Instead of metal pipes in private buildings and apartments, similar products made of polypropylene are widely used when installing utility lines. They are lighter weight and have a longer service life.

However, even such high-quality modern material can leak. To reduce the likelihood of repairing polypropylene pipes or quickly eliminating an emergency situation, you need to have information regarding the reasons for the leakage of polymer pipelines.

Kinds

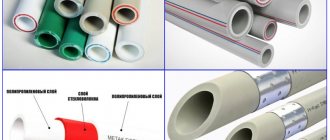

Metal-plastic Polyethylene

Such communications are divided into subtypes:

- Polyethylene - used for laying wiring inside buildings and external routes. They can be used on high-pressure pipe connections and at low ambient temperatures.

- PVC is used to reduce the cost of repairs.

- Metal-plastic ones are the most practical products, with a useful life of more than 50 years. Ideal option for replacing hot water supply.

The widespread use of this material is due to a number of reasons. Positive properties of such structures, in contrast to metal ones:

- Long service life.

- Low corrosivity.

- Easy to install.

- Does not require special skills.

- Environmentally friendly material.

- Economical and easy to use.

- Lightweight and easy to transport.

- Resistant to the harmful effects of microorganisms.

Using a clamp and rubber as a means to eliminate radiator leaks

If the damage is located at the junction of the main pipe and the radiator, then the leak can be removed for a while using wire and a rubber band (car clamp). A piece of rubber is wrapped around the damaged area and secured with wire.

If you cannot find a special remedy for eliminating radiator leaks, then you can simply cut pieces of rubber from a bicycle inner tube - the strips should be 30-35 centimeters long and 4-5 centimeters wide. Using a clamp, you can stop the leak for a while. For this reason, it doesn’t hurt to have a few clamps in stock at home - their price is low.

Methods for joining polypropylene

This polymer is thermoplastic: when heated, it quickly softens. When two parts are heated simultaneously and evenly, the molecules of the substance penetrate each other. This is called polyfusion. After the connected materials cool down, their technical characteristics do not change at all, therefore, with high-quality work, the unit turns out to be strong and monolithic.

This method of connecting pipeline elements is called polyfusion welding. The definition of “soldering” is also often found. Both words refer to the same process; there is no difference between the two concepts. Typically, in practice, two methods of joining parts are used - coupling and direct.

Cold soldering (welding)

This method cannot be called a formidable competitor to hot types of compounds. Polypropylene pipes are coated with glue, the active component of which is a strong solvent. When he softens the areas being connected, they are inserted into each other.

A huge drawback is the lack of a guarantee of tightness and strength of the pipes. Another disadvantage is the long drying time of the “welded” elements: it takes at least a day. Therefore, this method did not find a large army of supporters. Its “legitimate” niche is PVC pipes.

The most reliable (and necessary) method at home is sleeve welding. It is about her that the further story will go.

Socket welding

This method is more popular for simple reasons - it is accessible, simple, and always necessary. To connect two elements - a section of pipe and a coupling (tee, tap, threaded fitting, etc.) with an internal diameter smaller than the outer diameter of the pipe.

In this case, metal attachments (coupling and mandrel) are installed on the heating device under the pipe and the element necessary for the connection. After optimal heating is achieved, both parts are removed from the tool and immediately connected.

PPR connection without welding

There are situations in life when the use of traditional soldering of polypropylene parts is excluded. For example, the joint is located in a hard-to-reach recess, or during installation the power suddenly turned off, and you only have to weld the last connection. There are 3 one-time methods:

- heating with a gas burner and subsequent docking;

- use of Gebo type compression coupling;

- planting elements on anaerobic glue.

Why are these options considered one-time use? Gluing and heating with a torch cannot provide the required reliability of the joint and are used only as a last resort on cold water supply lines. It is highly undesirable to connect heating and hot water pipes in this way. Gebo couplings are reliable, but too expensive.

