Owners of suburban areas with high groundwater levels usually experience difficulties with the arrangement of autonomous sewerage and drains. In wetlands, cesspools quickly fill with sewage, and the cost of sewerage maintenance becomes quite high. But it is possible to install an effective septic tank at a high groundwater level if the owner of the site is ready to increase the volume of construction and incur additional costs for the purchase of a ready-made installation. The investment of additional funds will subsequently pay off in the impeccable operation of the sewerage system and the absence of problems with its maintenance.

How does a high water level affect the operation of a septic tank?

Ignoring the fact of high groundwater causes the following:

- partial flooding of the septic tank, which leads to frequent calls to the sewer truck and results in additional costs;

- complete flooding, which is fraught with the release of contaminated wastewater into the environment;

- waterlogging of the soil around the storage tank, the appearance of a persistent unpleasant odor, the danger of the spread of infections;

- the rise of the septic tank when the water supply system rises, accompanied by damage to sewer pipes, depressurization of the system and leaks.

A flooded or floating septic tank requires complete reconstruction or replacement with a more efficient and reliable design. Alterations involve considerable material and labor costs, so when there is close water, you need to be especially careful when designing and installing treatment facilities.

Why is it better to entrust sewer installation to professionals?

Some owners of private houses, wanting to save on installing a septic tank, install the station themselves. The result is errors that disrupt the operation of the treatment plant.

Installing a septic tank by professionals will provide the following benefits:

- development of an installation project in accordance with operating conditions and passport specifications;

- eliminating errors, with all the ensuing consequences for operation;

- possibility of service.

Even with self-installation, the owner violates the passport requirements, this automatically entails refusal of warranty service for the complex.

The specialized organization has experienced specialists on its staff, which guarantees the proper quality of work. Installation of the station requires the use of special equipment, the purchase of which is impractical for the owner of a private plot and is associated with serious costs.

When to determine the height of the groundwater level

The level of groundwater lying at a depth of up to 2 m from the surface of the earth is considered high. It may not be constant and may change depending on the season.

Groundwater level is determined during the period of greatest fluid influx into aquifers. This is the time of spring floods and autumn lingering rains.

The level can fluctuate quite significantly. An additional contribution is made by perched water, which is formed due to precipitation and melted snow seeping into the soil, as well as surface water. To protect yourself from them, it is enough to raise the structure above ground level and make a blind area around the perimeter.

If you use sewerage only in the summer, for example, during a summer holiday, then you don’t need to look for the highest water level. It is enough to know where it is located at the very beginning of your stay in the house.

How to prevent an accident

The best solution is not to correct problems, but to prevent them already at the septic tank design stage.

Such actions can not only save money, but also save the time and nerves of private sewer owners

The situation when the septic tank surfaced, and the photos presented below became a reality, is very untidy. To prevent this from happening, just follow a few simple rules:

- Choose a set of autonomous sewerage systems “with a reserve”, based on how many people will constantly live and use communications in the house. Choosing a septic tank based on price rather than functionality and capacity is not the best way to save money.

How to find the height of the groundwater level

The estimated groundwater level is determined from nearby wells or boreholes. Information can be obtained from neighbors living nearby. The best and most reliable way is to excavate an exploration pit or drill a test well.

To search for ground water using the last method, take a garden drill and make a hole 2-3 m deep. You can line the hole with a sewer pipe so that the walls do not crumble. Based on the established level, it will be clear where the groundwater is located at the moment.

It happens that liquid appears after 0.5-1 m of drilling. This phenomenon is often observed in areas adjacent to reservoirs or near the outlet of interstratal waters. If after a few weeks the level has not dropped, it means that your site is located in a zone of high groundwater level.

How to determine how close it is

The first thing to do is to identify the GWL and understand the scale of the problem.

Important: the liquid comes as close to the surface as possible in spring and autumn. In the first case, the cause is melting snow, in the second - prolonged rains.

Here are 5 ways to determine it:

- The easiest way is to ask local residents. Perhaps the neighbors already know at what depth the water supply system is located or they have a well on their property.

