Wooden balusters have been known since the mid-19th century. Three-dimensional vertical parts carved from wood were used by ancient craftsmen to decorate porticos and pediments of houses. They not only performed a decorative function, but were used as posts or fencing for balconies.

The platband of the window of the peasant's hut's lighthouse repeats the portico, and eight twisted balusters are equipped with capitals. If stone craftsmen have become famous in other countries, then we have wood carvers.

Nowadays, with the increase in the volume of individual housing construction, the need for wooden, artistically designed balusters is increasing every year.

How to choose the right balusters?

When choosing supports for fences of various designs, various factors are used. Among them:

- appearance;

- price;

- size;

- performance material.

When ordering fencing installations from specialized organizations, they produce structural elements from wood of the same species. The same principle must be followed when installing fencing yourself. You cannot install balusters made of oak, and railings made of alder or larch. The purchased products must have the correct geometric dimensions. They should not have:

- defects;

- deformations;

- blue on the surface;

- emptiness inside.

You should not buy products with fallen knots or made from raw wood.

Prices for various types of balusters

Balusters

Metal porch railings

Railings perform not only a purely practical function, but also serve as an important element of the porch design.

Such structures can be made of wood, metal or plastic. The carved and forged handrails are incredibly beautiful. Each type of railing has its own advantages and disadvantages.

We’ll talk about how to make the porch as comfortable and beautiful as possible by choosing the most suitable type of handrails in this article. We will also look at the basic principles of making such a fence for a porch.

Manufacturing technology of wooden balusters

The wood lends itself well to processing. This allows you to apply patterns of various types and complexity to the surface of the blank balusters. Craftsmen create supports suitable for interiors from modern to high-tech. Work begins with the development of a product sketch. After its approval, a drawing is drawn up indicating all dimensions, including bends and cuts. Before starting to manufacture the support, the dimensions indicated in the drawing are transferred to the workpiece and marks are made. Each of them is assigned a number. Cutting out decorative parts requires cutters of various shapes.

Cutters for cutting out decorative elements on balusters

Round supports are made using the rotation method. The operation of lathes is based on this principle. They are adapted for processing blanks made from various types of wood. In a lathe, the workpiece is fixed in the spindle head. It rotates at a given speed around its axis. The ornament is applied to the surface using a rigidly fixed support of the cutter. The position of the tool is adjusted using movable slides. They can move manually or automatically. The type of ornament applied to the surface of the blank depends on the position of the cutter.

On milling machines, a rotating spindle is used to secure the cutter. A stationary workpiece is fed to it using a support. The industry produces universal machines that combine turning and milling functions. They make products with complex ornaments. In the absence of universal CNC equipment, difficult-to-cut patterns are made on sequentially used lathes and milling machines.

Making balusters on a CNC machine

After applying the pattern to the surface of the products, they undergo finishing treatment. First, the supports are ground by hand or machine and then polished. Products prepared in this way can be coated with wood varnish or paint.

Find out how to age wood with your own hands, and also familiarize yourself with aging methods and mistakes when working in a special article on our portal.

Video - How to make Roman-type balusters yourself?

Concrete railings

Concrete handrails are perhaps the most substantial type of porch fencing. They will last even longer than metal porch railings made of stainless steel, since they have no joints or technological gaps. However, their construction is a somewhat more labor-intensive process.

Among other things, this is also the most expensive type of fencing.

Concrete solid structures can be supplemented with metal handrails

When choosing a material for making railings, be guided primarily by the design of the porch itself. In this case, you will get a harmonious and stylish design. For example, this one:

Flat balusters: step-by-step instructions

Flat supports are easiest to make yourself. Their production does not require complex equipment. Skillfully made supports have an attractive appearance. They can decorate any interior.

Step 1. The first stage of work is devoted to preparing the materials and tools necessary for the manufacture of balusters: jigsaw, paper, marker, scissors, ruler, sandpaper or sanding machine, dry boards or plywood.

Electric jigsaw

Prices for popular models of jigsaws

Jigsaw

Step 2. At the second stage, a sketch of the future support is developed. To do this, the full size of the contours of the product and patterns are applied to the paper. After this, a support template is cut out according to the dimensions marked on the paper.

Stencils

Step 3. The third stage is devoted to applying a stencil to the workpiece, drawing the contours of the future product on it and cutting out a support along them with a jigsaw.

Flat balusters cut with a jigsaw

Step 4. At the fourth stage of work, the surface of the products is processed. For these purposes, use sandpaper or a grinding machine.

Prices for popular models of sanders

Sanders

Sanding a piece of wood with an emery wheel

Step 5. To extend the service life of products, their surface is treated with an antiseptic. After it dries, the supports are coated with wood varnish. This improves their aesthetic appearance.

