Style trends in interior design are increasingly influencing the modification of staircase structures. Thus, cantilever stairs are gaining popularity. Its advantage is that it does not interfere with the spread of light indoors. This design looks quite non-standard, one might even say bizarre. The treads simply hang in the air on consoles lowered from the ceiling. But you shouldn’t be afraid to walk on it, because the design is well thought out. If you have construction experience and desire, you can make a comfortable and unusual cantilever staircase with your own hands.

Cantilever staircase

Design features

Design advantages:

- unusual appearance;

- low material consumption - such stairs do not have risers, and sometimes even railings;

- space saving.

It is important when designing such a structure to take into account the loads perceived by the tread . They must withstand 150 kg. – and this figure does not take into account the weight of the handrails.

Even organizations engaged in the manufacture of cantilever staircases do not have products ready for installation. They have only individual elements from which the march will later be assembled. Each design must be developed individually for the customer, taking into account all conditions.

But making such a staircase is quite difficult. Its installation takes place during the construction stage or before finishing the premises. There are several ways to attach treads :

- Embedding steps into the wall.

- Embedding brackets into the enclosing structure, onto which treads will subsequently be attached.

- Fastening steps using anchors.

- Ceiling mount.

- Brackets that are welded or screwed to a steel bowstring.

General information

Note: For safe use, steps can be reinforced without disturbing the overall design concept using metal cables or rods attached along the edge of the steps and the ceiling. So, the staircase seems suspended.

The following advantages of such structures can be identified:

- Lightweight and compact;

- Spectacular look;

- Saving costs on building materials;

- The useful area and the total volume of space are saved, which is especially appreciated for small rooms.

However, there are also disadvantages here. Due to the fact that there are no fences on it, it is not safe for movement, especially if there are children in the house. Also, the design, calculation part, and installation work are not very simple.

The wall to which the ladder will be attached must have a load-bearing capacity, preferably with a reserve. Here you need to take into account the mass of the steps themselves. For example, steps made of wood or glass will not require additional reinforcement of the wall, but cast concrete steps will require fairly reliable support.

Important: Even at the design stage, take into account the fact that the tread must withstand a load of 150 kg.

Materials

The following materials can be used to create an air structure:

- Metal elements because metal steps are a rare occurrence;

- Wood is a favorite when making stairs;

- Plastic parts for treads;

- Concrete. This material is also used, but it is very heavy for this option, requiring reinforcement of each part.

Attaching the ladder to the wall

As already mentioned, the cantilever staircase does not have a support as such, instead there are the following methods for their construction:

- Built-in niche. Steps are inserted into the depth of the wall 20-40 cm, depending on the material of the wall and the width of the cantilever flight;

- The steps are mounted on a stringer - a complex welded structure. This is a replacement for wall mounting in cases where the wall has low load-bearing capacity. This frame is located as close to the wall as possible and is made as little visible as possible.;

- On pain. The free part of the tread, with the load transferred to the subsequent element, before being secured to the floor or ceiling;

- On a cable. This is an additional support that replaces the handrails. Here the entire load from the free side of the step is transferred to the ceiling;

- Fixation to the profile is similar to a stringer. It is considered the most reliable method, where the steps are attached to the profile, after which they are sheathed with plasterboard.

If you are still at the stage of building a brick or block house, then it is better to install treads at this moment.

Important: The distance between steps should be one-fourth of the length of the step itself.

When installing steps using a cantilever support bracket, a cantilever support in the form of a 1 m pipe is mounted into the wall. The depth is taken from 25 to 30 cm. In this method, the use of solid wood and particle boards is allowed, since the tread here does not act as a load-bearing part and the bracket receives the entire load.

The fastening method using anchors is used on an already erected wall and when it is impossible to use a finished structure using fasteners. Of course, the main indicator here is the material.

Important: A block or brick wall with anchors cannot withstand heavy weight.

However, even if the wall is not strong, there is a way. To prevent the anchor from being pulled out, it will be necessary to expand the support. To do this, use a welded cantilever metal support with a platform.

Fixing to the ceiling surface is also considered an excellent alternative when the wall strength is low. It is better to fasten the steps before finishing. The method consists of using a heavy-duty metal frame made of corrugated pipe or channel. Fastenings can be made both to the ceiling and to the floor covering.

A bracket for the steps is welded to this rack. The finished structure is finished with plasterboard or laid out using light blocks.

Fixing the bowstring is considered a complex method that requires a professional approach. It consists of screwing the bracket to the string, which is fixed to the ceiling with an impressive support or anchor.

Important: This device must be equipped with welded trusses with perpendicular and diagonal stiffeners. This intricate structure is necessary to prevent the bowstring from rolling under significant loads.

