Mats (slabs) for heated floors are a substrate that retains heat from heating elements and provides good thermal insulation of the system. Basically, high-density polystyrene foam 28-30 kg/m³ is used for slabs.

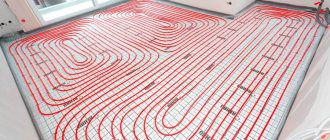

Water-based heated floors are a popular type of heating today, both in apartments and private homes.

However, not everyone knows that the effective functioning of the system is directly related to correctly selected thermal insulation.

The most suitable and practical model of insulation for a water floor is considered to be thermal insulation mats. We will talk about them in detail in this article.

Purpose of mats

The main task when installing water-heated floors is to minimize heat loss, and it is this function that the mats perform. If you place the circuit directly on the base, then it will be of no use, since most of the heat will go down.

This is what heat-reflecting mats are designed for. They protect the room from the penetration of cold air, while preventing heat from escaping outside. In addition, the formation of mold and condensation is eliminated.

Let's consider the main functions that the heat-insulating substrate performs in the “pie” of a warm water floor:

- Sound insulation - if the layer is 2 cm, noise absorption is up to 23 dB;

- Waterproofing - in the presence of a special film layer;

- Thermal insulation - directs warm flows upward, which reduces the cost of heating the house;

- Uniform distribution of heat flows in the room. This point is important for water floors, where heat is not distributed evenly due to the presence of straight and curved pipes in the circuit;

- Helps withstand operating loads due to high strength.

In addition, the presence of mats simplifies the process of laying the heating circuit of a heated floor due to the relief layer or markings on the surface. And special clamps and grooves on the sides make the installation process faster and easier.

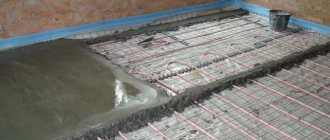

Features of pouring screed for finishing

The optimal screed height for finishing is about 30-50 mm. To accomplish this, you can use a standard cement-sand mixture or self-leveling floor.

Expanded clay and perlite cannot be added to the solution, as they disrupt heat transfer and can cause overheating of the conductor. After the screed is ready, it is necessary to begin finishing the floor.

Screed on a water floor

After the screed is poured, it usually hardens in 2-3 days. But you need to wait for it to dry completely before turning on the floor, and this can take more than a month.

What materials are used to make mats?

Today, mats are made from various materials, but the most modern models are made from extruded polystyrene foam, as it has:

- low vapor permeability - water vapor passes through it, and the material does not accumulate liquid;

- low thermal conductivity - which helps retain heat;

- high density - withstands enormous loads, made from raw materials with a density of 40 kg/m3.

In addition, the substrate is not afraid of rodents.

For your information! The level of density of the material plays an important role in the construction of a water floor, since the structure is heavy, per 1 square meter. m up to 200 kg.

The insulation, the lower part of the “pie,” experiences the main load, so its strength is important when constructing a water floor.

Advantages

- We can say that all such products are certified in accordance with European standards. In particular, self-extinguishing raw materials are used in production.

- The high density of expanded polystyrene provides increased strength, so thermal insulation boards do not change their original dimensions.

- Another important difference is that it is equipped with special clamps - they allow you to easily and quickly install a floor heating pipe system.

- Installation of heating pipes is carried out according to installation markings applied in a special way to the surface. This allows heat to be effectively distributed throughout the room.

- Both “wet” and semi-dry screeds can be laid on such a coating with equal success.

Pros of using mats

The mats are a modern heat-insulating product, manufactured using the latest European technologies, and meet the latest quality and safety requirements. They combine all the positive aspects of existing insulation materials. At the same time, there are no disadvantages inherent in other heat insulators.

