Often water heaters are purchased for use at dachas, for work “in the field”. Accordingly, there may be no centralized gas supply in dacha cooperatives and villages. There is a way out - install an electric water heater or choose a gas water heater with the ability to connect to a cylinder. Can a gas water heater run from a gas cylinder? Yes, if the manufacturer has provided such an option. How to connect it and what fuel to use - you will find answers to these questions below.

You can also reconfigure an existing column. To do this, carefully read the instructions in the final part of the article.

Manufacturers

| Manufacturer | Characteristic |

| Vektor JSD 20-W (Russia) | Power - 20 kW. Water consumption when heating 25 °C - 10 l/min. Weight - 10.5 kg. Dimensions (H*W*D) - 580*330*208 mm. Automatic independent electric ignition, powered by batteries. To start, just open the mixer tap. Operates at water pressure from 0.2 to 7.5 atm. Multi-level security system. The automatic protection and safety system turns off the water heater when: - there is no sufficient draft in the chimney; — the flame on the burner goes out; - reducing water flow; - overheating of the heat exchanger. The presence of a digital display that displays the temperature of hot water at the outlet of the water heater. The presence of a “Winter-Summer” mode, which allows you to save gas up to 40% in the warm season. Instability of operation when water pressure changes, auto-ignition failures and heat exchanger leaks due to thin walls. The problem is likely to occur after a year of operation. Low price - about 4,500-4,800 rubles. |

| Neva 4510-M (Russia) | Affordable price and excellent functionality. Work on natural and liquefied gas. Power - 17.9 kW. Productivity - 10 l/min. Possibility of connecting several points of consumption. Bottom gas supply. Quiet operation. The presence of a thermometer and electric ignition on batteries. Works at a water pressure of 0.1 atm. There are problems with the quality of materials used and reliability. |

| Bosch WR 10-2P (Germany) | Power - 17.4 kW. Productivity - 10 l/min. Heating water up to 60 °C. Convenient mechanical rotary switches for temperature adjustment. Two versions of the dispenser are available - P23 for natural gas and P31 for liquefied gas from a cylinder. Work at pressure from 0.1 to 12 atm. The combustion chamber is open type, requiring the installation of an air vent. Easy to operate and install, small dimensions, quiet operation. Installation is vertical, on the wall. Bottom gas supply. Presence of piezo ignition. Thermometer for monitoring water temperature. The model is sensitive to water quality. Relatively high price. |

| Electrolux GWH 265 ERN Nano Plus (Sweden) | Power - 20 kW. Capacity is 10 l/min, which allows you to shower comfortably. Average cost of the model. Work at water pressure from 0.15 to 10 atm. Convenient controls. Installation - vertical, on the wall. Communications connections are from below. Availability of electric ignition. The presence of a “gas control” function that prevents any leakage of flammable substances. Fine temperature regulation and high sensitivity to pressure. |

As a result, the operation of an instantaneous water heater using liquefied gas will allow you to autonomously supply your house or cottage with hot water.

Safety Recommendations

Converting the boiler and reconfiguring it to consume liquefied gas dictates the need to “reconfigure” your attitude towards the device for supplying and storing blue fuel.

You must remember that:

- Cylinders or gas tanks, which are gas storage tanks that supply fuel to household appliances as needed, need to be refilled periodically.

- To fill a group of cylinders or a gas holder with gas, you need to contact certified organizations that have equipment to record the weight of the gas in the cylinder and its actual volume in the gas holder.

- Filling closed gas tanks is carried out to 85% of the useful volume of the vessel. This reserve is necessary in case of thermal expansion of the fuel to avoid an explosion.

A non-hazardous situation that requires special attention when replenishing liquefied blue fuel reserves is the filling of liquid with a density different from the density of the previous liquid. Because of this difference, the remaining liquefied gas may not mix with the newly filled portion.

In the tank, due to the difference in density, a kind of two non-connecting sectors are formed, in each of which liquefied gas circulates. However, convective heat exchange will occur at the sector boundary after a short period. After the temperatures are equalized, the densities will be equal and the liquids will be able to mix.

Liquefied gas, like main gas, is a highly flammable, combustible liquid with a high flame propagation speed. To avoid catastrophic situations, you should strictly follow the operating rules and fill the cylinders no more than 85%

Usually this process, meaning direct mixing, is accompanied by intense evaporation of liquefied gas. To avoid associated losses, mixing devices should be used during the filling process. But it is better to choose a method that eliminates the above-described phenomenon.

Replenishing cylinders and gas tanks with blue fuel in general is a process that requires increased attention, otherwise problems can be very serious and even catastrophic. The rapid spread and evaporation of the liquefied gas mixture is recognized as a significant problem.