The connection technology without a soldering iron is simple - the parts are degreased, gently heated with a burner flame, joined and fixed for 6-10 seconds. The technique is demonstrated in the video below.

Bonding is carried out according to the instructions on the packaging of the anaerobic sealant. The end of the pipe and the fitting socket should be cleaned, degreased and glue applied with a small brush. The elements are then fastened together using compression.

Alternative to welding

In some cases, for example, in hard-to-reach places in the bathroom or other rooms, it is not possible to carry out welding work. The soldering process can be replaced by gluing the pipe to the fitting using an organic solvent. It has a very strong softening effect, but is also highly volatile.

After lubricating the end of the pipe and the internal cavity of the coupling, the plastic softens for a short period of time, and the connection can be made. Reverse polymerization begins after a few seconds.

However, this method is more suitable for PVC pipes that are less prone to thermoplasticity.

If for some reason this option is not suitable, for pipes NOT UNDER PRESSURE it is permissible to use a supercharged lighter instead of a soldering iron. This connection method is shown in the video tutorial below. It is important to understand: uniform soldering cannot be achieved precisely because of the alternating heating of parts, therefore the technology cannot be used for critical connections.

If the ball valve is broken

A ball valve has a more complex structure and differs from a two-valve valve. Most often, such products break due to dirt accumulated inside the case. It is this that disrupts the operation of the mixer. If water flows from the tap, it must be disassembled, cleaned well and reassembled. This requires:

Using a screwdriver with an appropriate tip, unscrew the screw that secures the lever. Carefully remove the lever and unscrew the threaded screw with a screwdriver. Then you should remove the plastic seal and the mixer dome. The gasket should be carefully inspected and then cleaned of deposits. If there is obvious damage, then it is worth replacing it. Now you can take out the ball and inspect it

If the part is damaged, it is worth replacing it. You can purchase a ball at any plumbing store. Using a thin screwdriver, you need to very carefully pry off the seal that secures the ball. If necessary, the sealing gasket should be replaced. Before assembling the faucet, all seals should be treated with a special compound recommended by the manufacturers. Finally, all that remains is to reassemble the faucet, proceeding in reverse order.

Methods for connecting polypropylene pipes

Polypropylene is a thermoplastic polymer. The structure of the material is subject to change during the heating process (soldering, welding) - it softens under the influence of high temperature. Two fragments heated to the same temperature undergo a diffusion process. Cooling of preheated parts of the product does not change its properties. With proper heating and connection, the creation of a monolithic unit is ensured.

The characteristics of technologies for connecting polypropylene pipes into one system are based on the heating method. The method is called polyfusion welding. It is carried out using a coupling or butt method.

During installation, the pipe itself and a coupling, the diameter of which is smaller than the diameter of the pipe, are used. Under normal conditions, docking of both elements is impossible. The mounting section of a tee, tap, bend, threaded screw and other components can act as a coupling.

The process of soldering polypropylene pipes involves simultaneously placing both elements on the heating element of the welding machine. A pair of the required diameter is pre-mounted coaxially on the working heater itself, consisting of a coupling on a metal base into which the pipe will be inserted, and a special mandrel for putting on the connecting element. When soldering, a belt of molten polypropylene is formed, approximately equal in width and depth. An important installation feature is the correct temperature setting. The pipes must not be allowed to melt over their entire diameter. The pipes are removed from the heating element and, with force, are connected together coaxially. The molten polypropylene will serve as a connecting element and seal, thanks to which the smaller coupling will fit securely into the pipe and provide a tight connection along the entire length of the heating area.

An important difference between the alternative method of soldering polypropylene pipes is the mandatory joining of parts of the same diameter. The first step is the precise adjustment of the ends for subsequent joining. The pipes on both sides are pressed forcefully against the end cutter. After fixing, a flat-shaped heating element is placed in place of the trimmer. As it heats up, both pipes will melt evenly. The tubes are then compressed to ensure polyfusion. Compression is carried out with force. As the material cools, polymerization occurs and a reliable seam is created at the joint. The conditions required for such installation can only be achieved with special equipment. It ensures uniform heating and joining.

