Many years ago, during the times of the Soviet Union, construction experts advised using paper or ordinary newspaper sheets as the first layer before gluing trellises. Such a backing for wallpaper improved adhesion to the wall and slightly increased the temperature of the walls, which was especially noticeable in the cold season.

Today, the range of substrates has increased significantly. And their main task was heat and sound insulation. This is especially true in new buildings with thin walls. The second is to hide uneven walls or even stains on them. This way, contaminants will not appear on wall surfaces. It is also important that any type of substrate will protect against the formation of fungus and mold; it consists of two layers of paper, between which there is another material. Let's consider its main types.

Purpose

The substrate is foamed polyethylene, covered on both sides with paper. In addition to paper, cork or non-woven backing is sometimes used, which have received excellent reviews from customers. This is an excellent material that has a high level of sound insulation and is a thermal insulation coating. The backing is designed for pasting any type of wallpaper directly onto it.

It has a number of advantages:

- it is durable;

- environmentally friendly;

- not susceptible to microorganisms;

- does not absorb moisture and prevents condensation from appearing on the walls;

- soundproof (has a high level of sound insulation).

Thermal and sound insulation are the main advantages of this material

It should be said right away that before gluing the substrate you need to know how to glue it correctly. First you need to prepare the walls. They need to be freed from old wallpaper. Old paint is also removed, and cracks and pits are leveled using putty or cement mortar. The surface is primed; PVA glue or any other wallpaper glue is suitable for this purpose.

The day before pasting the walls, you need to cut the material into pieces according to the size of the walls, let it rest and level out. Smooth sheets should be coated with glue on the inside and allowed to stand for five to ten minutes. Glue is used for gluing polystyrene or heavy wallpaper. The process of gluing the backing is similar to wallpapering. The same technology, only the sheets must be glued end to end.

Removing air bubbles from under the surface is done with a rubber roller. The seams must be sealed with paper tape or narrow paper tape. The next step is to wallpaper the walls, but you need to let the backing dry for at least 1-2 days.

The practicality of the substrate lies in the fact that it does not change its properties for twenty years (some manufacturers guarantee fifty years). This allows you to use the substrate for several repairs, covering it with new wallpaper. This insulating material will protect rooms from the effects of fungus and condensation for several decades, will increase soundproofing and heat transfer, and this will be especially noticeable in those rooms whose walls face the street or common corridors. In addition to all that has been said, the substrate also acts as a leveling material for uneven walls.

Advantages

Building materials intended for rough finishing of partitions simplify the process of gluing wallpaper. In addition, they increase the level of comfort in the room. Some craftsmen also use a backing for decorative work.

Along with the main advantages, the canvases have a number of advantages:

- strength. Resistance to mechanical damage is implied. Thanks to its elasticity, it is invulnerable to tearing;

- made from natural, environmentally friendly raw materials;

- blocks the formation of fungus and mold. Prevents the spread of insects;

- long service life;

- aesthetic appeal that allows you to create comfort;

- the substrate belongs to the budget price segment.

How to glue correctly

When gluing with a thick backing, use glue designed for heavy wallpaper. The underlay is used to insulate walls. It insulates concrete walls especially well, which do not have good thermal insulation, and adheres well to almost all building materials (plasterboard, wood, plywood, concrete), as many buyers say in their reviews.

Pasting can be done with your own hands: this work is no more difficult than wallpapering; final treatment of the walls with putty is not required, since the material itself smoothes the walls. You will forget what mold and dampness are.

Before gluing, cut the roll into sheets, the length of which will be equal to the height of the walls, and straighten them by placing some weight. When gluing the next sheet, do not apply glue to the joints, otherwise the glued sheet may stick to the next one, and the seam will turn out uneven. After gluing, carefully seal the seams between the sheets with paper tape or paper tape. This will allow you to better even out the unevenness of the wall, and the wallpaper will look better. Before gluing the wallpaper, make sure that the backing is thoroughly dry and free of voids caused by air bubbles appearing under the backing.

Polifom is a fairly popular brand

It is enough to paste over the backing once and you can change the wallpaper several times without changing it. Before pasting, several conditions must be met:

- Do not glue the substrate at a temperature lower than plus ten degrees and a relative humidity of seventy percent. Failure to comply with these factors will result in the quality of the pasting suffering and in some places it will not stick at all. Therefore, when pasting walls, at a time when the heating is not yet working (in autumn), or it is not yet warm enough outside (in spring), it is necessary to use heaters to maintain the temperature parameter. Or wait for suitable weather.

- Before pasting the wall, it is necessary to treat it with the glue that you will use to glue the backing.

- Immediately before gluing, coat the substrate with glue and wait ten minutes. After gluing the backing, avoid drafts for at least a day.

