- Why do you need a waterproofing film?

- Types of waterproofing films for roofing

- How to choose a waterproofing film for a roof

- Installation of waterproofing film

Rain and snow, high air humidity and wind are negative climatic factors that gradually destroy the roof covering and frame.

Atmospheric moisture can penetrate into the thickness of the roofing pie through the joints of roofing modules and mounting holes. Wetting of the thermal insulation under the roof significantly impairs the thermal efficiency of the building, and moisture ingress on the load-bearing structures of the roof can cause them to rot and collapse of the flooring. Dampness, mildew, mold, and an unpleasant odor inside the house are the inevitable consequences of water penetration under the ceiling lining. To avoid all these manifestations, a waterproofing film must be placed in the roof pie. It acts as a barrier and prevents moisture from entering the house.

Basic concepts of waterproofing for metal roofing

Today, the building materials market can offer a large selection of different materials for roofing. Among a certain part of developers there is an opinion that the choice of a high-quality type of roofing material and its correct installation makes the installation of a waterproofing layer unnecessary. In their opinion, this also applies to metal tiles. It's a delusion. And the answer to the question “Is waterproofing necessary for metal tiles of a cold and warm roof?” will always be affirmative.

The metal tile roof structure contains enough gaps through which atmospheric moisture can penetrate into it. Gradually, the waterproofness of the structure is compromised by weather conditions, such as strong winds, pressure from a layer of fallen snow, and flows of rainwater. In addition, the roof structure is affected by condenser pairs of rooms located directly under the roof.

To avoid future problems with roof leaks, a waterproofing layer must be included in the “roofing pie” of a metal tile roof. This is true for both warm and cold roofs. The tasks that such a layer performs can be described as follows:

- preventing the penetration of “external” moisture;

- preventing condensation from accumulating on the roof covering;

- increasing the thermal insulation properties of the roofing structure.

As already mentioned, the main requirements for a roof are durability and reliability. Metal tiles have these properties, but for this to last for a long time, you need to follow the technological sequence of laying the “roofing pie” and follow the principle of optional tightness.

Waterproofing under a cold roof

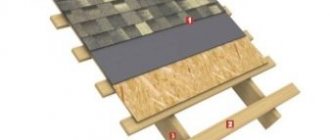

Typically, the design of the “roof pie” of a cold roof under metal tiles includes the following components:

- The sheathing and counter-lattice to which the metal tiles are attached. This layer is also responsible for ventilation, preventing condensation from accumulating under the roof;

- Waterproofing layer. Under a cold roof, it is better to use a standard roofing film - it will perfectly protect the rafters from external moisture;

- Rafter system;

- Finishing of under-roof spaces (if necessary).

Waterproofing under a warm roof

The “roof pie” in this case will have a more serious design:

- The sheathing and counter-lattice to which the metal tiles are attached;

- Waterproofing layer. In this case, the choice of material should be approached very responsibly. This is due to more severe operating conditions, such as a serious difference in external and internal temperatures, with the formation of a large volume of condensate steam. The purpose of this layer is to protect the insulation;

- Second sheathing. Its purpose is roof ventilation;

- Insulation;

- Vapor barrier layer. It protects the insulation from vapors coming from residential premises;

- Wall and ceiling decoration.

A little liquid can penetrate into the small gaps between the metal tile segments, and it is the installation of a high-quality waterproofing layer that will help drain the water, preventing it from accumulating. The list of advantages of a hydrobarrier includes the ability to equalize external and internal pressure, which allows the roof to easily withstand strong gusts of wind and ventilation of load-bearing wooden structures, which increases the service life. This is achieved due to mini-gaps in the coating and the presence of micro-holes throughout the entire area.

Which vapor barrier to choose for the roof?

There are the following types of vapor barriers for roofs:

- painting;

- pasting.

Painting room

It is used more often for high-rise buildings, soft roofs made of roofing felt, iron roofing sheets, where insulation is not used. This vapor barrier is well suited for flat roofs. The main difficulty in using mixtures of this kind is preparing the surface before application. For this type of insulation, the following compositions are used:

How:

- hot bitumen;

- bitumen-kukersol mastic;

- varnish based on chlorinated rubber or polyvinyl chloride.

Pasting (membrane)

This type is more popular, especially in individual construction . Materials for this type of insulation are produced in rolls and this provides some advantages:

- simplification of installation;

- ensuring a tight connection when overlapping;

- reduction in the number of seams.

