Modifications of this series:

"Series 1-507, modification, built in 1959-1965."

This modification is one of the most popular in this series. Derived from the 1-506e series by reducing the height of houses and living space in general. The houses are present in the Moscow, Kalininsky, Nevsky and Primorsky districts. This modification has balconies on the facades of apartments on the 2nd-4th floors. The first two houses of series 1-507: st. Pinegina 15 and 19

Serial configurations:

o 1-507-5: 5 floors, 5 front doors and 100 apartments; Project passport 1-507-5;

o 1-507-6: 5 floors, 6 front doors and 120 apartments;

o code 5179/30: 6-1 floor, 4 front doors and 80 apartments with the first non-residential floor;

“Series 1LG-504 and 1LG-507, modifications built in 1963-1966.” This modification is an edited series 1-507. The 1LG-507 series now also has balconies on the facades of apartments on the 5th floor. For the construction of housing cooperatives, a shortened configuration with balconies on the facades was designed. The layout has changed a bit. Based on the 1LG-507 series, the 1LG-504 series appeared - instead of balconies on the facades of such houses there are loggias. The houses are found mainly in the Moscow region. Also, in very small quantities, in the Kalininsky district.

Serial configurations:

o 1LG-507-4: 5 floors, 4 front doors and 80 apartments;

o 1LG-507-5: 5 floors, 5 front doors and 100 apartments;

o 1LG-507-6t: 5-1,5,5,5,5,5-1 floors, 6 front and 110 apartments with a non-residential ground floor in the outermost front

o 1LG-507-6: 5 floors, 6 front doors and 118 apartments;

o 1LG-504-3: 5 floors, 7 front doors and 139 apartments;

o 1LG-507-7: 5 floors, 7 front and 139 apartments with reduced apartments;

o 1LG-507-8: 5 floors, 8 front doors and 159 apartments;

“Series 1LG-504 and 1LG-507, modification, built in 1966-1972” as amended in 1964. It features a slightly modified roof. This modification is found in the north of Kupchino, in Ulyanka, Ligovo and Sosnovaya Polyana, as well as a little in Grazhdanka.

Serial configurations:

o 1ЛГ-507-4/64: 5 floors, 4 front doors and 80 apartments;

o 1ЛГ-507-5/64: 5 floors, 5 front doors and 100 apartments;

o 1ЛГ-507-6т/64: 5-1,5,5,5,5,5-1 floors, 6 front and 110 apartments with a non-residential first floor in the outermost front;

o 1ЛГ-507-6/64: 5 floors, 6 front doors and 118 apartments;

o 1ЛГ-504-3/64: 5 floors, 7 front doors and 139 apartments;

o 1ЛГ-507-7/64: 5 floors, 7 front and 139 apartments with reduced apartments and balconies;

o 1ЛГ-507-8/64: 5 floors, 8 front doors and 159 apartments;

o 1ЛГ-507-4/64: 5 floors, 8 front and 159 apartments consisting of two 4 front configurations;

Serial configurations:

o 1ЛГ-507-4/64: 5 floors, 4 front doors and 80 apartments;

o 1ЛГ-507-5/64: 5 floors, 5 front doors and 100 apartments;

o 1ЛГ-507-6т/64: 5-1,5,5,5,5,5-1 floors, 6 front and 110 apartments with a non-residential first floor in the outermost front;

o 1ЛГ-504-3/64: 5 floors, 7 front doors and 139 apartments;

o 1ЛГ-504-3/64: 5 floors, 7 front and 139 apartments with window frames without vents;

o 1ЛГ-507-7/64: 5 floors, 7 front and 139 apartments with reduced apartments and balconies;

o 1ЛГ-507-8/64: 5 floors, 8 front doors and 159 apartments;

Serial configurations:

o E5-58: 7 floors, 5 front doors and 139 apartments;

o E5-58: 7 floors, 8 front doors and 224 apartments;

Source

Series of houses. Regional series of houses

Regional series of houses are series that are mainly distributed in provincial cities and regional centers of the Russian Federation. As a rule, houses of these series were and are being built by local DSK. Houses of some regional series can be found not only in Russia but also in Ukraine and the Republic of Belarus.

