Lightweight but durable plastic plumbing fixtures have greatly simplified the installation of many appliances. In particular, the corrugation for the toilet allows you to connect the outlet of this type of plumbing to the sewer outlet much faster and without much difficulty.

Do you want to install the corrugation yourself? We will tell you how to do this - the article discusses the procedure for installing corrugations and options for connecting toilets with different types of outlet. Installation tips and recommendations for choosing the best corrugation are also provided.

Thanks to a detailed analysis of important nuances, the connection procedure is quite accessible even to a non-professional.

Types of corrugations and tips for choosing

Corrugation belongs to the class of drainage fittings. This is a durable stretchable adapter made of polymer materials and shaped like an accordion. Its properties remain unchanged even when it is heated and stretched.

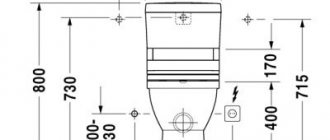

The corrugated pipe has the shape of a sleeve with a plastic cuff that has a rubber seal inside. With its help, toilets with different types of flush - oblique and horizontal - are connected to the sewer system.

Its dimensions range from 21.2 to 50 cm. The end of the pipe with the outlet has a cross-section of 11 cm, and the one connected to the outlet has a cross-section of 7.5 cm inside and 13.4 on the outer surface.

Types of corrugated pipe

Corrugations available for sale are unreinforced or soft, reinforced with walls reinforced with stainless wire, and rigid. The first ones are relatively cheap and do not have very high strength characteristics.

This property of flexibility is very important. It allows you to reliably connect the toilet to the sewerage pipe, even if it is located on a different level

Soft corrugation fits any structure and is easier to install. The bad thing is that after a few years of operation, difficulties with draining may arise due to sagging of the corrugated adapter.

Reinforced pipe has much higher characteristics, it is more reliable and durable, but also more expensive. These corrugated pipes have a rigid pipe with a turn, and its continuation is the corrugation. They are indispensable when you need to connect a toilet with an oblique outlet to the drain.

Detailed information about the types of toilets and types of release is discussed in our other article.

Reinforced corrugation is suitable for hidden connections. Her sizes are different. When selecting a suitable connector, you need to proceed from the dimensions of the toilet outlet and sewer pipe

Corrugations are also divided according to such criteria as length - they come in short and long. The length of the folded short corrugation is 21.2 cm, and if stretched it is 32 cm. The compressed long corrugation has a length of 28.5 cm, and it can be stretched up to 0.5 m.

Do not pull the connector end to end - this may lead to leaks. When choosing a corrugation, you need to look at the density of the material, the condition of the seals, and the uniformity of the cuff.

Which corrugation is more suitable - short or long - is decided based on the location of the plumbing fixtures relative to the sewer pipes

The corrugations and direction of the bell differ. It can be straight or curved at either 45⁰ or 90⁰.

When is corrugation used?

The use of corrugation is justified in 3 cases:

- When the bowl and bell have different types of outlet. This happens often because... The design characteristics of toilets are different. Not all types of these plumbing fixtures can be connected in a standard way, and then the corrugated pipe can act as an adapter.

- The toilet is offset in relation to the sewer pipe. This situation is possible when tiles are laid on the floor or when the location of the toilet is changed. It will not be possible to connect mismatched elements with any other pipes, and only the use of corrugation can easily solve the problem.

- As a temporary option for connecting a toilet.

Using corrugation provides many advantages, but this method is not without its disadvantages. The plastic walls are thin and if something sharp accidentally gets into the pipe, they will be damaged. Dangerous for corrugations and boiling water. All this reduces the service life of the plastic connector. If the corrugation is stretched and not fixed, it will sag.