How to properly install waterproofing under metal tiles

When deciding which waterproofing to choose for a metal tile roof in a particular case, it is worth keeping in mind that its installation begins after the assembly and installation of the rafter system, but before laying the roofing material. Let's figure out how to install waterproofing under metal tiles and in what sequence.

Moisture-repellent material is laid using the following technology:

- The material is cut into strips, and their length should be equal to the length of the slope plus 10-15 percent.

- The waterproofing is laid with sagging, so that during a leak, water pressure does not cause the material to rupture.

- Waterproofing strips are laid at right angles to the roof rafters with an overlap of 10-15 cm.

- The membrane or film is attached along the entire length of the rafters using a construction stapler.

- The roofing material must be secured to the rafters using galvanized nails.

- The joints of the strips can be sealed with moisture-repellent sealant, construction tape, or everything can be left unchanged.

- After fixing the moisture-repellent material along the entire length of the rafters, a counter-lattice is installed, which forms a ventilation gap.

Above, we discussed in detail which membrane to choose for metal tiles. Keep in mind that without high-quality waterproofing, the service life of a roof covered with metal tiles will be significantly reduced. This simple and at the same time inexpensive material will make it possible to extend the service life of the insulation, roofing material and the entire roof. As a result, the roof will last as long as possible, and you will not need to spend money on repair work again and again.

Which is better?

Roof insulation must have certain characteristics. The waterproofing material should prevent moisture from entering, while facilitating the removal of vapors. The period of operation should be equal to the service life of the metal tile itself. It is advisable to refuse the choice of roofing material.

This coating is not capable of allowing steam to pass through. In addition, roofing felt is less durable than metal tiles. Another nuance is the fact that when interacting with metal tiles, bitumen can destroy it. Therefore, roofing felt must be laid carefully, otherwise the roof may leak.

The best recommendations apply to film or membrane covering. The price will be a definite plus. But you should be careful when choosing. Since the film is essentially polyethylene (only thickened), it does not allow steam to pass through well enough. This point is not taken into account if the roof is not insulated. If there is insulation, it can quickly deteriorate.

The ideal choice would be membrane film. This is a polymer multilayer coating with specific perforation. Anti-condensation film, which has many advantages, is perfect for waterproofing. It has good durability. There is no risk of damage to the insulation during installation.

The membrane coating perfectly removes steam, while at the same time blocking the access to moisture. It is distinguished by a long service life. Typically, waterproofing replacement is carried out when the roof has already failed. With proper operation, replacement of the material will only be required after a few decades.

It is characterized by a simple installation process, so installation does not require special skills or knowledge. The cost of such material depends on the use of high-tech technologies.

Therefore, when purchasing expensive waterproofing, you should be careful and use the services of trusted manufacturers and sellers.

Waterproofing and thermal insulation of the roof

In addition to the substrate, the roof is additionally decorated with waterproofing and thermal insulation components. Depending on the climate zone in which the building is located, materials are selected accordingly. Mineral wool is often used for thermal insulation. With its help, it is possible to provide optimal protection for the house, and it itself is very easy to install.

Laying mineral wool

The optimal thickness of such a P-75 insulator for the middle strip is a layer of 200 mm. When using polystyrene foam boards, you must also focus on the density of the material and its thickness.

A prerequisite, in this case, is reliable sealing of the joints to prevent the formation of cold bridges. For example, mineral wool boards are often laid in a checkerboard pattern, and the joints of polystyrene boards are “shot through” with polyurethane foam.

Preparation for gluing vapor barrier joints

To ensure maximum protection of the insulation and proper removal of moisture, it will be necessary to provide waterproofing. It is laid in one layer, which is a special membrane or, in extreme cases, ordinary polyethylene film. Any ruptures or leaky joints are unacceptable.

Price

I suggest you familiarize yourself with the cost of all the coatings described above. Prices shown are valid for fall/winter 2021.

| Brand | Cost in rubles |

| Folinet, polyethylene reinforced, m2 | 34 |

| Novopolymer, m2 | 38 |

| Yutakon 130, anti-condensation, polypropylene, roll | 4200 |

| FineTek, polypropylene, 40m2 | 700 |

| Nanoizol SM, 70m2, diffuse | 2300 |

| Izospan-A, diffuse, 70m2 | 1880 |

For roofs with insulation

Waterproofing an insulated roof is more difficult and expensive. There are two options for waterproofing depending on the type of material used.

Waterproofing with two gaps

If a film with low vapor permeability is used, it is necessary to create two ventilation gaps - between the insulation and the film and between the film and the sheathing.

