Today, porcelain stoneware in the construction market is considered a popular material for finishing floors, especially among cottage owners. After all, the interior of a room with this flooring looks modern and aesthetically pleasing.

Porcelain tile is a durable man-made finishing product that comes in tiles of different sizes and textures. It is made from kaolin or illite clay - the main component, under high pressure.

The formed forms are fired at a temperature of about 1300 degrees.

Granite differs from ceramic tiles in the technological process; processing occurs at significantly higher temperatures.

Pros and cons of porcelain stoneware

Porcelain tiles, in addition to convenience and practicality, also meet the latest fashion trends.

The advantages of this material:

- long shelf life - compared to ceramic tiles or laminate;

- high strength - can withstand a load of several hundred kg per 1 cm2;

- an environmentally friendly product - this is confirmed by its composition: clay, feldspar, kaolin, quartz sand;

- does not require special care - wipe with a damp cloth;

- can be used for cladding both indoors and outdoors;

- resistant to humidity and temperature changes;

- There are many textures and color shades - this allows you to choose the product to suit any interior.

In addition, the material is not difficult to install, warms up well and easily distributes the resulting heat throughout the room.

The main disadvantage is that it has a low temperature. But this problem can be solved if you install a “warm floor” system under the slabs. Porcelain tiles are slippery, especially when exposed to water, so they are not recommended for kitchens and bathrooms. In addition, the material is not cheap, but this price is justified and is compensated during operation.

Let's go to the store - how not to make a mistake in choosing

When you come to the store to buy porcelain stoneware floor tiles, arm yourself with a pen and a notepad in which you write down:

It’s better not to buy the option you like right away. Return home, think everything over, and calculate the required number of tiles with a 10% margin and taking into account the format.

Consider what components you will need - grout, baseboards, corners, thresholds. If you want to save money, look for the tiles you like in other stores and online stores by article number or simply by brand name, collection, etc.

How to choose porcelain tiles

When purchasing porcelain tiles for heated floors, you need to take the choice of model seriously. It is necessary to take into account the features of the heating design and the characteristics of the coating. Experts advise paying attention to the following points:

- tiles with a glazed surface do not give off heat;

- If the method of laying tiles involves empty seams, then when heated the product expands, so you need to choose carefully, especially for the electric type.

It is worth saying that some tile models have features when laying. This concerns adhesive compounds that affect the installation of a number of heating systems.

It is better to entrust the choice of porcelain tiles to a specialist, then there will be no unexpected surprises in the operation of the device.

conclusions

Putting all of the above together, an autonomous heated floor in the hallway should be made from:

- Thermal electric mats (if you plan to lay tiles or porcelain stoneware);

- Infrared film, if you plan to finish the floor with finishing materials without glue.

©Opolax.ru

Articles on the topic

- Water heated floor temperature adjustment

- Restrictions on the use of water heated floors

- Installation of cable heated floors: 9 options

- Infrared heated floor, heating film

- Resistive heating cable: what is it, why is it needed?

How do different types of heated floors combine with porcelain stoneware?

When installing a heated floor covered with porcelain stoneware, the question arises - what kind of heating is best to install under this material?

Any type can be placed under granite tiles, the main thing is to follow some rules.

Watch the video

The best heated floor under CERAMOGRANITE. Garant Repair

Water heated floor

Installing a water floor under porcelain stoneware is a popular option, especially in private homes. In apartments, the difficulty of installing this design lies in the connection to the general heating system, and in raising the floor height. The coolant is an emulsion or water that circulates in the pipes.

The advantage of such a system is that it is economical, so it is often installed in large rooms. Despite the rather time-consuming installation, it is not complicated, but the result is complete heating.

The disadvantage is that it is expensive, installation of such a structure is not possible without major repairs, and there is a need for constant preventive inspection.

And in case of a leak, the consequences can be serious, which will require large financial investments, because it will be difficult to get to the place of the defect through porcelain tiles.

