is a successful combination of qualities:

- Simple in design.

- Suitable for projects with basements (unlike the pile-screw analogue) and heavy floors (reinforced concrete, monolithic).

- Does not require the use of special equipment.

Strip foundation in formwork Source profundamenti.ru

Despite its wide distribution, strip foundation also has limitations in use:

- Beneficial only on dry and rocky soils.

- Not suitable for installation on problematic (wet, heaving, peaty) soil; it will have to be poured to great depth, which is unprofitable.

The shape of the strip foundation is determined by the layout; it has a closed shape and is laid along the entire perimeter of the house, under load-bearing walls and internal partitions.

Strengthening the foundation - what is it for?

A well-designed and high-quality foundation is a guarantee of the durability of the structure. A strong, indestructible base will prevent shrinkage, which causes cracks and subsequent destruction of the structure. Therefore, strengthening the foundation is a serious issue that cannot be treated superficially. Increasing the strength of the foundation is achieved by reinforcing the structure with metal mesh or rods of a certain diameter.

Should the reinforcement for the foundation be welded or knitted - this is the main question that many people think about

For low-rise buildings, a strip foundation is most often installed. You can save money and fill the foundation with regular concrete without additional reinforcement. Most likely, after some time, cracks and deformations will appear in the foundation. To prevent undesirable consequences, carry out reinforcement work with a steel frame that:

- Increases strength.

- Evenly distributes the load.

- Compensates for soil reactions during freezing.

- Will increase the service life of the structure.

Reinforcement in concrete will protect the foundation from cracking and destruction.

Prerequisites: why reinforcement is needed

The foundation is created in order to withstand the load of the structure; It works best with evenly applied pressure. But in practice, the load is too often uneven and internal stresses arise in the foundation. The reason may be both changes in the soil and design miscalculations (unequal weight of individual parts of the structure).

Design errors will definitely become noticeable Source homeklondike.site

Concrete has excellent resistance to axial compression and weak resistance to tension. Reinforcing bars have natural plasticity and compensate for the lack of concrete. The latter, in turn, protects the metal from corrosion.

During operation, concrete (which resists compression) and metal (tension) are able to most effectively resist multidirectional loads, protecting the structure from destruction. Correctly carried out reinforcement not only increases strength, but is also a means of saving: it allows you to reduce the cost of concrete (reduce the massiveness of the foundation).

About “outdated” standards

At various sites, the dominant opinion is that the old Soviet standards of the 60s of the last century, which recommended installing foundation frames using welding, cannot work in modern realities. But it is not clear that the proponents of such statements saw something new and ultra-modern in knitting reinforcement with wire, forcing one to abandon the use of welding. They probably forgot that reinforcement was invented in the mid-19th century, when welding was only a dream. All reinforced frames were then tied together, but only a hundred years later they began to be welded. But then it turns out that Soviet welding standards and technologies are an unimaginable progress, but not a routine, and knitting a frame with wire is a completely backward old-fashioned technology.

Building codes and the standards created on their basis are based on practice, often negative and even tragic.

Today, there is a tendency for many work producers to reject Soviet standards; they prefer to be guided by information from the Internet and personal experience. Both may be of very dubious quality, but while making money, foremen have no time to monitor the updating of construction regulations. And they are constantly updated.

Not only rods with additional marking “C” are welded (the reinforcement is suitable for welding), for example, A500C. You can weld A240 and A400 reinforcement. Before inclusion in 2021 changes in GOST 14098 allowed welding of heat-strengthened metal At. But after welding, the heat strengthening disappeared, so the At brand is not used in the new edition of the standard.

Reinforcement requirements

The strip foundation is laid with a margin of safety; it must be resistant to external factors (mechanical and climatic). How to correctly knit reinforcement for a strip foundation is described in the provisions of SNiP 52-01-2003, which contain detailed requirements for design and materials. There are a number of requirements for fittings:

- The placement of the reinforcement cage should not interfere with the correct technological pouring of concrete.

- The reinforcement is installed with a given design step.

Calculation of the spacing of clamps when reinforcing a corner Source ep2nnov.ru

- At frame intersections, floating (movable) connections of rods are not allowed using any connection method.

- It is necessary to create a protective anti-corrosion layer for the structure.

- Replacing the type of load-bearing rods is allowed if the calculated load-bearing capacity remains the same.

See also: Contacts of construction companies that offer foundation repair and design services

Why should you choose such a device?

A professional tool is the key to a high-quality result that will last for many years.

The main advantages of using a knitting gun are:

- High quality wire knots.

- Operative pace of work.

- Easy replacement of wire cassettes.

