December 31, 2021

Pellets are small-sized (diameter 4–8 mm, length 0.5 to 7 cm) cylindrical wood pellets, manufactured using special equipment and intended mainly for heating. In Western European countries, pellets have long been successfully used for heating cottages and country residences. In our country, this product became popular not so long ago. One of the main advantages is the environmental friendliness of the raw materials. An important advantage and ability to use pellets in automated systems: loose granules are poured into a special tank and fed into the boiler in an automated way, without any human participation in this process. This is a significant advantage over other types of solid fuel: chopped wood, coal, briquettes, which regularly need to be added manually to the stove to maintain the combustion process. Fuel pellets retain heat well, which means that your house or apartment will always be warm and comfortable.

Fuel pellets

A low degree of humidity contributes to the rapid combustion of raw materials, high efficiency and heat transfer, and the high bulk density of pellets simplifies transportation and storage, and increases the operating time of the boiler on one load.

What are pellets?

Pellets

are a granular type of solid fuel, cylindrical in shape, made from compressed waste from agricultural production and the woodworking industry. The main materials for the manufacture of fuel pellets are:

- sawdust, wood chips, bark, slabs of coniferous and deciduous (the best option) wood species;

- peat;

- sunflower husks (the most common solution), rapeseed (the best option), straw of various grain crops, corn, husks, cake and much more;

- charcoal;

- household waste.

The base binder is a substance of plant origin - lignin, a natural polymer contained in almost any plant, capable of being plasticized during granulation under the influence of a sufficiently high operating temperature.

Features of heating with pellets

In order to use pellets as fuel more efficiently, you need to purchase a special boiler. Pellet boilers operate in an automated mode: fuel pellets are stored in special containers - pellet bunkers, from which they are fed into the boiler using an auger.

If you want to save money and buy gray rather than white pellets, we advise you not to buy a large batch of fuel at once: not all burners can handle them. First, buy a bag and test it. If the boiler is working normally, you can purchase a larger batch. Do the same with agropellets: first test the operation of the boiler with a small amount. But besides the ash content, there may be other problems: these granules do not tolerate transportation well, so already at this stage you will end up with a lot of waste. So it turns out that heating with this fuel, even if the boiler can handle it, is advisable if the production is somewhere nearby.

The ideal pellets for boilers are white. Their composition is usually homogeneous, and the ash content is low. Due to the characteristics of the raw material, the surface of such granules is dense, they crack and crumble less, and withstand transportation better.

Pellet classification

The main regulatory document predetermining the production of pellets is the European Union standard EN 14961-2, adopted in January 2011, on its basis an international quality certificate EN Plus is issued. There are three classes of granular fuel:

- ENPlus-A1 – best premium quality, diameter up to 8.00 mm, ash content up to 0.70%, another name is “white granules”;

- ENPlus-A2 – with ash content up to 1.50%, also called industrial granules, can consist of mixed wood species;

- EN-B – standard quality, with ash content up to 3.00%, an alternative name for agropellets.

In terms of cost, the most expensive pellets are ENPlus-A1 class, the cheapest are EN-B class, it is better not to take substandard fuel.

Sales on the domestic market

What is typical for our country now is the appearance on sale of inexpensive household boilers that use fuel pellets. In this regard, at first glance it may seem that there will be no problems with the sale of these products. It should be noted that there are certain difficulties in this issue. The fact is that now there are many wholesale warehouses that specialize in the sale of granular fuel. Moreover, many manufacturers have already managed to establish direct delivery directly to the consumer.

Basic parameters of pellets

Pellets for heating are granules of white or shades of brown, with a length from 10.00 to 30.00 mm, a diameter of 6.00 and 8.00 mm, less common fuel with a diameter of 10.00 mm, the maximum diameter of the granules is 25.00 mm. The darkening of pellets is associated with the presence in the structure of the material of various non-combustible residues (dust, earth, and a number of others).

The main parameters of pellets are:

- ash content (the lower, the better and the less ash, so the boiler will have to be cleaned much less often);

- humidity;

- calorific value (ENPlus-A1 – 18.0 MJ/kg, ENPlus-A2 – 18.0 MJ/kg, EN-B – 15.0 MJ/kg).

- total length;

- degree of density;

- diameter;

- bulk mass;

- abrasion class.

