Today, increasingly, plumbing and heating systems are made not from steel pipes, but from polypropylene. But this is plastic, and the question arises - what is the maximum temperature that a polypropylene pipe can withstand?

Let's look at this issue in more detail. Let's consider the properties of polypropylene material. Let's get acquainted with the types of polypropylene pipes and their characteristics. We’ll also talk about the temperatures that this pipeline can withstand, and the features of its use in hot water supply lines.

What is special about polypropylene pipes?

Polypropylene pipes have the following strengths:

- Light weight compared to a metal pipe. This greatly simplifies the installation and transport of pipes and fittings.

- Not afraid of rust, dirt, aggressive liquids.

- The organization of the pipeline occurs very quickly: no complex devices or special skills are required.

- Duration of operation – 50 years or more.

- Many types of polypropylene pipes have good sound insulation characteristics.

- Polypropylene for heating is completely environmentally friendly.

There are also some disadvantages:

- Significant coefficient of thermal expansion. Reinforced products have it at a level of 2-3.5 mm per 1 m, solid ones are 4-5 times more pliable.

- As for pipes with external reinforcement, it will need to be treated with special devices.

- The market is replete with counterfeits of polypropylene pipes: in this case, the outer layer is especially susceptible to defects.

- The high fluidity of polypropylene pipes means that even the product’s own weight can contribute to deformation. To avoid such phenomena, the polypropylene pipeline is equipped with special fasteners, which are installed every half meter.

- The significant rigidity of polypropylene implies the need for a large number of fittings when organizing rotary sections.

Voting for the best pipes for heating or for laying a water supply system

What pipes would you choose for heating or for laying a water supply system or would you recommend?

Pipe Valflex PR-R SDR 11

13.33 % ( 2 )

Pipe TEBO SDR 11

6.67 % ( 1 )

Pipe Pro Aqua SDR N11

6.67 % ( 1 )

Reinforced pipe Vikma PN 25

6.67 % ( 1 )

Pipe SPK 1020PM

6.67 % ( 1 )

Reinforced pipe Banninger WATERTEC Stabi

13.33 % ( 2 )

Glass fiber reinforced pipe Lammin 20 mm PP-R PN 20

6.67 % ( 1 )

Pipe VALTEC PP-FIBER PN 20

26.67 % ( 4 )

What kind of polypropylene pipes are there?

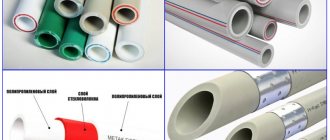

There are two main types of propylene pipe structures - solid and reinforced. The latter variety has a significantly lower thermal elongation rate, which compares favorably with solid products. The different lengths of polypropylene pipes will help you quickly and efficiently select pipe sizes according to the project. It is also important to know what kinds of polypropylene pipes there are according to the method of reinforcement.

Polypropylene products are reinforced as follows:

- The outside of the pipe is covered with aluminum foil.

- Aluminum is located inside the pipe, near the outer edge.

- The pipe is reinforced with fiberglass.

- Composite material is used for reinforcement.

General information about propylene pipeline

Quite a long time has passed since the use of polypropylene pipes for heating began for the experience of use to show that in the usual version they are not very suitable for these purposes. High temperature loads and pressure do their job, and the pipeline is subject to deformation.

As a result, propylene pipes, despite all their advantages, began to lose to classical metal in service life, although “de jure” manufacturers indicated completely different time frames for their products.

Engineers found a solution and began to use reinforcement when producing plastic pipes for heating. This made it possible to increase the service life of polypropylene pipes to 50 years, while maintaining all their advantages.

Solid polypropylene pipes

These products differ primarily in that special raw materials are used for their production. This is reflected in the differences in the characteristics and applications of solid polypropylene pipes.

Surfaces may have the following markings:

- P.N. Indication of stable internal pressure against a background temperature of + 20 degrees. The digital designation indicates the wall thickness. The most popular polypropylene pipes for construction activities are PN 10, 16, 20, 25, and the last two varieties are used for arranging space heating and pipelines for supplying hot water.

- Red or blue stripe. Blue color is used to indicate polypropylene pipes for cold water. The red stripe marks the material for hot water.

- The letters PP indicate the use of polypropylene as the initial raw material.

The following types of source material can be distinguished:

- PPH, PP-1, PP-type 1. Used for cold water and ventilation.

- RRV, RR-2, RR-type 2. For organizing hot water supply and heating.

- PPRC, PP-random, PPR. The innovative material “random copolymer” is used as a manufacturing material. These pipes are most often used in engineering communications. They are characterized by a high level of heat resistance. If installation is carried out outdoors, it is advisable to use products with solar protection.