Positive aspects of mats:

- high performance indicators:

- increased thermal and sound insulation;

- the possibility of laying the floor “pie” in any way - with or without a screed;

- not subject to deformation during prolonged use;

- ease of installation - equipped with a locking mechanism;

- have markings (most models) - simplifies the process of laying the contour;

- do not rot and do not form a beneficial environment for the proliferation of microorganisms;

- do not absorb water;

- do not harm humans - do not emit toxic substances;

- able to withstand high temperatures - from +180 to -180 degrees;

- service life up to 50 years.

For your information! Polystyrene without treatment is flammable, so when producing insulation from it, fire retardants are added, this makes the product non-flammable.

Such products are marked “C”.

Installation

The heated floor mat is laid starting from the position of the thermostat and ending at the point where it meets the obstacle. It can be a wall or a section of the room where heating is not needed - for example, where a closet or cabinet will be located.

After this, the fiberglass mesh is cut, and the mat is rotated 180 degrees and laid in the opposite direction. The number of turns can be any.

Mats for heated floors

After all the mats are laid, they need to be fixed. To do this, the heating elements are folded to the side one by one and applied to the insulation underneath them, a solution of cement-sand screed, and then they are laid back, pressed down with a block and the excess CPS is removed at the level of the heating cable. Immediately after this, you can lay the tiles.

Another option is to pour another screed. Thanks to its presence, the floor will become more solid and will warm up more evenly.

Types of thermal insulation mats for heated floors

There are several types of mats that professionals recommend using when constructing water-heated floors. Each model has its own characteristics and is designed for specific conditions.

The cost and size of the substrate directly depends on the type and popularity of the manufacturer.

Expanded polystyrene boards

An excellent option for insulating water-heated floors are polystyrene foam mats; they can be laid even on a cold subfloor. They come in several types:

- Foam plastic ones are the simplest and cheapest. When choosing polystyrene foam for a heated floor, you should take into account the density indicator, it should be at least 35 kg/m3. If it is less, then the substrate will not withstand the load from the water heating system.

- Extruded polystyrene foam - the substrate is high-quality and durable. Since the material has a rigid base, in addition to insulation, the product also acts as a subfloor leveler. Penoplex is considered the best representative in this segment; its thickness varies from 2 to 10 cm. The structure is cellular with increased strength, which makes it possible to withstand heavy loads.

Installation of extruded slabs is simplified by the presence of locking connections. A number of models have markings on the surface, which makes it easier to install the contour. And the pipes are fixed using brackets; they are simply stuck into the substrate.

For your information! To improve the thermal insulation characteristics of the slabs, roll-type insulation covered with a foil layer is often laid on top.

Rolled foil insulation

To make foil-coated mats for heated floors, foamed polyethylene is used as the basis; its thickness ranges from 3 to 10 mm. This is one of the simplest and cheapest insulating materials. Sold in rolls, which makes transportation easier.

This substrate is produced in several types: penofol, isolon, ecofol. All of them are equipped with a foil-coated aluminum layer or polymer film. It is this layer that directs warm air in the right direction and distributes it over the area.

Foil roll insulation for underfloor heating only conditionally refers to mats, since it does not have a high level of thermal insulation. Therefore, the scope of its use is quite limited. The foil product is recommended for use when the water system is planned as additional heating, and the floor is already equipped with other insulation.

These mats are not recommended for placement on the ground floors or above cold rooms, as their effectiveness will be zero. In addition, the process of laying heating elements on this heat insulator has some difficulties.

After all, to fasten underfloor heating pipes, special fixing parts are required: staples, clamps or reinforcing mesh. The product is placed at the joint, the foil surface should face up, and for better tightness, the seams are taped with special tape.

Despite its modest performance, it is worth noting that the use of rolled foil insulation is indispensable in some cases, and the only possible method of insulation is if the ceilings in the room are low and every centimeter is important.

Expanded polystyrene mats with foil and film

Thermal insulation in the form of polystyrene mats with a foil or film layer is produced:

- In slabs, they are equipped with a locking device. Their thickness is 2 - 5 cm, width 100 cm.

- In the form of panels - bonded into a single sheet with a film coating. The standard roll size is 5 meters.