- Flora as a guide. Certain types of plants can only survive when water gets close enough to the surface. The following table will help you navigate:

groundwater level, mm Plants 0-500 carex (sedge), reed, wild rosemary 500-1000 рhalaris, foxtail, reed 1000-1500 spruce, heather, blackberry, fescue from 1500 and below alfalfa, plantain, clover, lingonberry - Inspection of the site. If wetlands are present, it means that the groundwater level is located close to the surface or the soil is too clayey. And also inspect the area adjacent to the site.

- The old-fashioned way. To do this, you will need a clay pot, a tuft of wool, degreased white spirit and an ordinary chicken egg. Use a shovel to remove a small layer of turf in the area where the septic tank will be located. Place wool, an egg on top and cover with a pot. An inspection is carried out in the morning. If drops of water are clearly visible on the egg, the water level is close to the surface.

- Drilling pits at several points in a suburban area. This method is quite labor intensive. But it is 100% reliable. Step-by-step instruction:

- Find a good long drill - at least two meters - and a level pole, on which you apply marks every 100 mm.

- Determine drilling points on the site. You should not drill a well only in the intended location of the sump. It is possible that it will have to be moved, so select several points throughout the site.

- Drill wells. Place waterproof material on top so that precipitation cannot enter the shaft. Wait 24 hours.

- Using a prepared pole, determine the groundwater level: immerse it in the well, reaching the bottom, pull it out and subtract the length of the wet part from the depth of the shaft.

Folk signs also help a lot.

This is especially true in the summer, when drilling cannot guarantee 100% accuracy of measurements. The fact is that in hot weather the liquid drains into nearby bodies of water and the level sometimes drops – quite significantly. Places of possible flooding will help identify midges that sense the proximity of moisture and will swarm in this particular place. You can also navigate by the abundance of dew in the morning and the density of fog in the evening. The more clearly these signs appear, the closer the liquid is to the surface. Obviously, when constructing any underground structures, it is advisable to avoid such places.

A similar situation with a drop in liquid level is observed in the middle of winter. Only the reason is not in water drainage, but in the freezing of the top layer of soil during severe frosts. Measurements taken during this period can be easily misleading. With heavy rainfall, the liquid level in spring can increase 2–3 times.

Important: if possible, the groundwater level should be determined several times a year and the lowest value taken for calculations.

Where to install a septic tank

When choosing a location for treatment facilities, pay attention to the installation rules:

- You must retreat at least 15 m from the water well. Moreover, this condition must also be met for the neighboring water intake structure.

- According to the standards, the safe distance to the foundation of the house is 5 m. The maximum gap is not regulated. The main thing is that when connecting the pipe, there remains sufficient usable volume in the septic tank. For the same reason, it is not recommended to bury the pipe leaving the house by more than 0.5 m.

- The septic tank should be located near “wet” rooms, such as the kitchen, bath, toilet, so that the wastewater passes through the shortest possible path.

- It is necessary to leave access to septic tanks and sedimentation tanks for the sewer truck. The length of its hose, as a rule, does not exceed 5 m, but there are models with a hose 15-25 m long. If sediment is removed from the storage chamber with a drainage pump, regular cleaning can be done with your own hands.

- Perhaps in the future there will be additional buildings that require sewerage - a guest house, a bathhouse. Provide a convenient connection option.

- If the septic tank is located next to the entrance or recreation area, the visual component is important. It is advisable to install equipment where it will not spoil the appearance of the site or choose models with a decorative overhead part.

If groundwater is high, it is not recommended to install a septic tank at the lowest point of the terrain, where there is a high risk that the structure will be constantly flooded.

Choosing a location for a septic tank

To determine the optimal location for constructing a septic tank, you should study the current rules and regulations. There are several conditions that must be taken into account:

- the septic tank must be located at least 5 meters from the house or any building (see more about the distance of the septic tank to other objects);

- the road zone should be located at a distance of 5 meters;

- the sewerage and aeration station must be located at a distance of 30 meters from an open reservoir or reservoir and 50 meters from a well with drinking water.

Recommended types of septic tanks for high groundwater levels

When underground waters are close, in addition to the lateral pressure of the soil, the tank is affected by the backwater of water, and in winter also by the forces of frost heaving. Therefore, the walls of the structure must be strong and airtight. This can be provided by both factory models and construction-ready septic tanks.