Drywall, OSB and plywood

If the walls have strong unevenness, then in order to hide them, it is necessary to use more serious types of substrates. They can be sheet materials with a width of 4 mm or more:

- drywall;

- plywood;

- OSB boards.

These types of materials will easily hide the imperfections of the walls, but to apply them you will need to build a frame on which they will rest. To construct it, you will need rectangular beams (logs) with a cross-section of 2x4 cm. If the surface has strong convexities, then their dimensions can reach up to 5x5 cm.

The beams are attached to the wall in the form of a lattice using screws and dowels. First, vertical logs are laid; they should be positioned so that when installed, the panel covers half of its width. Next, horizontal bars are applied; they must be placed between the vertical ones. The distance between horizontal joists can vary from 0.3 to 1 m, depending on how wide the bulges in the wall are.

Instead of wooden beams, you can use a U-shaped aluminum profile.

Next, sheets of material are placed on the logs. They are fastened using 16–19 mm self-tapping screws. The distance between the screws should be approximately half a meter, but no more, since if the fasteners are set too widely, the substrate may begin to “walk.”

After the panels are securely fixed to the wall, it is necessary to work out the joints so that they do not show through under the wallpaper. This can be done using putty.

Advice

Putty can create additional unevenness, which is why the joints can stand out, especially on light-colored wallpaper without or with a weak pattern. Therefore, it is recommended to combine the panel backing with other types, for example, paper.

You can also increase sound and heat insulation by filling the cavities between the wall and the substrate. This can be done using polyurethane foam. To do this, you need to make two holes in the panels in the space between the joists with a 6 mm drill. They should be located at the top corners of the empty space. Next, you need to pump foam into one of them. This must be done until the foam flows through another hole.

After sealing, you need to wait a day and then close the holes with putty. This solution will preserve heat and prevent extraneous sounds from entering the room.

Main manufacturers

Before you start looking for where to buy underlayment, you should keep in mind that different types are made by different manufacturers. They differ in the thickness of the material, the quality and colors of the paper, and also in the selling price. We list the main brands offered for sale in Russia and the CIS countries:

Diagram showing the main advantages

To ensure that the subsequently pasted wallpaper does not change color or tone, you should choose a backing with white paper, since gray can appear on thin and light-colored wallpaper.

Like wallpaper, the backing is sold in rolls fourteen meters long and half a meter wide.

Benefits of use

It is worth knowing some features of the use of the substrate and its advantages:

- Do not use the underlay in rooms with high humidity (bathroom, bathhouse).

- If there is already fungus on the walls, then you should not glue the substrate on it; first, ensure the complete destruction of fungal formations mechanically or with chemicals.

- Any gaps that appear between the sheets of backing can be sealed with paper strips adjusted to the size of the gap and PVA glue.

- Wallpaper underlay is not an ideal panacea for noise; there are more effective materials for sound insulation, but their installation requires special fastening, and they have a thickness of three to fifteen centimeters. This is where the substrate wins: it is an inexpensive material, easily sticks to the walls, and the work can be done by an unskilled person.

- Thanks to the materials used in the backing, it is easy to cut and the paper backing is easy to glue.

- The material is odorless, does not emit dust into the air, is environmentally friendly, can be used in children's rooms, and is absolutely harmless to human health.

- The ability to increase thermal insulation in places where the walls have low heat-insulating properties: dachas, block houses.

Criterias of choice

Which type is best to choose for internal wall insulation will depend on a number of factors related to the circumstances and wishes of the home owner, including:

- the degree of thermal conductivity and noise absorption that they hope to achieve;

- the usual level of humidity in the room where the walls are covered with wallpaper with a backing;

- the home owner’s willingness or unwillingness to accept the fact that the walls will be soft to the touch;

- the susceptibility of apartment residents to chemicals used for finishing that can cause an allergic reaction;

- financial capabilities of the owners.

Benefits of use

Wallpaper backing structure

Wallpaper backing structure

The wallpaper backing is made of foamed polyethylene, covered on both sides with paper, non-woven fabric or cork:

| Photo | Name |

| Paper | |

| Non-woven | |

| Cork |

I do not recommend using paper backings in rooms with high humidity, as paper does not tolerate moisture well. Non-woven or cork products are better suited here.

Non-woven backing for wallpaper is better suited for rooms with high humidity than paper

The backing is glued to the wall, and wallpaper is applied on top of it:

Scheme for gluing wallpaper in case of using a backing

This approach to finishing work has its advantages:

- Increases the sound insulation of walls . Complete silence, unfortunately, cannot be achieved, but some of the noise coming from the neighbors can still be stopped;

A soundproofing layer under the decorative trim will make your stay more comfortable

- Provides uniform absorption of glue , thereby eliminating the appearance of bubbles that spoil the appearance of the finish;

- Partially levels the base. Small cracks or chips will be covered;

The substrate hides all minor imperfections of the finished surface

- Makes it easier to apply decorative coatings yourself. This especially applies to corners and joints;

I recommend gluing only thick thick wallpaper over the cover, since it can show through through thin ones.