The best pipes without reinforcement

Pipes that do not have a reinforcing layer are most often used when installing simple systems.

Pipe Pro Aqua SDR N11

The non-reinforced pipe for domestic use Pro Aqua can withstand a maximum temperature of 40 degrees. If this indicator is exceeded, deformation may occur. It is best to use a pipe for installing cold water systems.

Cost: 160 rubles.

Pipe Pro Aqua SDRN10

pros

- high quality;

- strength;

- sold in many stores.

Minuses

- overpriced.

According to buyers, the Pro Aqua pipe is comfortable and durable. It can be used in the bathroom and kitchen when installing a cold water supply system. Installation does not take much time if you select all the necessary components.

Prices for Pro Aqua SDRN10 pipe

Pipe Pro Aqua SDRN10

Pipe TEBO SDR 11

Maximum temperature – 20 degrees. The TEBO pipe can only be used for installing a cold water supply system. Installation does not require any additional equipment.

Cost: 92 rubles.

Pipe TEBO SDR 11

pros

- strength;

- durability;

- simple design.

Minuses

- not suitable for DHW;

- high price.

According to buyers, pipes from TEBO are of good quality, but practically no different from other single-layer pipes. They are overpriced in some stores.

Prices for TEBO SDR 11 pipe

Pipe TEBO SDR 11

Pipe Valflex PR-R SDR 11

To install a simple water supply system in an apartment, you can use Valflex pipes. They are sold in many hardware stores at low cost and are great for everyday use. Their installation does not require special equipment; it is enough to ensure a reliable connection. 10 bar is the maximum permissible pressure.

Cost: 34 rubles.

Pipe Valflex PR-R SDR 11

pros

- 7 year warranty;

- high quality;

- strength;

- sleek, simple design.

Minuses

- not suitable for heating systems.

According to buyers, if pipe installation is required at home, white unreinforced Valflex pipe is suitable. The main advantage is the manufacturer's warranty. If a tear or deformation occurs, you can get a refund or a replacement.

Prices for Valflex PR-R SDR 11 pipe

Pipe Valflex PR-R SDR 11

Aluminum reinforcement

There are solid and perforated samples of this type. The perforation itself looks like a fine aluminum mesh. The process of extruding polypropylene is accompanied by the ingress of a fluid and viscous substance onto the perforation, which leads to adhesion of the metal and the polymer. Thanks to aluminum reinforcement, a noticeable reduction in the coefficient of thermal expansion is achieved.

However, such engineering systems are installed with some difficulties. When carrying out socket welding, it will be necessary to remove the aluminum shell and the outer polymer layer before starting work. Subsequently, the pipe is cleaned according to the parameter of the inner diameter of the fitting.

As for pipes in which the outer layer does not need to be removed before installation, they have the following disadvantages:

- The fitting can only fix the outer part of the product: usually this is half the wall thickness.

- The welding machine must have a nozzle.

- When the pipe is cut, it must also be terminated.

Czech

The Czech Republic is represented on the domestic market by Wavin Ekoplastik and Fv Plast

Wavin Ekoplastik

The Czech company Wavin Ekoplastik uses random, a PP-R copolymer, for cold water supply pipes. And for heat-resistant pipes - high-quality heat-stabilized PP-RCT, similar to those from German manufacturers.

The products of this company are in demand in the domestic market due to high quality fittings and shut-off valves. Additional components allow you to lay a pipeline of any configuration. The price of Wavin Ekoplastik products is not much different from their German counterparts, and their reliability is not inferior to them. The only disadvantage of products from the Czech Republic is the not very attractive gray color of the products, which requires decoration.

/p{amp}gt;

Fv Plast

FV-Plast pipes are inferior to Ekoplastik in popularity due to the poorly developed dealer network in our country. The quality is no worse than that of its closest competitor. The pipes of this company are designed for use in cold and hot water supply pipelines, underfloor heating and heating systems.

It is necessary to note the exceptional lightness of FV-Plast pipes, which facilitates the installation of heated floors.

The FV-Plast company has made the production of reinforced polypropylene pipes a priority. The technology involves reinforcement with aluminum foil and fiberglass.

The manufacturer has provided a wide selection of related parts: fittings, shut-off valves and pipe fastening systems.

Conclusion: Having examined both options for Czech pipes, we can state that they do not differ in quality from German ones, and the price is still lower. The only indicator in which they are inferior is the fairly large coefficient of thermal expansion of unreinforced pipes.