Typically, insulation is laid between the rafters flush with their top surface. Therefore, to create the first gap, you need to nail the counter-lattice strips to the rafters and lay the film on them without sagging. Then, strips are placed on top of the film to the counter-lattice, providing a second gap, and to them the lathing for the metal tiles.

The advantage of the two-gap method is that a cheaper waterproofing film can be used instead of a diffusion membrane.

The disadvantage is that it is more labor intensive. In addition, ensuring double clearance in areas of valleys, chimney outlets and roof windows can be difficult, and sometimes impossible.

Waterproofing with one ventilation gap

In most cases, it is more advisable to use this option, which creates only one ventilation gap - between the film and the sheathing.

To implement it, you will need a diffusion membrane that can effectively transmit water vapor, even when laid without a gap, directly on the insulation. It is attached to the rafters according to the usual rules - with the upper strips overlapping the lower ones and sealing with adhesive tape.

Membranes require installation with a certain side up.

But even if a “breathing” membrane is used, the ventilation gap between it and the sheathing must be ensured - using the same counter-lattice nailed to the rafters.

| Strength*, N/50mm | Vapor permeability, Sd | Weight, g/sq.m | Note | |

| DELTA®-VENT N | 220/165 | 0,02 | 130 | The best choice if funds allow |

| Tyvek Soft | 165/140 | 0,02 | 58 | Very light and reliable membrane from DuPont |

| YUTAVEK 115 | 260/170 | 0,02 | 115 | Price quality |

| Izospan AM | 160/100 | 0,03 | — | Budget membrane, medium strength |

| Ondutis SA115 | 160/90 | 0,02 | 100 | Better steam permeability than Izospan, but less resistant to UV rays |

Functions

Metal tiles are a roofing material based on galvanized steel, coated with paint or polymer with a wavy relief. It has high thermal conductivity, therefore, due to the temperature difference inside and outside the house, it becomes covered with condensation, which significantly reduces the service life of the roof. If you do not install the waterproofing film, the following unpleasant consequences arise for the roof:

- Dampening of the rafter frame. If condensation gets on the rafters, the wood absorbs excess moisture, which leads to the spread of mold, mildew and rotting of frame elements. Ultimately, this ends in irreversible deformation of the roof structure.

- Moisture on the thermal insulation material. If the insulation is not protected by a waterproofing film or membrane, it becomes damp over time, which reduces its effectiveness by half. It is necessary to take into account that the properties of the thermal insulation material are not restored even after complete drying.

- Corrosion of roofing material. If waterproofing is not installed, condensation accumulates on the inner surface of the metal tile roof, contact with which causes the metal coating to begin to rust. The most vulnerable areas to corrosion are the places where roofing material is attached to wooden rafters. Rust, gradually corroding the metal tiles, significantly reduces the durability and reliability of the roof of the house.

Important! Waterproofing under metal tiles is a prerequisite for the durability, reliability and quality of a roof made of this material. If a waterproofing film or membrane is not used to protect the rafters and insulation, the service life of the roofing is reduced by more than half.

The modern construction market offers a wide range of materials for waterproofing, which differ in price, properties and application. The choice depends on the type of roofing pie at home and the financial capabilities of the buyer. To protect the rafters, insulation and roof covering from condensation, install:

- Ruberoid. Underlay roofing felt is the most accessible and inexpensive material for waterproofing under metal tiles. It has high water resistance, mechanical strength and an inexpensive price. However, it is used if the roofing pie of the roof of the house is of the cold type, since roofing material does not allow steam to pass through. Experienced craftsmen recommend installing roofing felt under metal tiles only in extreme cases, when there are no other options.

Note! If the roof structure is of a warm type, then only vapor-permeable materials can be used as waterproofing. In addition, the installation of the waterproofing film is carried out so that there is a ventilation gap between it and the roofing material. Waterproofing under metal tiles should not come into contact with either the roofing covering or the insulation.

Characteristics of waterproofing film

The roofing film, no matter what it is made of, must protect the attic space and the thermal insulation layer.

In other words, to prevent processes from starting under the metal tile that will eventually destroy it and have a detrimental effect on the base of the roof, special protection is needed. A priori, the waterproofing properties for metal roofing are micro-perforation to ensure ventilation of water vapor. To achieve this result, the substrate under the metal tiles must

- Consist of several layers

- Possess a reinforcing polyethylene grid

The thickness of each layer varies depending on the type of film. Moreover, in addition to moisture removal, the protective waterproofing film can have

- Fire resistance

- UV protection

Each manufacturer indicates what qualities are inherent in its material.

