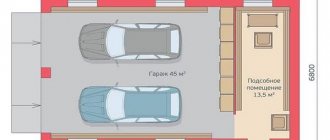

Major construction of a garage is necessary to protect the car from adverse environmental factors. Not only the walls and floor, but also the roof must meet special requirements.

It is necessary that the roof being erected provides a safe and dry room. This requires a detailed analysis and accurate calculation of the parameters of the designed structure.

Some points should be discussed with professional builders, but in principle, installing a garage roof with your own hands is a completely feasible task.

Types of roofs

The garage roof should comply with the principles of simplicity and economy. If the work is done independently, then preference is most often given to the lean-to form.

If there is a need for an attic space to store spare parts and tools, the roof is made gable. The process of its construction is more complex, and construction is more expensive.

Shed roof

This type of roofing is the most affordable and simple. Its construction has some nuances. Due to the difference in the height of the stop, it is necessary to observe different angles of inclination during installation.

Before construction begins, it is necessary to make a project, sketch a drawing. To do this, you need to calculate the height of the difference using the formula: H = garage width x tanα. The last value is found using the Bradis table.

The choice of roofing material affects the following indicators:

- roofing material - up to 5 degrees;

- slate – 20–35 degrees;

- seam roofing – 18–30 degrees;

- corrugated sheeting – up to 8 degrees;

- metal tiles - up to 30 degrees.

The main structural elements are rafters, which are made from coniferous trees and are smoothly planed beams.

To increase the fire resistance and waterproofing of the roof, the rafters are treated with antiseptics.

Construction begins by attaching the rafter system to the walls using mauerlat (guide beams) installed on top of the walls. The rafters are inserted into pre-cut nests on the surface of the mauerlat.

To give additional strength, they are attached using anchor bolts or wire.

If the width of the building is more than 4.5 m, the rafter system must be supported to prevent deflection. The step between supports is from 60 to 70 cm.

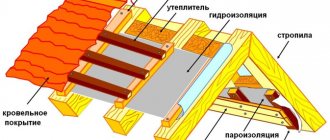

Then the sheathing is installed from dry timber. Its frequency is determined by the weight of the roof. After completing the main process - installation of the frame - installation of waterproofing and the main roof covering begin.

Gable roof

When designing a gable roof, the main point is the correct calculation of the rafter system and the general drawing made on their basis, since it is this design that guarantees the reliability of the upper part of the roof.

To determine the height of the roof ridge (H) and the length of the rafter leg (C), it is necessary to calculate the angle of inclination (Z). Since the roof is an isosceles triangle, the Pythagorean theorem should be used.

Only the correct methods for attaching corrugated sheets to the roof.

Gables are very important elements of the roof. In this publication, you can find out what materials gables can be made from, how and with what to cover them, and whether the gables need to be insulated.

Other necessary parameters are calculated using the formulas:

- H=0.5xH(Z:2);

- C=0.5xH/sin(Z:2).

The material used for rafters is smooth beams without knots or cracks. Durable pine wood is perfect for this purpose.

It is better not to use twisted wood, since unevenness occurs during the construction of the roof, which has a negative impact on waterproofing.

To erect a gable roof you need:

- wooden beam – 150x150;

- edged board size 150x15;

- waterproofing;

- fasteners (screws, nails, wire, bolts);

- roofing material.

, experts recommend building a very simple frame. The process is to use a drawing to form a triangle from two similar rafter legs and connect them at the ridge (upper part).

Preparatory work

It is extremely difficult to build a gable roof alone, so we recommend finding an assistant

The work of building a roof for a garage is complex and time-consuming. Most operations are performed at heights in uncomfortable conditions, so it is advisable to involve assistants. Before starting work, all materials must be delivered and prepared. First of all, you should deal with the lumber - stack it so that the wood does not deform, and perform the necessary processing.

The treatment consists of applying compounds that have fire-fighting and antiseptic properties - this will reduce the risk of fire and make the material resistant to fungal development, biological damage and infection of wood by insects. Antiseptic preparations are sold ready-to-use and in the form of a concentrated solution. The concentrate must be diluted with water according to the attached instructions. To improve the quality of processing, it is advisable to first remove small sawdust and dust from all surfaces.