| Series | Wall material | Number of storeys | Years of construction |

| 1-447 | brick | 3, 4, 5, 9, 12 | 1958-1980s |

| 1-440 | brick | 3,5 | 1958-1960s |

| 1-460 | brick | 4,5 | 1950s-1960s |

| 1-300 | brick | 5 | 1960s-1970s |

| 80 | brick | 5 | 1970s-1980s |

| 85(114-85) | brick | 6,9,12 | |

| 86(114-86) | brick | 2-5, 9 | |

| 87(114-87) | brick | 9 | 1980s-1990s |

| 124 | brick | 9-12, 14 | 1970s-1990s |

| E-93 | brick | 5, 9-12, 14 | |

| "Optima", "Makarovskaya" | panels | 3-16 | |

| 464(1-464) | panels | 4-5 | 1958-1960s |

| 1-466 | panels | 3-5 | 1959-1970 |

| 75 | panels | 5,9,10 | |

| 25 | panels | 2-5 | |

| 1-467 | panels | 2-6,9 | 1970s-1980s |

| 60 | panels | 3,5,9 | |

| 468(1-468) | panels | 5 | 1960s-1980s |

| 78(111-78) | panels | 9 | 1970s |

| 81 | blocks | 5-9 | |

| 83(111-83) | panels | 5-10 | |

| 84 | panels | 4,5,9 | |

| 90(111-90) | panels | 2-10 | |

| 91 | panels | 5,9 | ?? |

| 93 | panels | 5, 9, 16 | 1979-1990s |

| 93m | panels | 9,10 | 1985-1991 |

| 97(111-97) | panels | 5,9,10 | |

| 108(111-108) | panels | 5,9 | |

| 125(111-125) | panels | 5,9-10 | |

| 135 and 135m | panels | 5,9 | |

| 141(121-141) | panels | 5-10 | |

| KPD-4570 | panels | 5 | 1957-1990s |

| P-101 | panels | 5,9 | |

| 182-Mobile | panels | 3,5,10 | |

| II-60 | panels | 16 | 1970s-1980s |

Panel houses series 1-507

Explanation of reasons and discussion - on the Wikipedia page: Towards renaming/July 30, 2020

. Please base your arguments on article naming conventions. Do not delete the template until the discussion is concluded. Rename to the suggested name, remove this template.

| 1-507 | |

| Location | Russia, Saint-Petersburg |

| Construction | 1959—1972 |

| Usage | House |

| Technical specifications | |

| Number of floors | 5, 7 |

| Number of elevators | 1 (in houses E5-58) |

| Architect | Lenproekt |

| Developer | DSK-4, DSK-6 |

, 1LG-507

- Soviet standard series of large-panel residential buildings, developed by the Lenproekt Institute in 1956. Houses of series 1-507 were built in Leningrad in 1959-1972. Houses of the 507 series belong to Khrushchev and are in many ways similar to the Moscow standard series 1-515, but differ from them in design. Project 1-507 buildings were erected between 1958 and 1972.[1]

Series 1-335-With full frame. P3.3. Large-panel buildings series 1-335-С

Standard projects of the 1-335-C series were part of the existing ones from 1959 to 1971 and were used during the development of Irkutsk from 1960 to 1969.

Projects of the 1-335C series were developed for seismicity conditions of 7 and 8 points

The structural scheme is an incomplete frame with load-bearing external walls, columns along the middle longitudinal axis, staircase panels and transverse diaphragms. Horizontal seismic loads in the transverse direction are perceived by internal transverse load-bearing walls and external end panels, and in the longitudinal direction - by external wall panels.

Foundations. Under the columns of the central row - reinforced concrete columnar, under the load-bearing walls - reinforced concrete strip.

The incomplete frame is formed by columns along the middle longitudinal axis and purlins resting on the outer longitudinal walls and columns. The column spacing is 2.6 and 3.2 m.

The cross-sectional dimensions of the columns are 200×400 mm. Reinforced concrete purlins with a length of 5900 mm and a section size b×h = 200×350 mm are laid along the transverse axes of the building.

The outer walls of the building are single-layer panel walls with a thickness of 400 or 350 mm, made of non-autoclave-cured aerated ash concrete, and bear loads from their own weight and from the floors.

Panels of transverse internal load-bearing walls with a thickness of 280 mm are designed from heavy concrete.

Floors. Prefabricated reinforced concrete floors are made of flat panels of room size, thickness 100 and 110 mm. The floor panels are supported along their long sides by purlins and transverse load-bearing walls.

The staircases are two-flight, made up of prefabricated reinforced concrete flights and platforms.

Main defects: low heat transfer resistance of walls and attic floors, lack of anti-corrosion protection of reinforcement products in wall panels.

The main damage is observed mainly in external wall panels: corrosion of reinforcing mesh and frames, delamination of the textured layer, delamination of panels along the reinforcing mesh, destruction of concrete above and below the windows and along anti-seismic seams, deterioration of the joints of external wall panels.

P3.4. Large-panel buildings series 1-335AC and 1-335KS

Standard designs of 5-storey frame-panel residential buildings of the 1-335AS series were developed by LenZNIIEP for seismicity conditions of 8 points.

Supporting frame. Houses of the 1-335AC series have a full reinforced concrete frame, the transverse frames of which alternate with internal load-bearing walls. External wall panels are self-supporting.

Vertical loads from the floors and roof are carried by transverse frames and walls, and the walls of staircases.

The spatial rigidity of the building is ensured by the joint work of the transverse frame frames, stiffening diaphragms, external wall panels and staircases, united by floor disks that are rigid in their plane. Longitudinal diaphragms are installed near the walls of staircases.

Foundations. A typical project of the 1-335AC series provides for the use of two types of foundations - strip foundations for external and internal transverse load-bearing walls and stiffening diaphragms, as well as columnar foundations for frame columns.

In strip foundations, monolithic reinforced concrete columnar foundations are built under the outer walls in places where columns are installed.

The basement walls are made of FBS24.4.6 foundation blocks and 1.0 m high plinth panels.

Frame. The transverse frames are formed by precast reinforced concrete columns and purlins. The column spacing is 2.6 and 3.2 m.

Purlins with a length of 5800 mm and a cross-sectional size b×h = 200×350 mm are laid along columns in the transverse direction. Design grade of concrete M300.

Reinforced concrete columns are designed to be one floor high. The columns of the middle row have section dimensions of 200×400 mm, the outer rows – 200×200 mm. Design grade of concrete M300.

The joints of columns with purlins are platform joints on steel embedded parts.

The transverse walls are load-bearing, made in the form of prefabricated reinforced concrete panels with a thickness of 140 mm.

Floors. The interfloor and attic floors are made of room-sized prefabricated reinforced concrete panels with dimensions of 5770×3170×110 and 5770×2580×100 mm. Design grade of concrete M300. Structurally, the panels are supported along the long sides by purlins and transverse load-bearing walls.

