The volume of water or coolant in various pipelines, such as low-pressure polyethylene (HDPE pipe), polypropylene pipes, fiberglass-reinforced pipes, metal-plastic pipes, steel pipes, must be known when selecting any equipment, in particular an expansion tank.

For example, in a metal-plastic pipe with a diameter of 16, a meter of pipe is 0.115 g. coolant.

Did you know? Most likely no. And why do you actually need to know this until you are faced with the selection of, for example, an expansion tank. Knowing the volume of coolant in the heating system is necessary not only for selecting an expansion tank, but also for purchasing antifreeze. Antifreeze is sold undiluted to -65 degrees and diluted to -30 degrees. Once you know the volume of coolant in the heating system, you can buy an even amount of antifreeze. For example, undiluted antifreeze must be diluted 50*50 (water*antifreeze), which means that with a coolant volume of 50 liters, you will need to buy only 25 liters of antifreeze.

We present to your attention a form for calculating the volume of water (coolant) in the pipeline and heating radiators. Enter the length of a pipe of a certain diameter and instantly find out how much coolant is in this section.

How many liters of water are there in one meter of 32 pipes?

Internal volume of a linear meter of pipe in liters - table. Weight of water in the pipeline.

| Inner diameter, mm | Internal volume 1 m of pipe, liters = mass of water in 1 m, kg | Internal volume 10 m of pipe, liters = mass of water in 10 m, kg |

| 26 | 0,5309 | 5,3093 |

| 28 | 0,6158 | 6,1575 |

| 30 | 0,7069 | 7,0686 |

| 32 | 0,8042 | 8,0425 |

Existing materials for creating water supply networks

Before you calculate the diameter of a pipe for a water supply system, you need to select a material for it. It could be:

- metal (steel, copper, cast iron, their various compounds);

- polymeric materials - plastic, polyethylene, metal-plastic, PVC;

- combinations of metal and plastic structures.

Whatever the characteristics of the materials, the dimensions will also be important. In particular, the diameter of plastic pipes for water supply (metal and metal-plastic too) is divided into external and internal, and the permeability of the pipeline depends on it and the thickness of the walls.

The level of working pressure is also influenced by certain characteristics of the material. In particular, steel is characterized by reliability and strength, but is susceptible to corrosion and is also heavy, making installation of the system difficult. Also, limescale may accumulate inside the steel pipeline - consequently, the diameter will decrease and the permeability of the system will decrease.

Plastic is characterized by low weight, simple and easy installation. Such pipes do not accumulate plaque inside and do not rust; they are inexpensive and flexible. If the pipes are plastic, without a metal layer, then they can expand due to heating, but in metal-plastic products this drawback is eliminated.

Home heating design

Step-by-step description of the heating installation processStep one

Equip a boiler room

The boiler room must be equipped in accordance with the requirements, so this issue must be taken seriously.

Calculate the power and type of boiler

The efficiency of the entire heating system depends on the boiler power. If you choose a weak boiler, then get ready for additional expenses.

Calculate the number of radiators and sections in them

This is also an important parameter; an insufficient number of radiators reduces the efficiency of the heating system.

Select radiator connection diagram

The connection system for heating radiators can be one-pipe, two-pipe, radial or made according to the Tichelman scheme

Boiler installation, piping, connection of radiators

At this stage, you should carefully consider the boiler piping scheme, connecting radiators, circulation pump, expansion tank and other elements

Filling the system with coolant and starting

At the last step, all that remains is to fill the system with water or antifreeze, and then start and test the heating system.

To ensure comfortable living in the cold season, even at the stage of designing a private house, you need to take care of the calculation and installation of heating. Correctly performed thermal calculations will allow you to determine the optimal and cost-effective heating system. Any error can lead to you freezing or the building becoming hot and stuffy.

Independent calculations will not be a problem for people with technical education. However, not everyone has physical and mathematical skills, so an online calculator will be a good guide to calculations. It will help identify heat losses at home and calculate the power that the boiler should have. It will also determine the number of radiators needed and how many sections it should have. It will calculate heating costs for you, which will be useful for choosing a suitable heat source. Collect the necessary data for the calculation.

Determine heat losses. To do this, you need to know what material the external walls and floor coverings are made of, how they are insulated and their thickness. Measure the area of the house, windows and exterior doors. High intensity of heat loss from ventilation and sewerage. They also need to be taken into account in the calculations.

The climatic conditions of the location of the house play an important role in the choice of heating system. Find out the average annual and minimum temperatures in your area, as well as the average wind speed.

What formula is used to calculate

To get accurate data, you need to prepare:

First, the radius is measured, designated by the letter R. It can be:

The first allows you to calculate how much liquid can fit in the cylinder, that is, the internal volume of the pipe, its cubic capacity.

The outer radius is necessary to determine the size of the space it will occupy.

To calculate, you need to know the pipe diameter data. It is denoted by the letter D and is calculated using the formula R x 2. The circumference is also determined. Denoted by the letter L.