Image gallery

Photo from

Corrugated sewer drain Orio C-990

Corrugated pipe socket

Corrugated drain outlet

Length of the pipe in compressed and extended form

Features of choosing corrugations

When buying corrugation for connecting a toilet, you need to choose the highest quality one. This will reduce the possibility of leaks to zero and will make the product last longer. The difference in prices is small, so it’s better to pay a little extra and save yourself from unnecessary problems in the form of pipe contents on the floor.

Any comparisons between domestic and foreign corrugations are not in favor of the first. Our corrugation does not cover the pipe walls well. No tricks help - the domestic corrugation does not completely adhere to the inner surface of the sewer pipe.

Often a corrugated pipe forms waves, which causes a leak. Even professional installation will not help you avoid such troubles.

The technology for installing corrugation on a toilet is simple and does not require much effort. It is important to choose the appropriate size of flexible hose, focusing on the cross-sectional size of the riser

The best corrugated producing countries are Italy, the Czech Republic, and England. Having visited the market, you will notice that most of the products are supplied from China. Don’t be tempted by their cheapness; they won’t last long and what seems like savings will turn into additional costs.

When choosing a corrugated sleeve, you should look at the thickness of its walls. If the other characteristics are equivalent, then you should buy the one with thicker walls. It’s bad that this information is not always indicated in the description attached to the product.

Some corrugated pipes are designed to attach an elastic band together with a plastic ring. There are models that provide a direct connection - the elastic is inserted into the end and fixed to the herringbone. The second option is more reliable.

Briefly about the main thing

Watering hoses are made from various polymer compounds, which explains their elasticity, water resistance and restrictions on use regarding temperature changes.

To connect circuits, the simplest element is considered to be a fitting.

An adapter with one or two pipes of one diameter or another is inserted into the hose and clamped from the outside with a clamp.

Couplings for quick and repeated connection or disconnection of circuits are characterized by greater reliability.

There are three types of couplings: simple, repair and with aquastop function.

Ratings 0

Some useful installation tips

Despite all its advantages, plastic corrugation is not designed for heavy loads, so it cannot be mounted inside a wall. If the distance from the wall to the plumbing fixture is large, you should carefully select the length of the connector.

The corrugation stretches, but if this property is abused, the walls may become thinner and the strength of the structure will decrease. There is no need to stretch the corrugation before installing it - this will lead to sagging of the outlet.

Stretch it immediately before connecting to the sewer pipe. To avoid blockages, there is no need to allow sagging or counter-slope of the corrugation. When the sewer pipe and the outlet of the plumbing fixture are located relatively high, a support is built under the connector.

If the corrugation sag, a “pocket” will appear in it where deposits will accumulate. This may cause the connector walls to rupture. Stands or auxiliary clamps will help prevent this consequence.

When you decide to install a protective screen to mask communications, and use the fenced-off space as a place to store various small items, do not forget that a heavy object can damage the corrugation.

Before installing the plastic corrugation on the toilet, take into account that the product of standard sizes does not allow it to be installed flush against the wall. Here it is better to use an eccentric.

We must not forget about plumbing standards when choosing a slope. Do not turn the reinforced pipe at a right angle. If the device occupies a non-standard position, an offset connecting element is used.

Before you start work, you should make sure that the corrugation fits the parameters. You also need to check it for cracks. If, along with the corrugated pipe, it is also planned to replace the toilet, then it is put on before installing the plumbing

The corrugation can compensate for quite a significant displacement. Thanks to it, the device can be moved by a maximum of 200 mm. It can also be rotated to any angle you like. To do this, use an option such as a serial connection of two corrugated pipes.

You need to pay special attention to the angle at which the corrugation is bent. If the pressure is too high, draining cannot be carried out effectively. In addition to everything, the corrugation may crack at the point of pinching.

What materials?

Corrugation for cables and electrical wires is made of plastic and metal. Different materials are used, with different characteristics. They must be selected based on the tasks they must perform.

- Polypropylene (PPR). The color of this corrugation is usually blue, the material is self-extinguishing and does not support combustion. It is characterized by increased water resistance and can be used for laying cables outdoors or in rooms with high humidity.