Walling.

The external walls of the building are self-supporting, made of prefabricated reinforced concrete panels.

Wall panels with nominal dimensions of 3185×2690 and 2585×2690 mm are single-layer, 350 mm thick, made of non-autoclaved aerated concrete. Design grade of aerated concrete M50, volumetric weight 1000-1200 kg/m3.

Interior partitions are plaster with a nominal thickness of 80 mm, inter-apartment partitions are double.

The staircases are two-flight, made up of prefabricated reinforced concrete flights and platforms.

The roof is a hip attic with a wooden rafter system and a covering of corrugated asbestos-cement sheets (slate), external drainage, organized or not.

The main defects and damage correspond to the list for buildings of the 1-335C series.

Episode 1–507

This is the most popular and widespread series of gray five-story “panels” in Leningrad. It was developed at Lenproekt in 1959, although in fact it is an exact copy of the Moscow series 1-515. The only difference is the material of the internal walls. Houses of series 1–507 are considered one of the most successful versions of all Khrushchev-era buildings built.

Most of these houses can be found in the north of Kupchino, in Vesyoly Settlement and Ulyanka. The largest Leningrad quarter of Khrushchev 507 series is along the Vitebsk railway in the Moskovsky district. The first two similar houses in the city were built 7 and 11 on Babushkina Street.

Kitchens in houses of this type are tiny: from five square meters in one-room apartments to seven in three- and four-room apartments. The toilet and bathroom are separate, but the rooms in the two-room and three-room apartments are adjacent. The area of the rooms varies from 8.6 to 18.3 square meters. meters, and the entire apartment - from 30 to 72 square meters. meters. The ceiling height is only 2.5 meters.

The 507 series features a wide range of modifications. After the first batch was put into circulation, engineers began thinking about improvements. They mainly changed the shape of the roof, “painted on” the balconies and loggias, and played with the size of the windows and the shape of the frames. As an experiment, seven-story Khrushchev-era buildings with external elevators were built (code E5-58).

Khrushchev 45. Series LG 502,504,507

So, by popular demand, we are moving to the City on the Neva.

The mass series in St. Petersburg are different from those in Moscow, but they are also very different from the all-Union ones. The reason for this was that Len ZNIIEP, unlike most design organizations outside the Moscow Ring Road, was engaged in its own developments, which, by the way, were implemented not only in Leningrad and the region... So, with the presence of K7 in the development, modified 468 and 335 th series, the most common series are LG, 50*, 60* and series I-528, 527. Later there were 111, 114,121 and 137 episodes. I will briefly go over them in this and subsequent “St. Petersburg” posts. By the way, from an article about LenZNIIEP:

LG502 series

So the classic 502.

The series turned out to be extremely good, for those years, of course... However, LenZNIIEP, as you know, did not stop there.

Series LG502B And already in 1965-66 the Series LG502B

Unlike its predecessor, it is produced by DSK-2. The panels were finished with ceramic tiles and there was a loggia at the end.

Plus all sorts of little things discovered during the operation...

But otherwise everything remains the same:

In the early 70s, this version of the 502 was also produced:

I was unable to find any additional information on it. Series LG-507

Approximately simultaneously with 502B, the LG-507 series appeared, which was even produced in a variation of 7 floors with an elevator, but never became widespread, but became the prototype, both planning and constructive, of the LG504 , which also inherited the planning solution...

LG507-7

The only thing that is clear from the analysis of the 504th series is that 507 is also a series with longitudinal load-bearing walls and is covered with tent flooring, which differs unfavorably from its Moscow product I-515, which has round-hollow floors. External walls are load-bearing.

I don’t have plans for it, just a few photos.

Series LG -504

Let me quote from the same article: That is, apart from the hipped ceilings, the series is an analogue of the Moscow 515 series in its 9-story incarnation. Well, I already wrote about the delights of tent slabs...

Panorama of the 10th entrance house of the 504th series:

The entrance itself. And the kitchen.

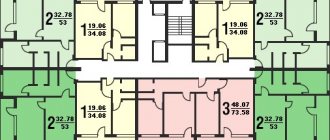

Floor layout:

The modern appearance of the series is as follows:

The LG 504 series turned out to be the most durable of all 500 Leningraders and in the 1-Lg504D2 -10 variation was built until the mid-80s.

The main advantage of the series is the ease of reconstruction and visually high ceilings.

Sources:

1. Forum MGSU-MISI. 2 Series of houses of the universe

Useful links:

1. The ever-hanging post “All Series” 2. Accidents of Civil Buildings. 3. Redevelopment in buildings with longitudinal load-bearing walls. 4. Search for a house by series, series by address

Previous series: 44. Khrushchev 44. Plattenbau and Panelak. _________________ No comments

GI series

Khrushchevs of this series were built in the Kirov and Krasnoselsky districts. Such houses were the least populated: there were only 10 apartments in the front door, two per floor. GI houses were built from 1958 to 1968. The walls of the buildings were not decorated with anything and were completely painted yellow, and even more often white. You won’t even find balconies on the facades.

However, the houses do not have one-room apartments or even two-room apartments. Rooms in three-ruble apartments occupy six, nine and 15 square meters. meters, and the combined bathroom is 2.2 square meters. meters. In living areas, the ceiling height reaches 2.5 meters, and in the bathroom it drops to 2.3 meters.

