Just as no apartment or house is complete without windows, windows are nowhere without window sills, the exception being floor-to-ceiling panoramic glazing, when part of the wall is replaced with double-glazed windows. In all other cases, a window sill is a mandatory window unit, a decorative element, and free space that can be used in various ways. Today, this interior element is made from various materials, and the white classic is generously diluted with bright shades, and the shape is not always a rectangle.

What wood is best to make a window sill from?

You can make a window sill from any type of wood, the main thing is to decide for what purpose and where this interior detail will be installed. Hard wood, such as oak, is resistant to moisture and temperature changes and has a long service life, but the cost of such a product will cost a pretty penny. This material is suitable for window sills that will be used as a work area or a stand for heavy flower pots.

A budget option would be pine or spruce. Window sills made from these species are easy to install and do not require antiseptic treatment due to their increased resin content. You can install a larch board. It is not as expensive as oak, but has the properties of coniferous trees. The shade of a larch window sill turns out to be more noble, which determines its demand among buyers. There are several criteria for choosing wood for installing a wooden window sill with your own hands:

- integrity of the board. There should be no defects (chips, cracks, knots, etc.) at its ends, as well as inside the wood structure itself;

- The type of wood must be strong. It is better to choose oak, beech, hornbeam. Less strong are larch, pine, chestnut, cedar, but they have a beautiful pattern;

- texture and color of the board. There are so many species, so many shades and patterns of wood you can find. The choice depends on individual preferences and interior design.

Wooden oak window sill

In addition to solid wood, laminated wood, chipboard and MDF are used. Unlike solid wood, laminated boards do not deform from moisture, are much cheaper, but look no worse. If you want to save even more, it is better to give preference to MDF or laminated chipboard. The raw material is pressed wood chips covered with a laminate on top. The material is also good because it has many options for textures and shades. With its help, you can give the window sill the look of marble, stone, with a matte or glossy surface.

If you approach the choice of material for the window sill with all responsibility, then in addition to the functional element, you can get a real decoration for the room. There are ready-made products on sale, or you can try and make them, and then install wooden window sills yourself.

Requirements

Their main types vary from wide ones, used for flowers, to narrow ones - only for window decoration. They can be with or without a launch behind the wall, rectangular or specially shaped to order.

Wooden window sills for PVC windows must meet certain requirements :

By size: narrow - up to 10 cm, wide - 100 cm, in increments of 10 mm; with a length from 0.9 to 3 m in increments of 100 mm; thickness from 30 to 50 mm.- By type of wood: coniferous species, tropical species, oak and ash above grade II and any tree resistant to biological damage.

- Resistant to temperature changes.

- Moisture resistance, with humidity levels less than 10%.

- The wood material must be uniform; there should be no chips, cracks or dents on the wood.

- Preliminary antiseptic and fire protection treatment must be carried out, as well as thermal modification of wood to increase the service life.

Necessary tools and materials for installing a wooden window sill

Before installing a wooden window sill, preparatory measures should be carried out. First of all, you need to prepare the tools and materials:

- window sill board (finished or made yourself);

- building level;

- square and ruler;

- measuring tape;

- polyurethane foam and a gun for it;

- marker;

- solution container;

- brushes and rollers;

- pegs or bars to regulate the installation of the window sill.

To install a wooden window sill you will need a level.

Check that you have all the accessories so that you don’t have to look for them during the work process.

Types of finishes for work

A variety of materials allows you to independently finish slopes in several ways:

- plastic panels;

- gypsum fiber or drywall;

- tree;

- MDF;

- sandwich panel;

- plaster.

Preparing walls before installation

Installation of wooden window sills begins with preparation. The surface on which the window sill board will be laid requires special attention. Surely, after installing the window structure, there was excess cement, dust, and other construction debris left behind. The surface must be thoroughly cleaned from them. The side parts are tapped. This is necessary to ensure that the board is firmly fixed in the wall. For better retention, it is better to “recess” the window sill into the slopes to a depth of 1-2 cm. If metal corners are encountered when making recesses, they must be carefully cut with a grinder and removed with a chisel.

Primer and water are applied to the cleaned wall. If there is a recess under the base in which communications pass, then horizontal supports made of metal or wood are placed on top of it to hold the window sill.

Window sill leveling

According to the construction rules, 2/3 of the window sill plane is located on a hard surface, and the rest is left in the form of a canopy. The maximum protrusion beyond the wall should not exceed 7-8 cm. If this point is violated, then subsequently the heat exchange in the house will be disrupted, and condensation will form on the glass.

Most houses cannot boast of perfectly straight walls. The base for the window sill is no exception. The surface is leveled and checked using a level. If there are even small errors and distortions, they are eliminated using wedges. The window sill may not be installed perfectly level. The standards allow a slight tilt, just a few millimeters, of the boards forward. After the window sill board is placed on the wedges, the angle of inclination is checked again with a level. It should be the same over the entire area. After this, the board is removed and the wedges are fixed to the surface using cement mortar.

Benefits of cladding

Most contractors who finish window sills with tiles highlight the following advantages:

- Visual. The apartment owner can choose tiles that suit the interior design of the room. The uniqueness of the work depends only on the imagination of the customer.