Nuances of work: how to solder plastic pipes without problems

The above instructions describe the general provisions for welding polypropylene pipes. But there are interesting points that can confuse an inexperienced master.

We work on the workbench and locally

Not all components of the future pipeline can be soldered comfortably on a prepared workbench. Of course, maximum work should be carried out there, and the point is not at all in the personal comfort of the master - this way there is less risk of incorrect connection of elements. But sometimes it is necessary to solder parts “in place”, so it is better to mark out the diagram of future communications on the wall, floor or ceiling in advance, and secure the clips that will hold the pipes in the desired position.

We fasten the welding machine

When inserting and removing heated elements, a tabletop “iron” that is not secured in any way will jerk in different directions. This leads to both problems with extracting fragments and burns (when trying to hold the falling apparatus), and its breakdown.

Therefore, it is better to fix the soldering iron on a workbench or desktop in any available way - using a “native” clamp or a clamp added to the design, self-tapping screws, and so on.

Cleaning is required!

One of the striking examples is the joining of products reinforced with aluminum not on the outside, but in the middle of the wall.

To properly solder such polypropylene pipes, it is necessary to strip the aluminum layer - but how to do this if it is between the layers of plastic and not outside?

For this, there is a special trimming tool that allows you to remove aluminum foil precisely between the layers.

The cutting edges, which “scrape out” the foil, are shifted towards the center of the product. Thanks to this, the aluminum is removed, the plastic remains in place - the pipe is ready for welding.

The photo shows what the joint looks like between prepared (right) and unprepared (left) fragments. It is clearly visible that in the first case the adhesion turned out to be dense, in the second the delamination is clearly visible. With short-term use, this defect does not matter, but for pipelines through which hot water is supplied (from a boiler or heating boiler), depressurization and failure of communications is possible.

The diagram demonstrates the consequences of a loose joint between two seemingly welded pipes, delamination of the product and swelling of the outer layer of polypropylene during operation.

Important: fiberglass reinforced pipes do not need to be stripped! This is due to the fact that the welding temperature adopted for polypropylene allows glass fiber to melt to the point of diffusion.

Correct cut

Sometimes users think that cutting the pipe obliquely - at an angle of 45 degrees - can increase the contact area and thereby strengthen the weld. This is actually true, but with this type of pruning problems arise:

- with the alignment of parts - it is difficult to correctly connect the pipe sections inside the coupling, a gap inevitably arises;

- with heating of the welded areas - an oblique cut does not allow the required fragment of the product to be completely placed on the heating element. One edge heats up less, the other more.

The last node is not welded!

This happens if an inexperienced welder inaccurately calculated the lengths and locations of pipeline fragments. When it is not possible to insert a mandrel with nozzles and a coupling between the last two elements to be welded, you can solve the problem differently - weld metal inserts into the elements to be joined.

Such a threaded pair with a union nut allows you to firmly and efficiently fasten two fragments and at the same time weld it in without any problems.

Wouldn't you, priest, chase something cheap...

An attempt to save money when purchasing pipes and fittings is fraught with leaks and swelling of pipes in the future, so it is better to purchase products from trusted manufacturers.

It is also necessary to avoid combining products from different companies - a slight difference in the composition or production technology of goods sometimes leads to critical problems in finished communications.

Other errors

Among the most “popular” errors are often found:

- excessive heating of elements. As a result, the pipe is severely deformed and closes the lumen of the coupling, thereby interfering with the free flow of water in the water supply system;

- refusal to degrease surfaces and/or clean them. In this case, diffusion does not occur over the entire surface; “islands” remain where the plastic has not fused. The result is failure of the connection when the pressure or temperature increases;

- water has not been removed (during the repair of an existing water supply system). This can be done using a rag and a warm (not hot!) stream of air from a household or construction hair dryer;

- loose connection. This happens if the pipe is not completely inserted into the fitting or the diameters do not match.

Another common mistake made by inexperienced craftsmen is not wearing protective gloves. The high heating temperature of polypropylene MUST require hand protection, and it is advisable to use gloves made of natural materials - preferably suede. They do not restrict movement and do not begin to smolder when heated, unlike cotton ones. Rubber and rubberized gloves cannot be used!

Typical mistakes are discussed in more detail in the video “How not to solder polypropylene pipes.”

Welding instructions

In domestic conditions, soldering of polypropylene fittings and pipes into a single structure is most often performed using the thermal polyfusion method. After heating with a special device, the pipes are quickly connected. The work, in accordance with the technology, is carried out in stages.

Preparation

At the preparatory stage, design documentation is developed, which must indicate the selected pipeline diagram. The places where the system is fixed to the walls are correctly determined, and if necessary, the required number of mounting holes is punched using a construction tool.

Polypropylene pipes must be marked and then cut into individual elements in strict accordance with a pre-prepared diagram, as well as field measurements. Such a simple event will allow you to verify the accuracy of the markings.

The pipe sections laid out on the most even surface should follow the correct sequence of connections. The foil parts are removed from the ends with a trimmer, after which the depth of insertion into the fitting is marked at the selected ends with a marker.

Heat

The operating temperature of the heater on the soldering device must be selected depending on the technical characteristics of the pipes. The process of soldering pipelines with aluminum reinforcement should be carried out at nozzle temperatures within the range of 260-300°C.

The soldering equipment used in the work must reach the required temperature before welding, so the thermostat is set to the appropriate position, and the plug of the device itself is plugged into the electrical outlet.

The readiness of the welding machine for welding polypropylene is signaled by the switching of a special backlight on the device. The alarm options vary on different equipment models. In order not to make mistakes in the operating rules of the device, you should carefully study the instructions supplied by the manufacturer.

Welding

Correct operation means simultaneous heating of the end of the polypropylene pipe and the fitting by the soldering device. In this case, the fitting used is located on a special mandrel, and the pipe is inserted into the sleeve with little physical effort. The insertion depth must be monitored in accordance with the marker markings applied to the PPR pipe.

| Diameter (mm.) | Welding depth (mm.) |

| 20 | 14,0 |

| 25 | 16,0 |

| 32 | 20,0 |

| 40 | 21,0 |

| 50 | 22,5 |

| 63 | 24,0 |

| 75 | 28,5 |

| 90 | 33,0 |

| 110 | 39,0 |

The standard heating time for all connected elements is selected depending on their diameter. It is necessary to combine polypropylene pipes and fittings quickly enough, thereby preventing temperature losses of the heated material. The joining of elements is carried out through a smooth translational movement without rotation.

The connected structure of the pipeline section should be securely fixed until the joined polymer elements reach maximum strength values. As practice shows, the system sets within 10-20 seconds (depending on the D of the pipe). The ideal option is to maintain the fixed position until the connection area has completely cooled.

| Diameter (mm.) | Cooling time (sec.) |

| 20 | 3 |

| 25 | 3 |

| 32 | 4 |

| 40 | 4 |

| 50 | 5 |

| 63 | 6 |

| 75 | 8 |

| 90 | 10 |

| 110 | 10 |

Stripping

After all welding work is completed and the material in the joints has completely cooled, the joining areas are carefully cleaned of natural plastic deposits. This event allows you to give welded structures a neat and aesthetic appearance.

A sharp knife can be used for this purpose, but stripping must be done very carefully. It should be remembered that an excessive amount of sagging of polymer material may well prevent the pipeline elements from fitting tightly into the fastening clips.

Cement-plaster dressing to eliminate leakage of the heating radiator

Before fixing a leak in the heating battery, you need to prepare the required materials and tools:

- cement;

- alabaster (plaster);

- container with water;

- salt;

- medical bandage

To eliminate the leak, a bandage is applied to the damaged area.