Reinforcement with fiberglass

The PPR-FB-PPR marking indicates that such a pipe consists of two polypropylene layers separated by a fiberglass gasket. This type of pipe is also called fiberglass.

Fiberglass reinforcement has some advantages:

- There is no need for calibration or cleaning during installation.

- Soldering here is the same as when connecting solid plastic or any polymer-protected pipes. This helps to increase the speed of work and reduce its cost.

- Thanks to fiberglass, delamination of polypropylene pipes is not observed. This is due to the uniformity of its structure, because the central fiberglass layer is literally fused into the polypropylene structure.

- Due to fiberglass, products become more rigid.

The disadvantage of fiberglass-type pipes is that they have greater thermal elongation when compared with pipes with aluminum reinforcement.

Distinctive features of polypropylene

Currently, these products have replaced steel structures due to the following advantages:

- aesthetic appearance;

- wide area of use;

- duration of the operating period (for cold water - 100 years, for hot water - 50 years);

- no fear of high blood pressure and significant temperature changes;

- low specific gravity;

- increased rigidity and strength;

- resistance to chemical components;

- environmental cleanliness;

- excellent sound-absorbing properties;

- vibration resistance;

- low thermal conductivity;

- maintainability;

- ease of installation;

- no operating costs;

- no silting of the inner surface;

- impossibility of corrosion;

- ease of use;

- reasonable cost.

In addition to a lot of positive characteristics, it is not without drawbacks. There are few of them, but it is worth paying attention to them:

- limited plasticity;

- slight linear expansion;

- fear of ultraviolet radiation;

- unacceptability of low temperatures (except for ferrous products).

Applying propylene to the internal surfaces of pipes

We are talking about metal-plastic pipes that have an outer polypropylene layer. They tolerate increases in temperature well.

The disadvantages of these products include the following:

- The presence of several layers. Three different substances are connected into one structure using an adhesive method.

- The fitting is attached only to the outer layer, which makes the connection not very strong.

- The transported medium often comes into direct contact with the reinforcement, which is why the material can gradually wear out.

Attaching pipes to the wall

To attach pipes to the wall, special fasteners are provided (they are often called clips); they are selected according to the diameter of the pipes and must fit exactly to them. There are fasteners that firmly fix the position of the pipe and ensure its stable location. They also use movable fixing fasteners; in some places you can’t do without them, for example, on long sections where pipes are subject to significant thermal expansion; take this into account not only when choosing the fastening material, but also the frequency of their use.

Fastenings - clips

Holder fasteners help pipes withstand loads in the event of increased pressure and protect them from sagging.

Types of sewer pipes

Polypropylene pipes are often used to construct sewer systems of various types. When going to a plumbing store, it is important to know which polypropylene pipes are best to choose. Intra-house networks are equipped with products with a diameter of 110 mm.

Corrugated pipe is used to organize external communications. Polypropylene sewer pipes have a diameter of 150 mm and a length of 5 m; a diameter of 600 mm is up to 10 m. If it is necessary to drain aggressive industrial wastewater, a double-layer corrugated pipe is used.

Communications arranged in this way are able to withstand significant loads on the soil: this is favored by their high rigidity. Highways, airports and bridges can be built over such lines.

The PP product of SN8 stiffness class can be laid to a depth of 6-8 meters. To organize a sewer system from them, great efforts will not be required. Each of the pipes is inserted at one end into the socket, where rubber O-rings are used for tightness.

Marking

In addition to the PN marking, which indicates temperature and pressure, all plastic pipes have:

- the word "pipe";

- abbreviated name of the material;

- SDR - the value of the ratio of the external size to the thickness of the walls;

- external profile size;

- operational class;

- working pressure limit;

- Standart room.

For example:

Pipe PP-R SDR 11-20´ 1.9 class 1/1.0 MPa GOST R 52134-2003, where:

- random polypropylene profile - SDR 11 copolymer;

- outer diameter 20 mm;

- wall thickness 1.9;

- class 1;

- permissible pressure 1 MPa.

According to their structure, profiles are divided into:

- S - single-layer;

- M - multilayer;

- TI - with a thermal insulation layer;

- PP - standard;

- PP-RP - high pressure resistant.

By type of material there are:

- PPB - they have high strength, their purpose is floor heating with hot coolant;

- PPH - have an increased internal diameter, mounted on ventilation systems and cold water;

- PPR is a universal type that can withstand elevated temperatures.