In winter it is very cold in such houses, and in summer it is too hot. In addition, asbestos, which is harmful to health, was found in the building materials from which the GI series houses were assembled. During the existence of the GI series houses in St. Petersburg, two houses on Chervonnaya Kazachestvo Street were insulated and renovated. The walls of the buildings were decorated, and window frames and pipes were replaced without relocating residents. Now several blocks with houses of this type are included in the renovation program.

Series 111-108

The series has been built since the 70s. Panel houses of 5-10 floors are being erected in Leningrad, Pskov, Novgorod, Smolensk, Penza and other regions and republics.

Read on our website: standard series of panel houses of 9 floors

Nine-story building 111-108

House structures:

- With spans of 5.1 and 6.3 meters and load-bearing longitudinal walls.

- With stiffening diaphragms at 3.0 and 6.3 m and transverse load-bearing walls.

Section floor layout

The first option is the main one. Recommended for construction using load-bearing external wall panels.

Houses with load-bearing transverse walls were built from lightweight panels. Now they use three-layer polystyrene concrete.

In both cases, the floors are hollow-core or made of solid prestressed slabs. Ceiling height 262 cm.

Layouts

The design of the series provides for different layouts. There are 2-6 apartments on the floor. There are houses where they are all one-room or all different, and the largest is 5-room.

The area of the one-room apartment is about 40 m2. Of these, 18 squares are a room, 10 are a kitchen, the rest are auxiliary premises.

Odnushka series 111-108

In two-room apartments, the apartment spaces face opposite sides.

The total area is just over 63 square meters. Of these, living space is 31 m2, kitchen is 12 m2.

Two-room vest

Three-room apartments of 72 m2 are oriented on two sides. The rooms occupy 39 m2, the kitchen – 13 m2.

Three ruble layout

Description

The structural design of the building consists of three longitudinal load-bearing walls. Cross walls provide rigidity. The external walls of the houses of the 1-507 series are made of expanded clay concrete panels 40 cm thick. The internal wall panels are 25 cm thick, and the panels with ventilation ducts are 28 cm thick. The bathrooms are made in the form of ready-made factory-made sanitary cabins.

The roof is flat and covered with bituminous materials.

Ceiling height is 2.5 m. There are balconies on all floors except the first.

Communications

Heating, water supply and sewerage are centralized. In a number of houses, heating risers were built into wall panels. The kitchens are equipped with gas stoves. There is no elevator or garbage chute.

There are 4 apartments on the landing of the house. Apartments are 1-, 2-, 3-, 4-room. In ordinary sections the most common set of apartments is 2-3-2-2, in end sections 2-2-2-1.

Apartments in terms of planning solutions differ little from other Khrushchev buildings. The area of the living room is 17-18 m2, the bedrooms are 9-12 m2, the kitchen is about 6 m2. Multi-room apartments have walk-through rooms. Bathrooms were initially combined in 1-room apartments, and since 1960 - also in 2-room apartments. Since 1964, all apartments have separate bathrooms.

Houses of series 1-507 are considered the highest quality of all Leningrad panel Khrushchev buildings. Houses of the 507 series differ from other panel Khrushchev buildings in their good thermal insulation due to thick outer panels, high quality construction and durability. The apartments in most houses have separate bathrooms, high-quality woodwork, and parquet floors.

The disadvantages of the houses are common to all Khrushchev buildings: small hallways and kitchens, walk-through rooms, low ceilings.

Khrushchev buildings of the 1-507 series were built by two DSKs and therefore are the most common in St. Petersburg: every fifth Khrushchev building (19%) built during the period 1958-1972 belongs to this standard series. The 1-507 series is most common in the Moscow region[2] - more than 200 houses. In total, just under 400 buildings of this project were erected. Several houses have also been built in Kolpino.

In recent years, major repairs have been carried out on the facades of the series buildings due to the breakdown of carpet tiles.

Typical projects

TechLib SPB UVT

Polina Dedyukhova

Series 1-335 with an incomplete frame is a residential building of 5 floors with longitudinal load-bearing walls. The structures were manufactured at prefabricated reinforced concrete factories of the USSR Ministry of Transport. Designs of the 335th series were produced at DSK from 1960 to 1968.

The series is widespread throughout the former USSR. The first house in this series was built in Cherepovets. In Moscow, the 335 series was built from imported structures; in block buildings it is found in the form of separate inclusions.

The largest number of houses in this series were built in St. Petersburg, where they were produced by Polyustrovsky DSK - 289 buildings, a total of 1,442 sections in the Krasnogvardeisky and Kalininsky districts of the city. In Omsk, 170 houses of the I-335PK series with an incomplete frame are in operation (more than 2% of the total volume of this series in the country). The most massive series of residential buildings in Kazakhstan.

In Tula, it was initially decided to build houses of a personalized series; the builders encountered a number of technological difficulties. Therefore, it was decided to introduce our own panels for construction, and thus the 1-335AT (Tula) series was born. Panels for it were produced at two factories - Aleksinsky Concrete Products and ZKD (Large Parts Plant). The first district where these houses began to be built was Proletarsky.

The appearance of 1-335 is characterized by wide apartment windows (double-hung ones look square), elongated windows on the staircases, almost the entire height of the panel. The end walls consist of 4 panels with windows on the outermost ones. Usually there is an external fire escape at one end of the house. For houses built in Moscow, a 4-pitched iron roof is typical. In another modification, including the one built by Polyustrovsky DSK (it is also found in the Moscow region), there may be a flat roof without an attic at all.

