Today it is difficult to imagine a country house without floor heating. Before you start installing the heating, you need to calculate the length of the pipe (calculator) that is used for the heated floor. Almost every country house has its own heating system; the owners of such houses independently install a water floor - if this is provided for by the layout of the premises. Of course, it is possible to install such warm floors in apartments, but such a process can bring a lot of trouble to both apartment owners and employees. This is due to the fact that it is impossible to connect the heated floor to the heating system, and installing an additional boiler is problematic.

The size and shape of the pipe for a heated floor can be different, therefore, in order to understand how to calculate a heated floor, you need to understand in more detail the system and structure of such a system.

How can I install a heated floor?

There are several ways to install heated floors. For example, we can consider 2 methods.

Grazing. This floor has a flooring made of various materials, such as polystyrene or wood. It is worth noting that such a floor is faster to install and put into operation, since it does not require additional time for pouring the screed and drying it.

Concrete. This type of floor has a screed, which will take more time to apply, so if you want to make a warm floor as quickly as possible, then this option will not suit you.

In any case, installing a heated floor is a difficult task, so it is not recommended to carry out this process yourself. If there are no additional funds for workers, then you can install the floor yourself, but strictly following the installation instructions.

How much heat is needed?

A simplified calculation of the need for heat generation in the presence of average thermal insulation indicators of walls, floors, ceilings, windows, doors can be done using the following algorithm:

- Basic value: 40*V, where: V is the volume of the heated space.

- Accommodation addition:

- If you have the first or last floor of a multi-story building, then the resulting value is multiplied by 1.2 -1.3;

- If you have a private house or cottage, then this coefficient is 1.5.

- Addition by structural elements:

- Each standard size window is 100 watts;

- Each entrance or balcony door is 200 watts;

- Ventilation (if equipped) another 300 watts.

Here are the figures for Moscow and the region, so take into account additional coefficients in other territories.

Concrete installation of heated floors

Despite the fact that it takes longer to lay heated floors this way, it is more popular. The pipe for underfloor heating is selected depending on the materials. It is worth noting that the price of the pipe will also depend on the material from which it is made. With this method, the pipe is laid along the contour. After laying the pipe, it is filled with concrete screed without additional thermal insulation materials.

Calculation and installation of heated floors

Before you begin installing the floor, you need to calculate the required number of pipes and other materials. The first step is to divide the room into several identical squares. The number of parts in a room depends on the area of the room and its geometry.

Calculator - the simplest calculation of pipe length:

Calculation of the required amount of pipe

The maximum circuit length required for a warm water floor should not exceed 120 meters. It is worth noting that these dimensions are indicated for several reasons.

Due to the fact that water in the pipes can affect the integrity of the screed, if it is installed incorrectly, the floor can be damaged. An increase or decrease in temperature negatively affects the quality of a wooden floor or linoleum. By choosing the optimal square sizes, you distribute energy and water through the pipes more efficiently.

Once the room has been divided into parts, you can begin planning the shape of the pipe.

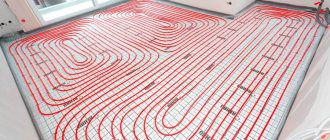

Methods for laying pipes for heated floors

There are 4 ways to lay the pipe:

- Snake;

- Double snake (fits into 2 pipes);

- Snail. The pipe is laid in 2 times (bends) coming from one source, gradually rounding towards the middle;

- Corner snake. Two pipes come out from one corner: the first pipe starts the snake, the second ends it.

Depending on which pipe laying method you choose, you need to calculate the number of pipes. It is worth noting that pipes can be laid in several ways.

Which installation method should you choose?

In large rooms that have a flat square or rectangular shape, it is recommended to use the “snail” installation method, so the large room will always be warm and cozy.

If the room is long or small, then it is recommended to use a “snake”.

Laying step

In order for a person’s feet not to feel the difference between sections of the floor, it is necessary to adhere to a certain length between the pipes, at the edge this length should be approximately 10 cm, then with a difference of 5 cm, for example, 15 cm, 20 cm, 25 cm .

The distance between the pipes should not exceed 30 cm, otherwise walking on such a floor will be simply unpleasant.

Type of flooring

The finish affects the efficiency of the system. Optimal thermal conductivity of tiles and porcelain stoneware - the surface heats up quickly. A good indicator of the efficiency of the water circuit when using laminate and linoleum without a thermal insulation layer. Wooden coverings have the lowest thermal conductivity.

The degree of heat transfer also depends on the filling material. The system is most effective when using heavy concrete with natural aggregate, for example, fine sea pebbles.

The cement-sand mortar provides an average level of heat transfer when the coolant is heated to 45 ° C. The efficiency of the circuit drops significantly when installing a semi-dry screed

When calculating pipes for heated floors, you should take into account the established standards for the temperature regime of the coating:

- 29 °C – living room;

- 33 °C – rooms with high humidity;

- 35 °C – passage zones and cold zones – areas along the end walls.

The climatic features of the region will play an important role in determining the density of the water circuit. When calculating heat loss, the minimum temperature in winter must be taken into account.

As practice shows, preliminary insulation of the entire house will help reduce the load. It makes sense to first thermally insulate the room, and then start calculating heat loss and parameters of the pipe circuit.

Calculation of pipes for heated floors

On average, 5 linear meters of pipe are needed per 1 m2. This method is easier to determine how many pipes per m2 are needed to install a heated floor. With this calculation, the step length is 20 cm. The required amount of pipe can be determined using the formula: L = S / N * 1.1, where:

- S – area of the room.

- N – Laying step.

- 1.1 – pipe reserve for turns.