- Scope of work – 1 person can do the work for a small team.

- Fairly light weight.

- Possibility of knitting multi-layer knots.

- Adjusting the stretch marks makes the frame more durable.

- Pull tightly.

- Continuity of work during the shift due to a powerful battery.

Expert opinion

Torsunov Pavel Maksimovich

Of course, any tool also has its drawbacks. In particular, for a knitting gun this is a high price, the need to spend money on wire cassettes and inconvenience when working in cramped conditions.

Materials and tools used for reinforcement

Since the reinforcement cage increases the stability of the structure by taking on a significant part of the load, its quality becomes fundamental. The frame is formed from interconnected reinforcing bars. Various are used for knitting the frame:

Types of fittings

Manufacturers offer fittings that can be divided into:

- Material of manufacture. Steel reinforcement is a classic, time-tested option; It is divided into 6 strength classes, it can be bent and welded. Composite reinforcement contains carbon, basalt, glass or aramid fibers. It is lighter, cheaper, does not corrode, does not bend and cannot be welded.

Reinforcement with a periodic profile has improved characteristics Source yar-limb.ru

- Profile. Reinforcement with a smooth profile is more often used as connecting jumpers. Reinforcement with a periodic profile has a relief surface, which improves adhesion to concrete.

Connection materials

Knitting of reinforcement for a strip foundation, the pattern of which can change, is done using:

- Knitting wire. Reliable and common knot connection technology. There are different knitting patterns.

- Threaded and crimp couplings (at mechanical joints).

- Metal paper clips. The reinforcement elements are connected without tying a knot.

- Plastic clamps and clips (fasteners). Plastic products provide simple and quick installation and are resistant to corrosion. Their use is not approved by all professionals.

Composite reinforcement bars secured with a clamp Source 1-detective.ru

- Welding. The process is fast, but the welds form a rigid connection, differ in density from the base metal and are susceptible to corrosion. When the load changes, they burst and reduce the strength of the foundation. The method is suitable for connecting rods of large diameters (in industrial facilities); To obtain a high-quality weld, you need a highly qualified welder.

Pros and cons of foundation components

Concrete is a special building material that, after mixing, acquires a fluid structure and hardens some time after being poured into formwork. On its basis, various supporting structures (foundations) are made. After hardening, the fluid material acquires the following properties:

- strength;

- durability;

- ability to withstand heavy loads;

- resistance to temperature fluctuations.

When studying the problem, you will have to take into account the negative properties of the concrete material, the main one of which is good hygroscopicity (the ability to absorb moisture). Therefore, when arranging foundations, the base immersed in the ground and the part adjacent to the ground (base) are subject to waterproofing, protecting the material from direct contact with the ground. This is also done because in winter, when freezing, moisture expands and can tear the concrete pour from the inside.

An example of installing roll waterproofing before reinforcing a slab foundation.

Another significant disadvantage of concrete is the dependence of strength indicators on the direction of the loads acting on it. While withstanding significant direct pressure, this material does not work well when stretching. The latter means that the poured concrete strip is able to withstand high external loads. At the same time, internal stresses emanating from the center outward can destroy it over time.

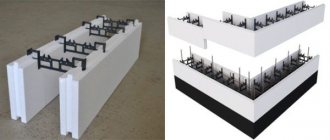

Requirements for reinforcement cage parameters

The rods that make up the structure differ in purpose:

- Working fittings. This is the name given to the longitudinal horizontal rods placed along the foundation strip.

- Clamps. They are divided into transverse horizontal and vertical, connecting the frame into a single whole.

The reinforcement frame of the foundation in private construction often has the following parameters:

- Fittings. Metal or composite, with a cross-section of 11-14 mm (for a small outbuilding), with a periodic profile and a cross-section of 12-18 mm (for reinforcing a strip foundation).

An example of how to knit foundation reinforcement with transverse clamps Source massimo.spb.ru

Methods for connecting reinforcing elements

There are various methods to increase the strength characteristics of the foundation. Private developers use any available material (waste metal, broken glass, etc.). For country houses this is an acceptable option. But to build a reliable house, even a one-story one, use proven technologies for strengthening with metal mesh or rods. If your choice is a mesh, then you only need to cut it correctly and install it properly in the prepared trenches. The use of metal elements implies the creation of a single structure from them, the so-called frame.

It is worth knitting reinforcement in cases where you need to get a good foundation on difficult soil

There are two ways to achieve this:

- tie using flexible wire for connection;

- apply welding to fix the structural elements.

Both options have strengths and weaknesses. Let's conduct a comparative analysis of each of them.