Load-bearing walls are longitudinal (as indicated by the I in the series title). The number of sections in the original modification is 3,4,5,6,8,10. There are 4 apartments on the site. The apartments are 1,2,3-room, ceiling height is 2.55 m. The central room in the 3-room apartment is a walk-through. Combined bathroom. Water and heat supply is centralized. There is no elevator or garbage chute.

Specifications for Series 1-335 Partial Frame

| Wall material | panel |

| Number of sections (entrances) | from 3 |

| Number of floors | 5, less often – 3, 4. First floor residential |

| Ceiling height | 2.54 m. |

| Elevator | No |

| Balconies | in all apartments |

| Number of apartments per floor | 4 |

| Years of construction | 1958-1966 |

| Total number of houses built | about 500 (in Moscow – 76 with a total total area of apartments of about 200 thousand sq. m) |

| Most of the houses of the 1-335 series were built in Leningrad (primarily the northeast of the city: Grazhdanka, Okhta, Polustrovo), etc. Dachnoe. Several blocks were built in the years. Cherepovets, Ulyanovsk, Volgograd, Novosibirsk, Omsk, Krasnoyarsk, etc. (including in several cities of Belarus). The series was built in less significant volumes in Moscow: 3-5 houses in the districts of Perovo, Sokolinaya Gora, Babushkin, Degunino, Kuntsevo, 1-2 buildings in a number of other districts. In the cities of the Moscow region, houses of the 1-335 series were built in single quantities, most of them in the cities. Shcherbinka and Podolsk | |

| Demolition of houses of the 1-335 series has been carried out in Moscow since the late 1990s. selectively (formally, the series is not included in the list of those to be demolished in the first place, since it is not among the most common series of “Khrushchev” buildings in Moscow, and in the BTI databases, 5-story buildings of the 1-335 series are often mistakenly listed as buildings of the undestructible series 1-515/5). The demolition of all houses of the 1-335 series in Moscow will be completed, according to experts from www.RussianRealty.ru, in 2015-2017. | |

| In St. Petersburg, houses of series 1-335 are undergoing sanitation (overhaul), some blocks are planned for demolition | |

| Areas of 1-room apartments | total: 30-31 sq. m., residential: 18 sq. m., kitchen: 6.3 sq. m. |

| Areas of 2-room apartments | total: 41-45 sq. m., residential: 26-35 sq. m., kitchen: 6.3-6.9 sq. m. |

| Areas of 3-room apartments | total: 55-58 sq. m., residential: 42-48 sq. m., kitchen: 6.3 sq. m. |

| Since 1964, modified versions of the 1-335 series have been introduced: 1-335A, 1-335K, 1-335AK, 1-335D with improved apartment layouts, improved design (full frame, better thermal insulation of external walls) and 9-story versions. No houses of modified versions were built in Moscow | |

| Bathrooms | combined in all apartments |

| Stairs | without a shared fire balcony |

| Garbage chute | No |

| Type of stove: gas. Ventilation: natural exhaust, units in sanitary cabins (bathrooms) | |

| Walls of houses of standard series 1-335 | External walls: two-layer reinforced concrete 30 cm thick or single-layer expanded clay concrete 40 cm thick. Floors: solid reinforced concrete slabs 10 cm thick. Interior partitions are made of gypsum concrete panels 8 cm thick, and inter-apartment partitions are made of the same panels in 2 layers with an air gap between them equal to 4 cm |

| Load-bearing walls | columns and external walls (partial frame) |

| Type of sections (entrances) | row (ordinary, set of apartments on the floor: 3-2-1-3, 2-2-3-2), end (set of apartments on the floor: 1-2-2-3). All apartments, except corner ones, face one side |

| Number of steps in a section (entrance) | 7 (in row sections), 6 (in end sections). Step width (distance between two adjacent load-bearing walls, floor span width): 260 cm, 320 cm. Body width: 11.6 m. |

| Cladding, plastering of external walls | facing with small square tiles (St. Petersburg), unveneered (Moscow, St. Petersburg, other cities) |

| External wall color options | tiles: blue-white, light grey, untiled: grey, white, yellow, beige |

| Roof type | 4-slope (Moscow), flat and flat-slope (other cities) |

| Distinctive features | 5-storey panel houses of the standard series 1-335 are recognizable by large, full-height panels, windows made of 4 horizontal sashes on the stairs, ends of 4 panels with 2 rows of windows |

| Advantages | availability of balconies, storage rooms |

| Disadvantages (in addition to the standard disadvantages of Khrushchev buildings) | extremely low thermal insulation of external walls, thin interior partitions, combined bathrooms even in 3-room apartments |

| Manufacturers | Polyustrovsky DSK (Leningrad), Vologda DSK, Petrozavodsk DSK, Tula ZKD, Large-panel parts plant No. 6-DSK-1 (Novosibirsk), Krasnoyarsk reinforced concrete plant No. 1, Omsk precast concrete plant No. 6, etc. |

| Designer | Design Institute "Gorstroyproekt" (Leningrad branch) |

| Varieties of standard projects of the 1-335 series (they differ only in the number of sections): | 1-335-1, 1-335-2, 1-335-3, 1-335-4, 1-335-30, 1-335-30sh |

| Cost of construction 1 sq. m of living space for frame-panel houses of the 1-335 series was 95 rubles. in 1961 prices - the lowest figure in the entire history of industrial housing construction in the USSR | |

| According to a number of experts, 1-335 is the most unsuccessful of all all-Union Khrushchev series | |

| 1-335 is the only series of houses found in both Moscow and St. Petersburg (the façade and roofing solutions differ significantly) | |

| RussianRealty.ru rating of type series 1-335 | 2.9 (on a 10-point scale) |

In support of the thesis that in frame-panel buildings it does not matter what parts and elements the frame is made of, and the standard durability will be determined by the attachment point of the horizontal structures to the fence itself, let us consider the example of a large-panel building of the 1-335 series with an incomplete frame. In appearance, it belongs to the industrial series with a durability of 150 years. However, the very design of such residential buildings, built since the early 60s of the last century, and most importantly, the qualities demonstrated during long-term operation, make it possible to classify such structures into the “Frame-panel” capital group.