The material is coated on all sides using a roller, turning over as processing progresses. After impregnation, the lumber is stacked and kept until the solution is absorbed. At this time, the base of the walls is being prepared for attaching the Mauerlat.

The upper edge of the load-bearing wall of the garage on which the Mauerlat is mounted must be well leveled. First of all, waterproofing is laid on top of the wall - rolled roofing felt is suitable for this. It is placed on mastic or “dry”. The Mauerlat fastenings are placed between the rafters; it is advisable to install anchors in increments of 600-800 mm. Since we already know the distance between the rafters, after attaching the Mauerlat, markings are made for the rafter legs.

Installation

Construction begins with the construction of an inclined frame and further assembly in parts. The mauerlat laid around the perimeter is attached to the garage walls using anchor bolts.

In this case, it is better to install additional insulation by laying a roofing felt pad on the wall in advance. Then proceed to the rafter system.

A beam should be prepared, the length of which corresponds to the length of the segment between the supporting beam nests located opposite. The support is attached in the middle perpendicularly.

The length of the support will be the required height of the roof ridge.

The rafter legs are installed at the ridge level. In order to accurately and quickly connect the entire system to the roof frame, it is necessary to mark the notch of the support beam at the lower ends.

The joint nests are made in advance. To properly secure the rafter legs, they need to be left slightly longer than the required size (30–50 cm).

In order to perform the work efficiently, it is recommended to tighten the cord. The pairs along the edges are installed in accordance with the step from 0.6 to 1.2 m. The connecting strip is fixed below the ridge.

The sheathing must be nailed in a direction strictly perpendicular to the direction of the rafters. The density of the sheathing is determined by the material chosen as the roofing covering at the initial stage of work, even during design.

Then they begin to waterproof and cover the entire structure. This completes the installation process.

Other types of foundations for unstable soils (comparative characteristics)

There are types of foundations that are traditionally used to build buildings on unstable soils. In addition to pile-screw foundations, slab foundations are often used on moving soils.

Slab foundations for a garage

The construction of such a base is a rather labor-intensive process that requires a large consumption of materials. Using this technology, you can successfully remove all deformations and loads of the soil under the foundation. The structure is a solid or lattice reinforced concrete slab, saturated with reinforcement. A monolithic foundation for a garage must be poured under the entire area of the future building, and the above-ground part will, in fact, be the floor of your garage.

Before arranging a slab foundation, it is necessary to conduct geological exploration to understand how to calculate the foundation for a garage: find out the level of groundwater and the degree of surface complexity. Only after this should the engineer calculate the thickness of the slab and the depth of the pit (it will be less than, for example, a strip foundation), the caliber and frequency of laying reinforcement. Of course, a slab foundation for a garage is also a good solution. But there are three big disadvantages - its high cost, complexity and relatively long installation and preparation time for operation.

Foam block garage foundation

This design turns out to be very light, essentially being a continuation of the wall. In terms of cost, only this type of foundation can compete with a pile-screw foundation: its construction is inexpensive, and due to the low weight of foam blocks, labor costs are significantly reduced, and the use of heavy equipment is not required. The low thermal conductivity of the material makes it possible to do without additional thermal insulation. A foundation for a garage made of foam blocks requires a depth of 40-50 cm into the ground, but only if the groundwater is deep (more than 2 m), the soil is homogeneous and hard. In other cases, the trench should be deeper.

Given the low bending resistance of this material, on heaving soils it will be necessary to use a monolithic slab with reinforcement elements, and this leads to an increase in the cost and complexity of constructing a foundation for a garage. Another disadvantage is the toxicity of foam concrete: when burned, it releases substances hazardous to humans. In general, this option can hardly be classified as a reliable and durable solution.

“Screw-on sole” is the right choice

The remaining types of foundations - strip and columnar - are very critical to the type of soil. They cannot be built on unstable heaving soils, areas with seasonal flooding, on slopes, or on soils with different bearing capacities. In addition, strip foundations are quite expensive in terms of materials and labor.