Features of varnishing stairs

Find out how to make a wooden countertop for a bathroom sink with your own hands in a special article on our portal.

Plastic structures

Plastic is also a fairly “warm” material and easy to cut. How to make a brick border with your own hands? Among other things, it is frost-resistant and resistant to moisture. Cleaning such handrails will not be difficult.

Practical railings for the porch. Photo of an elegant plastic version

Vinyl railings can last longer than wooden ones. Yes, and they are cheaper. However, of course, this material is not natural and cannot be compared with wood in terms of the beauty of its texture.

This option is simply ideal if the design provides for rounded areas. Bending plastic porch railings is very easy. To do this, you just need to heat them with a hair dryer.

Note: The design of PVC handrails is chosen based primarily on the material the porch itself is made of. There are options that imitate both wood and metal.

Mounting supports: options

When choosing the fastening of supports for enclosing structures, various factors are taken into account:

- wood type;

- size and shape of products;

- fencing design.

Professional craftsmen most often use wooden pins or dowels to attach volumetric supports. It is recommended not to make their diameter larger than 1/4 of the diameter of the baluster base. This may cause the product to crack.

Fencing fastening diagram

According to the requirements of the current SNiP, fencing is installed on stairs with more than 5 steps. The minimum distance between the supports is 10-15 cm. The upper part of the supports is attached to the handrails. The method of fixing the lower part of the balusters depends on the type of structure. They can connect:

- with steps;

- bowstring or stringer;

- landing.

It is not allowed to use nails to connect structural elements. During use they quickly become loose. This leads to loss of strength and imbalance of the fence. When fastening balusters to a narrow string, a special board of greater width is placed on it. It serves as the lower support of the baluster.

Staircase design elements

Incorrectly installed and poorly secured supports make the operation of the ladder dangerous. The most durable mounting should have support posts. Intermediate balusters are installed between them at equal intervals. When attaching the supports to the string, their base and upper part are cut to the slope angle of the flight of stairs.

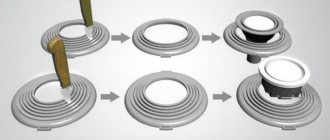

Fastening supports with dowels

The fastening process begins with marking the location for drilling holes for installing dowels. It is located exactly in the center of the base of the baluster. The depth of the hole is equal to 1/2 the length of the dowel inserted into it. The strength of the connection of structural elements is increased with the help of wood glue. They fill the hole before installing the dowel.

Scheme of fastening the structure with a dowel

The recesses are drilled in 2 stages. They start with a hole with a diameter of 5 mm, and then gradually expand it, changing drills of different diameters. The dowel should not go completely into the hole. The length of the outer ends of the fasteners must be at least 5.5-6 cm. Before installation in the base of the stairs, they are lubricated with glue and sprinkled with fine sawdust. This increases the adhesion strength of structural elements.

Fastening the supports with a metal pin

One end of the fastener should have a screw thread, the other should have a nut thread. The depth of the hole for the stud in the base depends on the length of the fastener. Usually it is from 10 to 20 cm. First, a 1-2 mm indentation is made with a drill in the center of the base of the support. After this, they begin to screw the fasteners into it. The ends of the studs protruding from the supports are inserted into the holes drilled through the steps, after which a nut and washer are put on them and tightened until they stop.

Fastener location diagram

Find out how to make a hatch to the attic with a ladder with your own hands, and also read the step-by-step instructions in a special article on our portal.

Fastening supports with self-tapping screws

The easiest and fastest way to attach. Self-tapping screws ensure the strength of the connection of the elements, but have one big drawback - after installation of the structure, their caps are visible. This spoils the aesthetic appearance of the staircase. This type of fastening is widely used for connecting flat balusters when constructing gazebos and porch railings.

Metal railings

Metal railings are the most durable type. Most often, handrails are made of stainless steel. Exclusive options are cast or forged. Using such designs you can make the porch unusually beautiful and original.

However, wrought iron porch railings are quite expensive. Sometimes in private houses, not iron, but aluminum and stainless steel handrails are used. They are also not too cheap.

Wrought iron railings on the porch. Photo of a complex decor imitating a vine

The disadvantages of metal fencing include some difficulty in installation. Typically, stainless steel porch railing elements are fastened together using welding. Do-it-yourself border from scrap materials? Therefore, for their installation you need to have special equipment.

In addition, painted structures made of non-galvanized steel must be periodically tinted.

Metal railings for the porch. Photo of a simple elegant design

Functional purpose and positive characteristics

Durable wooden deck balusters perform several important functions. That is why these products must be as durable and reliable as possible.

Main functions of racks:

- used as a support;

- provide the necessary stability to the ladder;

- give the stairs an aesthetically attractive appearance;

- provide the necessary safety for human movement from the first floor to the second.