| Appearance of the 1-335 series with partial frame | Plan of a typical end section with latitudinal orientation |

| Plan and section of series 1-335 with incomplete frame | Plan of an ordinary typical section with latitudinal orientation |

During the implementation of complex development in the 60s of the last century, these buildings were erected as a frame for the residential area being built up, they were also placed inside the microdistrict, but in place of the high-rise dominant - future 9-story buildings with elevators and garbage chutes, the mass commissioning of which started in 1968.

In the 60s of the last century, during the Cold War, there was a state housing program, during which each settlement, except for the mobile resettlement fund, had a set of structures for large-panel housing, assembled according to the frame-panel type.

It was believed that five-story structures used during mass development would be in use for no more than 15 years. Then they had to be dismantled and reinstalled in another place with a reduction in the number of storeys - as three-story buildings.

After 10 years of use, they were to be transported to the countryside and assembled into semi-detached single and double storey cottages with a lifespan of 150 years.

In order to facilitate installation and disassembly, columns were not installed on the outer longitudinal walls in these houses. A number of columns for supporting the crossbar of the floor slabs ran only along the internal longitudinal wall.

Thus, the crossbars, resting on the columns of the inner row with one end (highlighted in red in the figure), rested directly on the fence panel with the other end.

This needs to be sorted out. Why does the frame-panel system in Russia (where the heating season is on average 9 months) have such a low standard durability, regardless of the fact that in this case it is assembled from fully prefabricated durable elements designed for three cycles of installation and dismantling.

As we know, heat in a room rises. Thermal engineering calculation comes down to determining the thickness of the fence behind the end of the floor structures.

In this case, two-layer panels 150 mm thick were used as enclosing structures. Which did not meet the requirements of thermal engineering calculations. The "crossbar - outer fencing panel" assembly was constantly frozen. The calculation was that over the planned durability, the physical wear of the fencing panels during the “freezing-thawing” cycles would not exceed the permissible repairable level.

However, in practice it happened differently. The changed policy did not allow the planned operation of these unique “prefabricated” structures to continue. At a construction site, where the Soviet-era estimates included articles “Temporary buildings and structures,” which included buildings up to three floors, it is customary to say: “There is nothing more permanent than something temporary.”

Of course, the original idea of housing resettlement in 15-10 years was in itself utopian, given that the main instrument of housing policy was buildings with a standard durability of 150 years.

As a result, structures with a durability of 30 years, which should have been dismantled and reassembled back in the mid-70s of the last century, still stand among the structures with normal durability, not differing in any way from them in appearance.

There are 46 such houses in Izhevsk, they stand right among similar houses, where columns are placed on the outer walls, so their standard durability is far from exhausted, and the building itself has a normal microclimate.

Today, residential large-panel buildings with incomplete frames pose a huge threat to residents.

All these structures were already in a pre-emergency condition by the end of the 80s. The destruction of these buildings can occur at any time according to an unpredictable scenario - due to the brittle destruction of metal embedded parts that have significantly corroded over the period of operation. This kind of building was supposed to be reconstructed primarily in the mid-80s of the last century.

At present, they have not yet been reconstructed, although all permissible deadlines have been missed. At the same time, the authorities are deliberately demolishing not these houses, but similar ones that have a standard life of 150 years, but are located in places that are more attractive for modern development.

According to the results of external inspections carried out back in Soviet times, the standard durability indicators for horizontal protruding elements were significantly reduced - up to 25 years. These are canopies, balconies and loggias.

In the first mass series, metal fencing was used at the protruding elements. Practice has shown that during the heat exchange process, it is at the contact with the “cold bridges”, which will be all metal structures, that the main concentration of freezing condensing moisture occurs. When freezing, condensate droplets expand, forming shells and cavities. After 10-15 heating seasons, irreversible damage occurs.

Without taking this data into account, today attempts are being made to strengthen protruding reinforced concrete elements using metal parts and reinforcement structures.

Main advantages of the 1-335 series

- The minimum number of load-bearing internal elements, which allows the principle of “flexible planning” to be implemented;

- High technological effectiveness of manufacturing and installation of structures;

- Design of a technical underground, which allowed housing to be put into operation rhythmically throughout the year in the northern regions of the country.

| View of the balconies of a large-panel residential building built in 1962. Izhevsk, 2007 |

General information about houses of series 1-335

| Purpose | Residential building |

| Number of storeys | 5 floors, ground floor, basement |

| dimensions | 67.2 m / 12.0 m |

| Spatial rigidity | Longitudinal direction – longitudinal load-bearing walls, floors. Transverse direction – external end, transverse walls |

| Wed. apartment area | 39.7 m2 |

Description of load-bearing structures series 1-335

| Foundations | Prefabricated reinforced concrete strips |

| Walls | Double Layer Heavy Concrete Wall Panel |

| Partitions | Plaster t=80 mm |

| Floors | Reinforced concrete hollow slabs |

| Coating | Pitched, on wooden rafters made of boards “on edge” |

| Stairs | Prefabricated reinforced concrete marches |

Disadvantages of the 1-335 series

- Insufficient rigidity of the assembly of the balcony slab in the wall panel, floor slabs;

- Incorrect arrangement of layers in a two-layer wall panel;

- Unreliable waterproofing of the seams of the wall panels, as a result of which leakage of the seams was confirmed by inspection;

- Inconsistency of space-planning and design solutions of apartments with modern requirements.