The alternative in the form of building a garage on screw piles significantly outperforms these options.

A garage is a relatively small building, so the diameter and length of screw piles for it should be chosen smaller than for a house. This means that it is possible to build a foundation for a garage with your own hands, without hiring expensive equipment, and save a lot of money at the same time. After all, when tightened, piles with sharp screws make their own way in the ground, quickly and easily reaching the required depth. It happens that for this process the efforts of only two workers and a third one controlling the verticality of the immersion are sufficient.

It is also important that the “sole on a screw,” as pile-screw foundations are sometimes called, eliminates the most labor-intensive stage of work – soil sampling. As a result, you will be able to build a garage cheaper and faster than using traditional foundation technologies

Selection of roofing material

Let's find out what is the best way to cover a garage roof. Construction material is highly dependent on finances. Having decided on the price category, you should not lose sight of other points.

The roof should:

- protect from precipitation;

- guarantee protection from robbers;

- when located next to the house - match its design;

- have an attractive appearance.

When choosing an expensive roofing material for work, it is better to enlist the help of professionals, since its installation requires special skills.

Easy to install and cheaper material (roofing felt, metal sheets, slate) can be laid independently.

Laying roofing felt

It is better to cover the concrete roof of a garage with roofing felt. Before laying the roofing material, it is necessary to install a special frame. With a flat roof, the task is greatly simplified, since laying roofing felt on reinforced concrete slabs is not difficult. At the same time, the coating provides high-quality waterproofing.

Ruberoid is a very durable and economical material. Since it is produced in rolls, it is very easy to lay roofing felt. It is better to use three layers of material.

The first step is to fill the flat surface with lubricant or bitumen, and lay the first layer on top.

Ruberoid strips overlap. For greater reliability of the roof, it is recommended to nail the bottom layer along the edges (every 50 cm) using nails.

Bituminous lubricant is again poured over the first layer and a second layer of roofing material is placed on top. When laying this layer, the strips are laid perpendicular to the strips of the first layer.

The second layer of roofing material is also lubricated with bitumen, and the last layer of material is laid on top.

Roofing felt roofing has a fairly long service life: 15-20 years. To extend it, when laying the material, you must ensure that it lays evenly, without folds.

Today the market also offers rubemast and euroroofing felt, which are modern analogues of conventional roofing felt. Due to their plasticity, these materials can last 20 years longer.

The difference between simple roofing felt and euroroofing felt is that the second one is much easier to lay. You only need to heat the material, after which it sticks to the surface. There is no need to use mastic or bitumen.

The disadvantage of euroroofing felt is its high price: it costs twice as much as conventional material.

No. 2. Rubemast

This is an improved type of roofing felt . It is also based on thick construction cardboard (although fiberglass can also be used), which is impregnated with bitumen on both sides. There is much more of the latter than in roofing felt, which ensures higher ductility, waterproofing and resistance to cracks. Powder is used for additional protection. The bottom layer is a polymer film designed to be melted by a burner during installation.

Advantages:

- low price;

- relative ease of installation;

- excellent waterproofing properties;

- resistance to heat and precipitation;

- durability up to 15 years.

Minuses:

- cannot withstand even light loads. If a person weighing more than 50 kg walks on the coating, then the appearance of cracks is inevitable;

- the base must be level, otherwise cracks may occur during operation;

- under constant exposure to direct sunlight, microcracks appear after 1.5-2 years.

Installation can be carried out using bitumen mastic (as in the option described above for roofing felt) or using a gas burner. If the installation work is carried out correctly, then the problem of roof leaks in the garage will not affect you for a long time.

Galvanized iron

The low weight of the roof significantly reduces costs due to the construction of the roof frame, since the rafters can be installed in increments of 90–120 cm; for the sheathing, beams measuring 50x50 mm, as well as 30x70 and 30x100 mm are used (the choice depends on the load obtained when calculating the roof ).

Installing such a roof is not particularly difficult.