How to calculate the volume of a heating system?

Each heating system has a number of significant characteristics - rated thermal power, fuel consumption and coolant volume. Calculating the volume of water in a heating system requires an integrated and scrupulous approach. So, you can find out what kind of boiler to choose, determine the volume of the expansion tank and the required amount of liquid to fill the system.

A significant part of the liquid is located in pipelines, which occupy the largest part in the heat supply scheme. Therefore, to calculate the volume of water, you need to know the characteristics of the pipes, and the most important of them is the diameter, which determines the capacity of the liquid in the line. If the calculations are made incorrectly, the system will not work efficiently, and the room will not warm up at the proper level. An online calculator will help you make the correct calculation of volumes for the heating system.

How to calculate cross-sectional area

If the pipe is round, the cross-sectional area should be calculated using the formula for the area of a circle: S = π*R2. Where R is the radius (internal), π is 3.14. In total, you need to square the radius and multiply it by 3.14. For example, the cross-sectional area of a pipe with a diameter of 90 mm. We find the radius - 90 mm / 2 = 45 mm. In centimeters this is 4.5 cm. We square it: 4.5 * 4.5 = 2.025 cm2, substitute it into the formula S = 2 * 20.25 cm2 = 40.5 cm2.

The cross-sectional area of a profiled product is calculated using the formula for the area of a rectangle: S = a * b, where a and b are the lengths of the sides of the rectangle. If we consider the cross-section of the profile to be 40 x 50 mm, we get S = 40 mm * 50 mm = 2000 mm2 or 20 cm2 or 0.002 m2.

Complete environmental cleanliness and hygiene of drinking water supply systems

Every self-respecting person, reputable company or organization constantly cares not only about themselves, but also about the health of their relatives and subordinates. And it all starts with water, just like our life in general. So, first of all, you need to think about supplying environmentally and hygienically pure juice of the Earth - this is also called water.

This problem was solved by German specialists who use environmentally friendly fusiolen PP-R raw materials for the production of aquatherm pipes.

Professionals from Germany for a comprehensive study of the material used not only their own laboratories available at the aquatherm GmbH plant, but also took advantage of equipment that was kindly provided to them by many independent laboratories.

The results of the experiments confirmed the high environmental standards of the factory raw materials used for the production of pipe structures.

Moreover, due to many positive physical and chemical properties, a number of special requirements for drinking water supply and heating were taken into account when creating the materials. “Material of the future” is the name given to fusiolen PP-R raw materials.

Compliance with GN 2.1.5.1315-03, availability of Greenpeace and LEED USA certificates indicates that the material does not contain metals harmful to health (copper, iron, nickel, lead, etc.), and also eliminates the possibility of emission of harmful substances during operation into the environment.

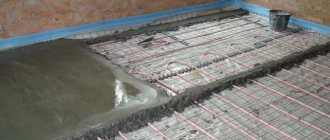

Preliminary preparation

There are several options for sealing seams:

- using concrete mortar;

- dry mixture of sand and cement;

- special putty mass.

Each method involves surface preparation. Before starting work, the paving stones are treated with water from a hose under pressure.

If a concrete base is used, the sealing is carried out after 3 days, after the solution has completely dried. Laying tiles on a cement-sand base involves grouting the cracks immediately.

Debris is swept away from the working surface, the distance between the paving stones is cleaned with a thin rod, a compressor or a vacuum cleaner. A jet of compressed air will more effectively and quickly remove excess dirt and speed up the drying of cracks. If there is no compressor, an old vacuum cleaner is used. By installing a tube on the exhaust pipe, a kind of compressor is created. After preparing and cleaning the required area, the grouting method is determined.

Porous materials (ceramic tiles, concrete) are sealed with a dry mixture of cement and sand; materials with a smooth and dense texture (marble, granite) are preferably sealed with concrete mortar. For colored tiles, a ready-made mixture is used.

Critical stage: calculating the capacity of the expansion tank

In order to have a clear idea of the displacement of the entire heating system, you need to know how much water is placed in the boiler heat exchanger.

You can take averages. So, on average, a wall-mounted heating boiler contains 3-6 liters of water, while a floor or parapet boiler contains 10-30 liters.

Now you can calculate the capacity of the expansion tank, which performs an important function. It compensates for the excess pressure that occurs when the coolant expands when heated.

Depending on the type of heating system, tanks are:

- closed;

- open.

For small rooms, the open type is suitable, but in large two-story cottages, closed expansion joints (membrane) are increasingly being installed.

If the tank capacity is smaller than required, the valve will release pressure too often. In this case, you have to change it, or install an additional tank in parallel.

For the formula for calculating the capacity of the expansion tank, the following indicators are needed:

- V(c) is the volume of coolant in the system;

- K is the coefficient of water expansion (the value is taken as 1.04, based on the water expansion rate of 4%);

- D is the expansion efficiency of the tank, which is calculated by the formula: (Pmax – Pb)/(Pmax+1)=D, where Pmax is the maximum permissible pressure in the system, and Pb is the pre-pumping pressure of the compensator air chamber (parameters are indicated in the documentation for the tank );

- V(b) - expansion tank capacity.