Other materials

Russia has vast deposits of peat, which is suitable for granulation. Peat pellets and briquettes are made using approximately the same technology as wood. The calorific value of peat is high - up to 21 MJ/kg, however, the ash content of such granules is increased - up to 5%. This fuel is suitable for industrial and municipal boilers. In Russia, granulation and briquetting of peat has mainly 2 prospects: providing heat and electricity to non-gasified areas and exporting granules to Scandinavian countries. In Northern Europe, peat is recognized as a partially renewable raw material, and its use in the energy sector is encouraged from above.

Granulation of waste paper is a fairly new but promising industry, since this type of raw material does not require expensive drying complexes. Granules made from paper and cardboard (and in some countries granulation of old banknotes has been established) produce a large amount of heat and have a tiny percentage of non-combustible residues.

Chicken and horse manure pellets are more expensive than wood pellets. It is a valuable and nutritious fertilizer for soils. Horse manure pellets sell for around €1.25 per kilogram. Processing manure and droppings into fertilizers is not only profitable, but also a necessary step, since storing such waste directly harms the environment.

The same can be said for the processing of hydrolysis lignin, a by-product of hydrolysis plants. In Russia, there is only one lignin granulation plant in the Arkhangelsk region, and meanwhile its reserves in the country amount to tens of millions of tons. In terms of calorific value (more than 21 MJ/kg) and ash content (less than 3%), lignin is an excellent raw material for pellet production.

Expanding the raw material base for the production of fuel pellets makes it possible to benefit from the disposal of huge amounts of biological waste, as well as solve environmental problems associated with their storage. Switching from fossil fuels to environmentally friendly fuels reduces emissions of harmful substances into the air. The creation of new pellet and briquette production creates new jobs in the agricultural industry and helps its overall development.

Pellet manufacturing technology

The production of pellets consists of pressing waste that has been previously dried to a certain moisture content and crushed to a given fraction under a pressure of about 300 atmospheres. At the same time, the use of glue and other additives is prohibited (sometimes unscrupulous businessmen add sand and other non-combustible impurities to them to increase the weight of the granules, and synthetic polymers to ensure adhesive properties).

Main stages of pellet production:

- Grinding. The raw material enters the crusher and is crushed to a given fraction;

- Drying. The resulting raw material is dried to the moisture percentage specified by the technology (about 10% plus or minus 2%);

- Pressing. The dried raw material enters a press granulator, in which it is pressed into granules of a given length and diameter. As a result of compression, friction, and adiabatic processes, the temperature can reach 100°C Celsius, as a result, thermal energy is generated that softens lignin and the particles stick together into granules. This process is called pelletization;

- Cooling. To ensure the strength of the fuel granules, the pellets are cooled after pressing;

- Packing and sending to the consumer.

In some cases, water treatment and additional grinding are performed before pressing; everything directly depends on the type and quality of the raw materials from which the granules are made. Pressing is carried out in molds, ring-type dies using rotary rollers (rollers), which press the raw material into cone-shaped dies located on the matrix. On the other hand, the resulting granules are cut with special knives. After cooling, the pellets are sieved and small particles are sent for recycling. Closed cycle technology is virtually waste-free; only non-combustible impurities are removed. In order to make one ton of pellets, three to five cubes of wood waste are needed. The raw material is compacted approximately three times. To prepare one ton of pellets you need from 30.00 to 50.00 kW per hour.

Characteristics

The chemical characteristics of the finished granules depend on the feedstock. The use of foreign materials such as glue and plastics is not allowed during the pressing process. The amount of thermal energy released depends on what the pellets are made from. Pellets always sink in water, since their density is greater than the density of water.

When burning 1 ton of granules, as much thermal energy is released as when burning:

- 1600 kg of wood;

- 475 m3 of gas;

- 500 l of diesel fuel;

- 685 l of fuel oil.

Necessary machines for the production of pellets

Equipment for the production of sawdust pellets includes:

- crushers (chopping machines) for grinding the raw materials used to a given fraction;

- dryers to ensure the required percentage of humidity of the initial, base raw materials;

- hammer mills (in some cases they are replaced by flaring machines, disintegrators, everything depends directly on the characteristics of the feedstock), make it possible to obtain raw materials with a fraction of up to 4.00 mm;

- screw mixers (used when using overdried raw materials with a moisture content of less than 8.00%, by dosed supply of steam or water);

- presses (differ in the type of matrix used, which can be flat or round).

Dryers, in turn, are divided into:

- principle of operation (can be drum or belt (cost more, but are more productive and safer to use));

- drying technologies (using flue gases, water vapor or hot air);

- the fuel used (gas, wood waste, coal, etc.).

