Warm floors have long become synonymous with comfort in the home. It will help cope with dampness and ensure pleasant movement around the premises. However, it should not only be pleasant to walk on, but also completely safe. This means that you need to be careful when choosing equipment and the finishing itself. Which coating is best for a warm water floor?

Which coating is better for a warm water floor?

Installation of water heated floor systems

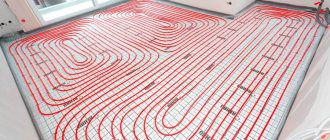

Underfloor heating, which operates thanks to heating water, is a structure created from a heating circuit, which is usually filled with a cement screed. But a water floor can also be made without the use of cement mortars - this is relevant for those rooms where the floors cannot experience significant loads.

Water heated floor diagram

Floors with concrete screed are the following design (pie).

- Rough subfloor . As a rule, this is a floor or concrete screed on the ground.

- A layer of waterproofing material . It is necessary that groundwater does not penetrate into the room from below. Relevant for rough floors on the ground, and for rooms located on the first floor above the basement.

- Insulation layer. Typically, polystyrene foam is used, which does an excellent job of preventing heat leakage into the ground, floor slab or basement.

Why do you need to insulate underfloor heating?

- Polyethylene layer . Usually laid in two layers. It will not allow water from the concrete mixture to go into the ground or be absorbed into the insulation. By the way, foil insulation, which is popular in the construction industry, cannot be used for these purposes, since the environment created by the action of concrete is very aggressive, and the substances contained in the cement mixture can corrode the material.

- Reinforcing mesh with cells about 5-10 cm . Necessary to strengthen the screed and secure the pipeline.

- Pipes for the heating system. A water circuit is created from it. It is secured with plastic clamps onto a reinforcing mesh. To create a heating system operating on hot water, it is optimal to lay the pipe in increments of 10-30 cm. Clamps are used 2-3 pieces per meter.

Pipe for water heated floor

- Layer of concrete screed . It is poured over the supplied and connected system.

- Substrate . Placed on top of the screed under the floor covering. You can use, for example, foamed polyethylene, isolon, etc.

- Finish coating.

It is the correct choice of the final coating that will be discussed today. It turns out that not every material can be laid on top of heated floor structures.

How individual floor coverings affect the passage of heat from the heating system into the room

It is worth remembering that a warm floor is not a home heating system, it is only an element necessary for a comfortable stay. It is not able to completely heat the room. Surface heating as a result of the heating system cannot exceed +29 degrees. And a water floor cannot be heated by more than +50 degrees. And the level of its heating is quite difficult to regulate - this is influenced by many factors. That is why choosing a suitable floor covering in this case is not as simple as it seems at first glance.

Warm floor

Heated water takes a long time to cool down. If the system is overheated, it will not cool down instantly. Unfortunately, some types of floor coverings react negatively to sudden temperature fluctuations and excessive heating, collapsing and losing performance, and can also begin to release substances into the air that have a negative effect on the human body.

On a note! If necessary, you can quickly cool only the now popular infrared floor. The floor on the water takes a long time to cool down.

Operating principle of IR floor

Advantages and disadvantages

The following other points count in favor of underfloor heating:

- savings during operation up to 45%;

- the ability to avoid installing radiators, which allows for better use of room space;

- The finishing coating is suitable from any material;

- the air warms up more evenly, there are no drafts;

- The comfort of being in a space heated by thermal radiation is much higher than with radiator heating.

However, there are also disadvantages, which include a drop in pressure in the heating system due to the coolant diverted to heated floors, as well as the inability to quickly find and repair a leak in the event of an accident.

In any case, the main argument in favor of underfloor heating is the ability to increase living comfort while saving significant money.

Thermal conductivity of floor coverings

There are a large number of different types of flooring, ranging from ceramic tiles to wood. All of them have their own specific properties, among which one of the main ones is thermal conductivity. Before we get acquainted with the thermal conductivity indicators of floor coverings, let’s figure out what kind of concept this is – thermal conductivity. In simple words, it is the ability of bodies or materials to transfer heat . The higher it is, the faster the material heats up, but also cools down faster.