If the rules for the safe operation of gas-consuming equipment are not violated, main methane rarely explodes. This only happens with significant leaks, if the technical state of the gas in the surrounding space changes dramatically. For example, in a kitchen with obvious signs of a leak, instead of mandatory ventilation, they turn on the light.

When liquefied gas expands in a closed container due to external heating, it will necessarily explode if there is not enough space left in the container for its expansion. Blue fuel burns extremely intensely. Since the gas is quickly absorbed by the atmosphere, the combustion zone expands at high speed.

Connecting equipment to the cylinder

Before you start connecting the equipment yourself, make sure that the model is really suitable.

Other brands of acceptable equipment: , (almost all the latest models). The instructions for the Bosch speakers indicate that a 50-liter cylinder will be enough for 10 hours of stable operation at a power of 25 kW. A conversion kit for Bosch speakers can be purchased from an authorized service center.

If it is necessary to carry out work on reconfiguring equipment, replacing collector nozzles and assessing the tightness of joints, they must be done strictly according to the rules. The nozzles must be smaller in diameter: as in gas stoves, the pressure produced by liquefied gas reducers is 2–3 times higher than when natural gas is supplied through pipes. At the same time, the calorific value of liquid fuel is 1.5 times greater than that of natural gas.

The equipment must be marked with a refurbishment date - day, month and year. The type of gas suitable for use is also indicated.

The connection diagram of the cylinder to the main valve requires it to have a reducer with pressure stabilization of 300 mm of water. Art. and a minimum steam phase productivity of one cubic meter per hour.

Parameters of the hose connecting gas equipment to the fuel tank:

- 250 cm - minimum length;

- 1.2 cm is the least permissible inner diameter of the tube.

Please note that on online forums there is information of the following nature: if you reconfigure the column correctly and carry out the work without flaws, problems with water pressure may arise and the column will not start. Then you will need to additionally install a pressure pump

When installing a shut-off valve, remember that it must be easy to access so that in the event of an emergency the user can quickly turn it off.

After completing the installation work, check the tightness of the connections and conduct a test run of the equipment.

Instructions. Conversion of the Neva 4511 gas water heater to liquefied gas

The gas column has jets with a diameter of 1.28 mm. This set of nozzles is installed in the burner ramp for operation on natural gas with a pressure of 130 mm. water Art. (130 mbar). The ramp at the Neva 4511 gas water heater is ten-sectional, i.e. The ramp includes 10 nozzles.

The set of liquefied gas nozzles we offer contains 10 nozzles with a diameter of 0.75 mm.

The offered kit is only suitable for this model,

because, for example, the Neva 4510 gas water heater has a ramp that is simply of a different design. Moreover, this model of Neva 4511 has been studied quite well by us. It is easy to install, repair and maintain. When converted to liquefied gas, the dispenser consumes about a kilogram of gas per hour of operation. Now you will see for yourself that altering the ramp will not take much time. To move the column we need a Phillips screwdriver and an adjustable wrench (38 mm). The column itself does not need to be dismantled at all.

Begin

First you need to separate the ramp. An ignition electrode (candle) and a flame presence (ionization) sensor are attached to the ramp. Separate them by unscrewing two screws.

In the photo they are indicated by number No. 1. After separating the sensor and spark plug from the ramp, you need to remove four self-tapping screws (No. 2), which secure the burner ramp.

After separating them, take an adjustable wrench and unscrew the ramp nut from the gas column assembly.

The ramp is in our hands. After the ramp is in our hands, it is best to turn out the jets with a 7 mm socket so as not to damage the splines when tightening the new nozzles with pliers or an open-end wrench (the wrench is the same as the 7 mm socket). As you can see, replacing the nozzles requires almost nothing from your brain.

Now we will understand the principle of operation of an instantaneous gas water heater using liquefied gas (also known as bottled gas). Let's see what advantages such boilers have and how to install them (install). Finally, let's look at the rating of manufacturers who produce the best models on the market.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

Owners of private houses and summer cottages are constantly selecting the best option for supplying users with hot water. One such option is an instantaneous water heater operating on.

Instantaneous water heater Vektor JSD

Neva-5514

Neva-5514

[gallery2 link=»file» size=»full» ids=»14329,14330,14331"]

| Net power | 28 kW |

| Thermal output | 24 kW |

| Productivity | 13 liters per minute, when heated to +25 C |

| DHW temperature values | From 25 to 65 degrees C |

| Liquid p parameters | 1 mPa |

| Maximum gas pressure | 2.9 mbar |

The model implements more modern principles that make the device more reliable and productive with an efficiency of 87%, so the user rating is a confident 4.