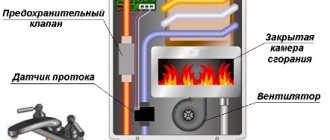

To burn pellets, special equipment is used - a pellet boiler.

.

The optimal solution in terms of price/quality/performance ratio on the Russian market is heating appliances from the Polish manufacturer Metal-Fach, including boilers from the SD DUO

,

SD DUO BIO

,

SMART

,

SMART EKO

,

SEG, SEG BIO

.

They have a steel heat exchanger (P265GH steel with a thickness of 4.00 to 6.00 mm is used for production), an efficiency of over 90%, an innovative, modern type controller FL 310LGRTC

, with continuous logic and PID control, as well as an upper combustion chamber and a retort type burner.

Also worthy offers are:

- domestic boilers created in Krasnoyarsk, ZOTA

Pellet

series ; - joint development of the Russian-Polish company Vulkan

, the

EKO

; - pellet boilers from the legendary Italian company FACI

Caldaie,

FACI SSL/SSP

.

You can purchase pellet boilers in a wide range, get the necessary advice, order installation, warranty and post-warranty service in Krasnoyarsk from the Kras-Kotel company.

Instead of an epilogue

An analysis of the Russian market for the goods in question has established that the middle and budget segments are completely occupied by domestic producers. However, such a product has a single and direct purpose - heating only. At the same time, reasonable prices and variability of supply indicate sufficient quality of products. The premium segment, as a rule, is entirely represented by foreign (primarily European and transatlantic manufacturers), is characterized by a high level of environmental friendliness and can be used in various fields. It is worth mentioning that the price of such quality and multitasking is very high, so the Russian consumer is unlikely to purchase premium samples for heating. They are ideal for grilling and other outdoor cooking tasks. In addition, it should be noted that the market for the goods in question in Russia is just beginning to develop and there is hope that domestic companies will soon begin producing multi-tasking granulates, and the prices for them will not be greatly inflated.

How to distinguish high, premium quality pellets from substandard fuel?

When purchasing pellets, you need to pay attention to:

- the surface of the material must be smooth, shiny, without signs of deformation (swelling and microcracks);

- diameter (this parameter is established by the standards, the minimum value is 4.00 mm, the maximum is 10 mm, also standard are fuel pellets that have a diameter of 6.00 and 8.00 mm, please note that a pellet boiler operates on pellets of a certain fraction);

- length (this parameter should be about 20.00 - 30.00 mm, this is the optimal value, although the equipment can work on pellets with a length of over 50.00 mm);

- smell (the granules should have a slightly sweet smell of freshly prepared glue, this is a clear sign of excellent quality);

- color (it is important to remember that the highest quality pellets are white or slightly cream-colored, agropellets are predominantly dark, and in wood pellets, dark color indicates that bark, other impurities have been added, or wood species have been mixed);

- dust (there should be a minimum amount of dust on pellets, so it is better to buy fuel in sealed packaging);

- impurities (the presence of non-combustible impurities in the granules themselves can only be checked by burning them and determining the residue in the form of solid particles).

Payback and profit

The gross monthly profit received from the sale of fuel pellets is calculated by multiplying indicators such as daily revenue and the number of working days. According to approximate calculations, subject to well-established implementation, it can reach 156,600 rubles.

If we take into account that the enterprise will produce the same amount of first-grade and industrial-type fuel, then we will have to spend 32,400 rubles on the material. In addition, it is necessary to add the above-mentioned production and management costs. Taking all this into account, net profit can reach about 77 thousand rubles. The payback period in this case will be less than three months. It should be emphasized that all this will happen under ideal conditions, when all produced fuel pellets will be successfully sold.

If we talk about more expensive lines, then this period sometimes reaches a year. On the other hand, their advantage is that they are more durable and designed for long-term use. In this case, there is no point in even comparing income with similar indicators of mini-factories.

Advantages and disadvantages of solid fuel in the form of fuel pellets

The main advantages of pellets:

- environmental cleanliness (when burning this type of solid fuel, carbon dioxide is released in volumes equal to the volumes formed during the natural decomposition of various wood wastes);

- fire safety (pellets are less susceptible to spontaneous combustion than other types of solid fuel);

- optimal humidity (8-10% versus 30-50% for logs) and density (one and a half times higher than that of firewood);

- remarkable calorific value, one ton of fuel pellets is enough to produce 3500 kW/h of thermal energy;

- constant and very high bulk density, which facilitates logistics, loading and transportation of pellets;

- the uniformity of the structure in shape and size makes it possible to automate all processes of loading and loading and combustion of fuel pellets in boilers.