Factory drive

The simplest and most cost-effective option for installing an autonomous sewer system in a country house or house for non-permanent residence is a storage septic tank. It is like a sealed cesspool or drainage pit. Wastewater flows through the supply pipe directly into the tank, from where, after filling, it is pumped out by a sewer truck.

Factory drives are made primarily of plastic. At high groundwater levels, polypropylene or fiberglass septic tanks are preferable, since products made of low-density polyethylene are not rigid enough and can fail due to frosty soil movements.

The containers are installed in the pit manually or using a lifting mechanism. The layout is preferable to a horizontal one, in which there is no need to dig a deep pit. This creates a lower groundwater pressure both during installation and operation.

In addition to ease of manufacture and installation, factory drives have the following advantages:

- complete tightness, no leaks;

- suitable for areas even with very high groundwater level;

- does not depend on power supply;

- meets the requirements of sanitary standards;

- affordable price.

Containers can be used not only temporarily, but also permanently. Free access for sewage disposal must be provided.

Made from reinforced concrete rings

Septic tanks made of reinforced concrete rings are very popular. To assemble the structure, products with a diameter of 1-2 meters and a height of 90 cm are used. Each element is installed on the previous one and secured with brackets. The seams are carefully sealed with waterproofing materials.

Concrete septic tanks can operate in 2 modes:

- gravity;

- with drain pump.

Since concrete is a permeable material, it is recommended to install a prefabricated septic tank when the groundwater level is no higher than 130 cm. In this case, it will operate normally.

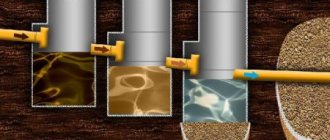

The storage tanks are installed in series in the amount of 2-3 pieces and connected by overflow pipes. In the first chamber, sedimentation of solid particles occurs, in the second and third, biological breakdown by bacteria of various types.

Due to the insufficient degree of purification, clarified wastewater cannot be discharged onto the terrain. Further processing is carried out by filter fields, trenches, wells or infiltrators.

Advantages of septic tanks made of concrete rings:

- high strength, allowing to withstand lateral soil pressure and frost heaving without any deformation;

- no or very low power consumption;

- long service life.

Deep biological treatment station

A more technologically advanced method of wastewater clarification is SGBO, in which water is purified up to 98%. For areas with high groundwater level with permanent family residence, this is a convenient option that eliminates the labor-intensive installation of filtration fields.

The station is a multi-chamber (3 to 5) container with compartments designed for a specific type of cleaning:

- mechanical clarification zone, where solid particles precipitate, grease and films are retained;

- anaerobic fermentation chamber, in which biological processes take place without access to oxygen;

- zone of aerobic oxidation in the presence of oxygen and bioenzymes.

Biotreatment stations are equipped with drainage pumps, compressors, valves, airlifts and other devices that consume energy. The water obtained after purification can be used for technical purposes. The equipment is operated for a long time without pumping, maintenance is required once every 3 years.

Monolithic concrete septic tank - instructions

One of the most common designs created independently for a country house or cottage. The walls and bottom of septic tanks are reinforced with lattice and have sufficient strength not to collapse under the pressure of groundwater and earth outside. Due to its heavy weight, it cannot emerge in the spring or during the rainy season. In this case, we will consider step-by-step instructions for creating a three-chamber monolithic concrete septic tank, which provides a significant degree of sewage treatment.

Construction of a monolithic three-chamber septic tank. Sewage from the sewer enters the first chamber, and solid residues settle at the bottom, decomposing over time. The liquid settles and is partially purified. Over time, water overflows into the second chamber, and the process repeats. A relatively clean liquid enters the third chamber, where the last solid particles settle. Then the process water is directed using a pump to a filtration field located on an embankment or to a drainage ditch

Step 1. Determine the location for the septic tank (Astra), its dimensions, then begin digging a pit. Depth – 3-3.5 meters. If possible, order the work of an excavator or a team of excavators - in this case, you can dig a pit on the first day. To prevent the walls from falling off, line them with plastic wrap. Compact the bottom of the pit.

Important! Additionally, it makes sense to build an awning over the pit so that it does not get flooded with rain. In order to minimize the problem with groundwater, start installing a septic tank in the summer during the driest period. If moisture still accumulates at the bottom of the pit and interferes with work, place a hose from the pump there.