- PVC (polyvinyl chloride). The color is gray pipes, self-extinguishing. PVC corrugation is not waterproof and can only be used in dry rooms.

Black cable corrugation is most often made of HDPE, but it can also be made of polypropylene (PPR) - HDPE (low density polyethylene). Color - orange, black, the material is flammable, but resistant to chemical influences and water. Area of application: laying in screeds and grooves in non-combustible walls, open laying on the street.

- Metal (stainless or galvanized steel). Non-flammable material, resistant to mechanical and chemical influences. Recommended for electrical wiring in flammable buildings (wooden, frame). Also good for outdoor installations.

If we talk about compliance with fire safety standards when installing gaskets in flammable walls, the ideal option is a metal pipe. It saves you from loads that may arise when the size of the building changes. Rodents cannot cope with it either. This is also the best option from a fire safety point of view: even if short-circuit currents occur and the circuit breaker does not operate, the probability of burning through a pipe with a wall thickness of 2 mm is very small. This means the fire will not start. If laying electrical cables in pipes does not appeal to you at all, then you can use metal cable ducts or corrugated stainless steel or galvanized steel.

Connection without corrugation

If the shapes of the outlet of the toilet bowl and the sewer pipe coincide, you can do without corrugation. When connecting a toilet without using corrugations, certain rules are followed. In this case, an adapter is used, which is also called a fan pipe or pipe.

The installation method is chosen depending on the shape of the toilet outlet: in the case of an oblique outlet, installation is carried out on the floor; in the case of a vertical outlet, the toilet is mounted in the wall at an angle of 90⁰; in the case of a horizontal outlet, the toilet is also installed in the wall, but at an angle of 30 to 40⁰.

Option #1 - vertical toilet outlet

The model of this toilet is equipped with a siphon with an outlet pipe. First, a place is marked for this structure, then a flange with a lock is installed.

The sewer pipe is mounted in its center and a plumbing fixture is installed. The toilet is turned until it is completely fixed. The pipe takes its place automatically.

This scheme is good because the wiring becomes invisible because pipes are hidden in the floor. This saves space. The downside is that to eliminate a leak, you will have to crack the floor covering.

A toilet designed with a vertical flush is aesthetically pleasing and looks neat in the interior. Yes, and it’s easier to clean around it

Option #2 - horizontal type of release

This release is directed back towards the wall. Here you cannot do without a sealing cuff. First, the toilet is fixed to the floor with dowels. We recommend looking at the best methods for attaching a toilet to the floor here.

Next, make the connection very carefully.

First, the sealing cuff is installed without sealant, then tested by pressing on the drain. If there are no leaks anywhere, the final installation is done.

Not every apartment can install a toilet of this design. The use of the diagram is possible only if there is a vertical sewer riser

Option #3 - oblique toilet outlet

To connect using a plastic pipe, mix red lead with drying oil and coat the toilet outlet with this. A seal is made on top in the form of a strand of resin. The seal is coated with red lead. The outlet is inserted into the sewer pipe and the toilet is installed.

A sealing collar can also be used here. Having dressed it for release, the latter is placed in the sewer socket. Be sure to seal the connection.

Toilet models with an oblique outlet are quite in demand among buyers. One of the significant advantages of this design is the ease of replacing the cuff if necessary.

Selection principles

It’s worth saying right away that permanent connections are used only when the line is long, as well as when there are increased requirements for the strength of the protective shell. Therefore, you should think about purchasing expensive polymer glue, and especially a welding machine, only in such cases.

If you only have to make 1-2 connections along the entire length of the cable line, which will be constantly visible, it is better to use the “socket” method. Detachable fastening methods based on a coupling and flange are used in cases where the cable line is laid through rooms or areas with particularly aggressive environmental conditions. They represent a compromise between strength and ease of maintenance of the pipeline.

What is it for?