Cons of pellets:

- high cost of solid fuel at the present stage;

- to burn pellets you need a special pellet boiler equipped with automation, which also costs more;

- the volume of supply on the market is low, the situation will improve over time, but pellets must be purchased in reserve and stored in warehouses, preventing excess moisture from entering.

Sales abroad

The pellet export market deserves special attention. In developed European countries, the consumption of this particular type of fuel is the most common. Most municipal and private buildings, as well as industrial boiler houses, are equipped with boilers operating on it.

In this regard, the Western European region is now considered the largest consumer of pellets. Currently, the share of domestic granular fuel in this market is very small. According to economists’ calculations, over the next ten years the need for this type of fuel here may increase tenfold, which we can try to take advantage of.

Pellet cost

Let's take the initial data:

- the average cost of industrial pellets in the Krasnoyarsk Territory as of December 2015 is 3,500 rubles per ton (3.50 per kilogram);

- the price of birch firewood is 1,300 rubles per cubic meter, in terms of tons (a cubic meter of dry birch firewood equals 650 kg of weight) is 1,846 rubles per ton (1.85 rubles per kilogram);

- the calorific value of birch firewood is 10 MJ/kg;

- The calorific value of wood industrial pellets is 18 MJ/kg.

In order to obtain 100 MJ of thermal energy, you need 10 kg of firewood (100/10), that is, 18.50 rubles, or 5.5 kg of pellets (100/18), that is, 19.44 rubles. The difference in cost is 1 ruble per 100 MJ. Moreover, it is necessary to note the undoubted advantages of pellets with an ash content of 1.5% over firewood with an ash content of 10%, the difference is obvious. It should be taken into account that the pellet market is growing dynamically, and with an increase in supply, the price will undoubtedly decrease. By the way, pellets can be made independently from agricultural or wood waste. Read below how.

Agropellets

One of the most popular types of agricultural pellet raw materials is straw from various agricultural crops (especially wheat and rapeseed). In terms of energy potential, this material is not much inferior to wood: up to 16 MJ/kg versus up to 18.4 MJ/kg. Straw is a renewable source of fuel; burning straw does not change the balance of nitrogen dioxide in the air: during growth, it consumes the same amount of CO2 as it releases during combustion. Straw pellets are also used not only for heating, but also as bedding for animals in livestock farms and stables.

A type of raw material similar to straw is reed, while its higher calorific value is 19 MJ/kg, and its ash content is approximately 4%. Such raw materials are very cheap; they are collected using swamp harvesting and grinding machines.

Sunflower husk is one of the most promising materials for agropellets. Sunflower pellets have an ash content of 3%, and give off almost as much heat as brown coal - up to 21 MJ/kg. Ash after burning husks is a valuable fertilizer. Buckwheat husks, millet husks, and rice husks are also granulated.

We make pellets with our own hands

You can make pellets with your own hands. To do this we need to assemble a granulator. It is necessary to take wood or agricultural waste, grind it to a particle fraction of 30.00-50.00 mm, dry it to a moisture content of 15.00%, grind it to particles with a fraction of 2.00 mm and place it in a granulator. In the case when you use agricultural waste, such as sunflower husks, rapeseed or sawdust, as the initial, basic raw material, you do not need to crush anything. But if branches, bark, or various substandard lumber are used, it is necessary to crush, although the use of a granulator allows you to omit this operation. The dryer is made from an ordinary metal barrel. It is better to use a granulator with a flat matrix (a cylindrical matrix in the shape of a perforated drum is a more complex solution) and a perforated disk with outlet holes in the shape of a cone with a diameter of 8.00-10.00 mm, this is the optimal solution. You need to buy a matrix and rollers (the production of spare parts is carried out by manufacturers of equipment for the production of animal feed). The matrix is also made independently, from steel with a thickness of at least 20.00 mm, and gears are used as rollers. You will also need a gearbox and an electric motor with a power equal to or greater than 15.00 kW. It is necessary to ensure rotation in the range of 60-120 revolutions per minute. The shaft can be installed both horizontally and vertically; the main thing is to make tanks for loading the raw materials and subsequent unloading of pellets.