Awning over the pit for a septic tank

Step 2. Place a compacted and moistened sand cushion 15-25 cm deep on the bottom.

Sand cushion at the bottom of the pit

Step 3. Proceed with the construction of the external formwork. Use fairly thick and strong boards, as a large mass of concrete will be poured. If the formwork is too weak, it can simply push it to the sides, especially in the lower part of the monolithic septic tank. Don't forget about the timber spacers.

Construction of formwork

Strengthening spacers

Step 4. Start forming a reinforcing lattice on the bottom and walls of the pit. Use steel rods with a cross-section of 10 mm, tie them together with wire. The side of each individual lattice cell is from 20 to 30 cm.

Before starting reinforcement, line the outer formwork with a waterproofing film or roofing felt, overlapping

Step 5. Form a reinforcing grid on the partitions that will divide the septic tank into separate chambers.

Formation of a reinforcing grid on partitions

Step 6. Fill the bottom of the pit with concrete; the thickness of the bottom of the septic tank should be at least 150 mm. Add anti-corrosion and waterproofing additives to the mixture so that the tank does not allow groundwater to pass through and is not subject to destruction due to the aggressive internal and external environment.

The bottom of the pit is filled with concrete

Step 7. Build the internal formwork that will form the walls of the septic tank and divide it into three separate chambers.

Construction of external formwork

Step 8. Start pouring the external walls and partitions of the septic tank. Don't forget to create overflow holes from chamber to chamber. When pouring, try to reduce the number of cold seams, as they will be the weak points of the structure, where leaks will occur first.

The walls are poured, the concrete has hardened

Chamber of a monolithic concrete septic tank

Step 9. Build the formwork for the roof of the septic tank. In this case, the boards must be carefully adjusted to each other. Don’t forget about hatches and ventilation - each septic tank chamber should have its own hatch for inspection, maintenance and, if necessary, sewage disposal.

Septic tank roof formwork

Step 10. Fill the floor with concrete, which will be the roof of the future treatment plant.

Pouring concrete

Step 11. Separately form a reinforced lattice around the hatches and fill them with cement mortar.

Reinforced grill around the hatch

Reinforced grating filled with concrete

Step 12. Install tees for overflow holes inside, fill the septic tank with soil on top, install manhole covers and a ventilation system.

Three-chamber monolithic concrete septic tank is ready

The three-chamber monolithic concrete septic tank is ready. Next, you just have to make a diversion from it to an embankment with a filtration field (for post-treatment of process water) or to a drainage ditch.

Treatment plant with drainage in the embankment

Filtration field design

Masking an embankment with a filtration field as a decorative hill with stones and bushes

A two- or three-chamber septic tank made from Eurocubes is constructed using a similar principle. In this case, it is necessary to take into account the high level of groundwater and, accordingly, the danger of floating. Therefore, plastic Eurocubes are mounted on a previously poured or laid anchor concrete slab. It also makes sense to protect the structure from the sides with something from compression during soil heaving.

You may be interested in information: do-it-yourself sewerage in a bathhouse diagram

Construction of a two-chamber septic tank from Eurocubes

When using an industrial-made septic tank, such as “Tank” or “Topas”, the same recommendations apply - a concrete slab is installed at the bottom of the pit under the treatment plant, the tank itself is fixed to it using anchor straps, as in the image below.

Septic tank "Tank"

How to fill a slab on a septic tank

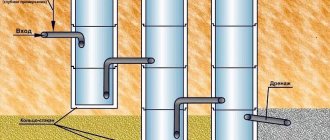

Installation diagram for high groundwater levels

If you consider yourself not very knowledgeable in construction and have doubts, then it is better to contact an experienced specialist who has encountered similar problems and knows the solution when installing both a homemade and industrial septic tank. Remember one important truth: when landscaping a site, money is spent either at the construction stage or after it, but on correcting mistakes and combating the consequences of savings at the expense of reliability.

You may be interested in information about the location of the septic tank on the snip site

Filtration facilities at high groundwater level

Recessed filter fields and trenches, when water is located close to each other, serve more as a receiver of seasonal precipitation than for soil purification. In order for the septic tank to function fully, special raised structures are used to prevent untreated wastewater from coming into contact with the ground and contaminating the soil.