The procedure after turning off the water is as follows:

- dilute cement in a container with water to the consistency of thick sour cream;

- cut the bandage into strips 25-30 centimeters long;

- thoroughly soak the bandage with the cement mixture;

- wrap strips around the damaged area.

The process is repeated until a durable bandage is obtained. If it was not possible to turn off the water, then instead of cement you need to use alabaster, which dries much faster. Then a cement bandage is applied to the plaster cast. If the heating battery leaks at the threaded connection, you can use salt:

- wet strips of cloth or bandage in water;

- roll the material thoroughly in salt;

- wrap the leak area.

The gap will close as a result of the salt dissolving in the water. A cement bandage is applied on top.

Connection of PVC pipes with metal-plastic pipes

How to solder polypropylene pipes with an aluminum layer?

How to connect them? Is it possible to solder polypropylene pipes from different manufacturers? In cases where such questions arise, special adapters must be used when soldering.

One side of them is attached to metal or metal-plastic by means of a thread, the other is soldered to plastic using standard technology.

The only difference in the work is that threads must be cut on the metal and the connection must be sealed manually to avoid leaks. It is best to use tow or sanitary flax fiber as a sealant. This material is affordable and effectively seals the joint.

Using the same technology, adapters are installed, on the basis of which mixers are connected. The products externally look as if metal threads were fused into polypropylene.

How to check the connection for leaks

Upon completion of installation work related to the organization of the water supply system, you can begin to check the quality of the pipeline.

To do this, water is supplied to it. The valve is opened to the house or apartment, then the faucet taps in the rooms are opened. The water pressure should be maximum.

First of all, they feel the joints, especially carefully observing the threaded connections.

Sealed joints leak very rarely if the work is carried out in accordance with the technology and the specialist knows well how to properly solder polypropylene pipes for heating, water supply, reinforced with fiberglass or aluminum, large or small in diameter.

But if a leak is detected in the welded pipes, the water is turned off, and the vulnerable pipe connection is redone, having previously been cut off. Before soldering, the pipes are wiped dry so as not to break the soldering iron and warm up the polypropylene well.

If a leak is detected at a threaded connection, it can be carefully tightened with a wrench so that the thread does not break.

Another option is to strengthen the seal. But in the latter case, you need to turn off the water and unscrew the connection.

Now you know more about how to solder polypropylene pipes with a soldering iron, what tools to choose for installation work and how to use a soldering iron correctly.

Follow the recommendations of experienced specialists when creating a pipeline, arranging it yourself, or seek installation services from professionals.

Poor quality taps

Often when purchasing plumbing fixtures, many people are guided by considerations of economy and choose products made in China or Turkey. At the same time, people are happy that they were able to save money in this way.

But this tactic when buying faucets is extremely wrong, and the joy from the amount saved does not last long. This small amount can cause a leak. It’s good if at the moment when the tap breaks down, someone will be at home and will be able to turn off the water very quickly or repair the equipment. But more often it happens differently.

You should never skimp on things like plumbing fixtures. Before purchasing, you must make sure that the product being offered is not made in China, but at least in Russia or Europe. Also, cheap products for a well-known brand are a reason for suspicion. Expensive branded products in our markets are 50% counterfeit.

Sometimes it happens that even on expensive equipment something can leak.

Then it’s worth checking out other reasons to understand how to fix a kitchen faucet. It also leaks in case of improper installation.

Mistakes when soldering polypropylene pipes

It is necessary to follow the recommendations for welding polypropylene pipes and follow all steps of the instructions.

Defective nodes in systems appear due to the following errors:

- Dirt and grease film are not removed from the surface of the parts being joined.

- Pipe products are not cut at right angles.

- The end of the pipe is not tightly inserted into the fitting.

- The time delay is not observed when heating elements on a soldering iron.

- The reinforced layer is not completely removed from the products.

- Correction of parts takes longer than the specified time.

On high-quality materials, an external defect may not be visible when overheated, but deformation still occurs inside. It leads to a reduction in cross section.