At the moment, these structures can no longer be dismantled and require urgent reconstruction measures to strengthen the entire building as a whole:

- External frame devices with unfastening of the crossbar support unit to strengthen and unload the existing building frame;

- Cutting worn balcony slabs;

- Expansion of openings in external wall panels, sealing of vertical and horizontal platform joints in them;

- Replacement of floors, window frames, door frames.

In addition, the planned reconstruction of the entrance areas with the installation of ramps for children and wheelchairs, installation of attached passenger elevators and garbage chutes is necessary.

During the reconstruction work, all residents would receive significant benefits, except for those living on the first floors. For them, back in Soviet times, special reconstruction projects were developed with the construction of separate entrance groups.

It is easy to notice that the installation of attached entrance groups with elevators and garbage chutes, attached loggias along the contour of the building - expands the building, allows you to unfasten the frozen joint of the crossbar to the fence.

This solution allows not only to strengthen an incomplete frame, but also to create new thermally efficient enclosing structures, dry and repair old fencing structures, and restore a normal microclimate in the building.

Redevelopment projects of the 1-335 series with an incomplete frame during reconstruction with the installation of attached entrance groups with elevators and garbage chutes and attached loggias

There are various solutions that involve partial dismantling of the fencing panels and the installation of attached structures that expand the body of the structure along the entire longitudinal contour. There are also more economical options, where only attached entrance groups and attached loggias are built, reinforcing the incomplete frame of the building from the outside.

| Reconstruction project for a large-panel house of series 1-335 built in 1964 in Izhevsk on the street. Vorovsky with the installation of elevators, garbage chutes, strengthening and expansion of the building, and the addition of the attic floor |

When expanding the building, problems arise with insulation of the premises due to the low floor height of the first mass series. However, this issue is resolved by constructing two-level apartments with a hall that has a “second light.”

| A project for the reconstruction of a microdistrict of large-block houses built in 1964 in Izhevsk with significant densification of the development by connecting three residential buildings in the most worn-out end part - into a single residential ensemble with two-level apartments | |

The current approaches to the reconstruction of large-panel buildings with external insulation have not yielded positive changes. In buildings, there was an increased growth of black mold in the upper corners of residential premises, that is, the process of freezing and destruction of structures did not slow down, but intensified.

Attempts to strengthen the angle of support of the crossbar on the outer panel of the fence from the inside, with a device similar to the internal frame, also did not yield results. In Soviet times, there were attempts to strengthen these nodes with the help of logs installed in the corners.

The internal frame, which does not have its own foundation and rests on floor slabs, only cosmetically solves the problem of frostbite, provided that it is covered with sheets of plasterboard. It should be taken into account that the majority of the examined crossbars had an unacceptable deflection back in the 80s.

In semi-frame structures of the 1-335 series, during the installation of attached loggias, it was planned to install a fastening unit for the head of the crossbar to transfer the load from worn units to the outer frame along the perimeter of the entire structure. Due to the fact that the reconstruction measures planned for the late 80s were not carried out, currently, during the reconstruction activities, the balcony slabs and canopies must be dismantled.

The installation of heated loggias had to perform the following functions:

— creation of an additional thermal protection belt before repairing and sealing panel joints; — improvement of insolation of interior spaces due to three-sided natural lighting; — increasing the comfort of living quarters; — creation of a rigid outer frame around the entire perimeter of the building.

All these measures must be carried out in a short time with the complete resettlement of residents on a permanent or temporary basis. Their implementation would help reduce social tension in society and solve the housing problem in an economical way beneficial for all participants in the reconstruction process.

Posted in Capital Group “Frame-panel”, Design of buildings and structures, Thermal engineering calculations, Technical typology, Technology of strengthening building structures

"Design of launch complexes at the Vostochny Cosmodrome"

Large-block buildings »

Series 1–527 and 1–528

Reinforced concrete 1–527 and brick 1–528 are decorated as much as possible in conditions of widespread simplification. Most often they are standard yellow, but there are examples with windows highlighted with white paint. The brick series was most often not plastered.

Brick Khrushchev series 1–528

Apartments in series 1–528 were praised for their high-quality parquet flooring, curly doors and high ceilings - 2.7 meters. However, the disadvantages remained the same: tiny kitchens and hallways, several adjacent rooms in large apartments.

Description[ | ]

The structural design of the building consists of three longitudinal load-bearing walls. Cross walls provide rigidity. The external walls of the houses of the 1-507 series are made of expanded clay concrete panels 40 cm thick. The internal wall panels are 25 cm thick, and the panels with ventilation ducts are 28 cm thick. The bathrooms are made in the form of ready-made factory-made sanitary cabins.

The roof is flat and covered with bituminous materials.

Ceiling height is 2.5 m. There are balconies on all floors except the first.

Communications[ | ]

Heating, water supply and sewerage are centralized. In a number of houses, heating risers were built into wall panels. The kitchens are equipped with gas stoves. There is no elevator or garbage chute.

