A garage is an important structure in the life of any car owner. It can be located on the territory of a private house, or in a cooperative, which is more important for residents of apartment buildings. With its help, the vehicle is protected from precipitation, wind, accidental falling branches, and so on. But it can also act as a box for protection from high and low temperatures. But without proper insulation, such an effect cannot be achieved. This raises the question of how to insulate a garage.

The answer to the question of whether it is necessary to insulate the garage should be given by the car owner himself. Much depends on the region of residence, the local climate, as well as the frequency of the car being in the garage and on the structure itself.

But practice shows that insulating a garage with polystyrene foam, mineral wool or other materials is a useful procedure, and most often necessary.

Some advocate insulating the garage from the inside. Others believe that insulating the garage from the outside is a more correct and rational solution.

Well, today I propose to discuss this issue, and also find an option on how to cheaply insulate a garage and get the desired effect from a car house.

What is the best way to insulate: outside or inside?

According to all construction canons, the best option is insulation from the outside. The thing is that the boundary between the thermal insulation material and the sheathing is the zone where condensation forms. And if you do insulation from the inside, then this zone falls between the insulation and the walls of the garage. At the same time, the latter freeze completely (through and through) in winter, which negatively affects the building material itself. Plus, condensation, which reduces the performance characteristics of any building material.

This is the first reason. The second is the ability not to reduce useful space in the garage. Insulation installed on walls takes up some space. Here you will have to add the thickness of the skin. That is, on each side of the walls there will be a reduction of approximately 3-5 cm.

The third reason makes it possible not to pay attention to the environmental friendliness of the thermal insulation material. It will be located on the outside, street side, which means that if the insulation releases substances harmful to humans, they will immediately evaporate. Moreover, such materials are much cheaper than environmentally friendly ones.

Insulation of the garage from the outside Source remstroiblog.ru

But it is not always possible to insulate the garage walls from the outside. If for some reason this cannot be done, then all thermal insulation work is moved inside.

Protecting the ceiling from the cold - some subtleties of the procedure

Thermal insulation of the ceiling in the garage is similar in technology to the insulation of walls along the frame. But there are some nuances:

- if there is an attic above the garage, then you can cheaply insulate the ceiling with a layer of expanded clay or sawdust;

- be sure to install reliable waterproofing; sheets of roofing felt are suitable, not plastic film;

- in a garage, it is safer to use mineral wool rather than polystyrene foam to insulate the ceiling;

- if insulation is carried out over the sheathing, be sure to make several ventilation holes to prevent fungus and moisture under the sheathing.

As a finishing touch to a foam-insulated ceiling, it is advantageous to use a foam backing under a foil-coated laminate. Safe, reliable and inexpensive. The dragon is mounted with regular glue directly to the foam sheets.

Overview of the thermal insulation materials market

Before moving on to the process of insulating a garage structure, let’s talk about insulation materials. About those that are used today for this purpose. There is a fairly large layer of building materials of this type that builders use today. There are traditional materials here, and others that have appeared recently, but have already gained popularity.

Mineral wool

This insulation has been used in construction for a long time. At the very beginning of its appearance, it was a roll-type material. Today it is still produced in this design, but the modern form of mineral wool is slabs. They are called mineral wool slabs.

It should be noted that a fairly wide range of materials is used as raw material in mineral wool slabs. But basalt-based insulation is very popular. This thermal insulation material is presented on the market in slabs of different densities and thicknesses. This makes it easier to select according to the required characteristics.

Mineral wool boards are a popular insulation material Source 2gis.kz

The only drawback of mineral wool is its hygroscopicity. That is, this material absorbs moisture well, while losing its thermal characteristics. To prevent this from happening, the heat-insulating layer is covered with waterproofing films on both sides. Today, manufacturers offer moisture-resistant mineral wool slabs, in which hygroscopicity is reduced to the maximum. This makes it possible to refuse waterproofing.

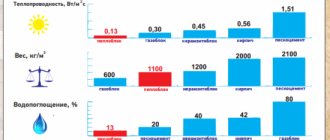

Will not talk about all the technical characteristics of mineral wool. Let us designate the most significant one, according to which you need to choose insulation. This is the thermal conductivity of the material.

On a note! Thermal conductivity is the property of a material or body to transfer heat. The lower this parameter, the better in terms of insulation.

So for mineral wool this characteristic is 0.035-0.04 W/m K.