Prefabricated filter well

If the level rise is not observed often and for a period of time from 4 to 7 weeks, a completely workable option is to install a filter well from reinforced concrete rings. It should be located no closer than 2 m from the septic tank, and pump liquid from the last chamber using a drainage pump.

At high groundwater levels, the drainage well is installed at ground level. A cushion of gravel and crushed stone materials 20-40 cm high is placed under the structure, depending on the type of soil: thinner for sandy soil, thicker for clayey soil. Holes are made in the side surfaces through which liquid will penetrate into the filter layer.

The well is sprinkled with crushed stone, geotextiles are laid, and a layer of soil is placed on top. It is imperative to install a supply ventilation riser.

Infiltrators or drainage tunnels

Outwardly, they resemble inverted trays made of thick plastic, inside of which drainage materials are placed - crushed stone, gravel, sand.

Wastewater is supplied from the septic tank through the inlet pipe by a drainage pump. After passing through the filter layer, they seep into the ground.

For tunnel construction:

- Prepare a pit with a crushed stone-gravel cushion 30 cm high.

- Install plastic drainage infiltrators with horizontal slots.

- Lay geotextiles to avoid rapid siltation of the drainage material

- Sprinkle the top with soil 0.5-0.8 m thick.

The design of infiltrators requires mandatory ventilation. With access to oxygen, the breakdown of organic matter occurs much faster.

Filter structures should not be located next to wells or boreholes. To calculate the number of infiltrators, soil permeability is taken into account. The lower it is, the more products need to be installed.

The links are connected to each other by overflow pipes. At very high groundwater levels, infiltrators are placed on the ground surface. The structure can be insulated with expanded polystyrene or other material that is resistant to moisture and rot, and then covered with soil on top.

Filter embankments

The close occurrence of groundwater is a big problem when installing septic tanks. It happens that they come to the surface, and the soil in the area becomes swampy.

But even in critical conditions it is possible to construct a full-fledged filter structure. For this purpose, the method of laying a dissipating pipe on an embankment 1 m high is used. The thickness of the crushed stone cushion is 30 cm. The filter is covered with geotextile on top and covered with earth to avoid freezing. For ventilation, the top of the pipe must be raised above the surface of the sprinkler.

Septic tank models for 15 people

Septic tank TOPAS 15

| More details | Users: up to 15 people Salvo discharge: 830 l. Processing volume: 3 m3/day Price: 287,100 rub. |

Septic tank TOPAS 15 Long

| More details | Users: up to 15 people Salvo discharge: 850 l. Processing volume: 3 m3/day Price: 332,800 rub. |

Features of installation with close underground waters

To prevent the infiltration of contaminated wastewater both inside and outside, the storage tank must be absolutely sealed. The best choice for waterlogged soils is a septic tank made of polymers - polypropylene, polyethylene or fiberglass. The walls must be thick enough, and the structures must have stiffening ribs to withstand heavy loads.

Installation stages

Installing a septic tank under standard conditions includes the following steps:

- Digging a pit.

- Sand cushion installation.

- Immersion and leveling of the container.

- Laying sewer pipes.

- Filling the structure with water.

- Condition check, commissioning.

- Backfill with layer-by-layer compaction.

Features of installation in close water

At high groundwater levels, work differs from usual in a number of nuances:

- Groundwater can flow in large quantities. You need to stock up on a drainage pump for pumping.

- It is advisable to choose a horizontal layout of the septic tank in order to raise the bottom of the pit as high as possible.

- If the slopes crumble, install retaining walls made of boards or panels.

- To secure the container, a reinforced concrete slab with outlets is placed in the pit or a reinforced concrete cushion is installed with anchors made of reinforcement. After immersing the septic tank, it must be secured with steel slings so that the installation does not float when lifting the water supply system. This is especially true for lightweight plastic structures and metal caissons.

- Sewer and overflow pipes, connecting elements, and drainage field must be raised as high as possible. If they are even periodically under water, the system will overflow and will not work.

- The neck of the structure is raised to a height of up to 30 cm above ground level, and an insulated blind area is installed around it.