By class they are divided into:

- class 1 - up to +60 C, intended for water supply;

- 2 - up to +70 (pipelines);

- 3 - + 60 (warm floors);

- 4 - +70 C, used for heating;

- 5 - + 90 (heating);

- class XB - for cold water supply.

Some manufacturers put a trademark on their products.

Temperature table

For clarity, we have presented a table of temperatures that polypropylene pipes can withstand.

| View | Purpose | Maximum temperature level | Working pressure (atm) |

| PN 10 | Cold water supply | +40 C | 10,2 |

| PN 16 | Universal model | +60 | 16,3 |

| PN 20 | Universal | +80 — 95 | 20,4 |

| PN 25 | Hot water | +95 — 120 | 25,5 |

Features of use in a heating system

Destruction temperature of polypropylene pipes.

Today, polypropylene profiles are increasingly installed both in central heating systems and are used to heat private buildings. They do not deform, do not allow oxygen to pass through, are able to withstand sub-zero temperatures and, as a result, freezing of water in the main does not cause damage to the system as a whole.

To the question of which polypropylene pipe for heating is best to purchase, you can give a clear answer - you need to take a pipe that can withstand a maximum temperature of +60 - +95 C. The most suitable models are PN 20 with a heating degree of +60 or PN 25 - +95.

When choosing polypropylene profiles for heating, in addition to temperature, you should consider that:

- Plastic products are rigid and difficult to bend. To turn the highway, you need to install an angle, which is not very convenient.

- The cross-section of the pipes must correspond to the size of the risers to which they will be connected. In a private house, the central wiring is made from a profile with a cross-section of 32 mm, the connection to the batteries is made with pipes measuring 20 - 25 mm.

- PP pipe fittings have a large cross-section, which worsens the appearance of the system.

- Polypropylene stretches when heated, this leads to thinning of the walls and sagging of the pipeline, which looks unsightly when installed openly.

When installing a plastic pipeline, it is important not to overheat it, as this will lead to a decrease in the passage when inserting it into the fitting. This error significantly reduces the efficiency of the system.

In addition, polypropylene products are not recommended for piping boilers. In the boiler room there is a frequent change in temperature, which is contraindicated for this profile.

If you take into account all the above points, then polypropylene types with a maximum temperature of +95 are quite suitable for heating.

Material for the manufacture of water supply and sewerage systems

These products can be used to organize water supply and heating. How to choose polypropylene pipes for water supply based on its purpose?

The following restrictions apply to the transported liquid:

- Operating temperature – no more than +70 degrees.

- The pressure at a temperature of +70 degrees should not be more than 10 bar, at a temperature from 0 to +25 degrees - 25 bar.

- Short-term increases in temperature up to +90 degrees are allowed.

Depending on the purpose of the system, the selection of appropriate products will be required:

- Gray polypropylene pipes are characterized by the ability to withstand operating loads more resistant than similar white products. For heating products they are a more preferable option.

- For hot water, thicker pipes are used.

- Products with aluminum or fiberglass reinforcement are sometimes used in systems equipped with geysers. However, this is a violation of their operating conditions, which leads to a reduction in service life.

Russia

Domestic manufacturers of polypropylene pipes on the construction market are represented by the companies POLITEK, RVK, PRO AQUA, SANTRADE and HEISSKRAFT. Good quality, a wide range of products on store shelves and a clearly structured supply chain distinguish the top three.

The RVC trademark belongs to Orenburg. The company produces unreinforced pipes PN 10, PN 20 with diameters from 16 to 125 mm. Reinforced with aluminum “speciAL” (PP-R/AL/PP-R) in the range from 20 to 63 mm and fiberglass “PBK-ORANGE” (PP-R/GF-PP-R/PP-R) with a diameter of up to 125 mm.

The company produces a full line of fittings and fasteners.

The main drawback of RVK pipes at first was the failure to maintain the exact diameter of pipes from different batches. Today, according to the company itself, this flaw no longer exists.

PRO AQUA

The only manufacturer producing polypropylene pipes capable of withstanding a pressure of 79.5 atm. This safety margin guarantees a long service life of the pipeline. The pipes are designed for an operating temperature of 95°C.

According to test data, the strength of PRO AQUA pipes is 1.6 times higher than that of Chinese analogues.

Pipe diameter from 20 to 125 mm. The company produces a full set of fittings, bypass elbows, fasteners and installation parts, valves, ball valves and filters.

Ventilation material

Ventilation pipes ensure the flow of fresh air into the room and the removal of exhaust air: their strength in this case is not the main criterion. The main thing is that these products were lightweight, since they are often supported only by partitions or suspended ceilings.