Expanded polystyrene boards

Many people call this material foam plastic, which is fundamentally wrong, although both materials are included in the group of foamed plastics made from polystyrene. It’s just polystyrene foam – a material originally created for packaging. It has low density and low thermal insulation qualities. The same cannot be said about expanded polystyrene, which was originally developed as a thermal insulation material.

Moisture-resistant polystyrene foam boards Source www.stroyportal.ru

See also: Catalog of popular plots in the Moscow region for the construction of a country house

This foam insulation has serious advantages:

- thermal conductivity – 0.028-0.034 W/m K;

- the extruded version does not absorb moisture ;

- passes air through itself;

- strength – 1 kg/cm²;

- inert to many chemicals;

- mold and fungi do not live on the surface of the insulation

- it is a good sound insulator ;

- service life – 30 years.

But polystyrene foam boards also have their drawbacks. And the most important of them is fire hazard. The insulation burns well and maintains combustion, while emitting acrid smoke. Today, manufacturers are trying to change the situation with this indicator. Fire-resistant boards have already appeared on the market, but there are not many of them.

And one more point that you need to pay attention to when choosing expanded polystyrene as insulation. This is the brand of material. The optimal option for a garage is PSB-S-35 (40) - self-extinguishing, with a density of 40 kg/m³. The thickness of the slabs should not be less than 50 mm.

Expanded polystyrene boards brand PSB-S-35 Source karkasdomproekt.ru

Polyurethane foam

This is a two-component material, the ingredients of which are mixed before application. In terms of its physical state, it is a foamed semi-liquid mass that hardens in air, forming a hydrophobic layer on the insulated surface. That is, not afraid of moisture.

Application of polyurethane foam requires special equipment. It is applied under pressure from a hose with a nozzle. The high adhesive characteristics of the material give it the ability to adhere to any surfaces that are previously cleaned of dirt and rust. In this case, the mixture fills all the cracks, gaps and holes.

This is a non-flammable insulation. Service life – 50 years. Thermal conductivity – 0.019-0.028 W/m K. moisture absorption is minimal – 1.2%.

Layer of applied polyurethane foam Source foamshop.ru

See also: Catalog of companies that specialize in the construction of small architectural forms

Warm plaster

This plaster solution got its name because manufacturers add particles of heat-insulating material to its composition. These can be polystyrene foam granules, so-called crumbs, vermiculite (foamed rock of volcanic origin), sawdust and other ingredients.

In fact, such a plaster mixture has higher thermal insulation characteristics than conventional plaster. But to achieve a good effect, the material must be applied in a sufficiently thick layer. It is used both for insulating the garage from the inside and for thermal insulation from the outside. It is understandable if the garage is built from bricks, blocks or concrete slabs. For a metal structure this option is unacceptable.

Warm plaster is applied to the wall in a thick layer Source tk101.ru

So, we have looked at the main thermal insulation materials that are most often used today when insulating a garage building. Of course, this is not the entire list of proposed options. They just use these more often.

Most often, many consumers are looking for how to insulate a garage from the inside inexpensively. The table provides a comparison of prices for the described insulation materials.

| Insulation | Mineral wool boards | Expanded polystyrene boards | Polyurethane foam | Warm plaster |

| Price | 13-20 rub. for 1 m² | 15-50 rub. for 1 m² | 1200-1500 rub. for 1 m² | 350-750 rub. for 1 m² |

The price range for each material is quite wide. This is explained by the fact that the basis for pricing is the thickness of the insulation and its density. The table shows that the most inexpensive option is mineral wool and polystyrene foam boards.

The most economical thermal insulation materials Source krysha-expert.ru

What to consider

Before we talk about how you can cheaply insulate your own garage with your own hands, you need to note several important nuances.

When a garage is built, materials such as brick, cinder blocks, or metal structures are mainly used. Walls made of cinder blocks and bricks usually vary in thickness from 120 to 250 mm. They provide virtually no protection from the cold. That's why we insulate the garage.

And you already know enough about insulating an iron garage. Therefore, I will not repeat myself.

Before insulating the garage from the inside, many actively seal the holes. In fact, this will not have much effect on the thermal insulation. But it can lead to other problems. If you close all the cracks, the air circulation inside will be disrupted. This will promote the appearance of condensation, which will ultimately lead to the formation of rust on the car.