When installing slabs into a water floor structure, they should be connected to each other using waterproof tape. If a panel type is used, then it is simply laid on the base.

There are models with a self-adhesive layer, which makes the process of joining them easier. The surface of many insulating materials has special markings for placing the pipeline - a step of 50 or 100 mm. This mesh makes pipe laying easier.

To fix the warm water circuit, plastic brackets or fittings are used; it is laid on top of the flooring.

The use of such a substrate allows you to simultaneously create not only good thermal insulation, but also waterproofing of the base before installing the water device.

Insulation with bosses

The insulating material with bosses is a modern thermal insulation product, it was specially developed for heated water floors. The insulating lining with protrusions is polystyrene foam with a density of at least 40 kg per m3, which makes the product resistant to stress. Standard sheet thickness is 40 - 50 mm.

The slabs are equipped with protrusions (bosses), which are formed using a special stamping technology - hydropilent. The shape of the bosses comes in the form of: circle, cylinder, cube and polyhedron.

The distance between them is the same, their standard height is 20 - 25 mm. This size of bosses is quite suitable for securing pipes with a diameter of 20 mm; they securely fix them in the desired position.

For your information! The use of thermal insulation mats with bosses in the construction of hydraulic heated floors eliminates the possibility of displacement of pipes during installation work and during the construction of screeds.

The film coating of different models of heat insulators with bosses varies. There are types that lack this layer altogether, but this does not affect the quality of the product.

The plates are equipped with special locking grooves, which facilitates the installation process and creates a reliable seal. A single canvas is formed onto which any screed can be poured. Another positive side is excellent noise insulation, the noise level is reduced to 25 dB.

Recommendations for choosing mats

Choosing mats for a warm water floor - an overview of the types of floor mats

When choosing an insulating gasket for water-heated floors, you should take into account technical indicators. Let's look at them:

- degree of waterproofing;

- the ability to withstand any load - statistical or dynamic;

- technical features of the premises. You should not purchase the cheapest and low-quality products.

When choosing, you must adhere to a number of rules:

- It is better to give preference to products with a foil or laminated layer - this will ensure waterproofing of the structure and the efficiency of the system;

- The diameter of the pipes and the pitch of their laying should be taken into account - they must be combined with these parameters of the mat;

- The thickness must be selected taking into account the level of insulation of the base - in this case, one should build on the thickness of the screed and flooring so that the height of the structure does not exceed the permissible size.

If there is no need for additional insulation, then the thinnest mat with bosses will be sufficient; they will facilitate the process of installing the circuit.

In order to buy quality products from a trusted manufacturer, and not purchase a “homemade” product, you must require the seller to present certificates.

Rolled underlays do not have a high degree of waterproofing, so they should not be purchased for placement on the ground floor, or for installation in apartment buildings where neighbors live below.

Since, if the circuit leaks, it is not able to hold back the water, and it will leak down. Sheet polystyrene mats with foil are suitable for water floors; they have increased waterproofing properties.

When constructing hydraulic floors, the density of the material and the level of load it can withstand are of great importance. In terms of this indicator, polystyrene and foil plates also win. These types of insulation are ideal if the system is being used as the main source of heating.

But the rolled product is recommended for structures that act as an additional heating device, as it has a low density.

Safety precautions when laying heated floors from thermomats

To avoid accidents and failure of the electric heating system both during its installation and during operation, it is important to comply with a number of safety requirements:

- Do not shorten the cables yourself;

- not me installation wires, breaking the coupling connections;

- do not touch the thermostat when trying to change its design;

- Do not install or repair the thermostat under voltage.

( 59 votes, average: 4.80 out of 5)

Water heated floor - types, features of do-it-yourself installation

Related Posts

Tips for installing thermal insulation

Before laying the mats, a number of preparatory works are required. Calculate the power of the floors and the area that the heating circuit will occupy.

Then, you need to decide on the pipe laying pattern: “spiral” or “snake”.