The obvious advantages of corrugated sheeting and seam roofing are the quick removal of snow and water from a flat, smooth surface, which do not linger on roofs of this type and ensure the reliability of the entire structure.

When laying a seam roof, equipment is required, but corrugated sheeting can be laid independently. As a rule, NS grade material is used.

Installation is greatly simplified due to the corrugated shape and the required dimensions of the finished sheet.

The sheets are secured using self-tapping screws or rivets 4.8x38, which are installed deep in the corrugations. If the roof is gable, then the material should be laid from the end side from bottom to top. Then the corrugated sheet is leveled along the overhang.

The sheets are fastened along the edges in waves in every second fold along the entire length of the overhang and along the perimeter every 0.5 cm in the sheathing bar. The sides, upper part of the roof and edges are decorated using special profiles.

No. 7. Metal tiles

Metal tiles, just like corrugated sheets, are made from galvanized steel sheets, only they are given not just a wave profile, but imitate the profile of natural tiles. A phosphate layer (additional protection), a primer and a polymer-decorative coating are applied over the protective zinc layer. A protective transparent varnish is applied to the back side. The greater the thickness of the sheet, the stronger the coating: for roofing it is better to take material with a thickness of at least 0.5 mm. Performance properties strongly depend on the type of protective polymer coating. The coating made of pural and plastisol has proven itself best. Matte and glossy polyester are cheaper, but if the installation technique is followed, they can also provide reliable protection.

pros:

- light weight, which simplifies installation and reduces the load on the foundation and rafter system;

- resistance to low and high temperatures, high humidity due to the protective coating. It also ensures free drainage of precipitation from the roof surface;

- relative ease of installation;

- excellent decorative qualities, wide range of colors;

- the material does not support combustion;

- relatively low cost.

Minuses:

- loss of a significant part of the performance qualities when the protective coating is damaged;

- difficulties when arranging a roof of a non-standard shape, but garages are usually built with fairly simple roofs, so this cannot be considered a minus in our case;

- heating in the sun and noise during rain, but with proper sound insulation, this disadvantage can be easily eliminated.

Metal tiles can be used on roofs with a slope angle of more than 15 degrees, otherwise snow removal will be complicated due to the topography of the coating. The material is often used when the garage is located on the same site as the house, so that all buildings have the same type of roof.

Slate covering

Slate is slabs based on asbestos cement. It is not very popular as a roofing material for garages, although it was used quite often in the past. Slate is not durable.

Before laying on the sheets, it is necessary to drill holes for special galvanized nails. During installation work, you must be careful and not step on sheets that can easily break.

The advantages of slate are its low cost and fairly long service life (about 40 years).

Polycarbonate

This material is durable and lightweight. The popularity of cellular polycarbonate is also due to its strength and flexibility, which makes it possible to install roofs of any level of complexity.

The transparency of polycarbonate allows you to significantly save on lighting in the garage.

The material is quite resistant to adverse external factors.

Another advantage of polycarbonate is its ease and simplicity of maintenance and repair. Roof installation does not require special skills

No. 3. Linocrom

Linocrom is a modern rolled material with a fiberglass base, which is treated with bitumen and protected with powder and polymer film.

Advantages:

- ease of installation;

- resistance to temperature changes;

- low weight;

- maintainability. If any part of the coating is damaged, then it is enough to simply fuse new material onto the desired area;

- tensile strength - the material can withstand significant loads;

- durability up to 10 years.

Flaws:

- the top layer is poorly resistant to aggressive substances;

- the material is only suitable for low pitched roofs;

- installation with construction tape is not suitable - the seams in this case will be a weak point.

Installation of linochrome is carried out in dry, windless weather, having previously cleaned the roof surface. The bottom layer is heated with a blowtorch or torch, and rolls of material are laid overlapping.

Garage roof waterproofing: is it necessary?

Regardless of the roofing material chosen, a waterproofing coating must be installed, especially when it comes to a flat roof on which rainwater and snow remain for a long time.

To waterproof the garage roof, you need to purchase a special membrane that protects the room from moisture getting inside. The use of a waterproofing membrane is especially important for additional insulation of the garage.