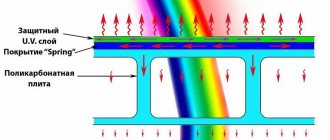

The water floor pie under porcelain stoneware consists of several layers:

- rough floor;

- hydro and heat insulation material;

- reinforced mesh;

- heating circuit;

- finishing screed;

- flooring - porcelain stoneware.

As mentioned above, installation work can be carried out independently. Most of the structure is occupied by a thermal insulation substrate and screed.

When installing on a rough surface, the minimum concrete layer is 45 mm, since the diameter of the pipes is 25 mm, and 20 mm is necessary to completely close them. To reduce the load on the structure, it is recommended to add a plasticizer to the solution.

Electric cable floor

Unlike a water-based design, the heating elements in an electric heated floor are not so thick. In addition, there are models that fit into the screed, and others directly under the floor covering.

A pie of this design is the presence of:

- primary floor or screed;

- heat-reflecting material;

- thermal films;

- polyethylene film;

- drywall;

- layer of tile adhesive;

- porcelain stoneware.

First of all, when installing an electric heated floor under porcelain stoneware, attention should be paid to protecting the system from moisture.

If there is a thin screed, it is recommended to add a plasticizer to the solution, or apply an epoxy primer to the surface to increase moisture resistance.

An important point when arranging an electrical structure is the foil layer. The main disadvantage is the concrete screed, which significantly reduces the height of the room.

There are the following types of electric cable floors: heating cable and thermomats, which are laid under a certain layer of screed:

- Thickness 50 mm - a heating cable is used here, it is filled with concrete screed. The advantage of this device is the ability to change the laying step, which allows you to install different power in different areas. Heating communication can be either the main source of heating or an additional one. To reduce heat loss, it is necessary to lay thermal insulation material with a reflective layer. This will reduce energy costs and improve the quality of the device.

When laying such a cake under porcelain stoneware, it is necessary to maintain the thickness of the screed. A size larger than 50 mm will lead to increased energy costs, and thermal conductivity will also deteriorate. When the screed is less than 30 mm, a thermal zebra is formed - the presence of cold and hot areas on the floor surface.

In addition, the surface must be smooth and free of air pockets. Their presence can damage the cable and disrupt the normal operation of the floor.

It is important to know! In order for the device to heat the floor evenly, the cable should be well secured. Then when pouring the screed it will not move.

- The thickness is about 3 mm - modern technology for installing heated floors. Recommended for laying thermomats with a small thickness. Such a warm floor pie for porcelain stoneware will be only 3 mm. The design is the way out if it is not possible to raise the floor height.

For your information! Heating mats are a cable located on a special self-adhesive mesh at a certain pitch.

The main condition when installing this structure is to choose the right adhesive for granite on a warm floor. In this cake, the heating elements will be located in a layer of glue.

Infrared film type

We consider film flooring to be a modern system that emits infrared waves, but there are no electromagnetic fields. A prerequisite is the presence of a layer of waterproofing, and in order to prevent the heat-locking effect, it is necessary to cover the system with plywood on which the tiles will be attached.

Infrared floors come in two types:

- With carbon heating elements - the connection diagram for such a system is parallel. The base is a film of lavsan. The product can be placed both on a horizontal and vertical surface. Some models are coated with graphite, which increases durability and reliability.

It is possible to spread film with carbon strips under the slabs, but the process is labor-intensive. The difficulty is that the glue does not adhere properly to the film, you will need to resort to additional actions. In addition, the effectiveness of the film under the tiles is reduced, while such a design is expensive.

- Bimetallic - in such films, heating elements are plates made of aluminum or copper, which are closed on both sides with elastic polyurethane. This type is not recommended for use under porcelain tiles.

Infrared rod

A relatively new species, therefore not very popular. Here, flexible rods made of carbon, silver or graphite serve as heating elements. Warm rod floors are sold in thermomats, in which the rods are located parallel at a distance of 10 cm from each other.

The advantage of such communication, unlike film communication, is that its operation is not affected by the furniture located on it. Compatible with any floor covering, including porcelain stoneware.

What type of flooring for porcelain tiles is better to choose?

Comparing all the heated floors and their compatibility with porcelain tiles, we can conclude that the most optimal solution would be the installation of electric cable heating mats under the porcelain tiles (two-core) .

Such a floor can provide efficient and uniform heating of the tiles, thereby creating comfortable living conditions in the room.

In addition, it should be noted that the installation of thermomats does not require much preparatory work. And as already mentioned, the heating elements are placed directly into the adhesive solution.

Reasons for installing heating in the hallway

The hallway is considered the place that determines the first opinion of guests about the house. Therefore, it is worth thinking about materials for finishing the room, because a correctly selected design creates a feeling of harmony. Well, a heated floor in the room will add comfort.

If it is snowing or raining outside, then a warm floor helps eliminate moisture - it is used to dry shoes. Moisture is unacceptable for shoes, and by placing them on a warm surface, they can be dried evenly.

Coming home from the street, it’s nice to take off your shoes and step on the heated floor. It is laid under such popular flooring materials for the corridor as laminate, tile, porcelain stoneware.

We lay a warm floor under porcelain tiles

Before you start making a heated floor, you should decide whether it will be the main or additional source of heating. This will help you choose the right power of the device; standardly it is 140 - 180 W.

Calculate the number of mats - this must be done, because if you cut them, the cable will be damaged. It is not recommended to place them under furniture, although in the case of mats this is not critical.

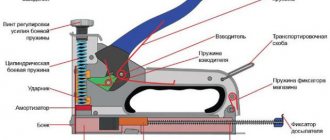

Let's consider the installation of heated floors under porcelain stoneware using the example of electrical cable mats:

- The base is prepared - the subfloor is thoroughly cleaned of debris, and cracks and irregularities are repaired. Then the primer is applied.

- The installation location of the thermostat is determined - it should be located on the wall, at a distance of at least 3 cm from the floor. A groove is made in the wall for laying the cable.

- The mats are laid - rolled out on the surface, with a distance of 10 cm from the wall. The mesh is cut where the cable turns. The washcloths are fixed to the floor with adhesive, pointwise. When the glue dries, the entire surface of the structure is filled with a thin layer of glue, this will protect it from external influences.

Advice! The glue should be heat-resistant, made on the basis of epoxy resin.

- The wire is connected to the temperature sensor.

- It is checked as follows: the floor should be turned on for the first time after the glue has completely dried to make sure that all parts of the structure are working.

- Porcelain tiles are laid directly on the mats with glue; there is no need for a concrete screed.

It’s up to you to decide which warm floor to choose for porcelain tiles. Each has positive aspects, and may well create an excellent microclimate in the room. The main thing is to correctly take into account the characteristics of the room and carry out installation in compliance with the required rules.

Getting ready to lay porcelain tiles - what is required for the work, leveling the base

Laying porcelain tiles with your own hands requires preparation. At this stage, the required amount of tiles, glue, and grout is calculated. To the amount of tiles obtained in accordance with the area of the room, 8-12% is added for trimming and other errors.

Porcelain tiles can be laid seamlessly, but this will require rectified material, with ideal geometry and very expensive.

Tools and consumables are being prepared:

The floor tiles themselves may also need preparation - sometimes the material comes with a protective wax or paraffin coating. Wax can be removed with a soap solution, and paraffin can be removed with a spatula.

The base for installation must also be prepared, since significant differences in height will not be eliminated with the adhesive mixture. Poor quality concrete floors are leveled with self-leveling mixtures. After drying, the new screed is primed and then cleaned.

The surface must be dry and clean before installing porcelain stoneware.