Therefore, when operating utility lines, the network capacity is reduced. The narrowing of the passage also causes faster clogging. This also blocks the movement of water.

If the cut is not made at a right angle, the pipe products are joined in a beveled plane. As a result, the elements' alignment is disrupted. It becomes especially noticeable when installing long sections.

As a result, it is often necessary to dismantle and carry out the entire process again. If the alignment of the product is disturbed, it is difficult to lay it in grooves.

Be sure to degrease the surfaces before soldering. Otherwise, so-called rejection islands appear. In such areas, polyfusion welding is poorly performed or does not occur at all.

This error will allow you to start using the utility line, but after a certain period of time a leak will appear. It also often occurs when the soldering iron temperature is set incorrectly.

If insufficient removal of the reinforcing layer occurs, residual aluminum foil contributes to the formation of unwelded areas. Leaks most often occur in such areas.

A serious mistake is scrolling through details. This action does not allow obtaining a uniform structure along the entire circumference of the joint. The connection made will not be complete, because it will collapse when the pressure in the system increases.

So, the faucet is leaking in the kitchen, what should I do in the bathroom?

First, you need to turn off the water in the riser. This will stop leaking and save you from unnecessary expenses. If the shut-off valve on the riser has not been used for a long time, and the pipes are metal, then it is possible that the valve is pretty rusty. In this case, you must first treat it with machine oil, and then try to carefully tighten it using a lever.

After this, you should determine why the faucet is leaking.

One of the most common causes of leaks is a worn valve gasket. Over time, the gasket becomes thinner, allowing water to seep into places where it shouldn't be. The thinning of the gasket is accelerated by the habit of over-tightening the faucet. Thus, a vicious circle is created: due to leaking water, you try to tighten the tap more, which leads to even more wear on the gasket.

The solution to this problem is to replace the gasket. You can easily find a new one at any hardware or tool store. Large-scale disassembly of the tap to replace the gasket is not required - just remove the valve. Let us remind you that before this you must turn off the water.

In most cases, in the center of the valve (behind the decorative plug) there is a mounting bolt, unscrewing which you can remove the valve. After this, you will have access to the gasket, which needs to be replaced with a new one. Wrap a little sealant (fiber or polymer) over the gasket and install the valve in place.

The second most popular problem is the wear of the sealing liner of the oil seal. This malfunction is easy to establish: the valve leaks in the area of the gland nut while the valve is open. There are no leaks when the valve is closed. This malfunction can also be eliminated by replacing the sealing insert.

If you notice a leak in a new, newly installed faucet

There may be two reasons: installation errors or manufacturing defects. Since the taps themselves are sold pre-assembled, the only place where you can make a mistake is the connection to the pipeline. Accordingly, leaks will be there. If the tap itself is leaking, most likely it is a fault. Then there is only one option left - to return the faucet to the store.

Note that all of the above concerned conventional valve taps. Leaking ball valves are a much more serious problem, mainly due to the complexity of the valve design. To eliminate such leaks, it is recommended to contact specialists. However, it is worth noting that ball valves leak much less frequently than conventional valves, since they do not have many weak points, such as the same gaskets.

Expert advice

To ensure maximum reliability of pipeline connections, experts advise adhering to the following requirements:

- it is correct to start welding work 10 minutes from the moment the soldering iron warms up;

- perform welding or soldering operations only at above-zero ambient temperatures;

- sections of pipes connected by welding must be allowed to cool, preventing them from moving relative to each other or twisting;

- For wall thicknesses greater than 6 mm, butt welding of products is performed using a double seam. With a smaller wall thickness, the joint can be sealed with one seam;

- all structural elements fixed by soldering must be from the same manufacturer, since they may differ in the composition of the ingredients in the raw materials, which will negatively affect the quality of the weld.