Residential premises are equipped with pipes with a diameter of 100 or 125 mm; industrial systems will require preliminary calculations. The cross-sectional shape of such products can be square, round, oval or rectangular. The installation process uses the socket method, so no welding machine is required.

Products from foreign manufacturers

Banninger

The company is registered and located in Germany. Representative offices have been opened all over the world, including in our country. Distinctive features of manufactured products: high quality, reliability, safety, wear resistance, long service life. In the manufacture of goods, heat-stabilized polypropylene PP-RCT is used. The manufacturer has launched the production of elements with particularly large diameters. The internal nominal passage ranges from 20 to 125 mm. Products with a diameter of 90 to 125 mm are often used for installing vertical risers in multi-storey residential buildings. To supply process water to enterprises, structures with a diameter of 160 to 400 mm are used.

Purchase price – from 70 rubles.

Banninger polymer pipes

Advantages:

- service life reaches half a century;

- availability of ISO 9001:2008 certificate;

- do not change the chemical composition of the liquid;

- preserve the taste of drinking water;

- are not afraid of alkaline and acidic environments.

Flaws:

- if you order a large batch of goods (up to 330,000 rubles) you will have to wait for some time;

- to install elements with a diameter of 100 - 400 mm, you need to purchase a special soldering iron;

- the fitting is expensive.

Wefatherm

This German company deserves special attention. It produces structures reinforced with aluminum foil or fiberglass. Products are purchased for installation of heating systems, hot water supply, supply of drinking water and for technical needs. Withstands significant pressure. Shut-off valves with transitions to flanges or threads for installing a heated towel rail are also available. Craftsmen have a high opinion of their products. The internal walls of the elements are perfectly smooth, which prevents the formation of plaque, which leads to a decrease in throughput. Linear expansion is minimal. Installation is easy and simple. No special equipment is needed.

The average cost is 150 rubles.

Wefatherm polymer pipes

Advantages:

- versatility;

- functionality;

- strength;

- practicality;

- reliability;

- environmental friendliness;

- no deposits are formed inside;

- The joints are connected without stripping.

Flaws:

- the price is high;

- If you overheat the soldering iron, the joint may become deformed.

Akwatherm

The company has been present on the goods market for more than four decades. Has proven itself on the positive side. Produces exclusively high-quality products. The list includes designs for hot and cold water supply, heating systems and heated floors. Elements are purchased for installation in hotels and high-rise buildings. The product undergoes full testing in our own laboratories. It is distinguished by flexibility, strength, resistance to high pressure, and environmental friendliness. The latest technologies and high-quality equipment are used in production. The structure can be buried underground or carried out in open space. In this case, no additional protection is required.

Purchase price – from 50 rubles.

Akwatherm polymer pipes

Advantages:

- products are extremely popular;

- positive reviews from professionals;

- acceptable price;

- safety;

- reliability;

- long service life;

- installation speed;

- Available in poles and coils.

Flaws:

- not always on sale;

- Some types are only available to order.

Wavin Ekoplastic

The company is the product of a merger of a Czech company and an international corporation. Products are sold in 25 countries. It is extremely popular among domestic craftsmen. Available in skeins and racks. Working pressure – from 10 to 20 atmospheres. Internal diameter control at height. The products belong to a new generation. Reinforcement is carried out with basalt fiber, which allows it to withstand temperatures of 90 degrees. There is virtually no linear expansion. You can lay elements in close proximity to boilers, boilers or other heating devices.

You can purchase the product at a price of 70 rubles.

polymer pipes Wavin Ekoplastic

Advantages:

- light weight;

- different diameter;

- fittings fit the pipes;

- availability of a quality certificate;

- strength;

- reliability;

- safety;

- maintainability;

- wear resistance;

- value for money.

Flaws:

- You can find fakes on sale.

Tevo

The manufacturer belongs to the young category, but the products are very popular all over the world. In addition to polypropylene pipes, the production of manifolds, fasteners, fittings, and shut-off valves has been established. In the manufacture of goods, innovative technologies and high-quality equipment are used. The quality of the material used is excellent. The products are environmentally friendly, reliable, practical, and functional.

The average cost is from 75 rubles.

Tevo polymer pipes

Advantages:

- designs are tested in our own laboratories;

- constant quality control;

- seven-year warranty from the manufacturer;

- use of Borealis raw materials;

- presence of a combination fitting.

Flaws:

- Not available at all retail outlets.