Table. Thermal conductivity coefficients.

| Name of coating | Coefficient value, W/m*k |

| Tile | 1,05 |

| Linoleum | 0,2 |

| Parquet board | 0,15 |

| Carpet, carpeting | 0,12 |

| Laminate | 0,1 |

| Cork | 0,034 |

The lower the thermal conductivity, the longer the coating retains heat. Based on the table, we can conclude that the material that retains heat the longest is cork. Tiles retain thermal energy the worst, but they heat up quickly.

Cork floor

In order for floor heating to be as effective as possible, the finishing material must conduct heat quickly and well. Ceramic tiles are the leader here, although they require fairly powerful heating.

Advice! Solving the problem with heating power is simple - just buy more powerful heaters; The pipe is also laid at more frequent intervals. Heaters with a power rating of at least 200 W/m2 are purchased for tiles.

Floor covering for heated floors

Use of ceramic coatings

The best coating option for this type of floor heating is ceramic tiles. Even with strong heating, it remains the most environmentally friendly material among all those used for the final stage of floor finishing. Also, even with repeated heating-cooling cycles, it does not collapse, has maximum moisture resistance, and is easy to clean. By the way, a high heating rate can also be a disadvantage of using ceramics - it is not always beneficial for the feet. Tiles as a finishing coating for a water floor are the best option for those whose feet are constantly cold and who often catch colds.

Warm floor under tiles

On a note! It is not recommended to install such a covering in a children's room, however, in the bathroom or kitchen, as well as in the hallway, ceramic tiles would be the best option.

In general, tiles of this type can be laid in absolutely any room if the owner is satisfied with it as a covering. It is worth remembering that heated floors are usually installed where there is long-term contact between the feet and the floor.

Tile over heated floor

However, you need to choose ceramic tiles wisely. For example, if the floors in the room will not experience significant loads, then you can lay fairly thin tiles. This will achieve maximum temperature. It is recommended to pay attention to the following indicators when choosing a material.

- Hardness of the material . It is characterized by the so-called ten-step Mohs scale. You can purchase tiles for your apartment that belong to hardness class 5-6.

- Water absorption. In rooms where the humidity level is high, tiles with the lowest value are laid - no more than 3%; for the rest, with the exception of the kitchen, this parameter can be any. For the kitchen, it is recommended to use tiles with a water absorption value of 6%.

Characteristics of floor tiles

- Wear resistance . According to this indicator, the tiles are divided into 5 classes. In rooms where the impact on the floor is insignificant, you can lay tiles of class 2, but in other rooms it is better to use material of class 3 or 4.

- Resistance to chemical reagents . Any tile itself is a fairly durable material in this regard, but this indicator is especially relevant for floors in the garage, kitchen, and bathroom.

Warm floor under tiles

Attention is also paid to the porosity of the material. Experts do not recommend using low-density material.

Laying tiles on water floors is done in this way: the heating system itself is installed, which is then filled with a cement-based screed. Next, the tiles are laid in accordance with the selected pattern and, using a special glue, are glued to the surface of the dried screed. It is important to check the evenness of the rough foundation using a horizontal level. You can turn on the system only after the glue has completely dried, otherwise you can ruin the quality of the work on laying the floor covering.

Laying a warm water floor under the tiles

Prices for popular types of floor tiles

floor tile

Finishing a water floor with a wooden covering

Natural wood floors have excellent environmental performance. They are pleasant to the touch and durable, which is the reason for their high popularity. However, this is not the best option for a water floor - it is not recommended to heat a wooden base above +27 degrees. Otherwise it will dry out. In general, it is possible to use this type of coating on a water heating system, but it is important to carefully monitor the temperature indicators - the floors should not work at full power.

Water-heated floor under wooden flooring

The same can be said for engineered and parquet boards. By the way, the latter can only be installed in a floating manner. It is better to use a parquet board that is 4 mm thick and has an oil rather than a varnish coating. The engineered board should not be thicker than 16 mm, otherwise it will take a long time to heat up.