There are 4 apartments on the landing of the house. Apartments are 1-, 2-, 3-, 4-room. In ordinary sections the most common set of apartments is 2-3-2-2, in end sections 2-2-2-1.

Apartments in terms of planning solutions differ little from other Khrushchev buildings. The area of the living room is 17-18 m2, the bedrooms are 9-12 m2, the kitchen is about 6 m2. Multi-room apartments have walk-through rooms. Bathrooms were initially combined in 1-room apartments, and since 1960 - also in 2-room apartments. Since 1964, all apartments have separate bathrooms.

Houses of series 1-507 are considered the highest quality of all Leningrad panel Khrushchev buildings. Houses of the 507 series differ from other panel Khrushchev buildings in their good thermal insulation due to thick outer panels, high quality construction and durability. The apartments in most houses have separate bathrooms, high-quality woodwork, and parquet floors.

The disadvantages of the houses are common to all Khrushchev buildings: small hallways and kitchens, walk-through rooms, low ceilings.

Khrushchev buildings of the 1-507 series were built by two DSKs and therefore are the most common in St. Petersburg: every fifth Khrushchev building (19%) built during the period 1958-1972 belongs to this standard series. The 1-507 series is most common in the Moscow region[2] - more than 200 houses. In total, just under 400 buildings of this project were erected. Several houses have also been built in Kolpino.

In recent years, major repairs have been carried out on the facades of the series buildings due to the breakdown of carpet tiles.

Typical projects[ | ]

House series 1-335 layout. Typical house series I-335 with apartment layouts

The series will be added to the group of Series of 5-storey panel houses

Houses of the I-335 series were built from 1958 to 1966 and are an example of a five-story panel Khrushchev housing type of construction. The series was not popular with developers, and therefore had many different modifications I-335K, I-335A, I-335AK and I-335D, which were produced until the end of the 1980s and in some cities grew to 7 or 9 floors .

The color scheme of external walls: is formed by applying cladding with small square tiles, so houses are usually white or gray, and those that are left without cladding are yellow or beige. In the houses of the I-335 series, the number of floors is about 5, in the older versions there are 3 or 4, with the first floor being mainly residential. The number of sections/entrances varies from 3. All houses do not have an elevator. There are four apartments on each floor. Balconies are available in all apartments.

One-room apartments have a living area of 18 m², a kitchen of 6 m²; in two-room apartments, living area 26-35 m², kitchen 6-7 m²; in three-room apartments, living space is 42-48 m², kitchen is 6-7 m². In three-room apartments, the central room is a walk-through room.

The bathroom is combined, the bathrooms are standard, but not sit-down. Ventilation is natural exhaust through a ventilation unit in the bathroom. There is no garbage chute. Stairs without fire balconies.

Internal walls: brickwork 51 cm thick. External walls - two-layer reinforced concrete panels, thickness varies from 30 cm. Partitions are gypsum concrete panels 8 cm thick. Floors are solid reinforced concrete slabs 10 cm thick. Load-bearing walls are all columns and external ones.

Advantages: good size of apartments, balconies and storage rooms. Disadvantages: low thermal insulation, combined units, thin interior walls.

Some of the I-335 series homes are on the "Demolition" list.

OD series

The first trial version of Khrushchev-era buildings in the USSR was the K-7 series, which was built in the Moscow district of New Cheryomushki. There were no houses with that name in Leningrad. An exact copy was built here, but with its own name - the OD series. They were erected by the Obukhovsky DSK until 1963 and mainly in the Nevsky district. Several houses can be found on Piskarevka and Grazhdanka.

End with one window in the middle

In this series, as in 1-335, it will not be possible to hide from the noise behind a four-centimeter wall inside the apartment. Apartments, according to tradition, have cramped bathrooms with an area of no more than two square meters. meters, five-meter kitchens. The houses in this series do not have balconies or loggias, and the floors are covered with linoleum instead of parquet.

Panel houses series 1-507

The location of Khrushchevka can be found throughout St. Petersburg, in developed areas, near the metro.

Architecture and layout The largest array of houses in this series is located in the expensive Moscow region, along the Vitebsk railway. The massive scale of such developments is evidenced by the fact that every fourth Khrushchev building is a series 1-507. Construction time: 1956-1972. The apartments consist mostly of 2-3 adjacent rooms, a kitchen up to 7 m2, and a fairly large storage area. Early buildings had a combined bathroom, later ones had a separate one. Such houses are considered to be of high quality: they have high heat and sound insulation properties, durable external panels and reliable floors between floors.

Double-leaf window: Order PRICE: 6,800 RUR. TURNKEY PRICE: 12,600 RUR. Prices include seasonal discounts.

Three-leaf window: Order PRICE: 10,500 RUR. TURNKEY PRICE: 17,500 RUR. prices include seasonal discounts.

Balcony block: Order PRICE: 11,500 RUR. TURNKEY PRICE: 20,700 RUR. Prices include seasonal discounts.

For houses of the 1-507 series, the service of glazing and insulation of loggias and balconies is also in demand. Its popularity is explained, firstly, by the shortage of usable space in the apartments of our densely populated metropolis, and, secondly, by the harsh local climate, which requires the creation of additional barriers to the cold wind and dampness. Our Company's prices for glazing loggias are among the most affordable in the city. Why is it profitable to buy plastic windows from us? We have our own window factory and therefore we will quickly and efficiently fulfill any order for plastic windows, balcony blocks or glazing of loggias.

Source