- Reduces the thermal conductivity of walls . The room will be warmer in winter, and cooler in summer;

Walls with a backing under wallpaper become warmer

- Strengthens adhesion . Wallpaper sticks better to paper than to concrete, brick or plaster;

- Increases the service life of decorative coatings.

Application Features

The instructions for applying the substrate are very simple, just follow a number of rules:

- Remove any remaining old trim and loose pieces of plaster. Fill large cracks and chips with putty;

The wall before facing should be as clean as possible and free from damaged areas.

- Prime the wall before gluing the wallpaper under the backing;

The primer will ensure maximum adhesion of the substrate to the wall

- Cut the roll into sheets of the required sizes in advance;

All substrates are very easily cut into fragments of the desired dimensions

- Make sure the room temperature is around +10 degrees Celsius . At a lower temperature, the glue will not be able to gain sufficient strength; at a higher temperature, it will dry out too quickly, not having time to fix all areas of the finishing fabric;

- After applying the glue to the substrate, wait a few minutes until it is well absorbed, and only then apply the canvas to the wall. It is best to use PVA for this purpose, rather than ordinary wallpaper adhesives.

The backing sheet is applied a few minutes after treating its back side with glue.

Is it possible to repaint such wallpaper?

Paper and non-woven fabric are painted up to 5 times, fiberglass and vinyl 10 or more. Before repainting, remove dust from the walls and wet clean the coatings.

Thin wallpaper sometimes shows through. Before gluing light, smooth coatings, it is recommended to prime the walls well and apply a finishing layer of plaster. If the wallpaper is already hung, the paint should be selected with a high hiding power or several layers of coating should be made.

Paper and non-woven fabric are painted up to 5 times, fiberglass and vinyl 10 or more.

Knowing the criteria for choosing wallpaper for painting, it is always easy to modernize the interior, which will retain its decorative effect and will advantageously emphasize the stylistic features of the room design. When the interior becomes boring, it will be enough to renew the paint layer on the wallpaper. You can change the color palette of rooms, classrooms, offices without extra effort and expense. When using durable options, the cost of purchasing wallpaper will soon pay off.

Offers from manufacturers

All prices in the article are current in the summer of 2021.

All substrates have the following qualities:

- Environmental Safety . They do not emit any harmful substances, so they can be used in places where children and allergy sufferers live;

- High insulating properties . Despite the small thickness, not exceeding 5 mm, the glued sheets increase the thermal insulation and sound insulation of the walls;

- High strength characteristics . The material does not tear during gluing.

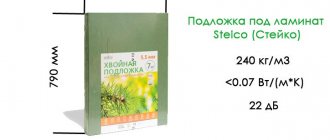

In a hardware store you can find the following brands of wallpaper backing:

EcoHeat

Due to mechanical production, Ecohit substrate has a uniform and dense structure

| Parameter | Meaning |

| Weight per square meter | 230 g |

| Coefficient of thermal conductivity | 0.037 W/(m×K) |

| Vapor permeability coefficient | 5.38 kg/(m×s×Pa) |

| Breaking force | 0.18 mPa |

| Sound absorption level | 22 dB |

| Flammability level | Flammable material |

| Roll width | 50 cm |

| Roll length | 14 m |

| Roll price | 1585 rubles |

Penolon

Due to the presence of air cells in its structure, foam insulation underlay for wallpaper is distinguished by high thermal insulation properties

| Parameter | Meaning |

| Manufacturer country | Russia |

| Flammability level | Flammable material |

| Blade thickness | 5 mm |

| Roll width | 50 cm |

| Roll length | 14 m |

| Roll price | 1690 rubles |

Polyph

Wall insulation with Polyfom is not only effective, but also profitable from an economic point of view

| Parameter | Meaning |

| Country of manufacture | Russia |

| Weight per square meter | 230 g |

| Breaking force | 0.18 mPa |

| Coefficient of thermal conductivity | 0.043 W/(m×K) |

| Density | 30 kg/m3 |

| Flammability level | G4 |

| Blade thickness | 5 mm |

| Roll width | 50 cm |

| Roll length | 14 m |

| Additional properties |

|

| Roll price | 1400 rubles |

Polyzol

Polyzol is made from cross-linked polyethylene foam and has a closed cell structure

| Parameter | Meaning |

| Weight per square meter | 230 g |

| Coefficient of thermal conductivity | 0.037 W/(m×K) |

| Vapor permeability coefficient | 5.38 kg/(m×s×Pa) |

| Flammability level | Flammable material |

| Blade thickness | 4 mm |

| Roll width | 70 cm |

| Roll length | 10 m |

| Price per square meter | 165 rubles |

Purpose of the base

Wallpaper bases have been used for a long time. About 30 years ago, old newspapers were used for this, and then they were replaced by special paper.