Engineering board - features

On a note! Wood coating has low thermal conductivity, which means it will reduce the efficiency of the heating systems themselves. A wooden floor can unwittingly serve as a barrier to the entry of thermal energy into the room.

A wooden floor installed on a water heating system can cause a lot of trouble in the autumn or spring. Due to sudden changes in humidity and temperature, the coating will begin to deform and cracks may appear.

For coverings laid on water-heated floors, it is better to use wood obtained from exotic tree species. Such materials are characterized by higher resistance to moisture, are not prone to shrinkage and have excellent thermal conductivity compared to other rocks. It can be teak, rosewood. But the cost of wood from these trees is quite high.

Installation of a warm water floor

On a note! The boards from which the floor will be made should not be thick, otherwise heat will not penetrate well into the room. However, the best option for heating wooden floor coverings is infrared floors.

Prices for engineered boards

engineering board

Laminate

Popular types of flooring include laminate. The material has excellent thermal conductivity, is resistant to various chemical influences, but is afraid of moisture. Also, when choosing this material, it is worth buying a laminate that is suitable specifically for laying on heated floors - it is marked with special symbols and must be at least 32 strength classes. Slats without markings cannot be laid on heated floors. The thickness of the laminate for laying on the floor should be no more than 8-10 mm.

Warm floor under laminate

It is also important to place a special underlay under the laminate if it is laid on a water floor. But in any case, heating the material above +30 degrees is not recommended. Most often, the laminate is laid on an IR film floor.

Attention! Cheap laminate cannot be used on heated floors, and the slats cannot be heated too much. This is due to the fact that the material is capable of releasing formaldehyde, a dangerous carcinogen, into the environment at high temperatures. Thus, indoor air becomes unsafe for health. Symptoms of formaldehyde poisoning are headaches, nausea, cough, etc. Laminate with the lowest formaldehyde content is marked with the designations E1 and E0.

Prices for Tarkett laminate

Tarquette laminate

Linoleum on warm floor

This type of coating is also one of the most popular types of finishes. It is used quite often, but can it be laid on warm water floors? So, for laying on the heating system, you can only use natural linoleums (marmoleums) or those made of PVC (vinyl). The second type is a cheaper option.

Linoleum

At the same time, there should be no insulation on the linoleum, since the thermal conductivity of such material is quite low. And in general, linoleum should be chosen with a minimum thickness.

Conclusion

So, if you don’t like the “house rolled up in tiles,” there are plenty of other compromise options. “Everyone chooses for himself...” and “Everyone chooses for himself...” Choose.

For those who prefer to collect as much information as possible, there are 57 pages of discussion about choosing coverage for TP. About what natural linoleum is, see the material “Marmoleum - new/old floor covering.” You can read about quartz vinyl tiles in this article. The video is about heating in Churchhouse, including underfloor heating.

Subscribe to our Telegram channelExclusive posts every week

How to choose a coating?

Let's summarize all of the above and answer the question - what type of finishing coating should you choose? For heated floors on water it is not recommended to use:

- coatings created on the basis of bamboo raw materials;

- low-quality and thick linoleum;

- classic parquet.

On floors that are heated by water, you can lay a certain type of laminate or carpet. They retain heat well, but it is important to ensure that the material does not overheat. This is the best option for bedrooms and living rooms. PVC-based coverings can also be laid over floors. Although such materials usually do not look very presentable.

Warm floor under laminate

Ceramic tiles are the best option, but they will not look good in a bedroom or nursery. But in the kitchen or bathroom it is irreplaceable.

In general, the choice of flooring will depend on a huge number of factors - the purpose of the room, operating conditions, the functionality of the entire heating system of the house or apartment, the strength of the coating, etc. The best option is to cover the hall and rooms with carpet or laminate, and in the kitchen, bathroom , bathroom and hallway, cover the heated floors with tiles.

