If you choose a finish for the facade solely for reasons of practicality, you should pay attention to corrugated sheeting. Strong, durable, not too expensive, this material is widely used in private construction. And if earlier it was used more for fences and roofs, now it is actively used for external walls. Sheathing a house with corrugated sheets does not require special skills, and if you know how to handle construction tools, the installation will not be difficult.

Sheathing a house with corrugated sheets

The corrugated sheet can have not only a colored decorative coating, but also imitate wood, stone

Sheathing a house with metal profiles

The facade is the face of the building.

In addition to decoration, it performs a number of technical functions to protect the foundation of the house. The façade system improves the energy efficiency of the building. Due to cladding, heating and air conditioning costs are significantly reduced. Read our article on how to install an air conditioner on a ventilated façade. Facade systems are divided into two groups:

Among framed facades, the metal ventilated facade is especially popular. With its help, facades of residential buildings, public buildings, production workshops and a number of other objects are equipped. Let's take a closer look at this technology, its pros and cons, types of facing materials, installation options, and methods of caring for the suspended facade system.

How to make a cornice hem with corrugated sheeting - we hem the roof correctly

The service life of the erected roof is positively affected by lining the eaves with corrugated sheeting. This process is simple, but it will protect the under-roof space from the penetration of rodents and birds.

The roof is the most complex part of a house being built, since it consists of a large number of elements that are closely interconnected with each other. Some novice craftsmen, due to insufficient experience, believe that after installing the roofing, the installation of the roof is complete.

In fact, such work as installing a drainage system and lining the roof eaves with metal profiles or other materials is of no small importance for its proper functioning.

What is a ventilated facade

A ventilated facade is a sheathing made of metal profiles, mounted on mineral insulation and covered with profiled sheets, siding, natural or artificial stone, and galvanized panels. The peculiarity of the system is the presence of a technological gap between the mineral insulation and the external cladding material. Air constantly circulates through it, which removes excess moisture, thereby preventing the appearance of mold and mildew.

A ventilated façade made of galvanized metal is often used for finishing private houses. The suspension system includes several groups of elements:

Let's look at each group in more detail.

Substructure elements

This is the framework of the system. It bears the entire load from the facade. Elements of the substructure must have sufficient strength and resistance to corrosion. They are made from cold-rolled, hot-dip galvanized high-quality steel. As a result, the warranty on the supporting system of the galvanized facade is at least 30 years. The substructure consists of several elements:

Coating

To construct a ventilated suspended facade of a private house, a metal profiled sheet or siding is most often used. These materials are made of galvanized steel with a polymer coating, which can be painted according to the RAL system.

The metal coating protects the facade from the negative effects of precipitation. It does not collapse and practically does not fade under the influence of ultraviolet rays. Metal profiled sheet or siding can withstand significant mechanical stress without losing its protective functions.

Fastening the metal profile to the wall is carried out quickly, with a minimum number of tools.

Additional elements

They complement the main cladding, giving the suspended facade system a finished look. Made from galvanized steel. There are several types of additional elements:

Shaped elements

The galvanized steel facade consists not only of the main surface, but also of window sills and slopes. There are special strips for their device:

Insulation

Thermal insulation is a gasket between the outer cladding and the wall. To install a galvanized ventilated facade, mineral wool with a density of 50 kg/m3 to 80 kg/m3 is used. The outer layer of insulation always has a density of at least 80 kg/m3. It has a low thermal conductivity coefficient and low weight. Mineral wool does not have the lowest water absorption rate, but due to additional protection it can be used for constructing a suspended facade.

Mineral-based insulation does not emit substances harmful to the human body. After completion of the work, the mineral insulation is securely hidden under a layer of vapor barrier and galvanized metal cladding.

Wind protection

This is a thin membrane material that covers the insulation. Its main function is to release heat exchange products in the form of steam and water outside, while not letting moisture in. This effect is achieved through high-tech membrane-based covering material. Each membrane releases water only in one direction. The facade is covered with windproof fabric before installing the metal profile on the wall.

Hardware

Fastening elements perform an important function in connecting parts of a ventilated facade to each other:

Basic properties of the material

To make corrugated sheets, thin sheet steel is used, protected from corrosion by a zinc coating. After rolling in machines, flexible metal turns into corrugated profiles with waves of different configurations and sizes, and acquires additional characteristics. To enhance the protective properties, the sheets are coated with a polymer composition, and a decorative layer is applied to the front side. Stiffening ribs give the product high strength with low weight, which helps reduce the load on the base. And the greater the height of these ribs, the more resistant the corrugated sheet is to mechanical loads.

The service life of the cladding depends on the type of protective coating: simple galvanized corrugated sheeting lasts about 30 years, and polymer-coated corrugated sheeting lasts up to 45 years or more. The material can be machined and is easy to drill and cut, making installation of sheets effortless. If necessary, corrugated sheeting can be dismantled and reused without deteriorating performance characteristics.

How to sheathe a house with metal profiles

At first glance, constructing a façade made of metal profiles may seem like an impossible task. This is not true, the work can be done with your own hands. The main rule is that you should not climb to a height above the second floor without preparation and skills. To perform high-altitude work, you will need the help of specialized teams. They will do the work quickly, efficiently, without risking your life.

Work on installing a ventilated façade can be divided into several stages:

Inspection

It consists of visual and, if necessary, contact sanitation. It is determined what material the load-bearing wall is built of, its age and visual strength. This is necessary to select the type and length of anchors for attaching the brackets.

The facade is measured, its area, the number and size of window and door openings are determined. This will allow you to order the required amount of material without overpaying for excess.

Ordering material

An important step that is carried out after making a sketch of the future facade on a piece of paper. A sketch is a development of a facade with window and door openings. It indicates all the required dimensions and areas. The sketch also indicates zoning if the façade is planned to consist of more than one color.

Types of canopies made of metal profiles

When building canopies, it is necessary to focus on their shape and spatial position.

Semicircular profile canopy

In accordance with these criteria, the following main types of canopies are distinguished: single-pitched, gable, arched.

Single-pitch canopy

This type of canopy is very convenient because it has the shape of an inclined plane located at an angle. This design provides maximum protection for the area and also has a natural drainage system. Water and other precipitation are not able to linger on the inclined plane, thus protecting roofing materials from premature deterioration.

If you want to make a lean-to canopy from a metal profile with your own hands, you need to take into account several features. First, determining the angle of inclination is key. If it is too steep, then there is a risk of unwanted moisture getting under the canopy, and there is also a high probability of damage to the metal under the influence of strong gusts of wind.

Single pitch carport

Secondly, it is imperative to consider the organization of the drainage system, since the constantly rolling liquid will turn into a water flow capable of eroding soils.

Thirdly, the choice of slope direction should be based entirely on statistical data on the predominance of air masses, or more precisely, their direction.

To obtain such data, you can use the services of meteorologists, or independently note the wind direction for six months.

And fourthly, additional strengthening of the canopy should not be neglected, especially in regions characterized by frequent gusts of wind. A lean-to canopy made of metal profiles will perfectly protect not only from precipitation, but also from excessive sun, which is extremely convenient for all seasons. Most often it is used not as a separate structure, but as an extension.

Detailed diagram with dimensions of a lean-to canopy

Gable canopy

In those regions where it is difficult to determine the prevailing wind direction, a gable canopy made from a profile is more often in demand. It differs from a lean-to roof by an additional plane; this design looks like a regular house roof, but has a slightly different structure.

Such a canopy has many more advantages, since its area allows it to cover much more territory than in the first case. To achieve maximum effect, as well as make the structure reliable, it is necessary to use a more serious fastening system that requires additional profile supports.

Multi-slope awnings

It is most convenient to equip exhibition centers, playgrounds and car parks with multi-slope canopies, which look like a cascade of gable canopies.

A multi-level arrangement allows you to maximize the area covered, but the installation process will take much longer.

This is due to several needs:

- measurements and drawings (in order for the multi-slope canopy to be durable and fully perform its functions, it is impossible to do without accurate measurements and design skills);

- selection of suitable material;

- mandatory arrangement of drainage and stormwater systems.

You can often find a multi-slope canopy in a private house, which plays the role of an extension of the garage, serving as an excellent option for protecting vehicles from precipitation.

Arched canopies

For those for whom a canopy is not only a means of shelter and protection, but also a decorative element, an arched canopy is ideal.

Option for installing an arched canopy from a profile

It has an attractive and neater appearance, which does not in any way affect its quality characteristics, giving any home or area individuality.

The main disadvantage of such canopies will be their higher cost. This is explained by the fact that it is almost impossible to make a canopy from an arched profile with your own hands. This will require special tools, as well as knowledge and skills in working with metal.

Stages of covering a house with corrugated sheets, nuances of the installation process

The topic of the article is covering a house with corrugated sheets. This building material has been used in construction for a long time. And if earlier these were gray inexpressive sheets, which were mainly used for cladding hangars and warehouses, as well as in the formation of barrier structures, today it is one of the most popular building materials. Today we will talk about corrugated sheeting, its varieties, and the technology of cladding houses using this material.

House sheathed on the outside with corrugated sheets Source remontik.org

How to calculate the required amount of material?

Sheathing is carried out both vertically and horizontally, in accordance with the choice of the owner. Calculating the amount of material needed begins with measuring the walls of the house.

For measurements, you will need to know how long the profile sheets are. It is this value that will be involved in calculating the volume of the required material.

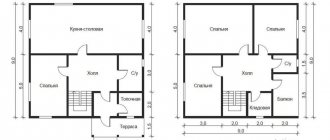

Let's give a detailed example: the height of one wall of the house is 2.8 meters and its length is 6 meters. The height of the other wall is the same 2.8 meters, but the length is different - 8 meters.

The square footage of the surface to be covered with the material is calculated as follows: (8x2.8) + (2.8x6) = 39.2 square meters of area for adjacent walls.

The perimeter of the house is made up of four walls, which means that the figure should be doubled, and the figure is 78.4 square meters.

The room takes into account the doorway, as well as windows. It is their parameters that are calculated and subtracted from all square meters of the surface to be covered.

In our example, the door will have a width of 1.4 and a height of 1.9 meters. Six identical window openings with parameters 1.5x1.3. As a result, it turns out that the total area that does not need to be covered with corrugated sheets is 14.36 square meters.

This figure is subtracted from the original area, and the result is a figure that should be followed when covering. In our example, it is 64.04 square meters.

In order to calculate the number of sheets needed to cover a house, you need to divide the resulting sum of the total surface area of the house by the area of one sheet already measured, then you will get the required number of sheets that will be used in the work.

It is important to know that you need to add another 10 or 15 percent of the material for backup options to the obtained figures. This is done for extreme cases of material damage or measurement errors.

What is corrugated sheeting

The production process of profiled sheets is quite simple. So, the raw material is galvanized sheet in a roll with a thickness of 0.35 to 1.2 mm. Profile forming technology – cold rolling. That is, a roll of steel sheet is untwisted by inserting the end into a rolling mill. The equipment system has rollers of different sizes. They are located sequentially. And the further you go, the larger their diameter.

That is, the sheet is rolled between rollers. Profiles are obtained on it. And in this way rolling continues until the required wave parameters of the corrugated sheet are formed. After which the sheet is cut on a special machine. The maximum sheet length is 13 m, the minimum is 0.5 m. In this case, trimming can be adjusted to any size in increments of 0.5 m.

Technology for the production of corrugated sheets Source one-stroy.ru

Today, corrugated sheets are not just galvanized panels, although these are also available for sale. These are sheets painted or treated with polymer compounds with a long service life. Manufacturers are gradually stopping using paint, because the material with a polymer layer has higher performance characteristics. For example, a painted sheet will last no more than 15 years, with a polymer coating - up to 50 years. It should be noted that the finished corrugated sheeting is not painted or polymerized. This ready-made raw material in the form of sheets in rolls leaves the factory in this form. That is, they paint it or apply polymer in a factory using special equipment.

Corrugated sheeting is a certified material, that is, a state standard has been created for it under the number 24045-2010. But it should be noted that not all manufacturers adhere to this document and produce their products according to technical specifications (TU), but this does not contradict current legislation.

Corrugated sheeting with trapezoidal wave Source roomester.ru

So, according to the presented GOST, profiled sheets are divided into three groups:

Since the topic of the article is covering a house with corrugated board, we will be mainly interested in the wall option. Although it should be noted that the other two can be used to decorate the walls of houses. They just cost more, so there is no point in resorting to their use.

So, the wall corrugated sheeting is marked with the letter “C” with the addition of digital parameters of the sheet, where the main one is the height of the wave. For a wall one, this size varies from 8 to 44 cm. It is the height of the profile that determines the strength characteristics of the material. The larger it is, the higher the strength.

Most often, the C-8 brand is used to decorate a house with corrugated sheets. Firstly, this is the cheapest option. Secondly, it has excellent strength characteristics. But when choosing a brand, it is necessary to take into account the loads acting on the building. For example, if the wind loads acting on the building are large, then it is better to carry out the cladding with sheets of grade C-15 (20 or 21). They have higher strength and are practically not prone to bending.

Single-pitch design

This canopy device is considered the simplest. The plane is flat, but there is a slight slope so that rainwater can drain without obstacles. There is no need to make a large slope, otherwise the lean-to canopy will become impractical and will not fulfill its intended role.

The optimal slope would be 10 cm by 2 m.

The construction of a single-pitch type canopy consists of erecting support pillars for the structure. Between them there are so-called purlins, onto which transverse veins are subsequently welded. It is on them that the corrugated sheeting will be screwed. Therefore, it takes a little time to make a canopy from corrugated sheets. That is why a lean-to canopy made of corrugated sheets is very popular among owners of private or country houses.

Purlins are welded on top of the trusses, onto which corrugated sheeting is screwed.

Sound insulation and installation of drip tides

Many people are faced with the problem that it is impossible to stay under a corrugated sheet canopy when it rains. The fact is that corrugated sheeting is made of steel, so when drops of rainwater fall on its surface, a roar is heard. To avoid this, before installation, you should spread a special soundproofing film over the entire surface. This will keep the structure quiet for a long time.

It is also worth taking care of the installation of ebbs, which will allow rainwater to drain away. At the end of the corrugated sheet canopy slope, brackets should be welded to the support beam. This must be done with a slight slope in the direction in which the water will flow. The brackets have special latches, so you can easily insert individual gutter elements into them. But to achieve maximum results, all joints should be coated with sealants or silicone. Plugs are placed along the edges of the gutters, which are also coated with silicone. Next to the plug there is a hole to which the drain pipe is connected. This way, even with heavy rain, all the water will drain in a certain place.

- Sheets of corrugated sheets come in separate packs. In order to avoid scratching, you should carefully lift them from both sides and under no circumstances pull them together.

- When cutting material, you should use only a hacksaw or special scissors. A grinder cannot be used for these purposes, because when cutting, the edge heats up and the protective layer in the cut area will be damaged. This, in turn, can lead to premature corrosion.

- When installing corrugated sheets, you do not need to apply excessive force. The screws must be tightened carefully. The rubber gasket should not be deformed so that water does not subsequently enter the hole.

- Before painting, it is best to pre-coat the canopy frame with 2 layers of primer. There should also be at least two layers of paint.

If you follow these fairly simple rules, the design can serve you for many decades.

Technology of house cladding with profiled sheets

Let’s immediately make a reservation that finishing a house with corrugated sheets is the construction of a ventilated facade. That is, a frame made of metal profiles is installed on the outer walls of the building. And then the profiled sheets themselves are mounted on it. Metal profiles for the facade of a house are either special elements or profiles that are used for installing plasterboard sheets.

Let us add that a ventilated facade is an opportunity to insulate the walls of the house from the outside. That is, thermal insulation material is placed between the cladding and the walls of the building. The design is really great. It turns out, as they say, two in one: thermal insulation plus decorative cladding.

Calculation of required material

In order not to increase the budget, it is necessary to accurately calculate the amount of corrugated sheeting required. To do this, the area of window and door openings is subtracted from the total area of the wall, which is the height times the width. Here you can add the area of the gables if they are sheathed with corrugated sheets.

How to calculate wall area Source vse-otoplenie.ru

Now you need to find out the usable area of the profiled panels you are purchasing. Please note that each sheet has a total width and a usable width, so to calculate the area, the latter is taken. And now the total sheathed area must be divided by the area of one sheet, we get the number of required panels.

In addition to corrugated sheets, manufacturers today also produce additional elements. There are few of them:

external corner

to decorate the outer corner of the house;

connecting strip

, with the help of which the joints formed between two adjacent sheets laid in the same direction are closed;

end and slope strips

;

All additions are selected in size in accordance with the dimensions of the house and its structural elements.

Useful width of corrugated sheet Source poctroyka.ru

Preparing the walls

First of all, the following are dismantled from the wall surfaces: platbands, flashings, drainage system, decorative items, lamps, etc. Then repairs are carried out. There is no need to level the surfaces, but it is necessary to repair cracks, holes, chips and gouges, as well as clean them from mold and fungi.

If a wooden house is finished with corrugated sheets, then all wooden surfaces are first treated with an antiseptic compound that will fight fungi and mold, and after drying, it is treated with a fire retardant compound. The latter increases the fire resistance of wood.

Choosing corrugated sheets for exterior finishing

For cladding a wooden cottage, choose a profiled sheet with a polymer coating. However, a protective layer made of polyester is not the best option. Yes, corrugated sheeting with such a coating costs less than a sheet protected with pural or, especially, PVDF, but this is a false economy. If you compare not only the price, but also the expected service life, then the polyester coating will be the most expensive. Moreover, without taking into account the costs of installation work when replacing the cladding.

As for the brand of corrugated sheeting, any wall type will do, including profiled sheet C8. But if you are looking not for something cheaper, but for a better way to sheathe the outside of a wooden house, we advise you not to get carried away with corrugated sheeting with a minimum profiling depth. Especially if we are talking about a large area. Grades C8 and C10 are good for small sheds, outbuildings, frame garages, cladding of very small houses and dachas. For a private home, it is better to choose a more rigid metal profile: C15, C18, C20, MP20 or even C21.

Wall grades of corrugated sheets suitable for cladding a wooden house

| Brand | Useful width, mm | Profile depth, mm | Short description |

| C8 | 1150 | 8 | Corrugated sheeting with a minimum profiling depth, and therefore with a minimum load-bearing capacity. This profiled sheet is suitable for cladding small cottages, sheds and other utility rooms, as well as for the construction of temporary fences. |

| C10 | 1100 | 10 | Corrugated sheet with a slightly higher load-bearing capacity than the C8 brand, with an asymmetrical profile. Thanks to this, it better withstands wind loads when cladding walls, but is still not suitable for cladding relatively large areas of building facades. |

| C15 | 1130 | 15 | Asymmetrical corrugated sheeting, which is well suited for installation on the walls of buildings. Withstands greater wind loads due to the higher wave height, but is manufactured not according to GOST, but according to the manufacturers' specifications. Because of this, the usable profile width varies from supplier to supplier. |

| C18 | 1150 | 18 | Finishing a wooden house with C18 corrugated sheet is a good choice due to two small intermediate stiffening ribs that are located on each wide profile arm. Unfortunately, such a profiled sheet is also made according to specifications, and this profile shape does not look good for sheets with a textured coating. |

| C20 | 1100 | 18 | A popular brand of corrugated sheeting, also with an asymmetrical profile. Ideal for cladding a wooden house due to its relatively high load-bearing capacity. Even if the building is being built in a region with high wind load. |

| MP20 | 1100 | 18 | A complete analogue of the C20 brand, which is produced by another manufacturer. |

| S21 | 1000 | 21 | Corrugated sheet with a symmetrical profile. It is used for cladding industrial and public buildings, as well as for covering roofs. It is also suitable for covering the walls of a cottage, but in most cases such a choice will be unnecessary. |

All brands with a profiling depth greater than 15 mm can be used for cladding a cottage made of wood. Therefore, when choosing, focus on the appearance, prices, and availability of a specific brand from your supplier.

Video description

The video shows how to properly repair the facade of a house:

Frame installation

The next stage is covering the house with metal profiles. It should be noted right away that corrugated sheeting can be laid on walls horizontally and vertically. Accordingly, the frame elements will be mounted vertically or horizontally. In this case, the cladding, both in the first and second cases, will be a structure with high protective functions. She is not afraid of heavy slanting rain, snow, or strong wind.

Vertical cladding of a house with corrugated sheets Source pinterest.co.uk

So, how to install the frame.

First, markings are applied

on the walls under mounting brackets. You need to start from the corner of the building. Mark the vertical using a plumb line or laser level. Marks are made on it every 50-60 cm.

Having retreated 40 cm, repeat the operation

. And in this way vertical lines are applied across the entire width of the wall.

a puncher, holes are made using the marked marks.

, where plastic dowels are driven with a hammer.

Install galvanized metal brackets

, which are attached to the wall with self-tapping screws. It is recommended to place a paranitic gasket between the bracket and the wall.

Next, install the guides

. That is, the profile is laid on installed brackets, aligned either vertically or horizontally, and secured with metal screws to the brackets. And thus all the elements of the sheathing. The main thing is that all the guide profiles are in the same vertical plane. Distortions and differences are not appropriate here. Even a small difference can affect the quality of the skin.

Some important tips from professionals

- Installation of profiled sheets on the sheathing should be carried out exclusively in a plumb line;

- The corrugated sheet should be secured to the sheathing using self-tapping screws with a press washer and a rubber gasket. This should be done along the lower edge. The fastening step is through 1 rib;

- You can achieve the best aesthetic qualities of the cladding if you fasten the screws strictly along one horizontal line. To do this, you can draw a line with chalk using a level or pull a string.

Useful little things

- The profiled sheet is mounted strictly plumb.

- Self-tapping screws attach it to the profile at the bottom of the wave. Step - through one wave.

- For high wind loads, installation of sheathing made from profiled thin-walled pipe is practiced.

- To ensure that all the screws are positioned strictly horizontally, pull a thread across the profile and guide yourself along it.

We described installation with a vertical wave arrangement. However, nothing prevents you from fixing it horizontally.

Beautiful examples

Houses finished with corrugated sheets are becoming more common today.

Thanks to production according to certain requirements and standards, this facade cladding gives a beautiful appearance to any, even the most modest building.

- One of the options for transforming a house could be metal siding “like a log.” Volumetric profiled sheets that imitate logs in texture and color are a profitable, practical and universal solution. From a distance, the house looks like a classic wooden structure, without having to look for ways to deal with problems such as mold and insects.

- You can choose another option as a façade cladding. Imitation brick or simply colored decoration can give the building a solid and “expensive” look.

Video description

The video shows how to assemble a frame for a profiled metal sheet:

As for the metal profile for drywall, it can also be used. To do this, choose a rack or ceiling profile as the most durable. And direct hangers are used as fasteners to the walls. The photo below shows just such an option.

Frame made of metal profiles for sheathing with corrugated sheets Source oooarsenal.ru

Often, to strengthen the structure of the metal sheathing, cross members are mounted between the installed profiles. These are sections of the same profile that are installed between adjacent long frame elements, fastening them into a single cellular structure.

And the last thing at this stage is laying the thermal insulation layer. For this you can use mineral wool or polystyrene foam boards. They are simply laid between frame elements, attached to the wall surface either with dowel-nails or special adhesives. To increase the strength of the fastening, craftsmen often use both the first and second options simultaneously. Do not forget that the insulation layer must be covered with a windproof membrane.

How to build a canopy with your own hands

If there is a need to build a canopy, then the easiest, fastest and cheapest way to build a lean-to canopy with your own hands. Let's consider a simplified version of building a small lean-to canopy.

Calculation of a metal profile canopy

Before you begin assembling and purchasing structural elements, it is worth carrying out at least an approximate calculation of the future structure. Both the price and the materials themselves will depend on the results of the calculation. If the canopy is small in size, and it will be covered with light material, then you can use lightweight hollow steel, especially if the level of winter precipitation is not too frightening.

If the level of snow cover is high, then it is better to play it safe and place the racks more often, and you can cover them with corrugated sheets or galvanized sheets.

The calculation is an individual matter, but on average, for a lean-to canopy with a light shelter, 25 mm square sections will be sufficient, and trusses can be welded from a 20 mm profile. For a six-meter canopy this will be quite enough. If the dimensions are larger, then the sections of the profiles need to be increased.

What is good about ventilation façade technology?

Professional builders highlight several main advantages of the technology of suspended ventilated facades:

By the way, thanks to the ventilated facade, the dew point moves from the walls into the insulation - thanks to this, the walls get less wet.

Some home owners are afraid that with a facade made of corrugated sheets the noise of rain will be very audible. These fears are unfounded. Firstly, because raindrops, as a rule, fall at an acute angle to the facade and create not at all loud sounds. And secondly, because thermal insulation dampens all noise.

Features of the cornice device

When developing a roofing project, it is always provided that it extends beyond the outline of the perimeter of the building. The roof overhang is the space between the lower edge of the slope and the walls of the house. According to building codes and regulations, it should be no less than 40-50 centimeters.

Roof overhangs serve to drain rain and melt water that rolls off the roof surface to the maximum possible distance from the walls and thereby protect them from getting wet.

There are two types of overhangs:

- cornice - it is formed between the lower edge of the slope and the side wall of the building;

- pediment - represents the extension of the roof beyond the gables of the building; it is equipped using sheathing or rafter structure.

By the way, cornices are built by lengthening the legs of the rafters or installing fillies - this is the name given to the bars used to lengthen the rafters so that the overhang becomes wider. Since the load on the roof outside the perimeter of the building is small, boards of a smaller cross-section are used for their manufacture. The fillies are secured to the rafters with metal strips or nails.

Which corrugated sheet should I choose?

There are a number of specific types of corrugated sheets that are best suited for constructing a ventilation façade. Builders advise taking the following (with a thickness of at least 0.5 mm):

S-21, S-44, MP-10, MP-18, MP-20, MP-35, NS-35.

Why these types of corrugated sheets? The answer is simple: because their relief will not spoil the appearance of your facade. In addition, their load-bearing capacity is sufficient to withstand daily loads.

Of course, no one will forbid you to use even N-114 corrugated sheeting. But not everyone will like its appearance with a relief height of 114 mm on the walls. And the load-bearing capacity for the facade is excessive.

By the way, for MP-18 corrugated sheeting, special elements are provided for framing the internal and external corners of the facade.

Types of profiled sheets

- Sheets marked "C". The level of rigidity allows it to be used as a material for finishing facades and walls, and installing low fences.

- Sheets marked “H” are the best roofing material.

- Sheets marked “NS” are suitable for all types of work. These are mixed sheets.

Sheathing houses with corrugated sheets is best done with material marked “C”.

As for the choice of color for building cladding, experts do not recommend using more than 3 colors. A sophisticated appearance can only be guaranteed by a properly selected color palette.

For example, the combination of white and blue gives the home a harmonious look. For the foundation, the colors of natural stone or brick are most often used.

Instructions for installing corrugated sheets on the facade

Corrugated sheeting using ventilated facade technology is installed in two stages:

Let's look at each one separately.

First stage: installation of the substructure

The substructure is the metal frame of your ventilated façade. There are two main types of substructure when it comes to corrugated sheet cladding. Each of them is used for different types of walls.

Now let's figure out how to install a metal substructure along with insulation and waterproofing. This is quite easy to do in 6 steps:

Don’t forget: you are installing corrugated sheeting using ventilated facade technology, so it is very important to leave this very ventilated gap. Calculate the distance between the thermal insulation and the cladding so that it is at least 4 cm. This way the insulation will be ventilated and function normally.

Choosing a suitable metal profile

Most often, a metal siding profile with a U-shaped cross-section is used to make a load-bearing frame system. This profile has a galvanized coating, and its dimensions have the following values:

- length – 3m;

- cross section – 60x27 mm.

A similar type of profile strip is also used in the construction of plasterboard structures for interior decoration. Why can’t I use a profile for metal siding with a smaller cross-section, for example 40x40 or 50x50 mm? Because it is not equipped with a special flange along the edge, which serves to give the bar additional rigidity.

Sheathing the plinth and foundation

The basement part of the house is one of the most important. The covering of such a surface must be done with high quality. When working, you need to remember that the result should be an acceptable appearance and protection from wet damage to the surface.

It is not enough to purchase only profiled sheets for such finishing. You need to stock up on waterproofing and heat-insulating materials in advance.

Finishing the base begins with measuring the sheets. It is important to decide in advance what height and size the corrugated sheeting layer will have on the base part.

To cut metal, you will need a grinder or special scissors designed for separating metal structures.

If the master's choice is a grinder, you need to take discs with the least thinness, but it is better to use scissors that can make a cut of the correct shape without defects.

Of course, working with scissors will slow down the whole process a little, but the edges of the product will be smoother than with other methods.

Ideally, it is better to select sheets in the store that do not need to be adjusted to your base, since they will already be suitable for use.

After cutting the sheets, they need to be impregnated with a composition of paints and varnishes. This will avoid burrs and cracks on the surface.

Sheathing process

Work on covering the basement of the building begins with the installation of a waterproofing layer. There are several ways of high-quality waterproofing of this building object:

- waterproofing using coating material.

- In recent years, builders have begun to use membrane waterproofing.

- If the task is to use dense waterproofing materials, it is best to use adhesive protectors.

Experts recommend using bitumen mastic as a reliable solution. The surface of the base is coated with this product several times so that it is thoroughly saturated.

It is also possible to use other compositions available on the building materials market.

This waterproofing material is distinguished by its high-quality composition, ease of installation and durability. To install this type of insulation, you need to cover the surface of the base with membrane material and secure it with special locks;

Any materials from the roll series are suitable for this process. The product is heated before gluing.

After carrying out waterproofing work, you need to make a frame on which the corrugated sheets will be held.

To create the sheathing, it is recommended to use wood or metal profiles. The sheathing is installed using dowels on special hangers.

If the master has chosen a metal profile as the base of the product, it must be fastened so that the lower ends serve as guides and are installed in a horizontal position.

Then the surface is insulated and finished:

- Insulation material is laid between the frame posts. It is recommended to use polystyrene foam or polystyrene foam.

- If the frame is made of a metal profile, then the corrugated sheet can be fastened using self-tapping screws.

- The process of cladding the basement segment of the building is carried out from the corner part.

- In the basement there should be places designated for ventilation openings of the building.

- If, after installing the corrugated sheeting, the corners do not turn out smooth, or defects appear on them, you can cover the inaccuracies with special corners, which are sold in hardware stores.

It is important to take into account that the screws must be equipped with water-resistant gaskets.

The joints will form cracks during reinforcement. Such gaps must be covered with additional materials.

It is through such openings that the subfloor and basement floor in the house will be ventilated. Such places are treated with finishing strips.

If the color of the installed sheets does not satisfy the interests of the master, it can be painted in a different shade. If the material wears out, after a few years it can be easily replaced with new sheets.

There are some types of corrugated sheets designed for repeated use. Sometimes craftsmen use used sheets to build fences or buildings intended for household needs.

How to cover the base of a frame house with a profile sheet with your own hands, see the video:

Preparation

Minor defects in a log or stone house are completely invisible under the sheets, so it is not practical to waste time on leveling. It will be enough:

- seal cracks;

- caulk the cracks;

- carry out treatment against fungus.

Before starting work it is necessary to dismantle:

- drainage system;

- platbands;

- lamps, etc.

Brick with traces of fungus is treated with chlorine-containing compounds. The tree is coated with a primer and antiseptic at least 2 times.