Differences between hydro- and vapor barriers for roofing, scope of application of materials

Of course, most professional roofers and builders have long been familiar with the purpose of various roofing films, but for an inexperienced developer the functions of vapor barrier and waterproofing for a roof are not always clear. Let us briefly note a number of differences between films, and also consider in which cases insulating materials are universal.

Installation of a roofing “pie” for a cold and warm roof

To begin with, you should present the correct diagram of the installation of a cold and warm roof. Such structures are often popularly called “loft” and “attic”, respectively.

Fig. 1 Warm and cold roof design

As can be seen from Fig. 1, in the case of a warm structure, the attic floor is insulated not only in the wall area; a layer of thermal insulation is also present in the roofing “pie”. Whereas for a cold roof, only the floor of the attic space is insulated. The location of the insulating films is clearly shown in Fig. 2.

Fig. 2 Diagram of the roofing “pie” for an insulated roof

Highlight in red the elements of the roofing pie that are present in both warm and cold structures. Insulation, vapor barrier and rough sheathing are layers used only when constructing an attic floor. Now you can move on to a description of insulating materials, their purpose and distinctive features.

Waterproofing windproof film

This material is used for both insulated attics and cold attics. Waterproofing serves as additional protection of the roof from precipitation or condensation entering the structure. Sometimes the material is called windproof film. It is laid directly in front of the roofing material with a small ventilated gap (counter-lattice) of about 40-50 mm. If the film is installed closely, the roofing material, as well as the wooden roof structure, may become unusable due to large amounts of moisture formed under the roof.

Remember, you cannot use a waterproofing film without a counter batten!

According to their purpose, roofing waterproofing can be divided into 3 types:

- Non-diffusion (vapor-tight) waterproofing (for “cold” roofs);

- Diffusion membrane with low vapor permeability coefficient;

- Superdiffusion membrane for insulated attics.

In most cases, waterproofing for non-insulated roofing systems (attics) is in the form of reinforced film or non-woven fiber material.

Diffusion and superdiffusion films are used in the case of an insulated roofing “pie” structure and serve not only as hydro-wind protection, but also as an element for removing steam from the thermal insulation layer. Therefore, in the event of condensation, moisture will accumulate on the outer surface of the film, and not on the insulation. Superdiffusion membranes have a high vapor permeability, which allows them to be laid directly on the insulation without additional gap.

Most often, it is the diffusion vapor-permeable membrane that is confused with a vapor barrier due to the similarity in the names of the films.

Vapor-permeable membranes and vapor barrier films are fundamentally different materials in purpose!

A description of vapor barrier films will allow us to determine the main differences in materials.

Vapor barrier film and its purpose

According to Fig. 2, the vapor barrier material is laid on the inside of the insulation - closer to the living space. The film prevents the penetration of warm steam into the heat-insulating layer, eliminating the possibility of any moisture forming on the insulation and wooden elements of the roof. Thus, the task of any insulating roofing material (waterproofing and vapor barrier) comes down to one thing - protecting the thermal insulation, sheathing and rafter system from the occurrence of condensation inside the roofing “pie”. The difference lies in the methods and location of installation of one or another material.

In addition to the main function, some types of vapor barrier have heat-saving properties due to an additional layer of aluminum.

more about vapor barrier films, their density and design in this material.

Hydro-vapor barrier or universal roofing film

In construction stores you can often see roofing film called “hydro-vapor barrier” or vice versa. What does this mean? Where is this material used? In fact, we are talking about a universal insulating film, which, as a rule, does not allow steam to pass through on either side. Or the material has low vapor permeability and is not intended for use as waterproofing for attic roofing systems.

The film can be used as waterproofing in the case of cold roofs and as a vapor barrier film in insulated structures.

Attention: the universal hydro-vapor barrier is not intended for installing a roofing pie for a warm roof, because not capable of transmitting vapors from the insulation.

As an exception, such insulation can be installed in attic roofs if there is an additional counter-batten (at least 40x40 mm) between the insulation and the film. This creates a ventilation gap to ventilate excess moisture. This method is ineffective and economically irrational, so we do not recommend using a hydro-vapor barrier film for a warm roof.

Among the manufacturers of insulating materials for pitched roofs, there are three main ones:

- DuPont (Tyvek films, AirGuard)

- Juta (Yutafol, Yutavek)

- Dorken (Delta branded products)

The companies have long established themselves on the positive side in the roofing market.

Let's summarize the differences between the two main types of insulation materials for pitched roofs. On the outside of the insulation, closer to the roofing material, a hydro-windproof film is laid, which prevents the penetration of moisture and wind into the layers of thermal insulation. In turn, the vapor barrier material is located on the inside of the roofing “pie” and serves as a barrier between warm steam from the room and the attic insulation.