- The joints in a prefabricated septic tank made of reinforced concrete rings are carefully sealed with waterproofing mixtures.

Purpose

A septic tank, in fact, is a combination of a cesspool and a treatment plant, which receives wastewater generated during the life of residents of private housing construction. As a result of using toilets, bathtubs, washing machines and dishwashers, a large amount of waste is generated that must be disposed of without harming the environment.

Modern septic tanks provide accumulation, biological treatment, and disposal of wastewater in two stages:

- Contaminated wastewater enters the first chamber of the tank, where it settles and undergoes primary purification. Solid heavy particles quickly sink to the bottom, and the water purified from them flows into the next chamber.

- In the second chamber, the organic compounds that make up the sewage are decomposed with the help of anaerobic microorganisms. The water becomes even cleaner and enters a third tank or a system of special filters for final purification.

Understanding the operating principle of a septic tank will greatly facilitate the selection and installation of a septic tank for the owner of a suburban area.

Common mistakes

Before installing a septic tank, you need to draw up at least a simple project. Thanks to this, it is possible to avoid many mistakes, including the most common:

- The outlet of the house sewer pipe is too deep. At a high groundwater level, this can lead to groundwater being thrown into the sewerage system, preventing flow. You will also have to bury the septic tank, which is very undesirable. It is optimal to make the exit at around -50…-60 cm, and insulate the communication itself.

- Incorrect pipe slope. With a diameter of 110 mm it is 2-3 cm per linear meter. Reducing or increasing the angle of inclination contributes to the formation of blockages. The flow rate must be optimal so that the solid part of the waste moves along with the liquid.

- Backfilling the pipe with soil. To protect communications from various types of deformations, it is recommended to use drainage materials - sand, crushed stone. The soil, especially clayey soil, is unsuitable for this, since it increases in volume when moistened and frozen.

- Narrow pit. If the pit size is too small, it is difficult to install the septic tank correctly. In addition, on clay soils, sand must be used for backfilling to protect the walls from frost in the soil.

- Incorrect installation order. Backfilling is carried out only after filling the septic tank with water, so that the soil does not compress the empty body, and also to prevent subsidence of the 2-3 ton installation during operation. Otherwise, this risks failure of the pipe connections.

Required tools and materials

Below we will consider in more detail the process of installing a storage sump. For self-installation you will need the following tools:

- motor pump;

- shovels;

- metal cable;

- building level;

- jigsaw

You need to prepare the following materials:

- wooden or metal tongue and groove;

- boards for formwork, AIII reinforcement Ø12 mm, B12.5 concrete (with a monolithic foundation) or prefabricated reinforced concrete slab;

- clamps for attaching the container to the base;

- sealant.

A brief overview of models of ready-made septic tanks for high groundwater

If there is not enough space on your site to construct filter trenches or wells, a guaranteed result can be obtained by installing ready-made biotreatment stations. Domestic and foreign manufacturers produce models of various performance and price categories that purify wastewater up to 80-98%.

Septic tanks "Topas"

In these installations, the effective decomposition of organic matter is facilitated by stepwise processing using colonies of aerobic and anaerobic bacteria. The station body is waterproof, so groundwater does not have any influence on the wastewater treatment process.

The device is energy-dependent, since the operation of the pumps, aerator and airlifts requires power. The performance of septic tanks of different models provides comfortable living for a family of 4 to 10 people, and a two-body station - up to 20.

Septic tank "Tank"

Non-volatile installations TANK, TANK UNIVERSAL, MICROB are made of thick durable plastic. The design has stiffening ribs that protect the septic tank from being compressed by the soil. Waste processing is carried out in 3 chambers. After clarification, wastewater requires additional soil treatment.

The BioTANK series of septic tanks is equipped with electrical equipment. An aerator is installed in the additional chamber, enriching the wastewater with oxygen. The breakdown of organic matter occurs quickly, and the output is clean water without any odors. The remaining sludge can be used as fertilizer.

Unilos Astra installations

The model range of this equipment is very wide - from Astra 3 with a capacity of 3 m³ to Astra 250 MEGA, where the volume amounts to hundreds of cubic meters. The devices are equipped with a sewage pumping station, a frame-fill filter, and an ultraviolet disinfectant.