Video description

How to properly crochet reinforcement in the video:

Calculation of the amount of consumables for tying reinforcement

The amount of material (in linear meters) is calculated based on:

- Foundation parameters (length, width, depth)

- Reinforcement schemes (number of layers and longitudinal rods in width)

Most often, reinforcement material is sold not by linear meters, but by kilograms. There are special tables for converting values. Plastic fittings are often sold by linear meters.

Scheme of strip foundation reinforcement Source kamtehnopark.ru

Reinforcement knitting pattern, corner reinforcement

The correct knitting of reinforcement for a strip foundation, optimal in many respects, is a “cage” connection of the reinforcing frame rods. In this case, the rows are secured with wire (or other chosen method) at an angle of 90°. The knitting pattern consists of several sequential operations:

- A fragment 25-30 cm long is cut from a coil of knitting wire (for rods with a cross-section of 8-16 mm).

- The wire is bent in half and placed under the overlap of the rods, placing it diagonally.

- The hook is hooked onto the loop (the place where the wire is bent), the opposite end of the wire is circled over the intersection of the rods and placed above the hook.

- By rotating the hook around the upper end of the wire, a twist of 3-4 turns is created.

- The hook is removed, the ends of the wire are bent inside the structure.

Video description

About the intricacies of reinforcement in the video:

The corners of a strip foundation cannot be reinforced by simply overlapping the rods; This is considered a gross violation of technology. To reinforce the corners and connect adjacent linear elements with them, bent rods are used; the corner fragment is reinforced with L-shaped or U-shaped anchors.

Rods laid at the corners of a building without bending, at right angles, are unable to create a rigid structure. Such sections of the foundation are highly likely to be subject to destruction in the future.

Reinforcement of corners requires compliance with technology Source zen.yandex.ru

Reinforcement technology: execution order and features of the stages

The frame for the future foundation is calculated and installed based on the dimensions of the trench, using working reinforcement and auxiliary wire. Its parameters are calculated in advance, taking into account the expected load; It is convenient to assemble the structure on a long workbench. Installation of fittings takes place in stages:

- Vertical elements (clamps) are assembled. The vertical position of the rods is checked using a plumb line.

- The lower horizontal belt is mounted. The lower belt works to deflect the foundation downwards. It is attached with a knitting wire to vertical clamps.

- The upper horizontal belt is mounted. Its task is to resist the upward bending of the foundation strip.

- Corner elements are mounted. They need to be given special attention because they connect the sides of the foundation. Additional rigidity is provided by additional vertical posts, which are laid twice as often.

- The formwork for the foundation is being prepared.

Installation of a linear fragment of a reinforcing frame Source beton-house.com

- The prepared reinforcing frame is being laid. During the installation process, pipes are laid between the reinforcement bars (the utility and ventilation systems will subsequently be laid through them).

- Concrete is poured. Filling is carried out in several stages, with each layer leveled (manually or with a vibrating platform). This technology ensures uniform distribution of the concrete mixture.

- The foundation is being waterproofed. After the concrete has dried, the foundation strip is covered with bitumen mastic or roofing felt. This operation is an important measure to preserve the foundation.

If the frame is assembled in a trench, rods are first driven into the ground, observing the calculated distances. Transverse jumpers, lower and upper reinforcing belts are fixed to them.

Boil or knit: which method to choose?

Careful consideration must be given before making a final decision about whether to use ties to fasten steel bars or fasten them by welding. Why do some builders weld reinforcement while others knit it? Each method has its own advantages and weaknesses.

To avoid mistakes, you should listen to the advice of professionals:

- For massive multi-story buildings that place a significant load on the foundation, it is advisable to use welding. At the same time, it is important not to burn out the reinforcement, so as not to weaken the strength of the connection;

- for small residential buildings and country houses, you can use the connection of parts of the reinforcing lattice using knitting wire. This method of fixation ensures the strength of such buildings.

When using welding, it is important to eliminate the possibility of burnout, which weakens the strength of the joints. It is undesirable to use the welding connection method in seismically active zones, as well as on problematic soils, where the integrity of the foundation may be compromised as a result of soil displacement.

However, welding has a number of advantages:

- allows you to perform work at an accelerated pace;

- provides increased rigidity of the space frame;

- increases the load capacity of the base.

When constructing private buildings, it is better to use the knitting method. Advantages of this method:

- ease of implementation and no need for special equipment;

- the ability to perform work without the involvement of qualified specialists;

- absence of increased stresses in the joining areas.

The disadvantage of the knitting method is the insufficient rigidity of the reinforcement grid. However, when constructing light buildings, this drawback is not significant.