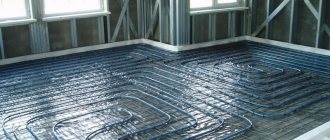

When starting work on installing insulation, the following rules should be observed:

- Regardless of the type of mat chosen, it is necessary to install a waterproofing layer. The base can be covered with a regular film, or a coating or penetrating insulation can be made. In addition, the perimeter of the entire room must be covered with damper tape.

- The mats are placed on top of the waterproofing and the canvas is connected using locking elements (if any).

- When using thin and light slabs, they need to be fixed to the floor. Glue is suitable for this, but metal fasteners are strictly prohibited, as they will damage the waterproofing layer and the strength of the product.

- When laying a flat substrate without locking joints, their joints are glued with waterproof tape. And if the plates have a foil layer, then the tape should also be foil.

- The foil side of the backing should face up.

The layout of the water circuit can begin only after installing the insulation over the entire surface of the floor.

Connecting the system

The heated floor is connected to the network through a thermostat, with which you can turn the heating on and off, as well as change the temperature. This device automatically turns off the electricity supply when the floor warms up to a set limit.

An example of installing a heating cable for a heated floor

The connection diagram of the thermostat is indicated on its body. From it to the floor you need to run a cable for supplying electricity, connecting to the heating elements using a coupling, and wiring for a sensor that will read the temperature.

Review of manufacturers and models

The modern market offers a large number of heat-insulating mats for the installation of warm water floors from Russian and foreign companies. But the leading place is occupied by the following manufacturers:

The German company Oventrop produces high-quality products with improved performance data. The company's product range: profile mats with bosses, plates for dry installation, products coated with polypropylene film in folded form and in rolls.

Knauf (Germany) is a popular company that produces high-quality slabs.

The German company Rehau - its thermal insulation products are especially popular. The company's product range includes polystyrene foam mats with bosses, equipped with a thermal and sound insulating layer.

Energoflex (Russia) - specializes in several models of thermal insulation with applied mesh markings (50 mm pitch) for installation of the circuit:

- boards with a foil surface and mats with foam polystyrene bosses;

- rolled thin product with a foil layer.

Russian company Ecopol - its products have excellent thermal insulation characteristics. The company specializes in the production of smooth slabs and mats with bosses for fastening warm water floor pipes, equipped with locking devices and a waterproofing film.

"Format" (Russia) - produces high-strength polystyrene foam boards of two types: laminated and non-laminated. The products are manufactured on German equipment using self-extinguishing raw materials.

When choosing a mat for a warm water floor, experts recommend paying attention to the following models:

Expanded polystyrene boards Knauf Industries - size 1200 by 600 mm. The product has large bosses that securely fix 16 or 20 mm pipes. The sheets are equipped with a locking mechanism and markings for laying the contour.

Rehau Varionova mats with projections are polystyrene panels measuring 1400 by 800. The price of the substrate fully corresponds to its quality. A water circuit with a diameter of 14 - 17 mm can be installed in increments of 50 mm.

Foam shield WF 16-50 - has a cellular-porous structure with a density of 25 kg per m3. This provides excellent thermal insulation. The sheet size is 1000 by 1000 by 50 mm. The design is equipped with protrusions and openings that easily secure a pipe with a diameter of 16 mm.

NP-35 from Oventrop are mats with bosses; they are recommended for the installation of self-leveling floors and for the construction of concrete screeds. They have increased heat and sound insulation.

As you can see, mats play an important role in the design of hydraulic floors. Their cost is not so great, but the benefits are enormous. They increase the efficiency of the system and its service life, and also improve comfort in the home.

Video description

How to install heated floors on mats - in this video:

Step 1. Preparation

The surface on which the underfloor heating will be laid is well prepared. It needs to be inspected for roughness and chips. All holes must be carefully repaired and the floor itself leveled. Otherwise, the floor covering will fit very poorly on the slabs. It would be best to put another layer of concrete screed.

Concrete screed Source homemasters.ru