Novaplast

The largest Turkish manufacturer supplies the market with high-quality products. It is extremely popular in more than 50 countries, including France, Germany, Spain, Italy, and Russia. Produced from Borealis granulated polypropylene or Basell raw materials. It is highly environmentally friendly and reliable. Used for installation of heating and water supply systems, including drinking water. The maximum cross-section of pipes is 4.5 mm. Can even be used for gas supply. Widely used in the construction of residential and commercial buildings.

Purchase price – from 130 rubles.

Novaplast polymer pipes

Advantages:

- constant thorough checks of product quality at all stages of production;

- can be placed in concrete structures;

- the internal walls are not affected by lime deposits;

- minimum service life - half a century;

- quality certificate;

- strength;

- practicality;

- ease of installation.

Flaws:

- The distribution network is not very developed.

Supratherm

The Romanian company has been supplying the market with high-quality polypropylene risers and connections for more than a decade. The products are certified by international agencies, there are no claims or complaints about them, they are completely reliable and safe. One of the directions of the enterprise is the production of stabilized pipes reinforced with aluminum foil for reinforcement. No pre-cleaning is required before soldering. Fittings with threaded connection. Mortgages from an Italian manufacturer are used. Puddles and leaks during operation are completely eliminated. Often used to connect heated towel rails, pumps and heating radiators.

Products are offered at a price of 65 rubles per meter.

polymer pipes Supratherm

Advantages:

- a huge number of certificates from international controllers;

- pipes are reinforced with fiberglass or aluminum;

- have both domestic and industrial purposes;

- wide choice of parameters;

- reliability;

- practicality;

- speed of installation;

- high quality.

Flaws:

- Some series are produced with a rough surface.

Pilsa

Another Turkish company that is actively filling the market with polypropylene products. The quality of the product is worthy of respect. Implemented in many countries around the world. It is extremely popular among craftsmen. In Russia you can find it in almost any specialized retail outlet. Withstands pressure of 20 atmospheres. Used for laying hot and cold water supply systems. The catalog contains several options: PPR-Al and PPR Fiberglass (reinforced with aluminum foil or fiber). Recently, the production of PPR Basalttherm pipes (using basalt fiber) has been launched. This model can be used to operate at temperatures up to 110 degrees. Linear extensions are completely absent. The product stands out among its peers with a thick red stripe on the side. Soldering is easy and quick. The soldering iron quickly softens the material, and the connection occurs quickly and without problems.

Sold from 87 rubles.

polymer pipes Pilsa

Advantages:

- resists acids and alkalis;

- withstands high pressure;

- value for money;

- positive reviews;

- safety;

- environmental cleanliness;

- durability;

- purchased for self-installation of systems;

- high quality material.

Flaws:

- There are interruptions in supplies to our country.

FV Plast

The well-known Czech company has been producing products for a quarter of a century. In the manufacture of structures, polypropylene of the third type or polypropylene - copolymers is used. In addition to pipes, the manufacturer offers high-quality fittings, shut-off valves, pipes, tees, elbows, valves and other necessary components of the system. Some models are used when installing heated floors. The throughput diameter varies from 16 to 110 mm. Working pressure indicators are from 16 to 20 atmospheres. The company has long mastered coextrusion technology, so the structures are used for installation in close proximity to boilers and boilers. The company also uses Stabioxy technology, creating an oxygen-protective circuit around the internal channel. This allows you to create an additional barrier for heat exchange, which helps reduce heat loss during transportation from the boiler to the radiator.

Retailers ask for products from 130 rubles.

polymer pipes FV Plast

Advantages:

- wide range of manufactured designs;

- maximum permissible temperature – 90 degrees Celsius;

- there is no need for cleaning before welding;

- reliability;

- long service life;

- installation speed;

- practicality;

- functionality;

- versatility;

- high quality of materials used;

- value for money.

Flaws:

- maximum internal diameter – 110 mm;

- Mainly has a domestic purpose.

Dizayn

The product from the Turkish manufacturer is very popular all over the world due to its durability, reliability and good price-quality ratio. The main purpose is the installation of water supply and heating systems. Independent experts have repeatedly confirmed the quality and environmental friendliness of the manufactured elements, which is confirmed by numerous international certificates. The company constantly introduces innovative technologies and controls the quality of products at every stage of production. Unique technologies make it possible to produce structures that have no analogues in the whole world. This applies to pipes with a diameter of 1600 mm. Large manifolds are able to withstand pressures of 12.5 bar. These products are used in industrial enterprises and large construction sites. It can be placed in tunnels and mines.