So, (V(c) x K)/D = V(b)

How to connect PPR PN25 pipes

Pipe welding is carried out using the thermal polyfusion method. The parts to be welded must be heated and quickly connected. A special soldering iron is used for heating. Some models have two heating elements at once, the power of which is designed to heat pipes of a specific diameter, but this does not always have a positive effect on the quality of welding.

Important! The use of two elements at once can lead to overheating of the plastic and overload of the electrical network. Therefore, the second heater should be used when the first one becomes unusable. The heating time depends on:

Heating time depends on:

- pipe diameter;

- welding belt width;

- ambient temperature - it should be within normal limits.

After heating, the material does not retain its plasticity for long. The connection must be fixed within a few seconds, without allowing distortions. The optimal temperature for heating is considered to be +260 ˚С. For a reliable connection, the pipe material must be very heated. But excessive heating can cause the shape to change. To avoid this, it is necessary to control the execution time of this operation. It should not exceed:

- 8...9 seconds for pipes with a cross-section of 20 millimeters;

- 9…10 seconds when welding a pipe with a diameter of 25 millimeters;

- 10...12 seconds for pipes with a diameter of 32 millimeters, etc.

Heated and already connected pipes must cool down. Fixing takes the same amount of time as heating. If the required time is not maintained, deformation of the connection will occur. Welding polypropylene pipes is a relatively difficult process. The quality is affected not only by the heating time, but also by violation of soldering rules. They are as follows:

- During operation, the welding machine must be constantly heated;

- Marks must be applied to the pipes in order to ensure the proper depth of the weld seam;

- The elements being connected must be heated simultaneously.

Selection of metal-plastic products

To make the right choice when purchasing metal-plastic pipes, you need to understand the purposes for which they are needed. Then, based on the purpose, product parameters are selected. These include:

- wall thickness;

- internal permeability and external radius;

- the weight of the pipe in accordance with the weight of the entire water supply system;

- minimum and maximum heating rates;

- maximum bending radius;

- life time.

All parameters are standardized; if there are deviations from the norm, they are small. Wall thickness is important. The installation of the pipeline depends on it. The fitting and shut-off valves are selected taking into account the thickness, especially when replacing old metal pipes with new, metal-plastic ones.

When choosing, it is worth considering the method of connecting the foil layer in the structure. It is indicated on the product labeling. More durable and resistant pipes are made using seamless butt welding. The thickness of the layer should not exceed the standard of 0.3-0.6 mm. The outer and inner shell material is cross-linked or heat-resistant polyethylene such as PERT or PEX. If the product is made from other raw materials, this will affect the further operation of the system. Upon visual inspection, the pipes should be intact. Cracks and delaminations are not acceptable.

High-quality products are certified and comply with international and domestic standards, so when purchasing, you need to find out whether the product has a certificate from the Scientific Research Institute of Plumbing.

It is better to purchase metal-plastic pipes from a reputable manufacturer. Different countries are engaged in the production of polyethylene products, among them Russia, Italy and Germany stand out. You can pay attention to pipes of the domestic brand “Nanoplast”, the Italian company Valtec or the German company Oventrop. The products are made of the highest quality material, the foil is made of pure aluminum.

To make the right choice, the buyer needs to familiarize himself with the markings that are applied with indelible paint to the pipe in accordance with accepted international rules. It may differ from one manufacturer to another, but most often it has a general appearance. The markings indicate:

- Manufacturer.

- Pipe name or certificate of conformity.

- Material type.

- Stitching method.

- Standard size ratio.

- Nominal sizes.

- Nominal pressure.

- Production standards (date of manufacture, batch number).

If questions arise when choosing pipes, you can contact a consultant for help in specialized stores.

Properties of polypropylene pipes

It is joined by polydiffusion welding, the joint is a homogeneous material and is safe in terms of sealing. PP-R pipes have a high thermal elongation, so the installations also use multilayer polypropylene called STABI (pipe with aluminum insert with PP-R / Al / PP-R structure) or GLASS (PP-R pipe reinforced with glass fiber) also on market under the name PP-R / GF / PP-R). PP-R pipes are manufactured with different wall thicknesses with the same outer diameter due to the nominal pressure PN. In accordance with the old standard, three pressure series PN10, PN16 and PN20 were distinguished. In accordance with the PN-EN ISO 15874-1 standard, which defines the operating conditions and typical areas of application of plastic pipes, PP pipes have a new marking. see table 1 and table 2..