Corrugated pipe provides protection and extends the life of electrical wiring.

Electrical cable and wires are laid in corrugation:

- for fire protection in case of fire of flammable walls made of wood or frame, lining or ceilings;

- for laying, for finishing materials: lining, drywall, PVC board, to ensure the safety of residents. When making repairs, owners drill or break through walls, which means they can damage products and suffer from electricity;

- under the floor to protect electrical wiring from the compressive effect of concrete poured into the base of the floor;

- under the floor so that the wires can be replaced if they become damaged or become outdated;

- for protection from external climatic and mechanical influences when installed outdoors.

For external installation, only durable shells are used that protect from moisture, sand, wind, snow and physical influences. On the street, corrugation is exposed to temperature, so its surface must be hard and resistant.

No matter how strong the corrugation is, it will not be able to stop the impact of the hammer drill if the user exerts sufficient physical force. The calculation is made for the timely stop of the drill if it fails during operation. You can warn the person who may be doing the repairs using photographs or a drawing.

For external installation, only durable shells are used that protect from moisture, sand, wind, snow and physical influences.

What else should you pay attention to?

If all installation operations are carried out carefully, then there will be no problems with the subsequent operation of the plumbing equipment. However, it is worth paying attention to a number of points.

A corrugated sleeve will last a long time if its length is chosen correctly. The product must not be installed in a fully extended or excessively compressed state, nor should it be allowed to bend sharply at turns. In the latter case, when space for the adapter is limited, a toilet eccentric can often be used instead.

The sleeve should not sag, otherwise a pocket will form in which deposits will begin to accumulate. This can lead to blockages in the drain or rapid rupture of its plastic walls. To avoid such consequences, you need to use auxiliary support clamps, stands, etc.- The corrugated plumbing adapter is a product intended for external installation only. It is not allowed to be walled up in the structure. This should be remembered, as well as the fact that sooner or later it will have to be changed, therefore, it is important to provide for the possibility of access to it.

Finally, it is worth recalling once again that when deciding how to choose a corrugated hose for connecting a toilet, you should initially consider the possibility of using any other rigid analogues from corners, swivel connectors or eccentrics. The strength of flexible adapters is quite limited, so the product can be damaged not only by hard sharp objects, but also gradually destroyed by natural wear and tear due to thinning of the walls.

Related posts:

Why do you need a vent pipe?

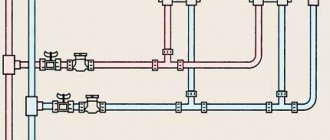

Water supply collector: what is it, how to choose and install it correctly?

- How to install a toilet: practical advice on installation and setup

DIY instructions for connecting hoses

To connect products with your own hands, you will need a certain set of tools, as mentioned earlier. In most cases, you can do without a workbench, but it is much more convenient and faster. For plastic nuts you will need a gas wrench and fum tape. For polypropylene, special pipe cutters are required.

The hose is connected to the water source. This could be, for example, a collector. The ¾ hose is attached with a clamp directly to a section of pipe welded to the manifold. There is no need to install an extra valve so as not to increase the weight of the structure. The second end of the hose can be led to a steel pipe about 20 m across the site (it can be replaced with propylene, but taking into account the protection of pipes from rodents, it turns out to be very expensive). A tee-splitter with 2 mini-valves is put on the end of the pipe. It is connected to it on one side via a ¾ connector and an adapter. The second valve is a backup valve.

Varieties

Corrugations have several varieties:

- Plastic. A budget option. There are many models of this type. But the general characteristic is the least air resistance that is created inside the pipe. It is easy to clean and works quite quietly. ATTENTION! It is worth remembering about the fragility and possible harm to human health, since a large amount of smoke is released during fire. In addition, the cheapest devices can emit an unpleasant odor. Installation is difficult. Afraid of high temperatures.

