Ideal parking for a car is almost the most important dream of any motorist. And this place can be made with your own hands. The article will focus on a garage with a canopy, which is not only convenient, but also a modern, economical, functional and efficient design.

This is a great way to make smart use of the space in front of your garage. We will tell you about the advantages and disadvantages of such a structure and how the work should be carried out in order to ultimately get a reliable parking space for your favorite four-wheeled assistant.

Construction of a garage with a canopy, 4.5x9.5 m (September-October 2018)

Dmitrovsky district, Tseleevo

Foundation - monolith slab

Basement - concrete blocks

The walls are made of aerated concrete blocks with a monolithic belt.

Canopy - on metal stands

The rafter system is wooden.

The roof is metal tile.

Step-by-step instructions for assembling a visor with your own hands

When starting to build a canopy over the garage with your own hands, you should first accurately understand the stages of construction. Therefore, for a beautiful and good result of the work, it is important to decide on the material in advance, measure your garage doors, draw up a sketch, and only then proceed with installation.

It is important to remember some nuances:

- it is desirable that the overhang extends no less than 60 centimeters from the wall;

- on the sides the overhang should be at least 20-30 centimeters wider than the gate opening;

- In order for the water to drain and the snow to fall naturally, the slope of the canopy needs to be at least 15 degrees.

Calculation of materials and preparation of tools

If the beauty of the visor is important, then materials are purchased with a reserve. It is recommended to buy 1.5 times more than necessary so that there are no problems with damaged sheets, and you can assemble the canopy with a minimum number of joints.

The work will require the following tools:

- for measuring: tape measure, ruler, level;

- hammer drill, screwdriver, grinder with cutting wheels (for the selected material);

- welding machine - for working with metal;

- hammer, hacksaw, nails, screws - for working with wooden rafters.

Selection of frame and roofing material

Since the frame structure is in contact with the external environment, it is important to fasten it securely. It is advisable to paint or varnish rafters (made of metal or wood) to protect them from rotting and corrosion after several cold seasons.

You can fasten wooden beams with self-tapping screws or nails. Metal frame - welded to metal inserts in the wall or mounted on anchor bolts.

A wooden frame is cheaper and simpler. It will withstand the load from slate, metal or tiles. Polycarbonate, corrugated sheets, and mineral glass are combined with metal rafters.

Frame assembly

The frame is calculated based on the weight of the material, with a reserve for accumulating solid sediments or leaves. Sometimes the corners of the fastenings are mounted only on two sides of the gate. But for structural rigidity or in complex projects, additional fasteners are installed in the center.

Installation work

When the material has been selected, a work plan has been drawn up, and the necessary tools are at hand, you can sequentially begin installing the canopy over the garage door.

Installation

First of all, the load-bearing beams are assembled. You can assemble the frame on the ground and then attach it to the wall. Some immediately erect a structure over the gate.

- First, the corners are assembled, which will be attached to the left and right of the garage door.

- Supports are laid in the central part, if this is required by the project. The corners are strengthened with transverse struts.

- The frame part is assembled between the rafters. First, the load-bearing corners are connected by a longitudinal metal profile or wooden beam. Then the cross beams are assembled for rigidity.

- It is important to remember that in addition to maintaining the pitch of the transverse floors (for slate and metal, no more than 40 centimeters of spans are recommended), for subsequent light coating with carbonate or glass, the frame is first covered with sheet material (wood, plastic).

- Holes are being prepared for attaching the material of the slopes and frame to the wall.

- Metal or wood is painted, varnished or painted.

- The structure rises and is attached to the wall with the garage door.

- Roofing material is laid on top.

Sometimes additional steps are needed. But they are individual and aimed at improving appearance. And designer, forged canopies, as a rule, are immediately ready for installation and are simply fixed to the wall.

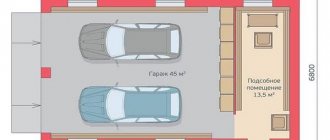

Construction of a garage with a basement and a canopy, total size 16.1x6.8 m (2018)

New Riga, Davydovskoye

Basement - monolithic, 6.3x2.5x2.3(h)

The foundation is a monolithic slab.

The base is made of solid concrete blocks with monolithic sections.

The frame of the canopy is metal structures.

The walls are made of aerated concrete blocks with monolithic belts.

The rafter system is wooden.

The roof is metal tile.

Construction progress in photographs:

What is important to consider when building a polycarbonate canopy

When erecting a canopy with your own hands on your site and using various fasteners and connections, it is important to remember the coefficient of thermal expansion.

Under the influence of heat and on sunny days, the polymer can increase in size; even with a slight increase and with strong fixation, it can collapse.

The use of special thermal washers or fasteners made of polycarbonate will help to avoid such consequences.

If you choose the right fasteners, the structure will remain quite strong and stable, and the polycarbonate canopy itself will last a very long time, protecting and decorating the area.

