Bimetallic radiators are a type of battery that is made of different metals: internal channels are made of stainless steel, the external heat exchange body is made of aluminum. Stainless steel is resistant to aggressive coolant environments. Aluminum has excellent thermal conductivity and heats up quickly. There are sectional and monolithic structures. Used in central and autonomous heating systems.

When studying the huge range of batteries for heating rooms offered on the Russian heating engineering market, the consumer often has the question of which bimetallic heating radiator is best to choose for an apartment or private house.

The choice of bimetallic radiators is becoming increasingly important today. This happens because in one design of a heating device, the positive qualities of two metals - steel and aluminum - are used to the maximum.

This combination provides a number of advantages compared to devices made from the same material. The frame made of steel water pipes in an aluminum alloy shell is a bimetallic radiator, comparable in thermal power to aluminum and steel heating devices, and in reliability to cast iron radiators.

Which bimetallic heating radiators are best suited for each specific case must be determined individually. A suitable model is selected based on a number of criteria such as the type of bimetal, steel thickness, and thermal power.

The type of model and the calculated pressure are also important. In addition to technical characteristics, the choice of a particular device design is influenced by its cost and attractiveness of design.

Bimetallic radiators: what they are made of, advantages and disadvantages

The structure of bimetallic batteries meets all the requirements for this type of heating equipment. This is due to the combination of two metals - aluminum and steel. Inside the battery there is a steel rod, which comes into contact with the coolant. Steel has anti-corrosion resistance and durability. The outer part is made of aluminum - a light metal with good heat dissipation, which accelerates heat removal and transfer to the air.

Design features of bimetallic radiators, advantages:

- Reliability. They are much stronger than aluminum. This is especially true for resistance to high pressure and power surges, which are typical for most domestic homes. And in terms of chemical resistance, they have excellent characteristics.

- A variety of models, visual appeal and compliance with any, even the most sophisticated interior design.

- High heat transfer and low inertia of the heating system, corrosion resistance.

- Compact, light weight, easy to install and transport.

Disadvantages of bimetallic batteries:

- high price;

- low bandwidth.

Advantages

In addition to various design solutions, tall radiators have several more advantages:

- at low media temperatures, they provide the highest possible heat transfer;

- Due to their light weight and the use of small volumes of water, the devices reduce energy costs;

- radiators are equipped with regulators that allow you to independently set the temperature;

- When installing devices with lower communication lines, the aesthetic appearance of the room is preserved.

The advantages of these models include the fact that while saving space, you can install several heating devices in one room at once.

Types of bimetallic aluminum batteries

Difference between types of radiators:

- Bimetallic - only the shell is aluminum, and all pipes are made of steel. In this design, aluminum does not come into contact with water. The main advantage of such batteries is their highest durability and almost complete absence of leaks. But the price for such devices is higher.

- Semi-bimetallic - in them, steel is used only to reinforce the vertical tubes. Contact of aluminum with water is allowed. The main advantages of this type are: better heat transfer compared to bimetallic ones and affordable cost.

Experts say that the choice of semi- and bimetallic radiators depends on the type of heating system to which the batteries will be connected. So, for houses with centralized heating it is better to choose bimetallic models. Only they will allow you to cope with 2 significant problems inherent in such systems - low-quality coolant and high pressure with sudden changes. In a private house, you can also install semi-bimetallic radiators.

Design features of bimetallic batteries

There are 2 types of structures - sectional and monolithic. The inlet may also differ; there may be a bottom or a side one.

In terms of performance characteristics, sectional structures are inferior to monolithic ones. In addition, the joints between sections are a potentially dangerous place for leaks to form. The main disadvantage of monolithic radiators is their cost, which significantly exceeds the prices of sectional models.

In multi-storey buildings above 16 floors, only monolithic radiators can be installed. This is due to the high operating pressure of the coolant, exceeding the capabilities of sectional batteries.

Bimetallic radiator

Comparative characteristics and parameters are presented in the table

| Indicators | Sectional | Monolithic |

| Service life, years | 20-25 | 50 |

| Working pressure, bar | 20-35 | 100 |

| Thermal power per 1 section, Watt | 100-200 | 100-200 |

Description and principle of operation

The peculiarities of the domestic climate dictate their conditions, because people are forced to spend a considerable part of their lives in heated rooms. The problem of lack of heat during the harsh seasons in modern multi-storey buildings can be solved by powerful and reliable heating radiators, which can return home comfort to apartments in cold weather.

Such devices, which, if necessary, regulate the temperature in the room, are designed to maintain optimal comfort. The main thing is to be able to find a winning option, to acquire ideal batteries, whose characteristics will best provide heating for an apartment, residential building, or office.

These can be bimetal heating radiators . But what are their convenience and advantages over other heat exchangers? Let's try to evaluate everything in order.

When choosing a radiator, of course, its cost and possible service life are taken into account. But the most important feature of a heating device is the level of heat transfer.

It all depends on the physical properties of the material that forms the basis of the battery case. For example, to operate a cast-iron structure that was common in the recent past, an excessive amount of coolant is required. Its role is played by hot water. It is supplied from one side and, heating the sections, comes out from the other, this is the principle of operation of almost any battery.

Aluminum radiators, which have replaced cast iron designs on the market, although they have poor resistance to corrosion, are attractive due to their high heat transfer, at the same time they have a nice design and are easy to install.

The listed advantages also apply to steel structures, which, together with the previous type of heat exchangers, came into use in our everyday life relatively recently. But having reliability, durability, and structural stability when in contact with chemicals: acid, alkali, which serve as additives to the coolant, at low temperatures, they can create big problems.

The reason is the high thermal conductivity of this material, so the steel heating system too quickly releases both heat and cold into the surrounding space. This greatly reduces the efficiency of such radiators.

Bimetallic heating devices, created from aluminum and durable steel, as a result, have the useful characteristics of both of these materials at once. Therefore, their thermal conductivity is high, as is their durability.

A bimetal radiator will be an excellent option for solving many problems; it is suitable for homes and offices, being corrosion-resistant, constructive and compact.

Such a heat exchanger consists of vertical steel tubes, the outer coating of which is aluminum, which helps to gently regulate the process of heat transfer.

In this case, the role of coolant is, as before, water and other liquid substances; they transfer the required amount of energy to the steel base.

Harmful additives do not corrode the structure, which is protected by the properties of a substance such as steel, and do not affect the external coating, which is prone to corrosion. Next, the heat is supplied to the aluminum shell, which heats the room according to its valuable physical properties.

Having replaced cast iron batteries, which do not have a very impressive appearance, as well as other monometallic devices, bimetallic heating devices have a very attractive design and are also resistant to hydraulic and air shocks.

Initially intended for working systems with enormous pressure and low-quality coolant, they are increasingly used as individual heating devices. As can be understood from the above, using the valuable properties of a combination of metals, they significantly increase the efficiency and quality of heating the room.

Having decided to buy a bimetal radiator , when choosing it, you should take into account that it is visually difficult for a non-professional to distinguish it from purely aluminum devices. More precisely, this can be done if the device is not yet connected to the heating system.

The main visual difference between bimetallic structures is the presence of a steel core inside the body. Another indicator will be the weight characteristics of the radiator, because pure aluminum structures are much lighter.

Technical characteristics of bimetallic radiators

When choosing a radiator, you should also pay attention to the technical characteristics. Usually the packaging indicates:

- Maximum operating pressure. In most models it varies from 16 to 35 atmospheres. In centralized heating it does not exceed 14 atm, and in autonomous heating it does not exceed 10. All manufacturers provide a sufficient reserve, so it makes no sense to overpay for excessive working pressure.

- Thermal power. The heat transfer indicated by the manufacturer is calculated for a coolant temperature of 70 degrees and is indicated for one section. The heat transfer of one element of a cast iron battery is approximately 150–180 watts. During operation, deviations from this value constantly occur. Therefore, when purchasing a battery, you must take this fact into account.