These models of the Neva trademark are characterized by a similar design. The products are made from high-quality materials, such as copper used for the heat exchanger. A 5-stage safety system is provided: when heating up to +90C, in case of failures in resource supply systems, and others. Their differences are only in size and operational parameters. All products can be easily converted to natural gas if a centralized pipeline is connected to your locality. The advantages of Neva geysers for consumers are as follows:

• affordable price for a wide audience of users; • high maintainability, availability of spare parts and their low price; • stable operation in Russian conditions, even with changes in pressure in the water supply; • compact dimensions and pleasant appearance; • the equipment is reliable and characterized by exceptionally quiet operation; • high-quality materials are used in production, which guarantee durability; • wide service network.

The actual resource declared by the manufacturer is 12 years.

Are there turbocharged models?

To heat water, you can use a turbocharged water heater. Such devices do not require a traditional vertical chimney; combustion products are discharged through a coaxial pipe led through the wall. It also supplies air to the closed firebox to maintain the combustion process. Turbocharged speakers have disadvantages: you need to make a hole in the pipe, ask the consent of neighbors above to install the equipment, the device is noisy due to the operation of the turbine. Plus, when working on propane-butane, you will also need to place a cylinder in the room. An important advantage of turbocharged versions is versatility; they can be placed in any room, since a chimney is not needed

The second important advantage is that they do not “eat up” the home air.

Equipment disadvantages

One of the significant disadvantages of this type of heating apparatus is the fire safety and explosion hazard of the fuel used during operation. In case of breakdowns, repair work must be carried out immediately. Only in this case will it be possible to avoid undesirable consequences in the form of fuel leakage, which negatively affects the human respiratory tract.

Before purchasing and installing such a water heater, you must first evaluate the supply power in the gas supply lines. If it is insufficient, then installation is absolutely not possible. In such cases, only storage type equipment can be installed.

The performance of the speaker can be significantly affected by the level of humidity in the room where it is installed. It is worth remembering that some manufacturers do not recommend installation in wet areas, and do not provide appropriate guarantees if this condition is violated.

Gas consumption

The average user is interested in how much fuel his dispenser consumes. If the device operates from a centralized gas supply, you need to know how many cubic meters are consumed per unit of time; If it's propane, I wonder how long one tank will last? Costs depend on various characteristics and, above all, on thermal power. An example of calculating propane-butane consumption. Initial data:

- specific heat of combustion - 14 kW/h;

- Efficiency - about 92%;

- burning 1 kg of propane-butane mixture gives 12.9 kW/h.

Let us have a heater that produces 5 liters of hot water per minute, and fuel consumption is 1.5 kg per hour. A 50 liter cylinder contains 42 liters or 23 kg of propane-butane. By making simple mathematical calculations, you can find out that one cylinder is enough to heat 4,600 liters of water. Translated into hours, this is a little over 15 hours of continuous heating. If you use hot water for 2 hours a day, you will need 4 cylinders per month.

How do you pay for gas without a meter?

How do you pay for gas without a meter?

Gas stove

So, if the apartment has a gas stove (but no gas water heater or gas heating), then it is assumed that each tenant spends 10 cubic meters of gas per month. A family of three people - 30 cubic meters, of five people - 50 cubic meters.

This calculation method is beneficial to the management company, but not to consumers. After all, you cook for the whole family at once, and not everyone for themselves. And small children do not use gas at all.

One cubic meter of gas in the second half of 2021 in Novosibirsk costs 5.835 rubles.

It turns out that each resident of an apartment with a gas stove pays 58 rubles 35 kopecks per month.

There are three Ivanovs in the family; gas costs them 30 × 5.835 = 175 rubles 5 kopecks per month. There are five Petrovs, for them gas costs 50 × 5.835 = 291 rubles 75 kopecks per month.

The Petrovs have a gas water heater. It is assumed that they spend 16.2×5 = 81 cubic meters of gas on heating water.

Therefore, they receive a monthly bill for 81 × 5.835 (dispenser) + 50 × 5.835 (stove) = 472.63 + 291.75 = 764 rubles 38 kopecks per month (of which 472 rubles 63 kopecks are for the gas consumed by the dispenser).

The house where the Ivanovs live has hot water supply, so they do not pay for gas heating of water. Otherwise, we would have spent 16.2×3×5.835 = 283 rubles 58 kopecks on this, and the total gas bill would have been 26.2×3×5.835 = 78.6×5.835 = 458 rubles 63 kopecks.

How to choose

Instantaneous water heaters operating on gas - natural or liquefied - have almost the same design. Differences in nuances - materials, control method, degree of automation. Important parameters when choosing a gas water heater:

- Ignition method. Older versions were lit by hand using matches and lighters. Today, manufacturers offer three ignition options - piezo, electric and from a hydrogenerator.

- Heat exchanger material. The service life of the device depends on the quality of this part. If you buy a cheap Chinese device, the heat exchanger in it may turn out to be tin. Such water heaters do not last longer than three years.

- The inner diameter of the tubes in the heat exchanger. Wide tubes do not need to be descaled as often as narrow tubes.

- Water block. Metal is preferable. A cheaper alternative is plastic.

- Performance. When choosing this parameter, you need to take into account the volume of water flowing from the tap per unit time. The easiest way is to note the time and look at the result on the water meter. If the flow is less than 10 l/min, why buy a model with a capacity of 15 or more l/min?

- Temperature control - manual or automatic. The first ones are cheaper. The adjustment is made by valves. In versions with power modulation, the temperature is maintained at a given level automatically.

- Removal of combustion products. It is safer to output through a coaxial chimney. Along with the power of the device, the diameter of the pipe increases. The second option is output through a traditional chimney. The third one has no chimney. The latter cannot be installed in a confined space and without ventilation. These are usually mini-speakers - devices with low power.

- Oxygen supply. In cheap versions, air is supplied through vents. Minus - combustion products penetrate back into the room. Expensive devices are equipped with a pipe leading from the bottom of the device. The housing is additionally closed with lids - from below and from above, so that combustion products do not penetrate into the room.

- Power. Mini-heaters of 17–19 kW are suitable for systems with low pressure and one water intake point. Powerful devices should be taken for a pressure of more than 10 l/min and with several water intake points. Versions for 21–31 kW are not installed in apartments, these are options for country houses.

Selection options

Once you have understood for yourself which gas water heater to choose based on its operating principle, it’s time to understand the important technical characteristics.

Power

The power indicator affects how quickly a certain volume of water will heat up. But it also affects gas consumption, and in the case of energy-dependent models, also electricity consumption. Therefore, the power should be optimal for specific conditions, and not underestimated or overestimated.

All equipment is divided into 3 categories:

- low power - here the values will be from 17 to 19 kW;

- medium - range from 22 to 24 kW;

- high - power reaches 28-31 kW.

For a family of 3-4 people, medium-power equipment is suitable. If you need to choose a gas water heater for an apartment where a family of 1-2 people lives, then 17-19 kW will be just right. The best geyser for a private house with a large area and a large number of water intake points is 28-31 kW.

Type of burner

Which gas water heater is the most reliable, based on the type of burner? Let's consider both available options, their pros and cons:

- Constant power. This is a standard scheme that was present in the very first models of gas water heaters until the development of modern systems. A constant power burner is characterized by inconsistent water pressure, requires manual adjustment, affects higher gas consumption, and it is not always convenient to set the desired water temperature.

- Modulating. An excellent option, since it assumes several burner operating modes, which change automatically, based on the water pressure and its flow from different water intake points. Stability of pressure, temperature, and the absence of additional actions for the operation of the system are the undoubted advantages of modulating models. But their price, naturally, is somewhat higher.

Heat exchanger

The gas burner heat exchanger is one of the main working units of the system. Therefore, its device must be of high quality and reliable. The following materials are mainly used today:

- Copper. Expensive water heaters are equipped with heat exchangers made of copper, which does not corrode, has high heat transfer, and is durable. The only negative is the price and heavy weight.

- Steel. The best option based on the criteria of durability, cost, anti-corrosion properties and strength. Of course, in general its characteristics are somewhat inferior to copper, but for many this is not critical. The main thing is that the manufacturer you choose does not skimp on the manufacture of the heat exchanger and that its design has a good alloy base and thick walls.

Safety

Gas water heaters have the following elements in the device:

- Traction sensor;

- Temperature control sensor;

- Flame sensor;

- Gas sensor;

- Overheating protection system.

Switching to alternative fuel

Most dispensers can be converted to an alternative type of gas - from natural to liquefied and vice versa. The changeover must be carried out by a service department that has the appropriate certificate. You must use parts kits from the manufacturer. When reconfiguring, the manifold jets are replaced: you need to install nozzles with a diameter suitable for the type of fuel used and its pressure. When performing work, turn off the device and turn off the gas valve. After completion of work, check the tightness of the connections. On the device itself and in its instructions it is written what it is used for, the date of completion of the work, and the organization of the performer of the work.

How to convert a heating boiler to liquefied gas

The main difference between natural gas and liquefied gas is that the former is supplied and burned at a higher pressure. The automation of conventional equipment is configured for indicators equal to 6-12 atm. When the readings drop, the pressure sensor is triggered, turning off the burner.

Operating a heating boiler using a propane-butane mixture requires changing the configuration and parameters:

- It is necessary to change the supply speed of the gas-air mixture.

- You will need to install a set of liquefied gas jets.

- Configure automation for other operating parameters.

Modern single-circuit and double-circuit heating boilers are designed to operate on liquefied and main gas. Conversion requires replacing the nozzles and switching the boiler to another mode.

The technical conditions for the use of liquefied gas in individual boilers not intended for this type of fuel differ significantly. In addition to replacing the jets, complex reconfiguration of the automation and control valves will be required.

It is difficult to correctly regulate the gas supply to the boiler when switching to liquefied gas, set the minimum pressure limit and perform other work independently, without special skills. According to current regulations, all work must be performed exclusively by licensed specialists.

The technical documentation of heating equipment indicates the minimum pressure at which the burner continues to operate. The lower this indicator, the more propane-butane mixture it will be possible to use from a filled fuel tank. Typically, 15-30% of the total volume remains in the container.

Nozzles for boilers for liquefied gas

In the section on how to convert a heating boiler to the flow rate of a gas boiler running on liquefied gas, the need to replace nozzles or nozzles was mentioned. Re-equipment is required for several reasons:

- The difference between nozzles for liquefied and main gas is the different diameters of the outlet. As a rule, jets for a propane-butane mixture are narrower.

- After installing a set of nozzles to convert the heating boiler from natural gas to liquefied gas, the pressure in the system increases slightly.

- The reduced diameter of the nozzle leads to a decrease in the flow rate of the gas-air propane-butane mixture. For normal operation of a 10 kW unit, the pressure is required to be no more than 0.86 kg/hour.

Injectors or jets are sold in sets. Some manufacturers include in the basic package all the fittings necessary for conversion. In other cases, the kit will have to be purchased separately.

What is the liquefied gas consumption of the boiler?

The volume of liquefied gas consumption in gas heating boilers is indicated in the technical documentation provided by the manufacturer. It is different for all models and depends on several factors:

- Performance.

- Burner type.

- Equipment setup.

The technical characteristics of liquefied gas consumption are also affected by how suitable the selected model is for a given type of fuel. On average, for a 10-15 kW unit, you will need 2 cylinders per week and per month.

Which gas is more profitable to heat - natural or liquefied?

Comparative consumption of natural and liquefied gas when operating a heating boiler shows that it is more profitable to heat a house when boiler equipment is connected to the main line. Heating with a propane-butane mixture should only be used in the following cases:

- Changes in the design and reconfiguration of the boiler when using liquefied gas are temporary. From the start of registration and ordering of a project for the installation of heating equipment connected to the main gas pipeline, it may take about six months. During this period, it is not economically feasible to heat the premises with electric or solid fuel heating equipment specially purchased for this purpose. The cost of converting a conventional boiler to liquefied gas ranges from 500-1000 rubles.

- Connecting a gas holder - in this case, the cost of using the mixture is more profitable than heating with wood, electricity or diesel fuel. The only condition is that a qualified specialist must adjust the pressure of liquefied gas and regulate the operation of the automation. Incorrect settings lead to an increase in consumption by approximately 15%.

The economic component, operational safety, the possibility of switching back to natural gas - all these factors make it advisable to use boilers running on liquefied gas.

Vector

"" - budget speakers assembled from Chinese components. Many consider them to be a thing of the past, but our consumers value them for their simplicity and low cost - the model range consists of devices whose price does not exceed 4,000 rubles.

Despite its cheapness, this equipment works properly, providing homes and apartments with hot water. All models have a stylish design; they can even become a decorative element. A distinctive feature is compactness. Chinese spare parts, if necessary, are easy to find in any market.

Controls - knobs for adjusting the gas and water passing through the heat exchanger. Some versions are equipped with a mode switch - winter and summer. The disadvantage is accelerated wear of spare parts. For example, the walls of the heat exchanger are made of copper, but this layer is so thin that they fade over time. There is no flame control module.

Vector JSD 20

Like all representatives of the Vector model range, the speaker is cheap - it costs about 4,000 rubles. Compact, fits in the cramped kitchen. There is a digital display and auto ignition. Color - white, gold and silver. Closed chamber. Electric ignition.

Vektor JSD 11-N

Compact version for small spaces. There is an automatic fire extinguishing sensor and overheating protection. Heats up 5 l/min. It weighs only 4.5 kg, but is designed for only one water intake point. Options:

Vektor Lux Eco 20-3

This new product from Vector has improved protection that reduces the risk of overheating. The closed firebox is cooled with water. Selecting and setting the temperature mode. There is a digital display. Case with mirror panel. The model was developed taking into account changes in pressure in water pipes. The average cost is 8,000 rubles.

Now we will understand the principle of operation of an instantaneous gas water heater using liquefied gas (also known as bottled gas). Let's see what advantages such boilers have and how to install them (install). Finally, let's look at the rating of manufacturers who produce the best models on the market.

You can find out the price and buy heating equipment and related products from us. Write, call and come to one of the stores in your city. Delivery throughout the Russian Federation and CIS countries.

Owners of private houses and summer cottages are constantly selecting the best option for supplying users with hot water. One such option is an instantaneous water heater operating on.

Instantaneous water heater Vektor JSD

Kinds

To choose a safe gas water heater for an apartment or house, you need to understand the appropriate type of equipment.

With open camera

Another name for such models is atmospheric. The essence of the operation of such a gas water heater is that for gas combustion, air is taken from the room. This happens naturally. The designs of such devices are simple from a technical point of view, and these models are also more profitable in price. But security, unfortunately, is not the highest.

Disadvantages of atmospheric geysers:

- High gas consumption.

- High technical requirements for installation and installation location.

- Low efficiency.

- It is necessary to have a chimney of the appropriate configuration, length, and size.

- The need to organize a high-quality ventilation system.

- Fire hazard.

- Risk of carbon monoxide poisoning if the system fails or the burner self-extinguishes.

With closed camera

These models are also called turbocharged.

The principle of their operation is somewhat different:

- The combustion chamber is sealed.

- Air intake is carried out not from the room, but from the street.

- The design has one or more fans that pump air for gas combustion and facilitate faster removal of waste combustion products.

Pros of turbocharged models:

- Economical gas consumption and better, complete combustion. When installing a water heater with a closed combustion chamber, gas consumption is reduced on average by ⅓ compared to atmospheric models.

- High efficiency.

- A high level of safety not only in terms of removal of combustion products, but also protection from overheating of the unit.

- Possibility of using a coaxial chimney.

- A fully automated system operation process that does not require frequent user control.

Minuses:

- Energy dependence. Typically, such geysers are also connected to the electrical network.

- There is background noise when the system is operating, so you need to think carefully about the placement location.

When choosing between the options described above, it is definitely better to choose a gas water heater with a closed combustion chamber, especially if you plan to install it in an apartment.

With piezometric ignition

Models with piezometric ignition have long appeared on the market, displacing equipment with manual ignition, proving to be simpler, more convenient, and safer to maintain.

Geysers of this type are equipped with a button on the front panel, pressing which activates the piezometric element. It provides a spark that ignites the pilot light. Then everything functions automatically - the gas supply valve opens, the water dispenser lights up, the water is heated and supplied to the water intake point.

With electric ignition

These are the most reliable and safe automatic gas water heaters of the latest generation. The ignition system operates from a set of pairs of batteries, which provide the charge necessary to produce a spark. When choosing such a model, you don’t even need to press any buttons - just open the water tap, and ignition is carried out autonomously, as well as stopping the burner from burning.

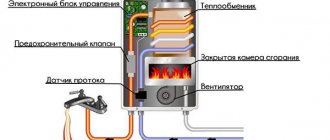

Principle of operation

The main function of geysers is to heat water in the shortest possible time. It looks like a housing in which the combustion chamber is located.

In a column powered by liquefied gas, water is heated as it flows through a heat exchanger, which in turn is heated by the burner. In addition, the device contains such elements as: a water cooling system, a control unit, temperature, pressure and draft sensors. Thanks to the electronic security system, the operation of the column is monitored throughout its entire operation.

Water heater Electrolux GWH 265 ERN NanoPlus

DIY boiler

From the geyser

To heat a small room, for example, for a garage or a sauna, if you have the “right hands,” you can make a heating boiler from a gas water heater by making some changes in it. How to make such a gas boiler and what drawings are needed for this modification? The column has a fairly high output, which is not needed for heating, and consumes a large amount of gas.

To reduce gas consumption, you can install two Chinese gas burners, drilling out the jets by 1 mm. For the expansion tank, you can use a gas cylinder or a plastic container. The expansion tank should be installed on the supply line so that no vacuum is created during pump operation.

You can buy a pump, or you can use a used one, for example, from a washing machine. If there is a timer in the automatic dispenser unit, it will periodically turn off your mini-boiler. The control unit should be replaced with a new one, without a timer. Such a device can also operate on bottled gas.

From a gas stove

Actually, making a boiler from a gas stove is problematic; you can make something like a boiler with your own hands using a gas stove. This device is used during the off-season, when the central heating is not yet turned on, and the apartment is already quite cool, since given the low power, it will not be possible to fully heat the home in severe frosts.

A metal container with water is placed on one of the heating burners. Pipes leading to a plastic pipeline are connected at the top of the tank, and the return line is connected to the side, at the bottom of the tank. A pump is installed that supplies liquid to the batteries.

In case of a power outage, you can connect an uninterruptible power supply from your computer. To ensure safe operation of such a heating device, an expansion tank should be connected; an unused small gas cylinder is suitable for it,

or a plastic container. It would also be useful to install a safety valve that will work in such a unit if you forget to turn on the circulation pump, or there are problems with the power supply to it.

From a cylinder

A gas cylinder is used for production; the boiler operates on the principle of a pyrolysis boiler, in which the coolant is heated by gas combustion. In order to make such a device yourself, you will need:

- gas cylinder of 50 liters (enough to heat a room up to 70 sq.m.;

- welder;

- electrodes;

- grinder or gas cutter;

- Metal sheet.

You can cut out the side door for loading fuel, or you can load it from above. The top of the cylinder is cut off, the cut part, after minor modifications and the installation of handles on it, is used as a lid. A piston with a lower nozzle is immersed into the cylinder. The nozzle consists of a hollow pipe through which combustion air enters. A “pancake” of slightly smaller diameter than the diameter of the cylinder is welded to the bottom of the piston.

Arc-shaped blades (can be cut from a cylinder) are welded to it to create a vortex flow over the smoldering fuel. A metal circle of smaller diameter than the “pancake” itself welded to the blades in the lower part will prevent the appearance of an open fire. This design ensures a slow smoldering of the fire, and the gas, rising, will burn in the upper part.

A hole for the chimney is cut out on the side of the cylinder, a drain pipe is welded and taken out. The chimney pipe is made of pipes of two diameters, the side bend is 0.15 m, the vertical bend is 0.2 m. The difference in diameters will create a two-stage draft, more passive than in a pipe of the same size, which ensures long-term combustion, up to 10 hours.

The water jacket for heating can be made in different ways - around the body of the cylinder or around the chimney. A unit with coolant around the chimney is more economical, as it uses heat that usually evaporates outside. Heating pipes are connected to the jacket, and an expansion tank is mounted on the upper supply pipe, which can be made from a small-capacity cylinder. A pump is installed to provide forced circulation.

From a solid fuel boiler

When connecting a gas main to their home, owners of solid fuel boilers begin to think about how to make a gas boiler out of solid fuel. If you simply insert a gas burner into the lower part, there will be no savings. Solid fuel boilers are not suitable for operation on gas and in this situation most of the heat will escape through the chimney.

It is possible to obtain a modernized device with high efficiency by significantly changing the design of the solid fuel unit. But with such a change in the heat generator, it will no longer be possible to use it in the future as a solid fuel one. The modification consists of welding one-inch metal pipes above the burner of the unit.

In this case, the burner flame will not go into the chimney pipe, but will give off thermal energy to the water circulating in these pipes. First, the boiler is dismantled and the casing is removed. Before starting remodeling work, there are several points to consider:

- pipes are placed at a height of 30 mm from the burner;

- to avoid stagnation of liquid in the pipes and its boiling, they are placed at an angle;

- the pipes are arranged in a checkerboard pattern in three tiers, the distance from one pipe to another should be 1.5-2.0 cm.

From the outside of the boiler, using a grinder, a hole is cut out in the water jacket with a small margin for ease of welding.

To drill holes in metal for pipes, you will need a crown with bits made of Pobedit. The diameter of the crown should be several millimeters larger than the diameter of the pipes to allow the pipe to be positioned at an angle.

Water the drilling area with soapy water from time to time to prevent the pobedite bits from flying off due to overheating. It is best to weld pipes with a gas torch. After all the pipes have been welded, it is necessary to seal the water jacket. Weld a reinforcement pin in the center, which will subsequently prevent the boiler from swelling.

Then weld a hole in the water jacket around the perimeter. Before installing the boiler, pour water into it and check for leaks. If detected, the window is cut out again and the leak site is welded.

Geysers powered by gas cylinders

If there is no centralized gas supply, you have to heat water and cook food using gas water heaters and stoves that can run on a gas cylinder.

The gas cylinder used to heat water contains gases such as propane and butane. They are by-products of oil, gasoline and gas refining. The cylinders may contain only technical butane or a mixture of butane and propane, which is available in summer and winter.

Compression of these gases converts them into a liquid of a smaller volume (and therefore such a gas is called liquefied), and as the pressure decreases, this liquid begins to turn into a vapor state. Since an increase in temperature causes a strong expansion of liquefied gases, the cylinder is usually filled to 85% of its volume, so there is always a layer of vapor gas above the liquid gases.