Construction of a garage for ATVs, with a utility block and a canopy, 3.6 x 8.1 m (2018)

Istra district, Kotovo, Znamya-2

Foundation - monolithic slab, made by the Customer

The base is made of solid concrete blocks.

The walls are made of Bonolit aerated concrete blocks with monolithic belts.

The rafter system is wooden.

The roof is metal tile.

Construction progress in photographs:

Rules for the use of raw materials

There are rules for handling polycarbonate sheets established by experience:

- You should not store the material in the light; you should consider the way they are stored in the warehouse;

- the material should not crack from twisting;

- The protective film can be removed only after finishing work with the sheets;

- work on installing the flooring should be carried out quickly;

- The slabs must be laid with the UV-resistant side facing outwards, as indicated on the surface of the protective film.

Leaving cellular polycarbonate in the film in the open light will cause it to stick tightly to the plate, that is, a photochemical reaction, causing the material to become unusable.

Construction of a garage with a canopy, 5 x 14 m.

Shishkin Les, New Moscow

Garage with a canopy.

The foundation is a shallow strip foundation.

The walls are reinforced masonry made of aerated concrete blocks.

The structure of the canopy is planed timber.

Open rafter system.

The roof is flexible tiles.

The building is functionally divided into 2 zones - a closed garage in the back and an open shed in front at the entrance. A garage with a shed is built under one gable roof. In order to optimize construction costs, according to the client’s instructions, the garage foundation was designed in the form of a shallow reinforced concrete strip. Despite the fact that the warranty does not apply to this type of foundation, adherence to construction technology and high-quality materials made it possible to produce a reliable foundation strip, which was not subject to deformation during operation and confirmed the correctness of the choice of design solution.

Details - follow the link.

Stages of constructing a canopy made of cellular polycarbonate

Due to the good parameters of the breaking force and the flexibility of the polymer, it is possible to construct structures with complex geometries and multi-level buildings from it.

At the same time, the stages of manufacturing canopies remain the same; for their implementation, it is imperative to follow material processing technologies.

Construction of a garage 4.5 x 6.5 m with a canopy and attic space (2016)

New Moscow, Zverevo village

Photo of a garage with an attic and a canopy.

The foundation is a monolithic slab.

The walls are reinforced masonry made of expanded clay concrete blocks.

The roof is pitched.

The roof is metal tile.

Construction of the structure

The main stage of constructing a protective or decorative canopy remains its assembly, installation and installation work.

It is better to trust such procedures to specialists or ensure the safest operating mode, acting according to step-by-step instructions and taking into account the advice of professionals.

Construction of a garage with a canopy, 13.0 x 6.0 m (2016)

Ramensky district, Tatarintsevo

Project of a garage with a basement, utility room, attic and canopy, photo report.

The foundation is a monolithic slab.

The walls are reinforced masonry made of foam blocks.

The roof is metal tile.

Arch

Such structures have a presentable appearance from the outside and inside, and most importantly, they can withstand large static loads due to their geometric shape.

They do not require restrictions on the size of the roof; they can be used as carports without fear of roof collapse.

Any flexible material can be used for coating. When using corrugated sheeting, it is necessary to make a slight slope along the length of the ribs to drain water. Treat the joints with silicone.

Such a design covered with polycarbonate will look impressive. It perfectly fits the contours of the arch, tightly connects to each other, thanks to a special profile, does not act as a drum in rain or hail, is not flammable, but is susceptible to deformation at high temperatures.

Construction of an extension garage with a canopy 19.5 x 6.7 m (2016)

KP "Pokrovsky", New Riga

Garage with a canopy.

The foundation is a monolithic slab.

The walls are made of aerated concrete blocks.

The roof is metal tile.

Strengths

Polycarbonate has a number of advantages that effectively distinguish it from the general background among other materials.

- Has excellent light transmittance

- Gently diffuses the sun's rays, creating even illumination

- It is very easy to attach, because due to its low weight it does not put a significant load on the frame

- The weight of polycarbonate is approximately 7 times less than that of glass

- At low weight it also has significant impact resistance

- The sheets can be strongly bent, taking virtually any shape without prior preparation.

- Excellent sound insulation

- The material retains heat well

- The material's resistance to temperature changes ranges from -50 to +115 degrees Celsius

- Has a lot of variations

Secrets of choosing material thickness

Depending on the chosen shape of the structure, it is recommended to use different sheet thicknesses:

- For an arched structure, the thickness is chosen to be about 8 mm;

- Roofs of small areas (above a door entrance, for example) may have a smaller thickness (6 mm);

- For large areas of canopies with a slope, it is recommended to use panels with indicators of at least 10 mm;

- Horizontal extensions with a slight slope require a thickness of up to 16 mm, taking into account the possible delays of a thick layer of snow.

The correct selection of building materials guarantees the durability and reliability of the structure while maintaining all its functional purposes.