- Aluminum. Not particularly heavy, high chance of long-term performance, high temperature tolerance. However, during operation it can produce specific sounds and increased vibration. There are inconveniences during cleaning.

- Insulated. Its peculiarity is the presence of a layer of foil with mineral wool. This type can be installed on any hood.

- Other. All of the listed disadvantages of previous models are absent (smell, noise, flammability, service life) + is durable. But this type is not cheap. Not everyone can afford them.

What are the diameters of corrugations for hoods?

There are the most popular corrugations, the values are 100 mm, 125 mm and 150 mm (for a kitchen hood). In industrial applications it can reach 200 mm, 250 mm, 300 mm. The choice depends directly on the power of the device. The diameter of the hood itself should be taken into account accordingly; they must match. If you want a large diameter, then you should also find an adapter to connect it to the neck. The dimensions of the corrugation for the hood have several classic parameters. You can always find the minimum value in the kitchen hood instructions. The most commonly used are 100 mm and 120 mm. If you still cannot find the size, then use a larger one; this is especially good for the kitchen: the noise will decrease due to the low flow rate. With a reduced diameter, air will be pushed through, experiencing difficulties.

Air duct maintenance

When removing polluted air from the kitchen area, the air duct collects some of its contents on its walls. Fat and soot accumulate in the folds of the corrugation. Outside, the pipe is exposed to the same factors as all kitchen surfaces - evaporation, splashes, dust.

A smart solution is to regularly remove the hood and wash it with products you normally use to clean your kitchen, taking into account the type of pipe material.

Each time the air duct is completely dismantled and then reinstalled. In the process of removing and cleaning the corrugation, it is easy to damage it, break the seal, and leave dents. It is also unlikely that it will be possible to install it back the same way it was.

Many owners of flow hoods refuse to wash the inside of the air duct pipe, limiting themselves to wet cleaning from the outside. The outer surface is carefully wiped with water or a detergent approved for this type of coating.

Internal accumulations of dirt can become a serious obstacle to the operation of the device only towards the end of the corrugation service life declared by the manufacturer, on average after 8-10 years. After this time, the air duct pipe is dismantled and replaced with a new one.

Note ! If dirty streaks appear at the joints and joints of pipes, this indicates the need to replace the corrugation.

Product Standards

The technical conditions for the production of PVC corrugation regulate:

- Electrical - GOST 32126.1-2013; GOST 50827-95 (IEC 670-89); EN 61386-1; EN 61386-22; TU2247-008-47022248-2002.

- Sewage and water supply - GOST R 54475-2011 and TU 2248-001—96467180-2008.

Dimensions

PVC corrugation with (and without probe) for electrical work is available in the following sizes:

| Outer diameter, mm | Inner diameter, mm | Quantity per bay, m |

| 16 | 10,7 | 100 |

| 20 | 14,1 | 100 |

| 25 | 18,3 | 50 |

| 32 | 24,3 | 25 |

| 40 | 31,2 | 15 |

| 50 | 39,6 | 15 |

| 63 | 50,6 | 15 |

A more rigid corrugated pipe, used for the installation of sewer and drainage systems, is produced in lengths of 2, 3, 6 and 12 m in the following diameter range:

- External - from 110 to 1135 mm.

- Internal - from 93 to 1000 mm.

About connecting watering hoses

Published date 08/04/2011

Last modified date 01/17/2019

Perhaps I will tell you obvious things that have long been known to everyone, but for me personally it was a pleasant discovery. It turns out there is a technology that makes it easier to work with watering hoses in the country. Previously, when necessary, we simply pulled a 3/4″ rubber hose onto a 1/2″ bend and used it. Yes, sometimes the water leaked out, sometimes the hose was thrown off, but we didn’t know any other way. The hose was spliced with a 1/2″ barrel. Long-term connections were tightened with a clamp.