The system is controlled by a remote control; in case of an emergency, an alarm is triggered. Consumers note that the station operates very quietly, and there are completely no unpleasant odors nearby.

Septic tank "Tver"

The Tver septic tank is perhaps one of the best solutions for areas with high groundwater level. Thanks to the horizontal layout, the station does not need to be too deep, and its internal structure is so simple that maintenance will not be a problem.

The manufacturer produces equipment with a capacity of 350 l/day, which is enough for a small family or temporary residence in the country. For 4-5 people, models with a volume of at least 3 cubic meters are recommended. This ensures deep processing of the entire amount of wastewater with the release of technically pure water, which can be used to wash a car or water trees.

Advantages of contacting

provides high-quality installation, maintenance and repair services for various types of septic tanks on the most favorable terms. All work is carried out by highly qualified specialists with relevant specialization and many years of experience.

Prices for reinstalling a septic tank in our company are the lowest in the area, and therefore affordable for every consumer. We are always ready to help in difficult situations, providing a whole range of services. Moreover, only we provide a 100% guarantee after installing a septic tank , i.e. recurrence of any accidents is excluded. You can also sign a contract for septic tank maintenance and use part of our services absolutely free.

find out the cost of reinstalling a septic tank after surfacing by calling our operator at the specified telephone number or dialing the phone number of a septic tank repair specialist from, as well as downloading the price list on the website.

Feel free to contact us! We guarantee that your problem will be resolved promptly, with truly high quality and in the shortest possible time!

Did you like the article? – click on the social network buttons!

0

- Back

- Forward

Drives

Budget septic tank for a summer residence with a high groundwater level, for example, for seasonal or temporary residence. It works on the principle of a cesspool. Those. There is no wastewater treatment. They only accumulate there and are subsequently pumped out by a sewer truck as they fill.

Modern factory storage septic tanks, like biological treatment stations, have a built-in module that alerts the owner when the chamber is full.

Advantages:

- compliance with sanitary standards;

- low cost of storage;

- energy independence;

- ease of maintenance.

Flaws:

- frequent costs for the services of vacuum cleaners (on average, with intensive use, you need to pump out once a month).

Drives are made from different materials:

- Plastic. Lightweight, reliable material (especially polypropylene). Inexpensive, sealed, wear-resistant structures with wall thicknesses from 15 to 30 mm. When installed correctly they last 50+ years. Be sure to anchor during installation;

- Fiberglass. Less durable material, because sensitive to loads and temperature changes. The average service life is up to 30 years. Due to its lightness, like plastic, the tank needs to be anchored during installation to avoid floating and deformation;

- Brick. If you have experience, you can make it yourself, but in conditions where groundwater rises to the surface of the earth, the structure will definitely be flooded;

- Reinforced concrete (RC). At high groundwater levels, only monolithic concrete structures with waterproofing are allowed. Such a tank will not float up in a swampy area and will not burst if a vehicle accidentally hits it. Installation is more expensive than polymer structures, and tightness remains questionable.

Note! For permanent residence in a country house, the option with a storage device will not solve the problem. Only the biostation will provide maximum comfort.

Septic tank models for 5 people

Septic tank AK ROSTOK Cottage Optima

| More details | Users: up to 5 people Salvo discharge: 1000 l. Processing volume: 1 m3/day Price: 106 865 |

Septic tank TVER 1.2PN

| More details | Users: up to 5-7 people Salvo discharge: 450 l. Processing volume: 1.2 m3/day Price: 121,000 rub. |

Wastewater treatment with filtration cassettes

The device is mounted in a distribution well. A submersible sewage pump is used to supply wastewater to the cassette.

The installation technology involves removing the fertile layer over an area larger than the size of the cassette, constructing a mini-pit 40-50 cm deep, and laying a compacted sand cushion. Concrete walls are installed along the perimeter of the pit. The resulting volume serves to accommodate the cassette itself, laid on a gravel base.

