For decades, slate remained the most popular roofing material among private owners - both because there was no worthy alternative and because it itself has impressive characteristics. With the advent of modern coatings, the situation has changed dramatically: today, slate roofing on a private new building is a rarity. In fact, the biggest drawback of slate is its unpresentable appearance - dull gray color, standard dimensions, and the annoying “wave”. However, by choosing an original installation method, you can get decorativeness along with the durability and versatility of slate. Users of the FORUMHOUSE portal have seen this from their own experience.

Advantages and disadvantages of slate

Wave slate is excellent not only for technical premises, but it is also often used in the construction of residential buildings, because it has the ability to retain heat and protect the home from adverse environmental conditions.

Although this material was invented a long time ago and has been used for a long time, it still remains the most popular roofing covering. Slate is made from clay shale, which is naturally separated from other rocks. The surface of the leaf can be wavy or flat. In the second case, to achieve good strength, the composition includes chrysolite fibers, which act as reinforcing screeds. Flat slate is used in the construction of fences and fences, as well as to create wall panels.

Flat slate for fences and fences Source globalrustrade.com

Wave slate is more suitable for roofing work. Today, this building material is constantly being improved and, thanks to this, its appearance and thermal insulation qualities are improving. The width of the sheet is measured not in meters, but in waves.

Slate for roofing Source de.decorexpro.com

Now let's figure out what the advantages of slate are:

- Such material, with proper care, can last half a century or even longer;

- Installation of slate is much easier than installation of other roofing materials. Therefore, construction companies set lower prices for slate roofing;

- Slate roofing significantly increases the waterproofness of the entire structure;

- The material is resistant to too low or too high temperatures;

- You can walk on such a roof even in winter, because it is very resistant to mechanical damage ;

- The slate roof has very low fire hazard ;

- This roof covering absorbs rain noise and is also resistant to solar radiation;

- The advantage of slate is its low cost ;

- Paint applies to such a roof very , so you can choose any color or shade;

- Sheets can be cut with a regular hacksaw , and this has a beneficial effect on the cost of installation work;

- Moisture does not condense on a slate roof , so you can save on vapor barrier.

Paint is easy to apply to a slate roof Source makebestphoto.ru

Of course, like any material, slate has its drawbacks:

- This is a very fragile material, which makes it very difficult to transport and store. It is better to carry it in a vertical position so that it does not burst under its own weight due to its small thickness;

- You need to be especially careful when walking

- After prolonged use, the coating loses some of its waterproofing qualities;

- often break off ;

- If the roof is located in the shade, then mosses and lichens ;

- Due to natural factors, slate changes its color .

Slate tiles - a classic of the genre, but side view

Current manufacturers adhere to either GOST 30340-95 or technical specifications, so sheets with different dimensions and thickness can be found on sale. In private construction, a standard 8-wave slate with a length of 175 cm and a width of 130 cm is usually used. Today, natural tiles, their imitations made of metal and composite, as well as soft roofing materials are at the peak of popularity, and the familiar slate wave has remained out of the topic.

If your financial capabilities do not allow you to take aim at the leaders in demand, but you want a roof that is not only durable and strong, but also beautiful, there is a way to both save money and show off - lay slate under the tiles.

To achieve the desired effect, the sheet is cut crosswise into two or three parts - short tiled waves are obtained that look more attractive than the standard layout. Portal users who have chosen traditional roofing material, but in an original design, prefer the first method - a sheet in half. So the look is transformed, and there is less fuss with cutting and fastening, as well as seams with gaps.

unkasFORUMHOUSE Member

The fact that you cut it into three parts, and not into two, will not add much to the beauty, but there is more fuss and the sheathing needs to be done more often than for ordinary sheets. And if you cut it in half, the lathing will even be simpler - you don’t need to make the middle board thicker.

By the way, some manufacturers offer already cut slate. If you find a similar supplier at a reasonable price (in Moscow this is quite easy), then there will be no need for cutting.

Asbestos slate

There are three types of slate covering: metal, Euro-standard and asbestos. Metal is made of thin galvanized steel coated with a protective layer of polymer. The composition of Euro slate includes cellulose and basalt fibers, fiberglass, and jute. The last type is the most popular. The material is characterized by very high rigidity, because asbestos fibers are stronger than even steel. They are connected by cement. Asbestos threads are evenly distributed over the sheet, which creates a good reinforcing mesh. This helps to increase the impact strength and strength of the coating.

Asbestos slate is highly durable Source rmnt.mirtesen.ru

There are different types of corrugated asbestos slate:

- VU is a wavy slate with a reinforced profile. This material is used for roofing work in the construction of industrial buildings.

- VO - slate with a regular profile, having a rectangular shape. Not only the sheets themselves can be made from it, but also other roofing elements, for example, a slate roof ridge.

- UV is a wavy unified slate. It has a good wave width and sheet size. All this allows you to significantly reduce the number of joints.