Ventilation is also needed to prevent harmful and dangerous gases from accumulating inside the box.

Insulation technologies

Having dealt with the question of how to insulate a garage, we move directly to the process itself. Let's start with external insulation. The simplest option is plastering. Everything is quite simple here. Warm plaster is applied to the external surfaces of the garage walls using standard technology. That is, they throw it onto the surface with a trowel and level it with the rule according to the installed beacons.

There is an option for mechanized plaster. To do this, special stations are used in which the plaster mixture is prepared and then immediately applied to the walls under pressure. In this way, insulation can also be carried out from the inside of the room.

What types of insulation are suitable for a garage?

Everyone's garage is different - some are metal, others are brick and block. You can insulate a garage with any type of heat insulator. More often, expanded polystyrene (foam) and extruded polystyrene foam (penoplex) are used for insulation.

Foam plastic and penoplex are materials that have two important advantages: they cut off the cold well and are not hygroscopic. Using them as insulation inside the garage will create a reliable separating barrier between cold and heat. The temperature inside is maintained above zero, and moisture does not condense on the cold walls because the insulation does not get wet.

If you use breathable mineral wool for insulation, then wet vapors pass through it without hindrance. Condensation forms on the walls, and the insulation gets wet and loses its thermal insulation properties. To avoid this, mineral wool is protected with vapor barrier and waterproofing films - their purchase means additional costs.

Video description

In order not to go into details of the technological process, we suggest watching a video that explains how to properly apply warm plaster to walls in two ways:

Expanded polystyrene boards for external insulation

If the garage is built from bricks or blocks, then polystyrene foam boards can simply be attached to the wall surfaces, laying them tightly together. There are two mounting methods:

- on mushroom-shaped screws or, more precisely, on dowel-nails for insulating materials;

- on the adhesive composition.

Usually the first one is used, because glue for polystyrene foam is an expensive thing. It is sold in cans. The contents are applied to the back of the slab in the corners and in the middle. And then they just press him to the wall.

As for self-tapping screws, these are special plastic fasteners consisting of two parts: a dowel and a nail. Under the first one, a hole is made through the insulation in the wall into which the dowel is inserted. At the same time, its wide cap will hold the insulating board. After which the second part is hammered into it, which bursts open the first.

Dowel nail for insulation boards Source de.decorexpro.com

Typically, two fasteners are used for each slab. When laying thermal insulation, it is very important to ensure that there are no gaps or cracks between its elements. It is optimal to use slabs with a tongue-and-groove connection for this purpose. If ordinary slabs with smooth edges are used, then when gaps form between them, the latter are filled with special foam. It is similar to the assembly one, only it does not expand in volume when exposed to air.

How polystyrene foam boards are attached to the wall with mushroom-shaped nails Source stroyfora.ru

Conclusion

Of course, looking at various photos of a high-quality insulated garage, everyone wants to reproduce such a decent finish in their own home. And this is quite real, there is nothing complicated about it.

Any “straight-handed” person is able to do everything himself without much expense or effort. It won’t take too much time, but there will be a huge amount of benefits. The car will be protected from the influence of an aggressive external environment, and its owner will be able to comfortably carry out car repairs during the cold season.

Sources

- https://garazhov.ru/inside/uteplenie-garazha-penoplastom.html

- https://pechiexpert.ru/uteplenie-garazha-penoplastom-01/

- https://www.tproekt.com/kak-uteplit-garazh-iznutri/

- https://www.plast.by/novosti/utepleniye-garazha.html

- https://garazhmechti.ru/kommunikacii/kak-uteplit-garazh-iznutri-deshevo.html

- https://mirstrojka.ru/uteplenie-garazha/

- https://uteplenieplus.ru/kak-uteplit/garazh/kirpichniy-garazh-iznutri/

- https://bibiauto.club/sovets/poleznoe/uteplenie-garazha-iznutri.html

- https://garazhmechty.ru/kak-pravilno-uteplit-garazh.html

- https://www.ivd.ru/dizajn-i-dekor/zagorodnyj-dom/vse-o-samostoyatelnom-uteplenii-garazha-iznutri-56901

[collapse]

Insulation of the floor and ceiling in the garage

The floor is easiest. This is a thick concrete screed, under which you just need to lay insulation. Expanded clay is most often used for this. They do it like this:

- At the site where the garage is installed, a pit is dug up to 50 cm deep.