Modern bases for wallpaper are high-tech materials that can not only facilitate the process of wallpapering walls, but also perform the functions of insulation and sound insulation.

Wallpaper backing is a wall covering with insulating properties.

Typically, wallpaper backings are made of polyethylene foam, lined with paper sheets on the back and front sides.

Instead of polyethylene foam, cork or non-woven fabric can be used to make the backing. The backings can be glued under any type of wallpaper.

This finishing material has the following advantages:

- high strength - it is difficult to tear;

- environmental safety;

- prevents condensation;

- serves as sound insulation.

The backing for the wallpaper is a soft roll finish, but despite this, it is highly durable.

There are reviews of the wallpaper backing that say it can withstand several re-pastings of wallpaper. New wallpaper is simply pasted onto the old backing without removing it from the wall.

The material prevents the appearance of mold on the walls and ensures silence in the room. In addition, using a wallpaper backing, you can even out unevenness on the walls.

Professionals increasingly advise sticking wallpaper not on bare walls, but on substrates, since the level of sound insulation in modern apartments leaves much to be desired.

Despite the fact that wallpaper backings are a universal material with many advantages, they also have disadvantages:

- not suitable for wet areas;

- not suitable for thin wallpaper - in this case the backing may show through;

- will not be able to isolate the room from extraneous sounds at high noise levels.

Soundproofing materials

So, technology has been developing more and more recently, there are a lot of cars driving around the city, also winds, rains - all this forces people to isolate their homes as best as possible from unpleasant sounds and unfavorable natural conditions.

Nowadays preference is given to materials made of foamed polyethylene. Although other raw materials are used, such solutions have a number of properties. Here are some advantages of this type of substrate:

- Durability. Manufacturers promise that such substrates will serve reliably for a period of 50 years. Moreover, you can paste wallpaper on them repeatedly.

- Strength. Such fabrics are tensile-resistant. They also perform well during shrinkage of the building foundation. Quite elastic.

- Environmental friendliness. Such fabrics do not emit chemical fumes. They are not harmful to both humans and nature.

These are just a few of the advantages of this material for decorating walls with wallpaper. Let's look at a couple more types of linings and the advantages of each.

Installation of the substrate

How to glue the backing to the wall:

- the surface is freed from wallpaper;

- remove water-based paint or whitewash;

- the recesses are leveled with putty or alabaster;

- The wall is primed with PVA glue

- 24 hours before sticking, the backing is cut and allowed to rest on a flat surface.

When working with non-woven backing, glue is applied not to it, but to the walls.

Tip: immediately remove excess glue from the joints with a napkin.

Pasting begins from the window and moves in a circle. At the junction of two walls, the sheets must be end-to-end - pasting a corner with one sheet with a bend is not allowed.

DIY wallpaper painting

The initial stage of decorating a room is pasting the walls. The gluing process begins from the corner from the window towards the exit. Thanks to this approach, joints or overlaps become less visible. The technology for applying glue depends on the type of wallpaper selected. For some, applying glue to the wall is enough, while others require applying adhesive to the strip and the wall.

See also: Plastic panels for the bathroom

After the process has been completely completed and the walls have dried, you can begin painting. If you don’t know how to paint wallpaper correctly, you can take the advice of experienced specialists. Provided that all recommendations are followed, the final result will bring the desired effect.

Tools and materials needed for painting

Before you get started, you should make sure you have everything you need:

- paint is applied with a fur roller;

- if you have chosen wallpaper with a smooth surface, and you plan to have a pattern in your design project, then you need a brush to create patterns from paint;

- plastic bath;

- container for performing the paint coloring procedure;

- colors;

- acrylic-based varnish, if you need to create an additional protective layer.

Preparing the Paint

Initially, you should decide on the type of paint that can be applied to the surface of the selected wallpaper. For non-woven bases, the use of oil-based paints is strictly prohibited; it is better to use water-based paints. While for glass wallpaper it is advisable to peel off alkyd or latex paints.

If we talk about choosing a color, then in stores you can find ready-made options, ready for application. Despite their wide range, most people want to use unique colors that can be created by coloring standard white paint with tints. The color is added to the white paint according to the already developed tinting table. Add the required amount of color to a separate container with cast paint and mix thoroughly.

Carefully apply the resulting composition with a roller to the wall in an inconspicuous area. If this color option suits you, then you can pour the resulting mixture into a bucket of paint.