Table 3 Application range of PP-R pipes according to PN-EN ISO 15874-1

Pipe dimensions - the PN-EN 15784-2 standard gives dimensions for PP pipes with a diameter of up to 110 mm, in practice there are already larger pipe sizes produced by Aquatherm. with sizes DN 125, 160, 200, 250 and 315

Physical and mechanical properties of PP-R pipes

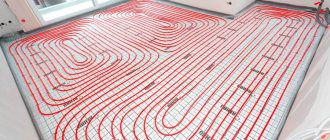

Polypropylene pipes are offered in the country by many companies in various system colors. In addition to pipes in straight sections, coiled pipes (16 and 20 mm diameters) are also available for roof approaches and even for underfloor heating installations. In addition, polypropylene consists of sewer pipes, gutters, manhole kinetics, and gutters in linear drainage systems. In general, this is a very common material.

Main types of coolants

There are four main types of fluid used to fill heating systems:

- Water is the simplest and most accessible coolant that can be used in any heating systems. Together with polypropylene pipes that prevent evaporation, water becomes an almost eternal coolant.

- Antifreeze - this coolant will cost more than water, and is used in systems of irregularly heated rooms.

- Alcohol-containing coolants are an expensive option for filling a heating system. A high-quality alcohol-containing liquid contains 60% alcohol, about 30% water and about 10% of the volume are other additives. Such mixtures have excellent antifreeze properties, but are flammable.

- Oil is used as a coolant only in special boilers, but is practically not used in heating systems, since the operation of such a system is very expensive. Also, the oil takes a very long time to heat up (it needs to be heated to at least 120°C), which is technologically very dangerous; at the same time, such a liquid cools down for a very long time, maintaining a high temperature in the room.

In conclusion, it is worth saying that if the heating system is modernized, pipes or radiators are installed, then its total volume must be recalculated according to the new characteristics of all elements of the system.

What situations can be avoided if you correctly calculate the volume of coolant

Many people install a heating system, relying on the advice of experts, friends or their own intuition. Choose a more powerful boiler and increase the number of radiator sections “just in case.” But the result is the opposite picture: instead of the expected heat, the batteries do not warm up evenly, the boiler “winds” fuel idle.

You can avoid the following unpleasant situations if you know how to calculate the amount of water in the heating system:

- uneven heating of the water circuit in the rooms;

- increased fuel consumption;

- emergency situations (broken connections, leaks in radiators).

All these “surprises” are quite predictable if the volume of coolant is incorrectly calculated.

Attention! Antifreeze should not be used in a heating system that uses galvanized pipes or other elements.

What is the displacement of one meter of 16 mm MP pipe?

How to design a kitchen with wood and not get an interior from the 2000s (95 photos)

6 smart options for designing a kitchen in a one-room apartment

Interior timeless: neoclassical and modern style in kitchen design

Are you a professional architect or designer?

IVD. Repair and finishing

Are you a professional architect or designer?

The IVD.ru website is a leading Internet project dedicated to the issues of reconstruction and interior design of residential premises. The main content of the site is the archive of the magazine “Ideas for Your Home” - exclusive author’s articles, high-quality illustrations, practical tips and lessons. A team of professionals is working on the project in close collaboration with famous designers, architects and leading publishing experts.

On our website you can choose comprehensive design solutions; view detailed reviews of the market for construction and finishing materials, furniture, machinery and equipment; compare your own ideas with design projects of leading architects; communicate directly with other readers and editors on the forum.

Classification of propylene pipes according to the composition of raw materials

- PPR pipes. This category usually includes structures that are created using a static polypropylene copolymer, which is distinguished by the presence of a crystalline molecular structure. These products perfectly withstand temperatures in the range from - 170 to + 1400 degrees Celsius. At the same time, they cope well with shock loads, which is why they are widely used when carrying out work on the construction of sewerage, plumbing and heating. These products are most often used in the construction of residential buildings. If we talk about their sizes, they are about 16–110 mm. The signs of their classification may include, first of all, a parameter such as pressure.

- PPH pipes. The material used to create these structures is raw materials, which are mixed with modifying additives. The latter can be antistatic agents, fire retardants, and nucleators. The effect of introducing the latter into the composition provides an increase in the impact strength of the polymer. Using similar structures, external cold water supply systems, as well as ventilation and drainage systems are erected. At the same time, they do not seem to be the best option for creating heating systems based on them. The reason for this is due to the low melting point. The diameter of structures in this category is usually quite large, since most of them are used in the construction of industrial sewerage and drainage systems.

- PPB pipes. If we consider the structure of this material, then its basis is formed by homopolymer micromolecules having different structures, compositions and locations. It is the special molecular structure that is responsible for the property of this product, which is its high resistance to impact. For this reason, they are most often used in the installation of underfloor heating systems and cold water supply.

- PPs pipes. This category is represented by polymers of the highest class, the main feature of which is a unique molecular composition. The advantages include high resistance to loads and heat. They also have high wear resistance and strength characteristics. The diameter of structures created on the basis of such polypropylene is about 20–1200 mm. Most of them are used in the installation of ventilation systems, hot and cold water supply, and heating.

What are there and which are better?

According to their structure, polypropylene pipes come in three types:

- Single layer. The walls are completely made of polypropylene.