1 - wastewater supply pipeline; 2 - filter base; 3 - supporting blocks made of concrete or reinforced concrete; 4 - reinforced concrete floor slab; 5 - filtration wells; 6 — ventilation riser; 7 - wooden cover; 8 - drainage tray; 9 — hatch; 10 - waterproofing; 11 - stone blind area; 12 - stone paving; 13 — cast iron hatch; 14 — jet barrier wall

The cassette is connected with a hose to the pressure pipe of the pump, and a ventilation riser is installed in the upper part. The finished structure is insulated with foam plastic, followed by backfilling with soil 20 cm high.

Sewage pumped by the pump is distributed over the surface of the filter load and, after cleaning, is discharged into the ground. To increase the productivity of the system, drilling wells is allowed.

The filter loading fraction is mineral screening with a fraction from 2 to 10 mm; for paving, stone with parameters from 60 to 100 millimeters is used. The jet deflector device is mounted with a 15-20 mm gap between the blocks.

Our works

October 4, 2019

Maintenance and cleaning of septic tank Tver

Moscow region Odintsovo district village.

Podlipki May 11, 2019

Installation of a septic tank Tver 0.85 PN

Turnkey septic tank installation in Ozersky district.

Object - Moscow Region, Ozersky district, Ledovo village, SNT Ledovo October 27, 2018

Installation of septic tank Tver in Bronnitsy

Tver-0.5PN, installation Ramensky district, Bronnitsy, Nikonovskoye joint venture October 27, 2021

Installation of a septic tank in the village of Ledovo, Tver

Installation of a septic tank in the village of Ledovo, SNT Ledovo, Tver

Dismantling the skeptic Odintsovo district, Nikolina Gora, Uponor Sako

Dismantling the skeptic Odintsovo district, Nikolina Gora, Uponor Sako

Septic tank type “Filter trench”

Trench septic tanks with a horizontal irrigation pipe are identical in principle to sand and gravel filters. For pipe lengths up to 30 meters:

- the operational loading height of the filtration trench is 800 mm;

- width 500 mm;

- daily productivity of one meter of pipe is up to 70 liters;

- sanitary protection zone – within 8 meters.

1 - coarse sand; 2 - irrigation pipe; 3 - backfill; 4 - ventilation risers; 5 - intermediate layer of sand; 6 - distribution layer of sand; 7 - lower drain; 8 - gravel backfill

What problems can you encounter when the water level in the area is high?

The design of the autonomous sewage system must be absolutely sealed, and the installation must comply with all building rules and sanitary and hygienic standards.

If you do not follow these rules by choosing an unreliable and unsuitable septic tank, here are the consequences that may occur:

Surfacing of the structure

The problem is typical for empty plastic products that are not secured to the concrete base with anchor straps. Often occurs in the spring due to frost heaving and strong water pressure. All this leads to damage to the housing, breaks in sewer pipes, leaks and complete failure of the system.

The structure floated due to soil pressure

A floating septic tank will have to be replaced or expensive repairs done, which will not be cheap.

Partial or complete flooding

This happens more often with structures made of concrete rings, when groundwater seeps inside through cracks over time. Then you have to constantly call sewage disposal equipment, which increases the cost of servicing such a sewer system.

However, depressurization can occur with any other septic tank if it is installed incorrectly. For example, during floods or rainstorms, due to strong pressure and temperature changes, the plastic case (if it was thin) will crack or deform. The device will have to be dug up and replaced with a new and more reliable one.

It's even worse when a flooded septic tank causes sewage to rise through the pipeline back to the plumbing fixtures and overflow into the house.

Waterlogging of the site, contamination of soil and drinking water

If the treatment plant is installed incorrectly, or its seal is broken, sewage seeps into the aquifer, a swamp forms near the septic tank and a persistent unpleasant odor appears. Fertile soil, a well or a well will inevitably become unsuitable for use, because... there will be a chance of getting an intestinal infection.

Violation of the soil purification process

Unlike VOCs, where the outlet water is clean, in non-volatile septic tanks, clarified wastewater after settling must enter underground filtration fields and pass through crushed stone and sand before entering the ground.

A prerequisite is that the thickness of the filter layer must be at least 1 meter, which is difficult to do with shallow groundwater.

Conclusion

: saving on sewerage and its installation is not a good idea. In the end it will cost more. You should immediately choose a septic tank that meets the requirements for installation in these conditions - durable with thick walls and lugs, sealed, with a high-quality drainage system.