What to use

As with many things, there are different materials used to accomplish the same task. Roof insulation is no exception.

Polyethylene films

To install a vapor barrier on a roof, high strength of the material is sometimes necessary, for example, if we are talking about insulating the attic floor. To increase the strength of polyethylene, they began to reinforce it. There are two types of such films:

- Perforated;

- Non-perforated.

It is generally accepted that it is the latter that are used as a vapor barrier on the roof. Perforated films have high vapor permeability, which is not suitable for solving our problem. Consider this point when choosing a film.

Separately, it is worth mentioning the films on one side, covered with aluminum foil. Their ability to resist steam is much higher than that required for ordinary premises. Most often, such films are used for saunas and baths, so there is no point in choosing them for the roof.

However, there are films that have two significant advantages over polyethylene films.

Polypropylene films

The notorious advantages of such films are:

- Higher strength;

- Resistant to ultraviolet rays.

For example, such films can protect exposed rafters from rain and snow throughout the year.

There is a particularly attractive type of film made from this material. Films with antioxidant coating. On one side, such films are covered with a layer of viscose fiber with cellulose. This coating is capable of absorbing moisture (condensed steam) and storing it for a certain time. After the cause of condensation disappears, the layer dries quickly, preventing moisture from penetrating into the thermal insulation. It is important to install this film correctly. The antioxidant layer should face down from the insulation.

The most commonly purchased films are the following brands:

- TechnoNIKOL,

- Izospan;

- Klober;

- Tyvek;

- Juta;

- Nikofol;

- Everlasting.

Experts recommend the Tyvek family of materials developed by the American company DuPont. The approximate cost of 1 square meter of such material is 110-120 rubles.

Did you know?

Glassine was previously used to insulate the roof. Now this material is practically not used. There are much more advanced and relatively inexpensive materials. Also previously used were roofing felt, roofing felt, or ordinary polyethylene film.

Which vapor barrier to choose for the roof? As we have seen, this mainly depends on two factors:

- Places where insulating material is used;

- Owner's financial capabilities.

By noticing the possible types of vapor barrier, you can more clearly understand which vapor barrier is better for the roof. We settled on polypropylene films with an antioxidant coating.

How to properly install a vapor barrier under metal tiles on the sheathing?

In order to correctly choose the best method of laying a vapor barrier, it is necessary to study in detail the characteristics of this material. The film, which protects all layers of the roofing “pie” from steam, is applied equally to all types of roofs. The main thing is to start installing the roof vapor barrier after the waterproofing and insulation layer have been laid.

The vapor barrier material under the metal tiles is laid on the sheathing as follows:

- The rafters are installed and the waterproofing and insulation layers are laid.

- A sheathing is constructed on top of the thermal insulation layer.

- A vapor barrier is attached to the sheathing on the inside of the building (with the absorbent side facing the sheathing).

- The vapor barrier film is laid overlapping. In this case, the joints of the film are taped with adhesive tape.

- The vapor barrier material is secured with staples or galvanized nails with a large head.

- After installing the vapor barrier film, you need to secure it with bars, placing them at a distance of 50 cm. They are necessary in order to better secure the material and provide a ventilation gap.

Laying a vapor barrier film on the roof sheathing should be done strictly according to the rules. Because if the material is installed incorrectly, the roof will not allow steam to pass through, which will lead to rapid destruction.

Types of adhesive vapor barrier materials

- Waterproofing . Prevents steam from penetrating into the insulation. They have special perforation , which allows vapors to penetrate outside. It is mounted with some clearance from the roof covering, which promotes air circulation between the outer and under-roof space. Has unidirectional vapor permeability, keeps the insulation dry. You can read about waterproofing materials here.

- Anti-condensation . They are equipped with a special fleecy layer , which is located on their inner surface. It retains moisture and prevents contact with thermal insulation. Moisture quickly disappears due to air circulation in the gap. This type of insulation must be laid with an adsorbent layer to the inside of the room. Attached using a counter-lattice.

- Vapor-tight . They provide impenetrable protection to the inside of the roof insulation. Sometimes they have a layer of aluminum foil , which is capable of reflecting part of the radiant energy back inside. It is laid with a ventilation gap to the insulation. Provides good protection from moisture while retaining heat.

- Membranes . They are modern vapor barrier materials that can prevent moisture from escaping while allowing air to pass through . When using membranes, providing an air gap is often not necessary. This material for roof vapor barrier has gained great popularity these days.