The product is sold at an average price of 135 rubles.

polymer pipes Dizayn

Advantages:

- reliability;

- quality;

- practicality;

- functionality;

- versatility;

- with corrosion protection function;

- affordable price;

- the level of linear thermal expansion is small;

- plastic and reinforced devices are produced;

- availability of international quality certificates.

Flaws:

- Some lines are produced in the Middle Kingdom, so the quality of an individual batch may be “lame”.

Blue Ocean

Despite their Chinese origin, the designs are distinguished by their quality, reliability and long service life. Three options are available: fiberglass reinforced, aluminum and conventional pipes. The products have color stripes indicating a certain temperature range of use. The color variety is impressive. On store shelves you can find elements of green, white, gray and blue. This helps to fit them into the existing interior of the room. They have increased flexibility, which is why they are very popular among builders. Ideally mounted in difficult areas (near the wall or ceiling). The pipes can be carefully removed from the surface and soldered.

The average price is 190 rubles.

Blue Ocean polymer pipes

Advantages:

- wide functionality;

- versatility;

- practicality;

- ease of use;

- environmentally friendly product;

- safety;

- various colors;

- reinforced with fiberglass or aluminum.

Flaws:

- the use of low-quality glue by the manufacturer leads to peeling of the foil;

- There is an unpleasant odor during the soldering process.

How polypropylene pipes are connected

All types of polypropylene pipes are connected to each other or other elements of the system by welding and connectors.

Polypropylene pipes and fittings are connected to each other in the following ways:

- Coupling or socket welding. Used for pipes whose diameter is less than 63 mm.

- Butt welding. Pipes with a diameter of more than 63 mm are directly welded together. In this case, no additional elements are required.

- Flange joint. Using this collapsible connection, pipes of large cross-sections are joined.

To connect a pipe made of polypropylene and metal, there are two ways: threaded and flanged. The first of them is suitable for products with a diameter of less than 40 mm: for this, various fittings are used that have a thread on one side and a smooth coupling on the other. Pipes up to 600 mm are connected using various types of flanges, since tightening the threads in this case is quite problematic.

To organize the transition between polypropylene and HDPE pipes, welding or fittings are used. Due to the different composition of materials, welding is less preferable in this case. It is better to choose compression or threaded fittings for these purposes. As for connecting polypropylene communications with this or that equipment, then fittings of various types come to the rescue.

Türkiye

Turkey, one of the first countries producing polypropylene pipes, conquered the Russian construction market. Among Turkish manufacturers, the most recognizable are TEBO, PILSA, VALTEC, KALDE, JAKKO.

TEBO

TEBO technics polypropylene pipes comply with all European standards and have a number of competitive advantages:

- High quality raw materials supplied from Germany and South Korea;

- Wide range of models;

- Long service life;

- No marriage.

A wide range of pipes and related materials provide a full cycle of installation operations for engineering communications for any purpose. The TEBO technics brand produces pipes with diameters from 20 to 160 mm, fittings, manifolds, shut-off valves and components. The service life of products for hot water is 30 years, for cold water - 50.

In addition to conventional PP pipes, the model range has been expanded to include reinforced pipes. Pipes reinforced with aluminum have a minimal coefficient of linear expansion. Fiberglass provides increased lateral stiffness.

PILSA

The most famous brand among professional builders. PILSA Plastik Inc. widely represented in 50 countries around the world. PILSA Plastik Inc is part of the Wavin industrial group, the largest European manufacturer of polypropylene products. Of particular interest to consumers is the versatility of using Pilsa pipes at temperatures from -10°C to + 95°C. The elastic material prevents frozen water from destroying the pipes.

Pilsa brand products have a number of advantages:

- Low thermal conductivity;

- High heat resistance;

- Good throughput;

- Pipes and connections do not require maintenance;

- Attractive appearance.

The range of pipes and additional elements is perhaps the richest of all possible. Excellent quality and low price guarantee the company great demand among customers.

But popularity carries with it danger. In the markets you can find fakes from Chinese handicraft workshops.

VALTEC

VALTEC offers consumers single-layer and multi-layer pipes and fittings made of high-strength polypropylene PPR-100 with diameters from 20 to 110 mm. The pipes are intended for drinking and domestic cold and hot water supply systems, as well as for process pipelines transporting non-aggressive liquids and gases. The company produces multilayer polypropylene pipes VALTEC PP-FIBER, reinforced with glass fiber and PP-ALUX - aluminum foil.

The form of delivery of pipes is 2 and 4 meter sections. A fairly modest set of fittings and shut-off valve elements.

The construction market reacts sluggishly to the products of this brand.

KALDE

KALDE is well known for its quality products. The line is represented by unreinforced, aluminum and fiberglass reinforced pipes with a diameter of 20 to 110 mm.