Sources

- https://VashPlastik.ru/kak-pajat-plastikovye-truby/

- https://dom-i-remont.info/posts/santehnika/payka-polipropilenovyih-trub-svoimi-rukami-pravila-sovetyi-oshibki/

- https://otivent.com/pajka-polipropilenovyh-trub

- https://ProUteplenie.com/otoplenie/payka-polipropilenovyh-trub-svoimi-rukami-polnaya-instruktsiya

- https://eurosantehnik.ru/pajka-polipropilenovyx-trub.html

- https://vse-otoplenie.ru/pajka-polipropilenovoj-truby-instrukcia-polzovania-utugom-tehnologiceskaa-tablica-sekrety-raboty

- https://iseptick.ru/truby-i-fitingi/polipropilenovye-truby/kak-payat-polipropilenovye-truby.html

- https://trubametr.ru/material/pp/kak-payt

- https://vseotrube.ru/montazh-i-remont/kak-payat-plastikovye-truby

What do you think of this article?

Health protection and working conditions

When carrying out work related to heating heating main joints, we follow safety rules to prevent injuries and burns:

- We solder using special protective gloves.

- We monitor the cleanliness of the floor in the room. Dirt will negatively affect the quality of welding and the appearance of the entire structure.

- The soldering iron is installed on a flat horizontal surface.

- It is necessary to start working after the device has completely warmed up and after the readiness indicator has turned off.

- We do not turn off the electrical outlet during the entire installation.

Soldering plastic pipes with your own hands is not difficult. The soldering process does not require professional skills or experience. Anyone can install life support networks in their own home. The mandatory composition of the required tool includes only a soldering device. The remaining auxiliary tools can be replaced with improvised means, a pipe cutter - with a sharp knife. A pipeline made of polyethylene structures and PVC is a reliable, durable and environmentally friendly system for supplying water and heating.

Correct check of radiators before the heating season

Battery checks should be carried out in the summer. Immediately after the heating season, it is recommended to perform pressure testing. To do this, increase the hydraulic pressure in order to identify weak points. If leaks are detected, they are repaired.

Checking radiators should consist of several stages:

- Thorough external cleaning of radiators . Dirty batteries weaken the system and cause unpleasant odors. In addition, uncleaned batteries can become sources of harmful microorganisms that can bring illness into the home. When servicing equipment, detergents should be used.

- Cleaning the batteries inside . To do this, you can use dust brushes with a long handle. You can buy periscopic devices on the market to get to the most inconvenient corners. It is advisable to carry out internal cleaning at least every 5-7 years.

- Adding water . When the radiators are already clean, you can begin ventilating the heating equipment. During downtime, a large number of air pockets could appear that block water circulation. The air should be completely expelled from the system.

Poll: Do you carry out annual inspection and pressure testing of your heating system?

Battery leaks in heating systems occur quite often. You always need to be prepared for this. Scheduled maintenance of the heating system guarantees uninterrupted operation for a long time. But it’s still better to always play it safe and keep the necessary tools and supplies at home in case of breakthroughs. The equipment must be monitored at all times to avoid unpleasant consequences.

Hermetic seal to eliminate leaks

As for how to fix a heating radiator leak, if there is minor damage, you can use a powder or polymer-based sealant. They can be found in hardware stores.

Such a composition polymerizes upon contact with air, and as a result of hardening, a strong filling is formed, which gives time for significant repairs. Some sealants are two-component polymer compounds, and harden as a result of mixing their two components. Other products harden as a result of a chemical reaction with air. Using sealants designed specifically to fix leaks, you can solve the problem in a matter of minutes.

Depressurization of the radiator wall or fin

This kind of damage brings big trouble. It is extremely difficult to fix a problem when the battery is leaking, but for a short time you can find a way out of the situation. The method is quite simple.

The small hole on the battery needs to be enlarged. Before doing this, you need to turn off the water and reduce the pressure. Using a drill, make a hole larger than it was. A wooden peg is inserted into the drilled hole. When exposed to water, it swells and stops water leakage.

You can also use a self-tapping screw with a rubber washer instead of a peg.

Of course, leaving the battery in this state for a long time is dangerous; the section must be urgently replaced with a new one.