Sealing the steps

If the house is made of brick or heavy blocks, a good option for installing a cantilever staircase would be to seal the steps during the construction stage . To do this, the ends of the treads must be embedded into the wall at a distance of 1/4 of the finished product. So, if you want to make a flight of stairs equal to 80 cm, then you need to lay 20 cm steps. Another requirement for this installation option is that the tread must be pressed down with at least ten rows of masonry.

Sealing the steps

In the case of using lighter building materials, such as porous ceramic, hollow expanded clay concrete blocks or slotted bricks, the depth of laying the treads increases by 1.5-2 times and will be 30-40 cm. This will be difficult to implement if the thickness of the designed wall is less than required.

Aerated concrete buildings also have their own design features for cantilever staircases. In the walls, it will be necessary to strengthen the places where all treads are sealed using embedded elements made of heavy concrete. There is no need to worry about the appearance, because there are decorative overlays, for example, wooden ones. Laminated panels, natural or artificial stone are also suitable. When using this design in a loft style solution, you can leave everything unchanged.

Sealing the brackets

Sealing the brackets

With this option for installing a cantilever staircase, it is necessary to wall up a profile pipe no more than a meter long into the wall . The depth of the bookmark should be at least 25-30 centimeters. The remaining outlets should correspond to 2/3 of the tread length. The requirements for the walls remain the same, and the possibility of choosing the material for the steps has expanded. For this fastening option, you can use engineered solid wood, as well as materials based on wood composite, such as chipboard, MOR. This happens because the treads no longer act as self-supporting structures. The entire load is transferred to the brackets embedded in the wall. Metal parts can be hidden in grooves or holes that are drilled into the treads.

Fastening with anchors

This method is used when the walls have already been erected and it is not possible to embed fasteners into the finished enclosing structure, as in the first two cases. But at the same time, the material also remains important . Walls made of porous block or slotted brick are unable to hold anchors.

To reduce the possibility of anchors being pulled out if the walls are not made of sufficiently strong material, it is necessary to significantly increase the size of the support areas.

In order to carry out such an installation of a cantilever staircase, you will need welded brackets with support platforms. The finished elements must be attached to the wall at the location of the steps using anchor bolts. Their number must be at least four, and their length must be from 15 cm, while the radius must be chosen more than 10 cm.

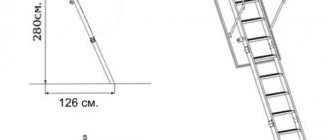

Parameters of interfloor stairs

What is a cantilever-type staircase with anchor installation?

Fastening with anchors will require special welded brackets on which ready-made platforms are supported. Each individual element is attached to the wall with anchor bolts - four or more. Components for cantilever stairs of this type are bolts with a diameter of 10 mm or thicker, with a length of at least 150 mm. The width of the march cannot exceed 700-800 mm. This method is applicable after complete completion of the main construction.

There is also a method of attaching steps, which does not depend at all on the quality of the walls and is possible in any building. Its essence is the construction of a powerful metal frame welded from channels/profile pipes. The structure is made up to the ceiling, located close to the wall, and tied to the upper and lower ceilings. The step supports are welded (or bolted) to the frame posts. The frame itself can be hidden behind masonry/cladding.

Photos and videos tell you how to make a cantilever staircase yourself. However, architectural supervision is desirable. When constructing a “floating” staircase, you must remember that each step must withstand a repeated load of at least 150 kgf. This is applied to the hanging edge - that is, the end that does not rest on anything. In addition to this weight, you need to take into account the weight of the railing, if any.

As a rule, console stairs are not sold ready-made, but are made to fit the dimensions of a specific room, taking into account the wishes of the owners.

Ceiling mount

This method will be an alternative for those whose house has already been built or whose boundary walls are not strong enough to withstand the loads . The steps must be secured before finishing work begins. To briefly describe the essence of this method, it consists in using a powerful welded metal frame made of a channel; a profile pipe is also suitable. This design spans the entire height of the room, because the metal frame will be attached to the ceiling.

The metal frame is placed along the entire length of the flight close to the wall. It also needs to be tied to the upper and lower floors. After this, it is necessary to weld the cantilever supports for the treads to the resulting racks; it is possible to use fastening bolts. The resulting frame can be hidden with plasterboard sheathing or masonry made of light blocks.

Calculation of the winder staircase

The calculation is carried out to determine the geometric parameters - length, height, width of the flight, as well as the number of rectangular and winder steps, thickness and shape of parts. You can use the manual method or use an online calculator.

Calculation methods

In all calculations, the laws of geometry are applied, since the winder structure is a complex spatial system. There is no standard solution for every case.