- Three-layer: fiberglass reinforced - fiberglass threads are sealed between two layers of polypropylene;

- reinforced with foil - the design is similar.

Now briefly about why polypropylene pipes are reinforced. The fact is that this material has a high coefficient of thermal expansion. When heated by 100°C, one meter of single-layer pipe becomes 150 mm longer. This is a lot, although no one will heat them that much, but even at lower temperature deltas the increase in length is no less impressive. To neutralize this phenomenon, compensation loops are installed, but this approach does not always save.

Types of expansion joints for polypropylene pipes

Manufacturers found another solution - they began to make multilayer pipes. They lay fiberglass or aluminum foil between two layers of pure propylene. These materials are not needed for strengthening or any other purposes, but only to reduce thermal elongation. If there is a layer of fiberglass, the thermal expansion is 4-5 times less, and with a layer of foil - 2 times. Compensation loops are still needed, but they are installed less frequently.

On the left is a fiberglass-reinforced pipe, on the right is a regular single-layer pipe

Why is reinforcement made with both fiberglass and foil? It's a matter of operating temperature range. Those with fiberglass can withstand heat up to 90°C. This is enough for hot water supply, but not always enough for heating. Polypropylene pipes reinforced with foil have a wider temperature range - they can withstand heating of the environment up to +95°C. This is already enough for most heating systems (except those with solid fuel boilers).

Which PPR pipes are suitable for which systems?

Based on everything said above, it is clear which polypropylene pipes are better for heating - those reinforced with foil, if high-temperature operation of the system is expected (from 70 ° C and above). For low-temperature heating systems, glass fiber reinforced products can be used.

Any PPR pipes are suitable for cold water supply, but the most rational solution is ordinary single-layer pipes. They cost quite a bit, and the thermal expansion in this case is not so great, one small expansion joint for the water supply in an average private house is enough, but in an apartment, with a small length of the system, they don’t make it at all, or rather they make an “L”-shaped one.

An example of a polypropylene water pipe

To install a hot water supply system, it is best to take polypropylene pipes with a fiberglass reinforcing layer. Their qualities are optimal here, but they can also be used with a foil layer

Please note that compensators are required

Which ones are easier to install?

When deciding which polypropylene pipes are better, pay attention to such a parameter as the complexity of installation. All types are connected by welding, and for turns, branches, etc.

fittings are used. The welding process itself is identical for all types, the difference is that in the presence of aluminum foil, pre-treatment is required - it is necessary to remove the foil to the soldering depth.

This is what the external reinforcement of a polypropylene pipe with foil looks like

In general, there are two types of aluminum reinforcement - external and internal. With the outer one, the foil layer is close to the outer edge (1-2 mm), with the inner one the reinforcing layer is located approximately in the middle. It turns out that it is filled with an almost identical layer of polypropylene on both sides. In this case, preparation for welding also consists of removing the outer layer of propylene to the entire depth of welding (and the foil too). Only under these conditions can the required seam strength be achieved. All this preparation takes a lot of time, but the most unpleasant thing is that if there is an error, we get a very unreliable connection. The most dangerous option is when water seeps into the foil. In this case, the polypropylene will sooner or later collapse and the connection will leak.

Foil-reinforced pipes must be welded correctly

Based on these data, we can come to the conclusion that if conditions permit, it is better to use single-layer or fiberglass-reinforced polypropylene pipes. Proponents of aluminum reinforcement say that foil further reduces the amount of air that penetrates into the system through the walls. But the foil is often made perforated and it does not necessarily go in a continuous strip, covering the entire diameter of the pipe. Often it has a longitudinal gap. After all, its task is to reduce the amount of thermal expansion, and even strips of more stable material can cope with this task.

https://youtube.com/watch?v=fKf2kG7gHvw

Calculator for calculating the total volume of the heating system

Sometimes owners of houses or apartments in which autonomous water heating is installed have a need to accurately determine the total volume of the system. Most often this is due to the need to carry out certain preventive and routine maintenance, during which the system will have to be completely emptied and then filled with new coolant. When using ordinary water, this may not be so relevant (although it is advisable to properly prepare it for such a “mission”), but when you purchase a special coolant, which can be expensive, you cannot do without knowing the volume to plan the purchase.

Calculator for calculating the total volume of the heating system

Information about the volume of the heating system is also necessary for other needs. For example, this value is required for the correct selection of an expansion tank. Some calculations carried out when upgrading the system and replacing certain equipment may also require this value to be substituted into thermal formulas. In a word, knowing this parameter will never be superfluous. And the calculator below for calculating the total volume of the heating system will help you decide.

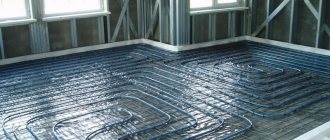

Coolant volume in 16 pipes for heated floors

How to design a kitchen with wood and not get an interior from the 2000s (95 photos)

6 smart options for designing a kitchen in a one-room apartment

Interior timeless: neoclassical and modern style in kitchen design

The best articles on the IVD website

Are you a professional architect or designer?