But while walking around OBI, I noticed interesting gizmos, namely hose connectors. They allow you to quickly connect hoses, connect various devices in one movement, and just as quickly disassemble everything back. Moreover, on one shelf there were branded gardena connectors with a wild price of about 230 rubles per piece. And next to it, which is not typical for OBI, are inexpensive and high-quality (!) Chinese plastic GardenCraft connectors. At a very reasonable price of 15-30 rubles per connector element.

Hose attachments are available for hoses of different diameters. There is a bushing (in the middle) to connect the hoses to each other. There are different devices for mounting on a faucet, but in my case a simple 1/2″ plastic fitting is sufficient.

To attach it to the hose, simply cut it straight, put on the connector and tighten the nut by hand, it will evenly crimp the hose. There are options for a connector with a valve (“aquastop”), which will prevent water from flowing out of the free end of the hose if no nozzle is inserted into it. But the price for the valve will be an even greater narrowing of the lumen to the flow of water.

Two hoses are joined through an insert:

The connectors are put on the fitting with a click and fixed on it. To remove the connector, you need to pull off the orange ring.

A huge number of attachments are available - sprinklers, mechanical watering time relays, watering cans, nozzles, tees, valves.

The bright color allows you to quickly find the end of the hose in the grass. The strength is sufficient not to break if accidentally stepped on. Let's see how they survive the winter.

Everything comes together and disassembles very quickly:

The rubber ring prevents the connection from leaking. Over time, as it wears, of course water will ooze out a little, but not significantly.

UPD. Chinese connectors work well at pressures of 1-1.5 atm. at high pressures they begin to ooze. To connect the pressure washer to the water supply at work, we bought hozelock connectors with a metal fitting. Pressure 8 atm. withstands without leakage

Do-it-yourself methods for connecting hoses

If you do not want to buy modern plastic devices for connecting products, you can use one of the proven traditional methods: through an inexpensive adapter, through a piece of pipe and through a fitting (if the hose is connected to a pipe).

Today, hose fittings for any pipe and any hose are available for sale, and they are quite cheap.

For polypropylene pipes, you can use similar solutions with external threads, screwing them into the fitting. The only point that you need to pay attention to is the thickness and length of the fitting. You can grab the hose using a special clamp, or you can use a wire twist. There is absolutely no difference in the quality of the connection, but the cost is reduced several times when compared with factory-made plastic connectors.

It’s a common thing when there are many different hoses lying around in a garden plot or vegetable garden. Pieces of products can be connected using a piece of pipe of a suitable size and used on the farm. This is done very simply: hoses are put on a length of about 10 cm on both sides and grabbed, as mentioned earlier, with wire or clamps.

Drain hose connection diagram.

The adapter-connector, like the pipe mentioned in the previous example, connects both pieces of the hose, only it has special notches at the ends that make the process of joining the hose easier and more convenient if the diameters of the connections do not quite fit each other.

You can make your own hose connector from a coupling and polypropylene pieces. When assembled, such a homemade connector looks quite good and holds the hoses at ¾ length. A tee for connecting hoses can be made in a similar way. The closest store-bought analogue is a coupling (products are clamped using a union nut and petals on both sides).

For a high-quality and reliable connection of hoses, prepare the necessary tools and materials, namely:

- pipe cutters;

- Workbench;

- couplings;

- adapters;

- nuts;

- clamps;

- wire;

- spanners.

Specifications

Technical parameters of PVC corrugated pipe:

- The material used is a self-extinguishing polymer composition.

- Outer diameter size (d) - 16-100 mm.

- Weight is light.

- The length of the pipe in the coil is 15, 20, 25, 50 or 100 m.

- Color - gray, blue, yellow, red-brown, black.

- Dielectric strength level - 2000 V.

- Heat and fire resistance - 650 ºС.

- The optimal temperature range for installation work is from -5 to +60 degrees.

- The permissible operating temperature range is from -20 to +60 ºС.

- Impact resistance index (unit) - >0.5 at -25 ºС.

- Service life - at least 50 years.