The first method is a simplified graphical one. This is not the most accurate option, but it is simple and affordable. Its essence lies in the fact that the approximate trajectory of movement is divided into intervals equal in width to a standard tread. Then the dimensions of the narrow and wide parts of the wedge in the winder part are noted. By constructing, the center of the circle is found and the remaining elements of the staircase are drawn, as close as possible to the most convenient ones. The disadvantage is the abrupt transition from the straight to the winder part.

Method of proportions. This is a more accurate method that achieves a smooth bend from a straight section to a rounded one. For the calculation, a drawing is drawn up with a line of motion and an axis of proportions. Segments equal in width to standard steps are laid on it. By connecting the ends of the segments with marks on the running line, we obtain the boundaries of the winder treads of a complex shape. Advantages - ease of walking, disadvantages - all winder steps are of different shapes.

Other calculation methods are also used - the “Danish” method of raising lines, spatial sweep. All of them are based on a graphical determination of the staircase parameters based on the rules of geometry, but with different approaches to solving this problem. If any difficulties arise, we recommend that you seek the help of professional designers.

Steel bowstring

This method of installing a cantilever staircase is perhaps the most difficult . It uses brackets that are welded or screwed to a steel bowstring. This is the only support. It must be secured to the floors using powerful support platforms and anchors. To prevent the bowstring from twisting under load, it is necessary to create a complex structure. It will have welded trusses with stiffening ribs, which are located transversely, diagonally and longitudinally. This design is a bit like the booms of a tower crane. You will also have to work hard with the console. It needs to be thought through to avoid the unsteadiness of the steps, provided that it is not embedded in the wall.

How to halve the cost of a cantilever staircase, even by resorting to the services of professionals.

When the need for comfortable and safe access to the second floor is thought about even in the process of designing a house, any type of staircase can be laid. This is much more effective than trying to squeeze in at least something digestible, not to mention aesthetics. One of the participants of our portal thought through everything in advance, and as a result he has a cantilever staircase, which is considered one of the most attractive in terms of “airiness”. His experience is interesting because, having remained a customer, he was still able to save a lot even in terms of finances, not to mention time and labor costs.

Content

- About cantilever stairs.

- Cantilever metal staircase from sergpn.

- Project.

- Materials and tools.

- Execution.

Strengthening the structure

If you doubt the safety of operation and reliability of your cantilever staircase, you can use some engineering tricks to strengthen the structure:

- Rigid connection of treads to each other. Loaches are suitable for this. They will transfer the loads to the floor. Bolts are hidden bolts that are used with a spacer sleeve. If we talk about the cantilever structure, then it is necessary to connect each pair of treads using one such bolt, placing it at the hanging edge. Since all the main loads fall on the wall mount, it becomes possible to use small bolts. This option for strengthening the structure will make it possible to reduce the brackets. So, for each step it will be sufficient to use one pair of rods, which will have the following parameters: length - 40-60 cm, diameter - 3-4 cm, embedding in the wall - 8-16 cm.

Cantilever staircase on rails

Bolts can be hidden by disguising them as parts of the enclosing structure, and also hidden in the inside of the riser.

- Mounting to the ceiling using ties. For this work you will need cables, the material for which is stainless steel 8-10 mm thick. You will also need to install screw hooks - a lanyard. They will help eliminate slackness of the cords. This type of hanging fastening will make the structure airy, unlike bolt-on.

Cantilever staircase on lanyards

Requirements and types

A suspended staircase is a very complex structure that must be built in accordance with all requirements. Due to its features, the finished structure cannot be purchased even from a specialized company, because it is necessary to individually select materials and fastening elements, depending on the operational features and customer requirements.

Such a structure can be classified according to several parameters:

- Based on the location of the stairs: internal and external.

- Depending on the method of fastening: monolithic, staircase on rails, on support columns, on stringers or bowstring.

- By method of use: transformable (portable), mounting, fire truck ladder.

- Depending on the materials used: glass, wood, iron, steel, combined.

Possible mistakes

When installing a cantilever staircase, there is a possibility of missing some features of its structure, which will lead to danger of use . The most common mistakes are:

- Incorrectly chosen method of attachment to the enclosing structure. For example, it would be a mistake to try to tie it to the masonry using anchors if the wall is made of slotted bricks or light blocks.

- Unreliable fastening of brackets to the wall. If the diameter of the steel anchor is chosen incorrectly or if a plastic dowel is used instead, loosening of the treads may occur.

- Using insufficiently thick metal as a bracket or frame. Selecting an element diameter of less than 3 mm. can lead to twisting of load-bearing elements under load.

- Installation of treads on brackets in the wall without using a special damping gasket. Its use will prevent the transmission of footstep sounds through the building envelope to adjacent rooms.

- Use of fairly heavy material for railings. It is worth abandoning cast or forged fencing, because it will place additional stress on the steps.