Are you a professional architect or designer?

On our website you can choose comprehensive design solutions; view detailed reviews of the market for construction and finishing materials, furniture, machinery and equipment; compare your own ideas with design projects of leading architects; communicate directly with other readers and editors on the forum.

Are you a professional architect or designer?

What is the displacement of one meter of 16 mm MP pipe?

How much water does one meter of 16 mm MP pipe hold?

elmix, the volume of the cylinder is calculated by multiplying S of the circle (base) by H (pipe length), i.e.

Goryn 68 wrote: pi * er square

Peterjela wrote: It's no secret - why do you need this?

To find out how many cubes fit into 100 meters of pipe.

C2h5-OH wrote: 95 milliliters approximately.

1 meter? I got 45:0 pi (3.14) * 12 square (144) * 100 cm

elmix wrote: To find out how many cubes fit into 100 meters of pipe.

Clear. Thanks everyone. Many other questions arose. But that's another topic, and I'll have to open a new topic.

elmix Internal volume of water per linear meter in a standard metal-plastic pipe MP 16 (2.0) = 0.113 g MP 20 (2.25) = 0.201 g MP 26 (2.5) = 0.314 g MP 32 (3.0) = 0.531 gr

MP 16 (2.0) = 0.113 l = 113 g MP 20 (2.25) = 0.201 l = 201 g MP 26 (2.5) = 0.314 l = 314 g MP 32 (3.0) = 0.531 l = 531 g

Tehnik-san wrote: Internal volume of water per linear meter

I read it again, but didn’t find anything about warm floors.

Just for a warm floor (warm, hot water) this equality, alas, does not dance

Volume of water (coolant) in the pipe: polypropylene, metal, matelloplast, radiator

The volume of water or coolant in various pipelines, such as low-pressure polyethylene (HDPE pipe), polypropylene pipes, fiberglass-reinforced pipes, metal-plastic pipes, steel pipes, must be known when selecting any equipment, in particular an expansion tank.

For example, in a metal-plastic pipe with a diameter of 16, a meter of pipe is 0.115 g. coolant.

Did you know? Most likely no. And why do you actually need to know this until you are faced with the selection of, for example, an expansion tank. Knowing the volume of coolant in the heating system is necessary not only for selecting an expansion tank, but also for purchasing antifreeze. Antifreeze is sold undiluted to -65 degrees and diluted to -30 degrees. Once you know the volume of coolant in the heating system, you can buy an even amount of antifreeze. For example, undiluted antifreeze must be diluted 50*50 (water*antifreeze), which means that with a coolant volume of 50 liters, you will need to buy only 25 liters of antifreeze.

We present to your attention a form for calculating the volume of water (coolant) in the pipeline and heating radiators. Enter the length of a pipe of a certain diameter and instantly find out how much coolant is in this section.

Volume of water in pipes of different diameters: performing calculations

It is important to consider the thickness of the pipe. The size of plastic pipes is the outer diameter, steel pipes are the inner diameter

After you have calculated the volume of coolant in the water supply, but in order to create a complete picture, namely, in order to find out the entire volume of coolant in the system, you will also need to calculate the volume of coolant in the heating radiators.

Calculation of the volume of water in pipes

Calculation of the volume of water in a heating radiator

Water volume in some aluminum radiators

Now it will definitely not be difficult for you to calculate the volume of coolant in the heating system.

Calculation of coolant volume in heating radiators

In order to calculate the entire volume of coolant in the heating system, we also need to add the volume of water in the boiler. You can find it in the boiler passport or take approximate numbers:

- floor boiler - 40 liters of water;

- wall-mounted boiler - 3 liters of water.

Did the calculator help you? Were you able to calculate how much coolant is in your heating system or pipe? Please unsubscribe in the comments.

A quick guide to using the calculator “Calculating the volume of water in various pipelines”:

- in the first list, select the pipe material and its diameter (it can be plastic, polypropylene, metal-plastic, steel and diameters from 15 - ...)

- in the second list we write the footage of the selected pipe from the first list.

- Click “Calculate”.

“Calculate the amount of water in heating radiators”

- In the first list, select the interaxial distance and what material the radiator is made of.

- enter the number of sections.

- Click “Calculate”.

How to calculate the volume of a membrane expansion tank

The formula for selecting an expander is V of water in the pipe + radiators + boiler * 10-12%

If you know the volume of water, you can easily select an expansion tank.

PEX (UNI-FITT) cross-linked polyethylene pipes for heating and water supply systems

Volume of water (coolant) in the pipe (polypropylene, metal, matelloplastic)

The volume of water or coolant in various pipelines, such as low-pressure polyethylene (HDPE pipe), polypropylene pipes, fiberglass-reinforced pipes, metal-plastic pipes, steel pipes, must be known when selecting any equipment, in particular an expansion tank.

For example, in a metal-plastic pipe with a diameter of 16, a meter of pipe is 0.115 g. coolant.