Balusters made from durable solid wood are very popular among private property owners. High-quality products have the following advantages:

- Wood goes well with all modern finishing materials and interiors.

- Long service life and maximum strength. High-quality racks can last for decades. The minimum service life of solid wood structures is 45 years.

- Environmentally friendly. The material is absolutely safe for the environment and human health, as it does not emit toxic substances into the air. Natural resins have a powerful healing effect.

- Aesthetic appeal. Manufactured stairs can boast of their sophistication and originality. In combination with properly selected decorative finishing, the interior of the room becomes extraordinary and luxurious.

- You can make original racks yourself.

- Huge selection of natural raw materials. Wood is ideal for realizing the most unexpected design ideas.

- Damaged staircase elements can be restored or replaced.

A universal model with an unusual pattern

What type of wood to choose

In order for the staircase to remain strong and presentable for a long time, it is recommended to make all elements: railings, balusters, steps from the same type of wood. When making supports for stairs, it is best to choose hard wood:

- Oak. Noble and strong, it has the highest performance characteristics. It is durable, resistant to temperature changes, moisture and decay. Oak products have a beautiful dark shade. The products practically do not crack or warp. Despite the density of the wood, oak can be processed in all available ways.

Example of carved oak balusters - Ash. It has a very beautiful texture of valuable wood. The main advantage of ash is its resistance to moisture and rot. The structure of the tree is elastic and dense, withstands heavy loads well, bends well, and is resistant to deformation.

- Beech. Beautiful and easy to process, beech is almost as strong and durable as oak. The wood is perfectly polished and sanded, and lends itself well to decorative finishing with various compositions. The disadvantage of beech is its susceptibility to rotting and deformation in places with high humidity. In order for beech products to be of high quality, you need to choose properly dried wood.

- Birch. Rarely used for making balusters. The main disadvantage of birch is its tendency to rot, cracks and severe shrinkage.

Drawings and patterns of birch balusters

Although wood has good strength indicators, it is easy to process, sand and paint. After appropriate processing, birch can be given the appearance of noble wood. - Larch. Over time, wooden larch balusters only become stronger. The wood is resistant to warping and high humidity, it does not rot and burns very poorly.

- Pine. A budget option with good resistance to fungi, moisture and temperature changes. Wood lends itself well to processing with cutting tools and is the most popular material for creating stairs.

To make balusters with your own hands, it is important to choose wood of the correct moisture content, without cracks, knots and other defects. Overdried wood is very fragile, and wet wood can crack after drying.

Various types of carved balusters

It would also be wiser for novice craftsmen to choose inexpensive types of wood - pine or birch, which are easy to process. Valuable species such as oak or walnut are too expensive to be damaged during the training process.

Practical application of products

Balusters are often used as additional supports for railings. Thus, entrance staircases, varieties of internal flights of stairs, fencing of balconies on the upper levels of floors of dachas and cottages, and so on are designed.

Such elements have been used for a long time. Their external shape and main focus make them popular even today.

High interest in balusters manifests itself precisely as construction parts that perform several functions at once. Firstly, as noted, they act as support posts, and secondly, in addition to their direct purpose, they participate in the artistic design of residential buildings and extensions.

Durable racks for strengthening stairs

Refined balusters made of durable boards look very aesthetically pleasing and give the staircase a more comfortable and aristocratic look. You can build such products yourself, resulting in a truly unique structure. All wooden stands are usually classified by grade. The most expensive products are those that require the most careful selection of texture and shade.

The material must undergo multifaceted finishing. Masters allow for slight tints and minimal differences in texture. Knots should not be more than 7 millimeters in diameter.

In your home workshop, you can create unique balusters from natural materials with partial selection of color and texture. The blanks must be repainted in dark shades. The changes can be dramatic. Beginners can create stands that are not matched by texture. Knots can be light or dark, but their dimensions should be minimal. Some balusters sometimes have fragments of sapwood. Craftsmen allow cracks and knots to be puttied at the manufacturing stage.

The height of the products is easily adjustable. Experienced craftsmen use volumetric point models. First, be sure to prepare a drawing in which the thickness is indicated, as well as the dimensions of each part of the staircase. The result is not a classic drawing, but a multifaceted artistic scheme, which the master will focus on.

An interesting video about the variety of wooden balusters:

Gypsum

It is much easier to make balusters from plaster. In the retail chain you can easily find ready-made casting molds suitable in shape. Stores dedicated to landscape design offer such forms in a wide range.

If the finished mold is not suitable for some reason, you can make your own using silicone or rubber. You will need to carve a sample according to which the mold is prepared.

When the issue with the form is resolved, the casting process begins. The two halves of the form are fastened together. Dissolve the gypsum powder to the consistency of thick sour cream.

The finished mixture is poured into the mold and left to harden for a day. If small defects are found on the casting, they can be easily eliminated by machining.