- Physical characteristics. By decorating the area near the window with ceramics, the apartment owner can avoid frequent cleaning. The tile is not so susceptible to dirt and dust and is easy to clean. In addition, it is able to withstand greater physical stress than conventional plastic.

- Duration of operation. Ceramic tiles benefit significantly when it comes to durability. In addition to the service life, the strength of the entire structure increases several times.

In short, in almost every component, ceramic or tile will be better for the home. If renovations in the house are being done “for yourself,” then it is recommended to opt for higher quality materials.

Window sill fastening

Before installing a wooden window sill, you need to treat its surface, especially at the point of contact with the wall, with a moisture-proof compound. This will prevent its premature deterioration and rotting. A cement mortar of such thickness is applied to the base that it rises 5-8 mm above the level of the wedges. In addition to cement, you can use putty or gypsum, but traditional mortar will hold the structure more firmly. The window sill is laid on cement and pressed against wedges. Excess mortar that appears is removed with a spatula, but before it sets. If there is any doubt about the quality of the window sill impregnation with a moisture-repellent agent, a plastic film is laid between the solution and the window sill.

Installation of a wooden window sill in combination with plastic windows

You can install a wooden window sill not only if the window structure is also made of wood, but also in combination with plastic. The market offers a large selection of shades and with the right approach to choosing a color, a wooden window sill board will harmoniously combine with a plastic window. In addition, a wooden element will add zest to faceless plastic and create individuality in the room.

Preparing the foundation

Alignment

The quality of installation will depend not only on the window sill itself, but also on how well the base is prepared:

- The entire area of future installation is thoroughly cleaned.

- Measurements are being taken. The distance from the plane to the bottom edge of the window is taken into account and compared with the height of the product itself.

- If the run-up is more than 5 cm, then you should not think that the foam will be able to compensate for everything. The best thickness for its polymerization is considered to be a layer of 4 cm. In this case, you need to reduce this distance. To do this, you can do a small fill. A piece of board is attached to the wall, which will serve as formwork, and mortar is laid in the middle. Its role can be tile adhesive or a plaster mixture, if such work is carried out simultaneously. In any other case, you can prepare a regular sand-cement composition. Using a rule and a level, a flat surface is made.

- Linings made from pieces of wood

In cases where it is necessary to compensate for only 1 cm, you can get by with pads made from pieces of plasterboard, plastic or wood. They should be placed every 30-40 cm. To maintain a horizontal plane, it is best to use a laser level. A small part of the adhesive base is applied, and stands are placed on it. A line is projected, and from it a tape measure is taken to one and to the second edge of the substrate. If necessary, the element is recessed into the solution or, conversely, raised.

Reinforcement and sealing

If laying a wooden window sill with your own hands is carried out in a panel or brick house, then it can be laid on polyurethane foam. After it hardens, the protruding residues are cut off. For additional strengthening, the window sill and window frame are secured with self-tapping screws on the outside of the window. At the same time, it must penetrate through the entire window structure and enter the rear edge of the window sill by no less than 4 cm. Thus, both vertical and horizontal stability are achieved.

A wide window sill, which protrudes significantly beyond the lower window slope, also needs to be additionally secured. To do this, metal corners or wooden blocks secured with self-tapping screws are installed on the slope. You can use pins that are mounted into the wall under a slope. First, holes are drilled for the pins in the window sill board itself. Only after these manipulations should the wooden element be installed on the foam. Keep in mind that the installation of a window sill in a wooden house should be carried out at the stage of installation of the window block itself.

At the end of the installation process, you need to seal all joints and small cracks at the point of contact between the frame and the window sill. This is done using acrylic. It is more plastic and resistant to negative influences.

Installing a wooden window sill with your own hands is not as difficult as it seems at first glance, but still requires some experience. If you are not confident in your abilities, and there is an opportunity to ask for help, it is better to leave this matter to professionals.

Installation

Even a beginner can install the cover without the help of specialists.

The installation process will not take much time, since dismantling of the old structure is not required. Before starting work, you need to check that you have all the necessary materials and tools:

- overlay of the required size and plugs;

- glue;

- silicone;

- fine-tooth saw or jigsaw;

- construction tape;

The work process includes several successive stages:

- Step 1. Preparatory. The surface of the window slab must be flat, so if there are chips and cracks on the concrete base, they must first be repaired with gypsum putty. Plastic or wooden surfaces do not require special preparation, but must be clean. If necessary, you can treat with an antiseptic.

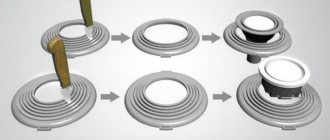

- Step 2: Cut it out. You can cut the overlay with a mounting knife or jigsaw. The parameters of the window recess must be carefully measured; to maintain accuracy, you can make a paper template preserving all the contours of the opening.

- Step 3. Installation. You need to apply mounting glue to the wrong side and distribute it first around the perimeter, and then in zigzags over the free space. After placing the pad, you need to press it and place the weight on the corners to secure it firmly. No further work can be carried out while the glue is drying.

- Step 4. Plugs. The plug must be cut to size and glued to the sides of the window slab.

- Step 5. Sealing. The joints along the slopes and the window frame are treated with sealant. A layer of silicone is evenly applied to the seams to hide the joining line. You can use rubberized profiles or special corners.