Did you know? Most likely no. And why do you actually need to know this until you are faced with the selection of, for example, an expansion tank. Knowing the volume of coolant in the heating system is necessary not only for selecting an expansion tank, but also for purchasing antifreeze. Antifreeze is sold undiluted to -65 degrees and diluted to -30 degrees. Once you know the volume of coolant in the heating system, you can buy an even amount of antifreeze. For example, undiluted antifreeze must be diluted 50*50 (water*antifreeze), which means that with a coolant volume of 50 liters, you will need to buy only 25 liters of antifreeze.

We present to your attention a form for calculating the volume of water (coolant) in the pipeline and heating radiators. Enter the length of a pipe of a certain diameter and instantly find out how much coolant is in this section.

Volume of water in pipes of different diameters: performing calculations

It is important to consider the thickness of the pipe. The size of plastic pipes is the outer diameter, steel pipes are the inner diameter

After you have calculated the volume of coolant in the water supply, but in order to create a complete picture, namely, in order to find out the entire volume of coolant in the system, you will also need to calculate the volume of coolant in the heating radiators.

Calculation of the volume of water in pipes

Calculation of the volume of water in a heating radiator

Water volume in some aluminum radiators

Now it will definitely not be difficult for you to calculate the volume of coolant in the heating system.

Calculation of coolant volume in heating radiators

In order to calculate the entire volume of coolant in the heating system, we also need to add the volume of water in the boiler. You can find it in the boiler passport or take approximate numbers:

- floor boiler - 40 liters of water;

- wall-mounted boiler - 3 liters of water.

Did the calculator help you? Were you able to calculate how much coolant is in your heating system or pipe? Please unsubscribe in the comments.

A quick guide to using the calculator “Calculating the volume of water in various pipelines”:

- in the first list, select the pipe material and its diameter (it can be plastic, polypropylene, metal-plastic, steel and diameters from 15 - ...)

- in the second list we write the footage of the selected pipe from the first list.

- Click “Calculate”.

“Calculate the amount of water in heating radiators”

- In the first list, select the interaxial distance and what material the radiator is made of.

- enter the number of sections.

- Click “Calculate”.

How to calculate the volume of a membrane expansion tank

The formula for selecting an expander is V of water in the pipe + radiators + boiler * 10-12%

If you know the volume of water, you can easily select an expansion tank.

Author of the article: Sergey Yushkov, articles written: 831. Commented: 609 times.

Ask questions in the comments, share your experience, any constructive criticism is also accepted, ready to discuss. Don't forget to share the information you receive with your friends.

What is cross-linked polyethylene?

You should not think that ordinary, familiar polyethylene, sold in the form of, for example, films of varying densities, is the same material from which heating pipes for water supply and heating circuits are made. For products that will experience considerable operational loads, cross-linked polyethylene is used. And the key word in the name is still “stitched”. Yes, the basis is the same, but the differences lie in the features of the molecular structure.

We will try to clearly explain the difference.

Ordinary polyethylene has a linear molecular structure. Long chains of linear molecules are not connected to each other. Therefore, the material is not very resistant - it is easy to break it by mechanical action, and even with not very high heating it begins to “float”.

Technological chemists tried to slightly change the molecular structure of the material, namely, to try to connect linear molecules with cross-links.

Simplified diagram of the molecular structure of ordinary and cross-linked polyethylene. Artificially created transverse intermolecular bonds, which are precisely called “cross-linking,” are highlighted in red.

During the production of this material, molecular chains are “cross-linked”, thereby creating numerous stable cross-links. Essentially, a linear structure becomes three-dimensional. It is important that the material not only does not lose all its positive characteristics, but also acquires much greater stability. The more intermolecular bonds are created, the higher the degree of cross-linking is considered.

One of the very interesting and useful properties acquired by polyethylene as a result of cross-linking is a kind of “memory” of the original shape of a product made from this polymer. So, with increasing pressure, with mechanical or thermal effects on the same pipe, its deformation is quite possible. However, after the loads are normalized, removed or weakened, the material tends to restore its previously specified original shape. Agree that this is a very important advantage for a heating system.

Cross-linked polyethylene for underfloor heating has a common name - PEX. However, the cross-linking of molecular lines is carried out using various technologies, which are also distinguished by their designations.

Pipes made from cross-linked polyethylene PEX can be considered the highest quality.

- REH-a. In the manufacture of this material, cross-links of molecular chains are formed as a result of chemical treatment of the raw material with peroxide. This production method creates the highest degree of cross-linking, reaching 85%, at which polyethylene receives high strength and elasticity with excellent recovery ability. The technological process for the production of PEX is quite complex and expensive, which also predetermines the increased cost of the product. But there is no doubt about its final quality - the process is subject to very strict control and the output is products that perfectly meet the required parameters.