The function of waterproofing is to protect the interior from moisture and at the same time rid the room of steam to reduce the level of humidity inside.

If there is thermal insulation, the membrane protects the insulation from getting wet and fogging. Thanks to it, the thermal insulation wool seems to breathe and does not lose its useful characteristics.

When installing waterproofing, be sure to leave gaps between it and the roof. They are needed for natural ventilation to occur.

The minimum gap size is at least 25 mm. A larger gap (50 mm) should also be between the insulation and the waterproofing membrane.

The gaps are made simply: the membrane is laid on the rafters, and the sheathing is installed on top. Another option: simply install the membrane on a ready-made frame. After this, bars are stuffed as fasteners.

The membrane is a material in the form of strips measuring from 10 to 15 cm, which are laid overlapping. This process is not difficult, since a dotted overlap line is drawn on the material.

The membrane is glued together using special tape, which also ensures tightness. Fastening to the frame is done using iron brackets. For this you need a construction stapler.

Since the waterproofing membrane is very thin, it can easily be damaged both during installation and during operation.

To prevent this from happening, you should not pull it too tight when laying it. It should also not sag on the frame. The film is rolled along the edges of the roof, leaving ends 20 cm long.

During operation, it is necessary to pay attention to the correct location of the upper and lower layers of the film, otherwise it will not perform its functions.

If there is a chimney, then waterproofing is also needed for it. In this case, a cement-sand mixture or a special sealant is used.

Hard roof repair

If not resin was used to cover your garage, but, for example, corrugated sheeting, then the nature of its repair will be different. In most cases, it will most likely be enough to replace the damaged sheets of covering. Although there are cases when a tree has fallen on the roof. In this case, the repair will be major, including the process of making sheathing for the flooring.

If it is necessary to carry out the repair partially, then first of all you dismantle the old sheet and apply a new one

It is very important that it matches the wave. It is also important to ensure that there is correct overlap.

The sheet is screwed with special self-tapping screws for corrugated sheets.

If the covering is made of metal tiles, then the process of repairing it is almost identical

The only thing that is important to control is the locks that connect the tiles

By following these recommendations, you will be able to carry out roof repairs. This will significantly reduce costs than having to build it all over again. And with all this, always remember that very often the coating needs partial repair, and this is a significant savings. But most importantly, you can do all the work yourself.

Is it worth insulating your garage roof?

Insulating a garage roof is not necessary in warm climates. But in cold areas, where in winter the thermometer often drops below 0 degrees, it is necessary to insulate the garage.

The insulation materials on the market make it easy to cope with this stage of work.

The most commonly used material is glass wool. It is produced in rolls, the width of which corresponds to the width of the rafter pitch. Another advantage of the material is its density.

If the beams are thick enough to drill a 50mm hole between the insulation and the waterproofing film, glass wool can be fixed between the rafters.

If the thickness is insufficient, the insulation will need to be reinforced over the installed rafters. In both cases, the thermal insulation material is about 10 cm thick.

A vapor barrier must be laid on top of the glass wool layer, the function of which is to protect the interior from water vapor.

Special bars are stuffed on top and the cladding is laid. As cladding you can use: dry plaster, lining, plasterboard and some other materials.

If you decide to make a roof for a garage, then you will find the article about covering the roof with roofing felt useful.

You can also study the general rules for arranging a roof made of soft materials here.

And by following the link you can get acquainted with the high-quality materials for the roof of the TechnoNIKOL company.

Let's sum it up

- To protect the garage premises, a reliable and durable roof is required.

- Roofs for garages come in single-pitch and gable roofs.

- The angle of inclination of a pitched roof will be determined depending on the selected roofing material.

- When erecting a gable roof, the main point is the correct calculation of the rafter system and an accurate drawing.

- When installing the roof, you must follow the established sequence of actions.

- Roofing felt, slate, galvanized iron, polycarbonate, etc. can be used as roofing material.

- Regardless of the roofing material chosen, waterproofing is required.

- In regions with cold climates, care must also be taken to insulate the garage roof.

Watch a video about roofing a garage roof yourself: