With proper care, parquet flooring does not lose its beauty and quality for many years. But the time comes when the floor covering will require care and attention from us: it has become dull, scratches have appeared on the surface. Restoring parquet with your own hands is most often not so difficult and does not require special skills.

There are many methods and techniques for restoring parquet flooring that do not require large financial costs. But with poor care and use in inappropriate conditions, this natural coating is subject to significant damage, which is no longer easy to eliminate and will require much more money.

And yet, restoring the old coating costs much less than completely replacing it with a new one. Let's consider the main types of parquet restoration without machine sanding the entire surface of the aged floor.

Performing scraping followed by varnishing is described in: Making parquet scraping with your own hands

Preparatory work for minor parquet repairs begins with removing furniture and other items from the room and wet cleaning.

Do-it-yourself partial parquet repair

Let's consider several cases of partial parquet repair, which you can do yourself.

- The parquet has lost its former brightness, has become worn or faded. For cosmetic repairs, you need to sand or sand, and then apply a new decorative protective layer. Prepare the varnish according to the instructions and apply it using a wide brush or roller along the parquet texture line in several layers. After 5 days, you can carefully bring the furniture into the room, and after 1-2 weeks the varnish will dry completely.

- Repairing chips and cracks in parquet flooring. If the gap is small, it is enough to clean it of debris and fill it with mastic. For large chips, more than 5 mm, thoroughly clean the flaw, deepen the gap and insert a wooden plank of a matching color, coated with glue. We plaster the repair area and varnish it.

- Scratches and shoe marks. Try to protect the space in the hallway with rugs and protect the parquet from walking on it with shoes. Stripes can be removed with special parquet care products, and small marks from impacts or scratches can be retouched with a pencil.

- Repair of old, rickety parquet. If the parquet floor has been in use for a long time in the house, or the air humidity in the room is often low, some parquet planks may become loose over time.

Local repairs can be made as follows: using a chisel, we break the loose board, and in its place we install a new one of identical material and color. The recess in the floor is carefully leveled and cleaned of glue residues; sometimes the hole under the cleaned parquet is filled with heated bitumen mastic.

It is worth noting that if the area of loosening of the parquet is too large, then it would be more advisable to replace the floor with a new one.

How to restore old parquet

The choice of technology for restoring an old parquet floor depends directly on the type of coating defect. Among the most common are: potholes and scratches, drying out or loosening of individual dies, creaking, mechanical wear, unevenness, swelling.

- Small scratches, gouges or dents are painted over using a special structured wax pencil. With sufficient opening and depth, they are filled with slightly melted wax and silicone putty. After the filler has hardened, the area is sanded with abrasive sandpaper and varnished.

- If creaking is observed in a small area, use the “Pumping” method.

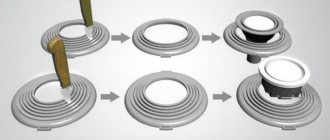

This repair technology is used to eliminate floor creaking and its “breathing” places without carrying out the process of dismantling or partially disassembling the base. Pumping is carried out with special restoration solutions, which are pumped directly under parquet dies or solid boards. A small hole is drilled in the problematic parts of the structure and a working solution is pumped into it, allowing the plank to be tightly glued from the inside to the base of the floor, filling the entire cavity. This method of surface restoration allows not only to strengthen the floor without dismantling, but also to save time and money on more labor-intensive actions. By filling in the unevenness that is the cause of such an unpleasant sound, its effect is also eliminated.

- If the parquet creaks over a large area, then you will have to go through the coating: the planks are removed and carefully re-glued onto the adhesive or binder applied to the base. Bitumen mastic often plays this role.

- If the adhesive properties of glue or bitumen mastic are damaged under the influence of moisture, flooding of the room or over time, the process of divergence of the planks or their detachment may begin. This problem is solved by gluing the structural elements using 2-component polyurethane glue, which does not contain water. This method of restoration is the most reliable and durable measure.

- If individual dies are severely damaged, they are pulled out, the floor under them is cleared of glue, and a new one is installed in their place using special glue. The new die can be attached to the adjacent ones using thin nails, driving them in at an angle. It may turn out to be higher than the floor plane, then it can be adjusted by processing it with a sherhebel and a plane. It is better to pre-moisten the die with water, this will make it easier to plan.

- If several planks laid side by side fall out, first the new dies are firmly connected to each other, and only after that they are placed in the hole. For a couple of days, additional weight is placed on them.

Advice

It will be very useful to tap each floorboard. This way it will be possible to identify all the voids where the plank also needs to be replaced. Of course, it would be great to choose planks that completely match the color of the old ones, but if not, it doesn’t matter. Using a tone contrasting with the existing one, most likely, you will be able to lay out a new original drawing.

Repairing old parquet floors when the color of the parquet changes

The color of parquet may change due to exposure to sunlight. Moreover, different woods have different reactions to ultraviolet radiation. Any type of tree requires a certain time to mature. Wood that has a shorter ripening time becomes darker faster. Such a type of wood, for example, is cherry. If you properly care for the floor covering, the color change of the parquet can be significantly delayed. Here are some care tips:

- If water is spilled on the parquet, it must be removed as quickly as possible. If the strips are damaged, they must be replaced.

- When the floors are completely laid, you should give some time for the parquet to mature. Only after this can it be covered with carpets.

- Any defects in the parquet floor that appear over time will certainly change its appearance to one degree or another. In order to restore the attractiveness of the parquet board, you can scrape it.

- It is always easier to prevent any problem than to solve it. Therefore, regular and qualified repairs will be more expensive than proper maintenance of the parquet floor.

In order for the parquet to last longer without repair, it is recommended to do the following:

- Install a humidifier in the house.

- Periodically polish the floors with polish.

- Felt pads should be placed on the legs of tables, chairs and other heavy moving objects.

Parquet repair options depending on the type of damage

- For example, greasy stains are removed using a gruel that contains washing powder and a small amount of water. The composition is briefly applied to the dirt, the area is moistened with water and thoroughly wiped with a special stiff brush. At the end, traces of powder are carefully removed.

- If scorch marks or dark spots appear on the parquet, say, from furniture, they are removed using sandpaper, steel wool for washing dishes and tile paste. The dirt is first rubbed off with detergents, then the surface is carefully sanded. After it dries, varnish it.

- And small potholes caused by sharp heels or furniture legs, falling objects and other incidents are more difficult to get rid of. Armed with thick burlap, warm water, an iron and paper, they begin “rescue” work.

- First of all, the planks are steamed to make the wood elastic. Thick paper is moistened in warm water, and several layers of it are laid on the floor and pressed on top with a slightly heated iron.

- After a couple of minutes, the paper is removed and with quick movements, using a burlap swab, they begin to rub the die towards the pothole. Gradually, the fibers will fill the recess, after which the procedure is repeated with paper and an iron.

- After allowing the surface to dry, apply varnish, and finally rub the surface with a stiff hair brush.

- Sometimes high air humidity contributes to the formation of whitish deposits. You can try to wipe the damaged areas a little with solvent, then re-varnish. Work should not be carried out on a cold floor. In some cases, this method may not be effective, and then the parquet will have to be completely restored.

Types of work

Before you restore parquet with your own hands, you need to master several simple manipulations. Let's talk about each of them in more detail.

There are ready-made putty pastes and mixtures on sale that can be used to fill cracks and crevices (for more details: “Which putty for parquet is best suited”). However, in some cases you can prepare such a mixture yourself. To do this, you will need remnants of the old parquet left in reserve. They need to be sawn into small sawdust and mixed with parquet varnish to a paste-like state, or with epoxy varnish in a ratio of 4:1. This grout is ideal if you want to accurately match the tone of the wood.

Imitation of joints

You can disguise the putty by simulating joints, which can be done using a ruler and an awl:

- First you need to wait a little until the putty hardens to the state of gelatin, that is, it will be plastic, but not sticky. Alkyd and uralkyd varnish hardens within a few minutes after application and quickly crystallizes.

- For straight joint lines, furrows are drawn with an awl under a ruler.

- Wavy lines are pressed with a metal ruler.

- If the putty has already hardened, then to create false joints it will have to be scratched with an awl.

Manual looping

To scrape small areas of parquet, you can use a hand scraper, which can be purchased at a specialty store. If desired, a hand scraper can be made from a plane blade.

Sanding with feet

You can sand small sections of parquet using two types of sandpaper glued to the soles of old shoes. For roughing, paper No. 40 is suitable, and for finishing – No. 80. Sanding with your feet is faster than by hand, and the processing is more delicate than, for example, with a whetstone.

The main reasons why parquet floors lose their appearance

The need to repair and restore parquet will arise sooner or later in any case, and the main reason here is constant and long-term operation. After all, people not only walk on parquet flooring in house shoes, they also move furniture on it and damage the flooring with sharp heels or rough soles. Other causes of defects include:

- Constant excess humidity. Wood is distinguished by its ability to swell when wet, the same applies to wooden parquet blocks. If this is a basement floor and a special waterproofing layer is not laid under the parquet, then the coating will sooner or later swell and walking will be accompanied by squeaking.

- Excessively dry air. Constant high temperature in the room causes the wooden elements to dry out, which is likely to cause deformation and distortion of the base.

- Improper cleaning. Frequently carried out wet cleaning with a regular mop or steam cleaner leads to the accumulation and retention of liquid in the crevices, which can cause the wood to rot.

- No processing. If the purchased parquet has not been pre-treated with special agents that prevent the growth of fungus or wood pests, then such a floor will quickly become unusable, even with proper care.

Parquet flooring can deteriorate due to high humidity or excessive dryness in the room.

Among the main reasons why you will have to repair parquet boards is surface discoloration. This happens mainly due to the use of unsuitable detergents, excess moisture or the ingress of aggressive chemicals, such as ammonia. The main problems also include:

- Appearance of cracks. The main reason is considered to be dry air, which often occurs in winter with active use of heating devices. The preferred humidity in a room with parquet is 40-50%.

- Blistering of boards. It is formed due to the accumulation of water under the surface of the board or due to improper repair of the parquet after the room has been flooded.

- Lack of heat resistance. Associated with improper installation of insulation or poor processing of joints, and can also be caused by insufficient preparation of the base.

- Displacement of boards when walking. It occurs due to a violation of the screed technology, the absence of a soil layer or the formation of mold on the inside of the boards.

- Peeling of parquet from the base. The problem occurs when there are uneven surfaces on the floor, due to uneven application of the adhesive mixture, as well as when the dies are incorrectly attached to the wooden base.

- Gaps between boards. The main reason for the appearance is the use of too wet material.

- Glue protrusion. Occurs as a result of applying a very thick layer, improper laying of boards or due to incorrectly sized sheets.

- Scratches and dirt. This happens mainly when the floor covering is not used carefully.

The appearance of defects on the parquet may be the result of improper cleaning.

The most common problem that causes the need to replace parquet is subsidence of the floor, which occurs due to the destruction of the screed under heavy load.

Defect Elimination Technology

If you plan to repair the parquet yourself, you will need step-by-step instructions for each type of work. Let's look at ways to eliminate common flooring defects and breakdowns.

Mechanical damage

Cracks are filled with a special compound and rubbed with sandpaper.

During operation, careless handling causes scratches and gouges to form on the coating. The coating can get scratched even if you move a heavy chair without lifting it.

Types of mechanical damage and methods for eliminating them are discussed in the table:

Fill with colored putty. If the color is chosen accurately, the restored areas will be invisible.

The sequence for restoring deep scratches on parquet:

- We clean the coating from dust using a vacuum cleaner.

- Fill the crack or scratch with putty.

- After the putty has dried, sand it down with sandpaper.

- We remove all dust generated during the grouting process.

- Apply a thin layer of varnish to a clean, dry surface.

When black marks form, we wipe them with polymer mastic.

Wax putty is applied in molten form, and is preheated with a gas or battery-powered wax melter. To learn how to remove small scratches, watch this video:

You can independently prepare putty from two-component epoxy glue with the addition of sawdust until a homogeneous mass is obtained.

Timely restoration of the coating will help maintain the ideal appearance and integrity of the floor for many years.

Mechanical scraping

After sanding, the parquet is varnished again.

To make the parquet floor shine, it is rubbed with wax-based compounds, mastics, various oils, or varnished.

With careless handling, heavy foot traffic and cleaning using abrasive products, the coating can wear off and lose its shine and color. In case of significant tarnishing of the surface, sanding and sanding are carried out with further coating with a decorative layer.

In case of significant tarnishing of the surface, sanding and sanding are carried out with further coating with a decorative layer.

After rough sanding, go over the surface with fine sandpaper.

Sanding is the removal of the top layer of parquet using a special apparatus with sharp metal knives that remove the decorative coating and the top layer of wood.

Sequence of scraping:

- We remove the baseboards and remove dust with a vacuum cleaner.

- We dismantle all protruding fastening materials (screws, nails).

- We perform rough sanding, which includes removing uneven surfaces and old varnish. This procedure is performed using a surface grinder or drum machine.

- Use wood putty to seal joints, seams and irregularities.

- Sanding the parquet floor is done with sandpaper in the direction along the dies. The appearance of the surface will depend on the quality of this stage. We clean all the unevenness of the parquet and the protruding plaster mixture.

- Vacuum the floor surface.

- Apply varnish in 3 layers. Apply each subsequent layer after the previous one has dried. Apply the varnish with a roller or wide brush.

- We install skirting boards. To learn how to achieve high-quality sanding of a parquet floor, watch this video:

To remove the stickiness of the last layer of varnish, after it has completely dried, wipe it with a cloth slightly moistened with soapy water.

Manual scraping

Let's look at how to repair parquet using a manual scraper, which is a tool for restoring the top layer of parquet boards manually.

The device is a plane, the blade of which is bent with a hook. With its help you can restore small areas of the floor.

Manual restoration will take a lot of time, and the result will be worse than using professional equipment.

Imitation of joints

On the puttied surface, you need to create imitation joints between the dies.

To complete this work you will need a metal ruler and a shoe awl. The putty should set well, but still be soft. Many mixtures harden within a minute, so you need to make the joint quickly.

If the joint is smooth, apply a ruler and draw a line with an awl. A curved connection can be formed with the edge of a ruler. If the putty has hardened, you can scratch a line along it under the ruler.

Fighting the squeak

If one die creaks, it may have come off; you just need to put it in place and fix it.

If your entire floor is creaking, you first need to determine why this is happening.

Possible causes of parquet creaking:

What to do if dies become loose and fall out

If the boards become loose and come off, they should be restored. Remove those that have become unusable, replacing them with similar ones. At the same time, do not forget to thoroughly polish the fresh ones.

Prepare the base. First, remove the old adhesive base. Then we insert new planks, placing them on the glue.

When “playing” adjacent parquet floors, do not forget to place them on glue. Inject the substance inside using a syringe. Refuse to replace or fix the boards with screws, self-tapping screws, nails, or any mechanical fasteners.

Preparing the premises

Before you start repairing the parquet, you need to prepare the room. Furniture and all interior items are removed from the premises. The craftsmen note that it is enough to take out only the furniture and everything that is located on the floor. But you should understand that restoring parquet is accompanied by dusty work, so it makes sense to completely vacate the room and wash the floor.

After this, the condition of the floor covering is assessed and the scope of work is determined. To understand how to renew old parquet, you need to determine the type of damage.

Note. It is better to outline floor defects with chalk to eliminate the possibility of missing any area.

Depending on the complexity and type of damage, the work may require:

- parquet grinding machine for parquet (surface grinding);

- angle grinder – “Sapozhok” SO?337;

- sandpaper of different grits (number from 40 to 120);

- household or construction vacuum cleaner;

- putty (you can knead it yourself using wood dust extracted from a vacuum cleaner);

- finishing decorative coating for parquet: varnish, wax, oil, tinting mixtures.

Designer items

Old parquet has high performance characteristics. Decorative items made from flooring are very durable and will last for decades. Due to their uniqueness, designer items will become a beautiful extension of the interior.

Kitchen equipment

It is easy to assemble a cutting board from old parquet, following the laying method you like. Compact models can be hung on the walls, completing the composition of a rustic or Provencal style. Large structures whose dimensions match the tabletop look very nice.

What can be made from lamellas Source trikon.kiev.ua

Restoring the parquet surface

Wood looks great, gives the floor a wonderful look, makes the atmosphere softer, and the room itself cozy. But unfortunately, over time the wood darkens and loses its attractive appearance. The process of restoring the top layer of parquet is quite simple; it does not require special efforts, knowledge or skills. To update the floor color with your own hands, you will need the following:

- Skirting boards are removed.

- The layer of old varnish is removed. For this purpose, scraping or grinding machines are used. And in corners and in all hard-to-reach places on the floor, an angle grinder will do. You can also remove the varnish with a special industrial hair dryer. The varnish is heated and then easily removed with a spatula.

- The surface is thoroughly cleaned of dirt and dust. After which all damage is clearly visible. putty

is used ; it copes well with all cracks, scratches, etc. - The surface is evenly treated with stain. But only if there is a desire to change the color of the parquet floor.

- If no damage is found, then the surface is treated with a grinding machine with a fine-grained emery attachment. By grinding, all unevenness, roughness and dark areas are eliminated. The surface becomes more uniform and monochromatic. Do not forget that during restoration work only soft shoes with shoe covers are used.

- A vacuum cleaner is used for thorough cleaning. There must be perfect cleanliness.

- Now the first layer of varnish is applied. This layer is more of a primer than a decorative or protective one. The varnish is applied with a roller or brush, after which the surface is sanded again with zero sandpaper. Next, another layer of varnish is applied. Once the varnish is completely dry, the surface is sanded again. The number of layers can be up to nine. Parquet varnishing occurs strictly in the direction of the wood grain. Instead of varnish, you can choose mastic.

- After all necessary repair procedures,

the surface dries for at least three days. This requires certain conditions: closed windows and doors (drafts are extremely unacceptable), temperature 17-22 °C, humidity 40-70%.

Renewing an old parquet structure

Old parquet requires special care. It is necessary to promptly repair microcracks, replace raised boards, and eliminate scratches and minor defects. The problem can be solved by varnishing. But this can become the embodiment of the task only for a while. Be sure to include the following details in the workflow:

- The raised dies are sealed and restored without resorting to dismantling and scraping.

- Eliminate cracks and chips, restore blackened areas.

- Get rid of squeaking.

- Restore the varnish layer.

Carefully inspect the floor structure. Remove any existing defects. Only then cover with a layer of varnish.

Do-it-yourself parquet repair at home - methods and tips

Parquet is a floor covering made of wood. Parquet flooring is quite durable, has good sound and heat insulation properties, and is an environmentally friendly material. Parquet flooring comes in a wide variety of designs. It will create an atmosphere of warmth and comfort in any room and is compatible with all interior styles.

As for repairs, parquet here also has one significant advantage: if the floor is damaged in one place, then the parquet can be replaced without affecting the entire coating, but only in fragments.

Despite the large number of advantages, parquet flooring requires special treatment. Wood is very sensitive to humidity, temperature changes, and mechanical shocks; the appearance of varnished parquet is easy to damage simply by moving furniture from place to place or wearing high-heeled shoes.

How to repair worn coating

Any type of flooring is subject to wear and tear, which also applies to parquet flooring. It loses its respectable and impressive appearance, as a result of which the interior of the room does not look as aesthetically pleasing as before. In order for the coating to look luxurious again, it is necessary to take a number of measures to eliminate defects.

The following sequence of actions must be followed:

- The old parquet floor is scraped to remove worn varnish and a small layer of the upper part of the block along with any irregularities on the surface.

- Then the parquet is puttied and sanded.

- The prepared floor surface is covered with either mastic or varnish. In this case, the first layer dries for about a day and only then can you begin to apply it again. There should be at least two layers of varnish, and preferably three or four. Of no small importance for the result of the work is the correct choice of composition for the parquet coating and its consistency.

According to experts, two-component varnishes are considered the best. But they have a big drawback - it is a sharp and very unpleasant smell. For this reason, many property owners refuse them, preferring to apply water-based compounds, despite their fragility and the need to update the parquet surface every 3-5 years.

Swelling of parquet after flooding the floor with water

The worst thing for a wooden floor is exposure to water.

The tree swells, heaves and loses its original properties. The degree of destruction of the floor in the area of the bay largely depends on the quality of the wood and the laying of the parquet itself. If the area of damage is small and the parquet planks are not broken, then to repair the parquet you need to dismantle the floor surface and replace it with identical boards using the technology described above.

If the area of floor repair is too large, then it is better to replace the parquet floor with a new one.

To avoid sagging of the parquet or the appearance of depressions, you need to make sure in advance the quality of the work being performed. Irregularities on the parquet flooring can be eliminated by sanding, and if the planks sag, the floor will have to be dismantled.

If you decide to repair a parquet floor with your own hands, do not skimp on materials and glue.

Repairing parquet in Moscow, St. Petersburg or Kyiv will not cost much, and professional workers will do the job efficiently and quickly.

Repair or restoration of old, worn parquet in an apartment is carried out using sanding. The process involves removing the top layer of varnish using a tape machine. The floor is puttied, thoroughly sanded and several new layers of varnish are applied.

Experts recommend sanding your parquet every 5-6 years; this will preserve the beautiful appearance of your floor and protect you from costly repairs and replacement of the floor in the future. It is better to entrust the scraping to specialists. since it is very difficult to do such work manually, and workers will come to your home with ready-made equipment.

You can entrust parquet repair to a private craftsman, but keep in mind that although the price of such repairs may be less, the quality of the work will differ significantly from professional work, and it is better not to skimp on construction.

Whether it is a local repair or a complete replacement of the floor, in any case, the parquet should serve for many years without peeling or creating squeaks when walking. The appearance of such defects largely depends on the materials that the master chooses during installation.

The materials for parquet repair recommended by craftsmen in Moscow are of high quality and reliability. Professionals will repair or restore the floor at a low price and with a guarantee that the coating will serve you for many years.

Creaking parquet floor

Parquet has a not very pleasant property that manifests itself over the years - creaking. To get rid of it in the case of a small area, that is, if the creaking is only local in nature, there are several ways:

- A small hole is drilled in the center of this area. This will be enough for the parquet in this place to stop creaking.

- If the base of the coating is hard concrete, cement laitance is poured into the hole - this is a mixture of cement and water, prepared in equal proportions (1:1).

- Laitance of cement can be replaced with another liquid composition, which is based on hot wax with the addition of some solvent.

- You can also try liquid lubricants like WD-40. Lubricant is pumped under pressure into the drilled hole. At the end of the operation, the hole is sealed with a wooden decorative plug.

If the creaking area is extensive, then the only drastic way to get rid of the squeaking is to rebuild the coating. This method is expensive, but it guarantees the complete elimination of such an unpleasant creaking parquet floor. Read how to eliminate the creaking of a wooden floor in our other material.

Sanding parquet

Parquet scraping is a type of work that involves removing a large layer from the floor surface - up to 1.5 mm

When performing scraping, it is important to adhere to the sequence of work. If the damage to the floor is insignificant, you can immediately sand the parquet

Parquet sanding is a type of work, the essence of which is to remove a thin layer of wood - 0.5-1 mm. They sand the parquet in several directions using special equipment that allows you to achieve the ideal level of smoothness of the parquet surface.

The purpose of the treatment is to remove the worn surface layer of the coating and part of the surface of the parquet strip or solid board.

Note. Sanding and sanding are accompanied by the appearance of dust. Despite the fact that modern equipment is equipped with a dust collector, after repairs it is necessary to clean the room.

Restoring the surface using the scraping method

To restore the surface, the parquet should be mechanically treated. Using the looping method ensures the following:

- Remove the surface layer of varnish.

- They level the parquet by restoring areas damaged by swelling or deformation of the glue.

The floor is scraped using manual or machine scraping methods. In the first option, the surface is freed from the varnish layer, penetrating 1-2 millimeters deep. In the process, the texture of the material is restored.

Parquet boards are often scraped by machine. In this case, penetration occurs deep into the structure with subsequent leveling of the parquet surface.

Materials for restoration

To protect the parquet floor from external influences, it is opened with special varnishes.

There are 4 types of parquet varnishes:

- Alkyd and uralkyd varnishes. They are inexpensive, do not emit toxins, dry very quickly, so you can be indoors within an hour after varnishing. However, such varnish will last no more than 10 years. Uralkyd varnishes are somewhat more durable, although they are more expensive. As a rule, they are used for short-term repairs followed by sanding and varnishing, as well as around the perimeter of the room.

- Based on epoxy resins. Such varnishes provide a durable and reliable coating for 30-40 years, although they are not cheap. As they cure, they release toxic volatile substances, so you should not start working without personal protective equipment (gloves, respirator, goggles). Windows should be open, but the door to adjacent rooms should be tightly closed. It will take about a week for the epoxy varnish to harden and gain density. Only after this can you be in the room.

- Acrylic varnish consists of a base and hardener, which are mixed immediately before application. This composition is practically non-toxic, but much more expensive than epoxy. With proper care, the service life of the coating will be 50 years or more.

- Water based. Rather, it is a finely dispersed suspension of some polymer, for example, PVA, in water. This varnish dries in a day, while it is non-toxic and inexpensive. Provides long-term protection to wood by penetrating deep into its structure. Mastic can be applied over the coating. The treated surface becomes less sensitive to minor mechanical damage. However, such varnishes somewhat change the color of the wood and quickly fade in direct sunlight.

Parquet restoration

Removing stuck gum

Parquet should not be treated with solvent to avoid unsightly stains. Place an ice pack on the plasticine or chewing gum and leave for 20 minutes. The dirt will fall away on its own or begin to rise along with the bag, so that there will be no traces left.

Repair of minor surface defects

In this case, we mean cracks, chips or gouges on the parquet planks. Before you remove the varnish from the parquet with your own hands, you do not need to remove the furniture if it does not interfere. Using a hand scraper and sandpaper, you need to scrape off the old varnish and start filling the defects. After applying the putty, when it hardens to the desired state, false joints are cut on it and left to harden. Next, apply parquet varnish of the desired shade, preferably in 2 layers. You can apply the second layer after the first has dried. You can also paint the hardwood floors if that option works for you.

Sealing cracks

The appearance of cracks between the parquet is a consequence of the natural drying of the wood. Often they do not interfere with the full use of parquet in the future. If the gap is narrow and single, it can be closed in the same way as other small defects - remove the old varnish, putty, apply a false joint, and then varnish.

Here's how to restore parquet if the gaps are more than 5 mm wide:

- Parquet with parallel laying of planks must first be heated with a hair dryer for 10-20 minutes. As soon as the smell of mastic appears, you can stop.

- All the planks are pulled together using a laminate hook and a rubber hammer until one large gap is formed.

- The wide gap is filled with a rivet and putty, driving it flush with the parquet.

- As the putty hardens, you can begin further sanding the area, puttying, sanding, applying false joints and subsequent varnishing (for more details: “How to varnish parquet according to the rules”).

- For herringbone parquet floors, an individual approach is used for each crack. They are filled with small wood chips.

Loose parquet planks

If there is wobbling of individual parquet flooring in different places of the coating, then they can be secured to adjacent planks with small nails, driven at 45°. Fastening is done along the long ribs 1.5-2 cm from the corner. The heads of the nails need to be sunk into the wood with a hammer or hammer. Small recesses from the caps are puttied, after which the surface is sanded and varnished.

In cases where several adjacent parquet floors are loose at once, the covering can be strengthened with bamboo. Being a grass, bamboo absorbs moisture more strongly than wood, absorbing it from the air.

To perform repairs, you must perform the following steps:

- At the joints along the long sides, 15-20 mm from the corners, holes of 4-6 mm in diameter are drilled.

- Bamboo pieces are driven very tightly into the resulting holes, and the remaining protruding section is scraped off with a chisel.

- After a week, the repaired section of parquet can be sanded, cracks filled, false joints made, sanded and varnished.

Repairing creaking parquet

The most common reason for parquet floor repair is squeaking. There can be two reasons for this phenomenon: natural drying and aging of wood; violation of installation rules (read: “How to repair parquet flooring yourself - step-by-step instructions”). If you need to restore parquet laid with bitumen mastic, there is still a chance to extend its life for several years. But a poorly laid floor is unlikely to be saved.

The first thing you can try to help with squeaks is to screed the parquet from the edges:

- Air humidity is checked first. It should be within 40-60%, but not more, otherwise it will not be possible to remove the parquet.

- Having removed the baseboards around the perimeter of the room, you need to check the condition of the spacer wedges. Often, due to the drying of the parquet, such wedges end up loosely lying in the cracks.

- If, instead of wedges, the gaps near the walls are filled with polyurethane foam, you need to cut it off with a chisel until a clean groove is formed.

- Every 50-60 cm you need to firmly drive in new spacer wedges.

- Next, you need to drive the wedges deeper every day, while checking whether the floor creaks. If after a week it is no longer possible to drive the wedges deeper, and the floor still continues to creak, then nothing can be done to help it. You can only completely change the coating. Alternatively, you can lay plywood on top of the parquet on top of the waterproofing layer to last for several years until a major renovation of the apartment. Instead of film, you can use red lead or whitewash, but then the old parquet will have to be completely thrown out.

Elimination of swelling

Such defects can only be repaired independently if the area is small and very little water has gotten on the floor.

The sequence of actions in this case is as follows:

- The swollen area should be heated with a hair dryer for one to one and a half hours, interrupting only briefly. If you smell mastic, the parquet may be able to be saved.

- You need to cover the heated floor with thick fabric and distribute pressure over the floor area, taking into account that for every 10 cm2 there is 10 kg of weight. You can use any available means - bricks, buckets of water, books, dumbbells mounted on a 40 mm board or thick plywood.

- After a day, you can check the condition of the parquet. If the swollen area begins to noticeably fall off, then you can repeat the procedure again.

Unfortunately, if this approach does not lead to tangible results, it means that it will not be possible to restore such parquet.

Note that the effectiveness of the fight against bloating can only be expected if you get down to business immediately. If a week or more has already passed, the process of rotting has already begun in the wood, and it is no longer possible to help such parquet.

Craftsmen advise that when working with parquet made of straight-layer wood (walnut or oak), first slightly moisten it - leave a well-wrung out damp cloth until it dries. On the contrary, thin-grained wood (beech, rowan, birch) and tropical trees must be thoroughly dried before laying.

Small voids near baseboards

The cracks that are located near the baseboards are probably the most unpleasant. They start by removing the baseboard. Between the wall and the outer board, there should usually be a spreading wedge inserted: if it gets loose, just strengthen it.

If instead of an expanding wedge you find foam, press the plank away from the wall and install a suitable wedge in the resulting space.

Wide holes

There is no point in filling a deformation of more than 5 mm; it will crack anyway. We will fight such deformations “by contradiction” - first we will deepen them. If the edges are uneven, they should be trimmed with a chisel and the resulting groove should be cleaned.

We cut out a plank from suitable wood, grease it with wood glue and hammer the insert between the planks.

We coat it with varnish, having first cleaned and sanded the repair. Gaps in parquet are formed mainly due to significant changes in humidity throughout the year. They can be prevented by maintaining relative humidity of about 20% in winter. For these purposes, in particular, an artificial air humidifier is used.

Repairing wet parquet flooring

Swelling of the planks after the parquet gets wet is the most unpleasant type of damage to the floor covering. This can happen as a result of burst pipes, when the floor is completely under water. Wood has the ability to absorb moisture well, after which it becomes deformed. The only way out of this situation can be a complete replacement of the entire coating.

If you do not dismantle wet parquet flooring, mold will immediately appear underneath it and they will have to be replaced in any case, but during this time the fungus can spread to the walls and an unpleasant odor will appear in the room, which will not be easy to get rid of. For the above reason, parquet elements must be dismantled. You need to clean the base from glue, dry it well, and then just start installing the final coating.

It will take a long time to dry the planks, and before laying a new parquet floor, you need to make sure the concrete base is dry. For this purpose, the concrete surface is covered with a thick polyethylene film and waited for 12-15 hours. After the allotted time, the waterproof material is inspected and if it is dry, then you can begin installing the parquet floor. The presence of even a small amount of condensation on the film indicates that the concrete layer must still dry out and it is too early to lay the decorative coating.

If a small area of the parquet surface gets wet, then not only these parquet floors will have to be lifted, but also the floor elements located around the emergency area. This is necessary to ensure that the rest of the coating is dry.

You can try to dry the dismantled dies, but, as a rule, you have to purchase new products, matching them by color and texture relative to the rest of the parquet surface.

Frequent parquet defects and their repair

Any floor covering loses its original appearance over time. Parquet is no exception. To increase its service life and maintain a neat appearance, parquet flooring must be maintained using various special products - oils, waxes, mastics.

However, they often provide only a temporary effect. If, when laying parquet, the technology was initially violated, and then such a floor covering was used for a long time and was subjected to mechanical stress, then defects appear on it. Correcting these defects in order to return the parquet to a neat appearance can only be done through repairs.

Defects on parquet

- Examples of such defects are:

- scratches and gouges on the parquet surface,

- loosening and drying out of individual planks,

- the appearance of a squeak when walking on it,

- partial wear of the parquet flooring,

- the appearance of irregularities on its surface,

- swelling after flooding the parquet floor with water.

The photo below shows standard scratches on parquet.

Major parquet repairs - step-by-step instructions

When it’s not just a few floorboards that are creaking, but almost the entire floor, and a lot of “parquet flooring” is cracked and deformed, then cosmetic repairs won’t help. The parquet needs to be completely renovated! By the way, if it suddenly turns out that your parquet is assembled not from individual planks, but from panels with glued floorboards, then, most likely, it can no longer be repaired. This method was used back in the Soviet Union to speed up installation, but repairing such parquet is very difficult, almost impossible.

The most difficult cases

Sanding old parquet and subsequent varnishing is always quite expensive, because it requires time and labor. However, there are a number of cases when the condition of the coating leaves no other choice.

So, the most labor-intensive restoration of parquet with your own hands will be required in the following cases:

- The parquet floor looks unkempt, trampled, with significant abrasions, gouges, and cracks in the planks. In such a situation, the old parquet can still be preserved, although you will have to work hard. However, we recommend that you entrust the restoration of old parquet in this case to specialists - it’s cheaper and faster.

- Due to water flooding, the parquet covering swelled across the entire floor plane, and in some places the planks became detached from the base. This problem can only be solved by completely replacing the parquet. True, some planks can still be reused after drying. However, sanding and varnishing are necessary.

- The parquet canvas has become loose, the wood has turned black, and when pressed with an awl, it fits into the plank by 5 mm. This indicates that the parquet floor has begun to rot and mold. In this situation, there can be no other options other than a complete replacement of the parquet. In addition, the room needs to be thoroughly dried and the subfloor needs to be updated.

In all other situations, you can safely take on restoring the parquet with your own hands. Such work will not require much skill or time from the owner. Let us note that in case of simultaneous renovations in the apartment, the restoration of the parquet should be undertaken last.

When repairs can only be performed by specialists

In some cases, restoring a parquet floor will require the involvement of professionals with experience in this field and professional equipment.

When it is difficult to eliminate defects yourself:

- Severely worn flooring with deformed boards and cracks can be restored without replacing the entire floor.

- If, after flooding, the dies are swollen and deformed, they must be removed and dried. Severely deformed elements must be replaced. After laying the floor, the old boards need to be sanded and varnished.

- The parquet has darkened, its strength has decreased, fungal infections have appeared, the wood can be pierced with an awl to 5 mm. Such a covering will have to be re-laid and the subfloor completely dried.

Related article: How to hang a refrigerator door: instructions from an expert

In other cases, you can perform the restoration yourself.

We check the condition of the board by pricking the dies at an angle of 45 degrees with a shoe awl. With a medium degree of pressure, the awl should pierce the surface of the oak board less than 5 mm; birch, walnut and ash - less than 7 mm.

If the tool goes deeper, then the floor element needs to be replaced.

How to remove swelling from the surface of parquet

Schemes for polishing parquet.

If you are faced with such an unpleasant phenomenon as the appearance of swelling on some parts of the parquet, do not panic. Even if this phenomenon is not capable of causing positive emotions, it can be eliminated.

Parquet swells in case of improper use or violation of installation rules.

In the latter case, you can call the craftsmen who performed this work and ask them to fix the defect.

You can eliminate the swelling of the parquet only by completely re-laying it.

If the swelling is small, you can try the following:

- The swollen surface must be heated with a hair dryer. You can also use a household appliance, but then you need to heat it at maximum power and for a longer time.

- After a distinct smell of glue appears in the air, place a weight on the area to be treated. Calculation of at least 10 kg of load for every 10 cm of surface. It should be left for a day.

After 24 hours, carry out an inspection. If the defect remains, the procedure can be repeated.

Whatever type of damage you encounter, remember that restoring parquet flooring yourself is a complex and time-consuming task. If you doubt your success, you should turn to professionals.

«>

Partial replacement of parquet

If the parquet boards have moved away from the base or are severely damaged, then a partial replacement of the coating will have to be carried out.

First of all, you need to dismantle the hopelessly damaged areas of the parquet flooring. During dismantling, you need to be extremely careful not to damage the remaining parts of the parquet. After dismantling, you should clean the base from old glue, get rid of dust and dirt - this will ensure excellent adhesion of the adhesive composition and the base of the floor. All that remains is to apply wood glue to the prepared new parquet elements and insert them in place of the damaged ones. Sometimes it happens that new boards literally stick out on the general surface of the floor - in this case, you will need a plane, which simply removes extra millimeters of wood along the grain from the underside of the parquet board.

If it is necessary to replace several parquet boards at once, they must be knocked down/fastened before installation begins. This can be done with glue or small nails. By the way, you can also attach new parquet elements to existing ones on the floor not with wood glue, but with nails - in this case, the nails are driven in at an angle, fastening one element to another.