- PEX-b. The manufacturing technology of this type of cross-linked polyethylene was developed as an alternative to the production of PEX, as simpler and more affordable. Processing of the source material also occurs chemically and using water steam, which requires virtually no additional costs. However, the developed cross-linking method did not fully live up to expectations, since as a result the material lost significantly in its qualities. Not only did the degree of cross-linking decrease to 65%, but the elasticity of the polymer decreased, which led to a limitation in the bending radius of the pipes. In addition, it is not possible to take full control of the technological process itself, so it cannot be guaranteed that the expected characteristics will be obtained. In many foreign countries, pipes made from PEX-b are generally not allowed for use in heating systems.

This, by the way, is explained by another negative feature of PEX-b - the process of cross-linking molecular lines does not end even when using ready-made products. Therefore, the material is capable of shrinking and becoming more rigid, that is, changing its characteristics. Moreover, it is difficult to keep track of these changes, since it is unknown how it will behave under various influences. Definitely, regular inspections of connecting nodes and their tightening are required. Otherwise, leaks or even more serious emergencies cannot be ruled out.

What can you take from the documentation?

Technical data sheets for devices, if available, will help you find out how much water will circulate in the heating radiator and boiler during operation of the heating system.

If you need to choose a radiator based on coolant volume, you can compare different options:

- aluminum and bimetallic with a height of 300 and 500 mm hold 0.3 and 0.39 l/m, respectively;

- cast iron MS-140 with a height of 300 and 500 mm. holds 3 and 4 l/m respectively;

- an imported cast iron radiator with a height of 300 and 500 mm will include 0.5 and 0.6 l/m.

Thus, the volume of a bimetallic radiator is the same as that of an aluminum radiator.

Another “cheat sheet” will help when selecting cast iron radiators of different models (the amount of coolant per section is indicated):

- MS 140 – 1.11–1.45 l

- World Cup 1 – 0.66–0.9 l s;

- World Cup 2 – 0.7–0.95 l;

- World Cup 3 – 0.155–0.246 l;

As for pipes, the calculations are as follows.

Based on the internal diameter of the pipes, in the documentation you can find out the amount of liquid they contain per linear meter:

- 13.2 mm - 0.137 l;

- 16.4 mm - 0.216 l;

- 21.2 mm - 0.353 l;

- 26.6 mm - 0.556 l;

- 42 mm - 0.139 l;

- 50 mm - 0.876 l.

The calculations are simple. So, for example, a 5-meter pipe with an internal diameter of 50 mm will hold 4.4 liters of water: 5x0.876 = 4.4

Attention! If you compare how many liters of water are in heating radiators of different models, you can choose the appropriate option that matches the power of the boiler.

Soldering of polypropylene pipes

For this, a special soldering iron is used, on which nozzles are installed that can heat pipes of different diameters. One side of the nozzle heats the pipe from the outside and from the end; it is shaped like a small glass, and the second heats the connecting element (tee, angle or coupling).

The task is to simultaneously melt the outer part of the pipe and the internal cavity of the transition. It is at this moment that many novice plumbers make one significant mistake - they must not overheat the pipe and connector. This is fraught with the fact that the small internal hole intended for the flow of water is, at best, almost halved, which reduces the throughput of the pipe, and at worst, it seals it tightly. And then look for where it happened, it’s good if you haven’t had time to wall it up yet.

We insert the pipe and the “connector” into the nozzles, forcefully press them into it until it stops, count two or three seconds, remove the pipe from the soldering iron and connect the two elements together. Here you need to understand that the larger the diameter of the pipes being connected, the more time it takes to warm them up. Let's just say that 2-3 seconds of warming up is an axiom for a pipe ø20 (in the old days it is ½ inch), and for the subsequent diameter (ø25 or ¾ inch) the warming up time increases to 5-6 seconds. And so on with each diameter.

Then another nuance arises. Firstly, the elements to be joined must be held with force until the polypropylene hardens - as a rule, this is 15-20 seconds. Secondly, at the moment the polypropylene hardens, you need to hold it firmly and securely so as not to turn or move the pipe in the connector. If you disturb the joint at this moment, you're guaranteed to leak.

Droplets of water that may remain in the plumbing system during its repair or the addition of any elements have the same detrimental effect on the joint. The steam generated at high temperatures simply will not allow the polypropylene to combine into a single whole. In this case, ordinary bread crumb is used. It is packed into the pipe and gives several additional tens of seconds, during which you need to have time to solder everything. Subsequently, the crumb is completely dissolved by water, and there can be no talk of any plugs.

If you are soldering polypropylene pipes for the first time, it would be good to invite a person who has already done similar work as an assistant. Experience is of great importance, and in some moments, competent advice on how to properly solder polypropylene pipes can be very helpful.

At first, when mastering this type of work, soldering propylene pipes will not be done quickly at all. But you shouldn’t rush, because if you rush, the quality will suffer. Do you need leaks?

By gaining experience, you will learn to work more efficiently, and the time spent on soldering polypropylene pipes will be reduced.

Who knows, over time, having learned how to solder propylene pipes, you may want to improve not only the plumbing in your home, but also the sewerage and heating systems, and you will be able to help your friends in repairing communications.