Preparing for slate installation

First you need to measure the area of the future slate roof in order to calculate the required volume of material. This process will allow you to roughly estimate the upcoming costs of constructing the structure. In order to take measurements, you can use the building design, or hire a professional.

After purchasing roofing material, you need to check if there are any defects on it. Damaged sheets should be replaced.

Slate sheets need to be checked for defects Source krovlyakryshi.ru

See also: Catalog of companies that specialize in roof design and repair.

Also, during the preparation process, mounting holes are drilled, and the material itself is cut to length.

You definitely need to pay attention to the fact that if you are going to cover the roof with slate, you will need reinforced sheathing. In order to create it, it is better to hire specialists, because the service life of the structure, as well as your comfort, depends on the quality of the support.

Reinforced roof sheathing Source stroyvolga.ru

Minimum tilt angle

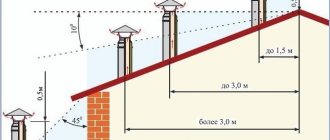

The slope of the roof is one of the key parameters on which its reliability, safety and service life depend. Depending on the type of slate and the weather and climatic conditions in the region, this indicator can vary within a wide range.

For asbestos slate, the optimal angle of inclination of a pitched roof is within 20-25 degrees . At lower values, snow masses will accumulate on it, and their spontaneous removal from the roof will be difficult due to the rough surface of the material.

If the slope is too great, the slate sheets may fall off the fastenings under their own weight, since the surface density of the material often reaches 8-10 kg per square meter.

Soft slate should be installed at an angle of 30-35 degrees , since ondulin has a higher coefficient of friction than asbestos cement. Accordingly, to prevent snow from accumulating on the roof, it should have a steeper slope.

If the building is covered with metal slate, you can reduce the angle to 5-8 degrees - to the same value as for corrugated roofing sheeting, which has a similar structure of the working surface. This material is smoother than asbestos or soft, so snow masses slide off the roof surface even with a relatively small slope.

What should be the minimum angle of inclination of a pitched roof, read here.

How roofing work is done when using slate

The slate sheets are attached from the bottom to the top vertically. The point of this is that the upper wave overlaps the lower one. In this case, one sheet must overlap the other by at least 10 cm. To ensure that all sheets protrude at the same distance, a tape or rope is stretched along the edge.

There are two ways to lay sheets. The choice depends on the roof slopes. If the vertical slope is narrow and the horizontal slope is wide, then offset laying is used. This option is notable in that it does not involve cutting the sheets at the joints. The sheet is attached to the sheathing one wave to the side. Each subsequent sheet is fixed on the previous one, overlapping one wave. In this case, laying is done in horizontal rows.

Correct installation of slate on the roof Source proroofer.ru

In the case where the vertical slope is narrow and the horizontal slope is wide, an installation with cut corners is used. In this case, the corners of the diagonal sheets are removed, and the joint is made with a small gap. This method allows you to avoid the appearance of cracks and defects in the roofing.

Installation of slate with cut corners Source www.remontyes.ru

Pie structure

Since slate has a wavy shape, moist air can penetrate into the space between the ridges in the lower parts of the roof (the upper parts are sealed with special metal ridges). To minimize the negative impact of moisture on the wooden elements of the roof frame, it is necessary to use a multi-layer roofing cake.

Its structure consists of several elements , which must be arranged in the specified order (from bottom to top):

- inner lining;

- ventilation gap;

- vapor barrier;

- insulation;

- waterproofing;

- counter-lattice;

- sheathing;

- slate covering.

Inexperienced builders often confuse the location of vapor and waterproofing, mistakenly believing that these materials perform identical functions. This leads to a noticeable reduction in the service life of the roof, since the vapor barrier layer is designed only to retain water vapor, and not rain or melt water in its liquid form.

The insulation, in turn, must be reliably protected from moist air penetrating from the premises of the house, as well as from precipitation, which can penetrate under the slate from the outside if it is accidentally damaged or improperly fastened.

Therefore, the thermal insulation material must be located between the vapor and waterproofing . Otherwise, it will quickly lose its properties.

The sheathing should not be attached close to the waterproofing layer. There should be ventilation gaps below and above it. Otherwise, condensation will accumulate.

Slate painting

Carrying out this operation will increase the service life and decorative qualities of your roof. An acrylic film will delay the destruction of slate for several decades. But the choice of paint must be approached very responsibly. It is better to use compounds from trusted manufacturers that are resistant to solar radiation and temperature changes.

It is recommended to paint slate with acrylic paint Source regstroy.com

The use of water-dispersion paint has a very important advantage: the mixture seals all microcracks on the surface of the material. In winter, roofing slate coated with this composition becomes more slippery, which helps remove snow and moisture.

Alkyd paints make the surface more elastic, and this prevents the appearance of defects. This type of coating also protects the roof from fading.

Special matte paint for slate Source tr.decorexpro.com