When calculating, it is also necessary to add the number of meters from the floor to the collector and back. Example:

- Floor area (usable area): 15 m2;

- Distance from floor to collector: 4 m;

- Step for laying heated floors: 15 cm (0.15 m);

- Calculations: 15 / 0.15 * 1.1 + (4 * 2) = 118 m.

What should be the length of the water heated floor circuit?

These parameters must be calculated based on the diameter and material from which the pipes are made. So, for example, for metal-plastic pipes with a diameter of 16 inches, the length of the water-heated floor contour should not exceed 100 meters. The optimal length for such a pipe is 75-80 meters.

For pipes made of cross-linked polyethylene with a diameter of 18 mm, the length of the contour on the surface for a warm floor should not exceed 120 meters. In practice, this length is 90-100 meters.

For a metal-plastic pipe with a diameter of 20 mm, the maximum length of the heated floor should be approximately 100-120 meters, depending on the manufacturer.

It is recommended to select pipes for laying on the floor based on the area of the room. It is worth noting that their durability and quality of work depend on what material the pipes are made of and how they are laid on the surface. The best option would be metal-plastic pipes.

Floor installation steps

After you have chosen high-quality and reliable pipes, it is recommended to begin installing the heated floor. This needs to be done in several stages.

Installation of thermal insulation

At this stage, preparatory work is carried out, the floor is cleared and a layer of thermal insulation is laid. Polystyrene foam can act as thermal insulation. Layers of foam plastic are laid on the subfloor. The thickness of the foam should not exceed 15 cm. It is recommended to calculate the thickness depending on the size of the room, its location in the apartment, as well as the individual preferences of the person.

Installation of waterproofing

After the foam has been laid, it is necessary to lay a layer of waterproofing. Polyethylene film is suitable as waterproofing. Polyethylene film is fixed to the walls (near the baseboard), and the floor is reinforced with mesh on top.

Laying and securing pipes

Next, you can lay the pipes for the heated floor. Once you have calculated and chosen a pipe laying scheme, this process will not take you much time. When laying pipes, they must be secured to the reinforcing mesh with special braces or clamps.

Crimping

Pressure testing is practically the last stage of installing a heated floor. Pressure testing must be carried out within 24 hours at operating pressure. Thanks to this stage, mechanical damage to pipes can be identified and eliminated.

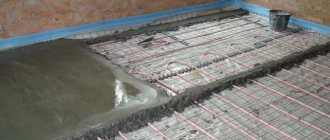

Pouring concrete mortar

All floor pouring work is carried out under pressure. It is worth noting that the thickness of the concrete layer should not exceed 7 cm.

After the concrete has dried, you can lay the floor. It is recommended to use tiles or linoleum as flooring. If you choose parquet or any other natural surface, due to possible temperature changes, such a surface may become unusable.

Basic parameters for TP design

The location of heating elements that influence the specific power of a heated floor per 1 m2 is designed based on the thermophysical characteristics of the structure. In this rather complex process, many different factors must be taken into account, including:

- regional thermal standards - minimum outside air temperature in the coldest period of the year;

- the average temperature in each room and their location;

- features of building structures - material and thickness of walls, floors and ceilings or interfloor ceilings;

- the number and type of windows, their total area, heat loss coefficient, which largely depends on the type of double-glazed windows installed;

- positioning of the building relative to the cardinal directions;

- the height of the premises, as well as a number of others.

The proposed list of parameters that influence the calculation of heated floors is far from complete - an experienced heating engineer will indicate a dozen more important thermophysical characteristics.

However, the primary task of such a design is to select such a thermal performance of the TP that is guaranteed to be able to compensate for all the energy losses of the heated building. We must also not forget that it is recommended to increase the calculated theoretical power by 10-15% so that the thermal installation does not operate at the limit of its capabilities.

Regardless of whether the calculation of heated floors is carried out with your own hands or by specialized specialists, in all cases they are based on the requirements of GOST R 55656-2013 “Energy characteristics of buildings. Calculation of energy use for space heating." Below is a simplified method for independently designing a small apartment floor heating installation.

Date: September 25, 2021

Manifold cabinet and its installation

Before calculating the pipe flow required for installation on the surface and underfloor heating, you need to prepare a place for the collector.

A manifold is a device that maintains pressure in pipes and heats used water. This device also allows you to maintain the required temperature in the room. It is worth noting that you need to buy a collector depending on the size of the room.

It is recommended to install and connect the collector with the help of professionals. If the manifold is not installed correctly, it may not work or may not function properly.

How and where should the manifold cabinet be installed?

There are no restrictions for installing a manifold cabinet; at the same time, there are several recommendations.

It is not recommended to install the cabinet too close to the floor. Calculate how many centimeters will be spent on screed, heat and waterproofing, as well as pipes, and only then plan the installation of the cabinet.

It is also not recommended to install the manifold cabinet too high, since ultimately the water circulation may occur unevenly. The optimal height for installing a cabinet is 20-30 cm above the bare floor.

What room requirements must be met when installing the system?

During installation work, the most correct decision would be when the pipeline is installed at the initial stage of construction of the floors. This method is 30–40% more economical than the radiator method. It is also possible to install a water heating structure in a ready-made room, but to save the family budget, you should pay attention to the following requirements:

- The height of the ceilings should allow the installation of heated floors with a thickness of 8 to 20 centimeters.

- The height of doorways should not be less than 210 centimeters.

- To install a cement-sand screed, the floor must be more durable.

- To avoid airiness of the contours and high hydraulic resistance, the surface for the base of the structure must be flat and clean. The permissible level of unevenness is no more than 5 millimeters.

And also in the building itself or in individual rooms where the heating system will be installed, plastering work must be done and all windows must be installed.