Video - Coatings for heated floors

Types of equipment

The main element of the system is communications. Recommended diameter is 20 mm. This is enough for normal coolant circulation in a private home. In addition, due to the small size of the pipes, the overall thickness of the screed over the underfloor heating system will be minimal. It is recommended to use polyethylene (made of cross-linked material) or reinforced multilayer communications.

The second important element of a warm floor covering system is the collector. This is a universal unit that performs the function of a distributor, and additionally, with its help, the heating of the system circuits is adjusted. The manifold often contains thermostats, pumps, and pressure stabilizers. In order for this unit to function efficiently and without failures, it is recommended to determine a suitable location for its installation.

The manifold is often offered assembled, with all components combined in a cabinet. It is recommended to choose this option when installing a warm floor covering if you plan to carry out the work yourself. It is advisable to install the most economical boiler, since the costs of operating the heating circuits will increase. It is allowed to use gas, electric, solid fuel and diesel boiler equipment.

Making a water heated floor

Step 1. The rough base is thoroughly cleaned. Debris is removed and dust is removed using a construction vacuum cleaner.

Preparing the subfloor

Step 2. A layer of waterproofing material is laid. Individual strips of waterproofing are connected to each other using tape. Insulation is laid on the surface. If the waterproofing is under the screed, then it does not need to be re-installed.

Laying insulation

Step 3. The insulation boards are fixed to the floor using special “fungi”, holes for which are drilled with a powerful drill or hammer drill.

Drilling holes for "fungi"

Insulation boards are attached to the floor

Step 4. A reinforcing mesh is laid on the surface of the insulation and secured using “fungi”. The mesh is laid with an overlap in 1 cell, and the individual webs are fastened to each other using plastic clamps.

Connecting reinforcing mesh sheets

Drilling holes for fasteners

Fixing the reinforcing mesh

Step 5. A manifold is installed to which the water floor pipes will be connected. The collectors are wall mounted.

Installed floor heating collector

Step 6. A special compensation tape is attached to the wall along the floor to compensate for the thermal expansion of the screed.

Compensation tape

Step 7. In accordance with the laying diagram, the pipe for the heating circuit is laid on the reinforcing mesh and secured to it using plastic clamps.

Laying pipes for a heated floor circuit

Heated floor pipe circuit length calculator

Go to calculations

Step 8. Pipes are connected to the collector. Before pouring the screeds, they are filled with water.

Connecting pipes to the collector

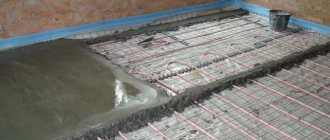

Step 9. Beacons are installed on the floor. The beacons are leveled using a construction laser level. It is important to remember that the thickness of the screed, starting from the level of the pipes, should not be less than 4 cm.

Beacons installed

Step 10. The cement screed is poured in accordance with all the rules. After it has completely dried (about 28 days), the selected floor covering can be laid on the floor. You cannot turn on the heated floor until the screed is completely dry.

The screed is poured

SNiP 2.03.13-88. Floors. Downloadable file (click the link to open the PDF in a new window).

SNiP 2.03.13-88

Video - Warm floor under laminate

Selecting and connecting the collector and boiler

When it is clear how many circuits will be connected to the manifold, you can begin to select its length and decide on the number of valves, but also take into account that in order to be able to regulate the warm coating mode, you will need a pressure sensor, air vents, and drains.

The manifold with its lower pipe should be located at the same level as the supply pipeline, slightly above the floor level.

There are specially developed plumbing standards for the assembly of this unit. It is best to hide the collector in a niche in the wall, approximately in the middle in relation to all the contours.

The boiler is selected based on its power sufficient to heat water, plus a certain power reserve. The total required power is determined as follows: 20% should be added to the sum of the circuit powers for the reserve.

For greater efficiency of the system, it is advisable to install a circulation pump; in most boiler models, the pump is already included in the kit, capable of providing hot water to a one- or two-story house with an area of 120-140 m2. For large areas, additional pumps are needed.