Advantages of KALDE reinforced pipes:

- Reduction of linear expansion by 75%;

- Increased throughput by 20%;

- High impact strength at low temperatures;

- High stability.

All pipeline elements are made of white and gray polypropylene.

The range of fittings includes polypropylene, combined with metal, threaded brass, compression and press fittings. In addition to pipe products, there is no shortage of manifolds, wall kits, ball valves and valves on the market. The manufacturer offers coarse filters, equipment for installation and welding.

JAKKO

Jakko was founded in 2002 in Kazakhstan as a joint venture with Turkey. The company quickly established a wide dealer network in the CIS and ensured the supply of high-quality products. In 2006, it switched to its own production in Turkey.

This brand produces a standard set of polypropylene products in the diameter range from 20 to 125 mm. The brand is little known, the products are little studied, and the reviews are contradictory. For this reason, it is very difficult to recommend Jakko products. Practitioners refer to the identity of Jakko products in terms of quality and range of related materials with VALTEC. And here the price of products in a particular region can play a decisive role.

Installation of a new system

As in the previous case, installing a heating system in a house begins with careful planning. We emphasize that for private sector housing the most preferable scheme is a two-pipe one. But initially it is determined what type of boiler it is planned to install. The boiler can be:

- gas;

- solid fuel;

- electric.

In areas with centralized gas communications, the first type of boiler is the most common. They are easy to maintain, but require increased safety precautions. The second type of boiler is installed, as a rule, in rural areas that do not have gas supply. In this case, this is the most economical option in terms of fuel. As for electric boilers, despite their ease of operation, energy costs can become quite significant.

Heating made of polypropylene in a private house Source santex-tomsk.ru

Replacing old pipes

Taking into account the fact that we have quite a lot of housing built in the last century, the issue of replacing dilapidated communications is very relevant. Last but not least, this applies to heating systems. It is highly desirable that such work be carried out by qualified specialists. This will allow you to make correct calculations and perform installation correctly.

Even just when replacing old pipes, it is advisable to at least “with one eye” evaluate the heating scheme, because who knows how conscientiously the calculations were carried out two or three decades ago, especially taking into account the materials that were in use at that time.

Generally speaking, room heating can be organized using a one-pipe or two-pipe scheme. The type of heating system directly determines the complexity of installation work, cost, number of consumable components and quality of heating.

Propylene pipes and an old-style radiator Source aqua-gel.ru

In most cases, two-pipe circuits require the installation of more radiators. The optimal diameter of heating pipes in such systems is considered to be 32 millimeters. Of course, a single-pipe heating system is more economical in terms of costs. However, it must be taken into account that in such systems the liquid temperature, as a rule, decreases with each subsequent radiator. To level out this drawback, radiators have to be equipped with thermostats.

Modern radiators are much lighter and more elegant compared to their older cast iron counterparts; they also require the installation of a Mayevsky crane. It is necessary to bleed air during the start of the heating season. This requirement applies to both single-pipe and two-pipe heating systems.

In addition to the pipes themselves, many auxiliary accessories are used during installation:

- plugs;

- couplings;

- adapters;

- tees;

- fitting;

- clamps and others.

These and other necessary elements are selected in accordance with the type of communications and the diameter of the installed pipes.

Propylene pipes and a modern radiator Source www.daynews.com.ua

When deciding which pipes are best for heating, one should not forget that the welding speed depends on the diameter of the product. To connect propylene structures, a special apparatus is used, which craftsmen call an “iron”. To heat up and connect products with a diameter of about 25 millimeters, about 7 seconds are enough. Accordingly, pipes with a larger cross-section will require longer heating and installation.

It is advisable to consider the general procedure for installing a heating system for an apartment - as the most complete. It consists of the following steps:

- The first step is approval and obtaining permission for the upcoming work in the responsible utility organizations. This is required to quickly shut off the water supply. This may also be true for a private house if it is connected to central heating.

- When completely replacing the riser, it is necessary to coordinate these actions with the neighbors living above or below. Since not all people are eager to let strangers into their homes, completely replacing the riser will probably be impossible. In such cases, they resort to special adapters, through which it is possible to connect metal pipes and propylene.

- After all approvals, work is carried out to dismantle the outdated heating system. In this case, especially in older buildings, extreme caution will need to be taken. Over time, cast iron pipes begin to “crumble” at the slightest touch. This often leads to clogging of communications with fragments of the old pipe.

Warm floor made of polypropylene pipes Source otoplenieblog.ru