For a dacha, choosing a heater that uses gas from a cylinder as an energy source is often the only way to get hot water in a dacha. In situations where there is no main gas pipeline connected to the dacha, and there are also problems with the electrical network, a gas water heater of this type will be a real salvation.

When operating a water heater connected to a gas cylinder, on average one gas cylinder with a capacity of 50 liters is enough to provide the minimum daily hot water for two to three people for a month.

First of all, you need to make sure that your gas water heater is configured to use the gas that is present in the cylinder. If required, work is carried out to re-adjust the column by replacing the collector nozzles and assessing the tightness of the connections. In this case, the equipment must be marked with the date of reconfiguration and the type of gas that can be used in the device.

The cylinder that will be connected to the gas water heater must be equipped with a reducer with a stabilization pressure of 300 mm water column, as well as a minimum vapor phase capacity of 1 m³ per hour

They also pay attention to the selection of the hose - its length should be up to two and a half meters, and the internal diameter should be from 12 millimeters

It is important to purchase a hose that can withstand working with a gas cylinder dispenser.

When installing the hose, do not bend or twist it. If the hose has to be installed with a bend, adapters are used for this and the radius of the bend is monitored (it should not be less than 90 mm along its outer line). In addition, the hose must not bend within 50 mm of the ends of the nozzles.

The installation of a gas shut-off valve must be carried out in front of the column so that this valve can be easily reached. After completion of installation work, the hose and other connections should be checked to ensure that leaks are detected in a timely manner. Only after this can the column be used to heat water.

www.o-vannoy.ru

User reviews

Alexey Revenko, Moscow

I have been using a Neva Transit gas water heater for 3 years now. It is very convenient to manage, since it does not require unnecessary knowledge and skills from me; everything is controlled by a standard program. I would like to note that this type of heating is more profitable than centralized supply. In the latter case, it was very difficult to count on even warm or room temperature, but now I have the opportunity to choose the degree of heating myself, while saving significantly.

Nina Alekseeva, Ekaterinburg

After purchasing a new apartment, we immediately began replacing the plumbing and all related components. We thought for a very long time about what to do with the central water supply, and the craftsmen advised us to use a gas water heater, since the pressure in the pipes facilitates installation. I can say one thing: we were very pleased with the resulting effect and never regretted it.

Oleg Golod, Perm

This type of technology is a real find. This is what it means: technological progress does not stand still. Despite the fact that I only recently purchased the Neva 4011, I have already experienced all the advantages.

Useful article? Rate it and add it to your bookmarks!

Main characteristics of the speakers

Now let's talk about the practical aspects of using the speaker. One of the main characteristics is performance. It directly correlates with power, which is indicated in kW and shows the volume of water heated per minute by 25 °C.

The characteristics are usually indicated in the device passport. A regular water heater heats 10-20 liters of water per minute at 25 °C, although this value can vary significantly.

Another characteristic of modern speakers is power modulation. It shows how the power of the column can change depending on the flow of water and is measured as a percentage of the initial power.

For modulation, the columns are equipped with special fittings with a membrane, which changes the gas supply to the burner depending on the flow. Modulation in the range of 40-100% of the device power is considered normal.

The best storage gas water heaters

Such devices have a capacious body with an internal tank. The latter is equipped with a heating element heated by a flame from a gas burner.

The device operates without a network connection. Some models also operate on liquefied gas. Thermal insulation of the housing ensures that the temperature of the heated liquid is maintained.

Ariston SGA 200 R - with a huge tank

This is the best gas storage water heater for a large family or for arranging a shower in the gym, in a locker room at work, because the tank capacity is 195 liters. At the bottom of the structure there is a small combustion chamber with a submersible heating element and controls.

Due to its large weight and size, the boiler is installed on the floor, and the water inlet and outlet connections, as well as the smoke removal channel, are located on top.

Pros:

- The heating time of the huge container is only 75 minutes;

- you can connect up to 5 taps;

- simple floor installation with top connection;

- heats water to a temperature of 75 degrees;

- operates from a minimum system pressure of 0.2 bar;

- the inside surface of the tank is covered with enamel;

- the tank is insulated with polyurethane foam;

- in the upper part of the case, a dial thermometer always reports the temperature;

- ignition of the burner by a piezoelectric element;

- control of gas flow without flame;

- the anode is made of an anti-corrosion alloy and coated with magnesium;

- gas valve with three safety stages;

- steel body;

- work indicator;

- there is a drain valve;

- capable of running on liquefied gas.

Minuses:

- cost from 43,000 rubles;

- large sizes 50x35x170 cm are more difficult to place;

- 1 year warranty;

- the adjustment is located at the bottom, so you have to bend down every time to change the settings;

- There is no overheating protection.

READ ALSO

5 best Thermex water heaters