Stages of making pellets:

- we take or make a matrix, make a hole in the center for the gearbox and always a groove intended for landing;

- gears (rollers can be used, the width of which must match the width of the working surface of the matrix used), are put on the shaft strictly perpendicular to the axis of the installed gearbox shaft using a conventional coupling;

- the cylindrical body is welded from sheet steel or steel pipe, taking into account the dimensions of the matrix, which should rotate easily and freely, providing holes for unloading pellets and a tray also made of sheet steel or steel pipe, the bottom and top of the structure can be made detachable to facilitate maintenance;

- the output shaft of the selected gearbox is strengthened in the lower part of the machine using a coupling and always bearings;

- the matrix, as well as the rollers, are installed in a cylindrical body;

- the resulting structure is mounted on a frame made of a channel or an ordinary angle and is rigidly fastened; all that remains is to install the engine and connect the output shaft to the installed gearbox.

The future belongs to pellets and pellet boilers. Kras-Kotel specialists will help you make the right choice of pellet boiler, taking into account all your wishes and the characteristics of your home.

Share on social media networks:

Difficulties in choosing quality granules

In principle, to choose the most suitable option, you should focus on the following points:

- Length and diameter of granules - the most common diameter is from 2 to 8 millimeters, and, as practice shows, smaller diameters are more often a foreign product. Larger variations are produced by a domestic manufacturer (they usually use equipment that was previously used for the production of granulated feed). However, the dimensions of the granules used should not differ too much from each other, so the simultaneous use of different types of fuel is undesirable.

- Surface – the quality of a substance can be determined by its appearance. If the surface is smooth and shiny, then this means that the production process took place at the proper temperature in compliance with all the rules. If there are a large number of cracks on the granules, then their heat transfer may be in question.

- Hardness – the harder it is to break an individual granule, the better. This also speaks to fuel efficiency and helps eliminate risks during storage and transportation. Situations often arise when, during the movement, most of the substance crumbles into dust, which qualitatively reduces the positive heat transfer during combustion, and, accordingly, a large mass of the substance is spent on heating.

- Color - it will depend on the production raw materials used. If there are too many dark inclusions on the wood granulate, this indicates a fairly high presence of sand in the composition, which will impair heat transfer.

- Liquid Solubility – An excellent way to check quality is to test water solubility. A small handful of pellets is dropped into a container with liquid, where it remains for several hours. The water should completely dissolve them, turning them into a dark, damp mass. When this does not happen, this indicates that polymer substances were used for gluing, which is extremely undesirable. To determine the amount of sand in the composition, you need to shake the container and the sand will sink to the bottom of the container.

IMPORTANT! It is preferable to purchase pellet products in bags, but not in bulk. Such a loose version is more easily damaged and is not able to retain its beneficial properties for a long time, while a plastic bag can protect against the negative effects of moisture and other negative environmental phenomena.

Maintenance

Heating a home using pellet boilers requires little maintenance.

They usually have an open heating system, so you need to monitor the water level in the system. You can automatically supply water replenishment to the heating system. The boiler itself must be cleaned of soot, especially the heat exchanger jacket, as this affects the consumption of pellets. Smoke exhaust pipes need to be cleaned. This does not take much time, and the moment when cleaning is necessary can be determined visually by looking at the water jacket, or if the consumption of pellets has increased. The deadline is when the boiler begins to smoke into the room.

If pellets are supplied using a rigid auger, then it is necessary to periodically clean this system from dust that accumulates in the air supply channels.

Introduction

Pellets are solid wood pellets made by pressing waste from various industries. Heating with pellets is much more economical than many other types of fuel, since they provide high heat transfer and the price does not tend to increase. Pellets are environmentally friendly; they do not contain a large amount of chemical additives. Often the consumer asks himself the question, which pellets are better?

It is not necessary to burn pellets in specialized boilers. They will burn in the stove, in the fireplace, and in the camp fire. But it should be taken into account that for proper combustion a constant flow of air is required, which is maintained automatically in pellet boilers.

This is due to the combustion process of wood pellets, as a result of which they release pyrolysis gas. At the proper level of boost, it does not go into the chimney, but burns, releasing additional heat and increasing combustion efficiency.

If you want to achieve the required efficiency, then you cannot do without purchasing automatic heating equipment. However, with the low cost of fuel, the boiler will cost much more than its conventional counterparts, and the use of low-quality pellets can lead to its failure. So what pellets should you buy ?