Please note: if replacing parquet boards is carried out using wood glue, then a weight must be placed in the location of the new boards for several days.

Causes of defects

Before considering ways to restore the flooring to its original appearance, it is necessary to find out the root causes of the deterioration. Most often, defects arise due to improper installation of the planks. This directly depends on the qualifications of the installer and the quality of the source material. The installation technology consists of the following steps:

After this, the surface is treated with varnish or other protective material. After drying, the floor is completely usable. Knowing the basics of parquet flooring installation technology, you can independently carry out basic repair and maintenance work.

The main reasons for the loss of the original appearance of parquet are as follows:

- Superficial wear due to long service life: cracks, chips and abrasions.

- Loss of individual slats due to a violation of the clamping density or their deformation.

- With prolonged exposure to moisture (burst pipes), the tree absorbs water and, after drying, changes shape, which also leads to a change in the appearance of the coating.

There are effective methods to solve these problems. They are used depending on the type of defects, their location and volume.

Whether it will be a cosmetic repair, whether it will be necessary to replace only a section or the entire floor, it is best to advise a specialist. But quite often, having assessed by eye the scale of the work, some of which do not require special professional skills, we can take it upon ourselves and carry out parquet repairs ourselves.

Causes of coating defects

Over time, parquet planks become loose and fall out.

Sometimes, during long-term operation, situations arise when it is necessary to repair a section of parquet floor with your own hands.

Possible causes of defects on parquet floors:

- abrasion of the top layer during a long period of use or heavy traffic;

- damage to integrity as a result of careless handling: dragging furniture, walking on sharp heels and other mechanical damage to the surface;

- with frequent cleaning using a large amount of water, moisture is absorbed into the parquet and gets between the dies;

- the formation of rotting, fungal infections and insect damage;

- use in rooms with temperature changes and high humidity; these factors significantly reduce the service life of wood.

If you do not pay attention to the damage, the defects become noticeable and will require more serious repairs.

When you tap the floor, you can detect by the sound of parquet boards that are loosely adjacent to the surface.

Gaps in the coating

Throughout the year, parquet experiences changes in humidity, sometimes even significant ones.

It gets excessively moistened and then dries out, and as a result, gaps appear between the slats. It is impossible to completely eliminate this process, but it can be mitigated if in winter, when the relative air humidity in the apartment drops below 20%, you use a humidifier. Gaps in parquet flooring pose a potential danger to the floor. And it’s not just about the aesthetics and beauty of its appearance - dirt and debris will get into them, unnecessary moisture during wet cleaning, which will increase the cracks. Long-term absence of repairs and regular exposure to moisture will cause the planks to rot at the site of damage.

For the most part, in these cases, you can repair the parquet yourself.

- If the width of the gap is not very large (less than 3.5 mm) and is located somewhere in the middle of the floor, then it is cleaned with something sharp and thin, for example, thin wire or a knife, and putty with mastic or suitable putty. By the way, you can prepare the putty yourself from birch, beech or oak sawdust (you need to match it to the color) and wood glue.

- If the gap is large, more than 5 mm, then the putty is no longer an assistant - it spreads quickly and “will not stay in the gap.” But it’s still possible to cope. It is deepened, the edges are trimmed with a chisel, if necessary, and cleaned. An insert is cut out of suitable wood, coated with mastic or wood glue and driven into the gap.

- The cracks near communication pipes are sealed differently - using sealant. It is applied with a special syringe. Since this paste is based on acrylic resin, it should not be exposed to water until it dries completely. Excess paste is removed with a spatula. After waiting for complete drying, the surface to be repaired is carefully sanded with fine-grained sandpaper so as not to scratch the dies. Then they paint over it with a stain or paint matched to the color of the parquet using a special swab or brush. The repair work is completed by varnishing or treating with mastic.

Rules for repairing loose boards

Without proper care, parquet flooring will dry out sooner or later, especially if the air temperature in the room is higher than normal or there is a frequent temperature change. As a result, the dies dry out, decrease in size and begin to wobble.

When a problem with parquet occurs on a large area, then it is completely replaced, since partial repairs will take too much time. In addition, replacing one part of the floor surface does not mean that other loose elements will not soon need to be restored.

If you need to update several parquet floors, you need to find products of the same wood species that are similar in color and size. Deformed and loose elements are dismantled using a chisel. In the vacated area where the removed slab was located, the remaining adhesive is removed from the subfloor and the area is thoroughly cleaned. If you need to level the base, use putty.

If it is necessary to change one strip of parquet, the ridge is cut off from it, and the end of the product is processed with a plane. When replacing individual elements of a parquet floor, they are placed in place using an adhesive composition or preheated bitumen mastic.

If you need to replace several adjacent parquet floors, you can assemble a so-called “cage” from dies away from the repair site and then install it entirely so that it visually fits into the surface of the coating. A load is placed on the laid section of parquet and on the adjacent long-glued parquet flooring. When excess glue appears along the edges of the “cage”, it should be removed without waiting for it to dry completely.

After the dies are finally fixed, the area of the floor that has been restored is cleaned with sandpaper, the resulting dust is removed and covered with varnish, mastic or other composition that was previously used to treat the entire floor surface.

Types of repairs

With careful care of the coating, serious repairs can be avoided.

Even such a high-quality and expensive coating as parquet requires regular maintenance and preventive restoration work.

Types of repair work:

- Planned repairs include regular elimination of even the smallest defects. In addition, parquet requires compliance with care recommendations and treatment with special products that extend its service life. Care products can be purchased at hardware and construction stores. Repairs are carried out if the coating has become dull, stains have formed, the dies have begun to creak, or the tightness of their abutment has been compromised. Sometimes it is necessary to remove a floor part for restoration or replacement.

- A major overhaul involves restoring or replacing a large section of pavement. It can be planned, to restore coating defects during long-term use, or unforeseen, when, due to some emergency, a large section of parquet has deteriorated.

If you want the coating to last for decades and at the same time have a beautiful appearance, you need to carry out scheduled repairs of the parquet floor with your own hands or with the involvement of specialists every 3-5 years.

How to solve the problem of squeaking planks?

An old floor, although apparently intact and quite aesthetically pleasing, often begins to irritate with the creaking of individual floorboards. In this case, repairing parquet floors will involve working not with the coating, but with the joists underneath it.

If wooden slabs were originally used as flooring, it is not surprising that after a certain time they become less elastic. In places where the slabs dry out, the floor begins to creak. If the problem is not with the wood, then perhaps the reason is the sagging of the dies. In this case, the beam is leveled by hammering bars under it.