- Crushed stone is poured into it in a layer of 15 cm.

- Then sand in a layer of 15 cm with compaction.

- Cover with roofing felt in two perpendicular layers.

- Expanded clay is poured.

- Another waterproofing layer .

- A reinforcing grid of steel reinforcement is laid.

- Pouring concrete.

You don’t have to fill in expanded clay, but use expanded clay concrete mortar instead of concrete. Instead of expanded clay, you can fill in perlite or lay polystyrene foam boards.

Layers of insulated garage floor Source mirstrojka.ru

As for the insulation of the ceiling, everything will depend on what this building element of the garage structure is.

- If it is a concrete floor slab , then it is better to assemble a suspended structure into which insulation is placed. You can use warm plaster.

- If it is a metal roof , then it is optimal to treat it with polyurethane foam.

- Since the roof of a metal garage is assembled, like the walls, in the form of a frame sheathed on the outside with iron, slab insulation . The technology is the same as on the walls.

Required Tools

Each stage of garage insulation work requires its own set of tools. The list also depends on the selected material, but mainly the changes will affect cutting devices. For example, mineral wool can be cut well with a construction knife, but polystyrene foam is easier to handle with a homemade “hacksaw” made of steel wire on wooden handles. You can, of course, use a jigsaw, but in this case the sheets will crumble a lot, so you will have to work slowly. The rest of the set of tools is standard.

To prepare surfaces:

- a hard synthetic brush (in some cases - a hand brush or a cord brush for an angle grinder);

- grinder - to remove protruding reinforcement and large protrusions of the main surface;

- narrow spatulas for sealing cracks.

To attach the insulation:

- drill/screwdriver;

- construction stapler;

- notched trowel or mounting gun for adhesives.

In the case when the insulation layer is laid in the sheathing, do not forget to select a tool for making the frame: a jigsaw for a wooden beam, a hacksaw, an angle grinder or scissors for a metal profile.

Warming paint

Insulating paint is a modern innovative heat insulator that forms a protective layer with a low heat transfer coefficient. Heat-saving paint is based on acrylic components and synthetic polymers. The consistency of this paint resembles regular paint, but the applied layer of 1 mm is equivalent to 5 centimeters of another heat insulator.

The cost of covering with heat-insulating paint is far from budget: from 300 rubles per 1 sq.m. surfaces.

Advantages of the material:

- Can be applied to any type of surface.

- The paint has an anti-corrosion and anti-fungal effect.

- Allows all possible application options - roller, brush, spray gun.

Flaws:

- Requires careful surface treatment - sanding, degreasing, etc.

- Application at sub-zero temperatures is unacceptable.

"Warm" plaster

Installation diagram of insulation boards.

A modern method of thermal insulation. Used as external insulation. Suitable for buildings whose walls are made of blocks or bricks. Externally, such plaster is similar to ordinary plaster, but the composition is different.

The insulation contains fillers with low thermal conductivity: sawdust, expanded polystyrene, vermiculite, pumice and expanded clay. Among all the additives in the top are polystyrene foam granules. This option is universal - used both outside and inside.

“Warm” plaster has many advantages:

- simplicity (does not require preliminary preparation and leveling of walls);

- ease of operation;

- exclusion of reinforcing mesh.

The only requirement is good ventilation so that the plaster dries quickly.

The thickness of the layer when applied should not exceed 5 cm, otherwise the material will peel off and crack.

The method will be especially effective if combined with additional types of insulation.

Reflective Thermal Insulation

Reflective thermal insulation is polyurethane foam with a thickness of 3 to 10 mm, with a glued heat-reflecting element, which is ordinary foil. The material is glued so that the side with the foil faces inside the room. Installation is carried out using a furniture stapler or special glue. The cost of the material starts from 35 rubles per square meter.

Advantages of reflective thermal insulation:

- Compliance with all environmental standards and requirements. It does not emit harmful elements. Low flammability.

- Easy to install due to low weight.

- Ease of transportation (material is supplied in rolls).

Flaws:

- Softness. Does not allow finishing of the room (for example, plastering work) on top of the laid material.

- Possibility of deformation and damage to the material during installation, because it tears and cuts easily.

- The heat-saving properties are reduced if the material is nailed to the surface.

- The greatest effect of reflective thermal insulation is achieved when used with other insulation methods.