Parquet repair option using dowel nails

A simple and effective method of solving the problem of floor squeaking is to fix the squeaking plate through the joists to the concrete base with dowels. This option will be especially appropriate in the case of repairing panel parquet, given that its elements are quite large and during the repair process will not affect adjacent parts of the structure.

If you need to repair a piece-type parquet floor, then it would be correct to drive pins between the squeak-reducing dies. To accomplish the task, it will be enough to drill holes along the diameter of the pin. The sides of the pin are coated with special glue, after which they hammer it into the hole and cut off the excess protruding part.

How sanding is carried out: the cost of repairing old parquet

As for grinding, you can use a variety of abrasives. Sandpaper is considered the simplest. Of course, doing the work manually is quite long and difficult. To speed up the restoration, some people attach sandpaper to the base of the shoe, but this method is not widely used due to the fact that it is difficult to control the work of the legs and maintain the same pressure.

A more advanced repair option is the use of a drum-type sander. The device is mainly used for deep sanding, because coarse abrasive cannot leave behind a perfectly smooth wooden floor. In one pass, the machine removes 1.5-2 mm of coating. To prevent dust generated as a result of removing the coating from spreading throughout the room, the device is additionally equipped with a dust collector. The most popular model of parquet sanding machine is considered to be SO-206, the price of which varies from 56 to 70 thousand rubles.

During the process of both grinding and sanding, scratches may appear when large abrasive grains leave marks. This is especially noticeable on soft types of wood, such as pine. In this case, you can re-grind or cover the damaged areas with restoration paste. After completing all restoration work, you need to apply a protective varnish coating, which not only makes the parquet attractive, but also protects the surface from mechanical damage.

A drum sander is best suited for sanding parquet.

On a note! It is recommended to repeat floor polishing at least once a year. The more layers, the stronger the coating. All work on applying the varnish layer must be carried out in a respirator.

As for the price of restoring old parquet, it directly depends on the original condition of the coating. If the parquet is in satisfactory condition and you only need to go over it with a sander and also restore the varnish layer, then the cost will be about 850 rubles/m². When you want to make the floor covering perfect, you need to carry out a variety of work: sanding and sanding with a drum machine, re-sanding with a surface grinder, tinting and applying varnish. Such work will not cost less than 1250 rubles/m².

Parquet is an expensive floor covering that has long been admired. Even the cheapest parquet option will always look better and last longer than the most expensive laminate. In order not to have to carry out major repairs of parquet, it is recommended to carry out restoration and restoration work from time to time, which can extend the life of the material. Even a simple application of an additional layer of varnish will help refresh the parquet and restore its shine.

Removing old floors: secrets of successful renovation (read more)

Features of parquet repair without sanding

After laying parquet or parquet boards, scratches are inevitable, because the floor is constantly damaged by shoes, furniture legs, animal claws, as a result of children's games or when heavy objects fall onto the surface. In some cases, you can try to restore the parquet without sanding, using a retouching pencil or putty that matches the color of the main coating. If the area is small, you can do without sanding and using varnish.

If the defect is minor, you can use a special putty or pencil.

Damage and scratches from the boards are removed using cosmetic putty, which is applied using an ordinary thin spatula. Finding the right color is not difficult, because retail establishments offer a wide selection of materials.

On a note! The second name for parquet putty is restoration paste. If you can’t find the desired option on store shelves, you can try making the paste yourself.

To make decorative putty, you need to mix crushed sawdust and epoxy varnish in a ratio of 1:4. After this, the required amount of dye is added to the mixture. The finished paste is applied to the damaged area, which is then treated with fine sandpaper.

Sometimes, after restoring oak parquet, in order to create a complete picture, it will be necessary to imitate joints in some areas using an ordinary awl and a metal ruler. Work should be carried out when the restoration paste is partially dry; it should not be very hard, but it should not stretch. Step-by-step instructions for repairing parquet with your own hands:

Cosmetic putty is applied to the damaged area using a spatula.

- Using a ruler applied at the end, make a small indentation at the joint.

- Using an awl, apply the end false joints along the attached ruler.

The final stage of such a restoration is considered to be varnishing the parquet. It is appropriate to use any type of varnish here: alkyd, epoxy, acrylic or water-based. Before using the composition, it is recommended to study the application features specified in the instructions. You also need to take into account that to obtain a perfectly smooth surface you will need to apply at least 2-3 layers of varnish. After the varnish has completely dried, to obtain a better result, it is recommended to rub the surface with mastic, after which the restoration of the old parquet with your own hands without sanding is considered complete.

What tool is used to restore and repair old parquet: sanding

The main tool for manual scraping is considered to be a scraper, the task of which is to scrape, rather than plan, a wooden covering. The device itself is a simple design and consists of a metal plate sharpened at an angle with a fixed handle.

Main technical characteristics of the device:

- Blade thickness. It is selected based on the height of the coating, taking into account the applied paint layer. A blade with a thickness of 0.7-0.8 mm is considered optimal; in this case, the size of the peeled layer should not exceed a few millimeters.

- Blade width. The wider the base, the larger the layer you can remove in one pass. Experts recommend purchasing a tool whose width does not exceed 45 mm; If the blade is wider, the scraper will be difficult to work with.

- Handle length and material. It is more convenient to control the pressure if the tool has a short handle. Recommended length – 45 mm. The material is chosen based on personal preferences, but still many note that when working with a wooden handle, the hand sweats less than after working with a plastic one.

Manual scraping of parquet is carried out using a special tool - a scraper.

Additionally, for ease of use, many product options are equipped with a pressure handle, which allows you to increase the pressure on the working tool. Separately, we should highlight the figured cycle used in the repair of block parquet to decorate the figured wooden plinth. The estimated cost of the device, depending on the characteristics, varies from 100 to 200 rubles. If a blade breaks during operation, it can be easily replaced by purchasing a new one. At the same time, the price of blades ranges from 30 to 50 rubles.

The main advantages of using cycles:

- low cost of the device;

- the ability to carry out repairs in hard-to-reach places;

- maintaining the appearance of the coating;

- absence of dust during operation.

It should be noted that when repairing artistic parquet, the use of cycles makes it easy to carry out actions, observing the correct direction of the wood fibers.

In addition to the advantages, there are also some disadvantages:

- time-consuming work;

- removing a fairly thick layer of coating;

- the need to exert a large amount of physical effort;

- working in an awkward position.

Work is done much faster and easier using a sanding machine.