- Maximum coolant temperature. If it is indicated that it is more than 95 degrees, then the manufacturer is somewhat disingenuous, since no one really makes it more than 90 degrees. But if a maximum of 90 degrees or less is specified, that’s also bad. The correct range is 90-95 degrees.

- Center distance. To a greater extent, this factor is important for product labeling (most often there are models with 350 and 500 mm between the axes).

- Weight and dimensions of equipment. Naturally, before purchasing a battery, you should measure the space into which the battery should fit (taking into account that there should be a small gap between the radiator and adjacent surfaces). Lightweight designs are more popular among the population who are tired of heavy cast-iron batteries.

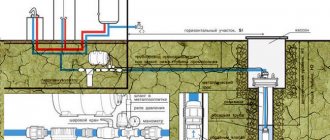

Features of installing high radiators

Installing vertical radiators is not much different from installing a conventional battery. They can also use underwater pipes made of steel, polypropylene or polyethylene. But still, there are small installation subtleties. Since the coolant has a large area, and therefore weight, it must be fixed only to a solid wall that can withstand the large weight of the product. In addition, when choosing a radiator with a top connection, you should take into account that the pipe will run along the entire height of the radiator and spoil the overall aesthetics of the room with its appearance.

You can select and buy vertical radiators for heating in the Dom-Termo online store. You will be surprised by the variety of models and their affordable prices.

How to calculate the number of battery sections for an insulated room

If you are too lazy to delve into all the intricacies of calculating the heat loss of a room, then you can use average values and not take into account the difference in materials.

For an insulated private house, the average figure is approximately 75 W/sq.m. for multi-apartment 100 W/sq.m.

To find out the area of the room, you need to multiply the width by the length. We multiply the resulting figure by the average loss rate and divide by the power of one section, which we take from the technical characteristics indicated on the radiator packaging.

An example of calculating the number of sections of a bimetallic battery:

A room in a private house is 5 by 5 meters: 5x5x75/180 = 10.4 sections, rounded up and we get 11 sections by 25 squares. This is an approximate amount. The rule here is that it is better to take one or two sections more than to freeze later. In addition, there is usually a window for ventilation. For an apartment building, it is considered the same, only we use the number 100 instead of 75. But it is best to contact specialists who will select the optimal dimensions of the heater.

Thermal power of radiators with different center distances

The second key characteristic of bimetallic radiators is thermal power . Using this parameter, it is determined how many radiator sections are needed to effectively heat a room of a certain area. This characteristic of a bimetallic radiator directly depends on the value of the center distance :

- 500 mm - thermal power ranges from 170 to 200 W.

- 350 mm - from 120 to 140 W.

- 300 - from 100 to 145 W.

- 200 - about 100 W.

The exact value of the thermal power depends on the modification of the device; this characteristic of the bimetallic radiator is indicated in the technical data sheet for the product. It is calculated as follows: the amount of heat given off by the radiator is estimated at a working environment temperature of +70 degrees Celsius. Let us remind you that in Russia the following standard is used: to heat a room with an area of 10 square meters, a thermal power of 1 kW is required .

To determine the required number of sections, you can use the following formula: N=S*100/Q , where:

- N is the optimal number of sections.

- S is the area of the room.

- Q is the section’s passport indicator.

Which company should I buy a bimetallic radiator?

When purchasing a product, the most important thing is who and in what country it was manufactured. This also applies to batteries. In the domestic market it is worth highlighting the following manufacturers:

- Italian. It was the specialists of the Italian company Sira Group who once invented bimetallic radiators. The market also offers products from companies such as Radena, Global Style and Royal Thermo. All Italian batteries are elegant, durable, compact, with high-quality finishing and interesting design;

- Russian. The most famous brand is Rifar. The quality is not inferior to Italian manufacturers, but the cost of these products is much lower;

- South Korea. Manufacturer: MARS. The core in these batteries is made of copper rather than steel;

- Poland. Trademark: REGULUS-system. The core is also made of copper. The company guarantees up to 25 years of normal operation of radiators.

- China. Chinese bimetallic radiators do not shine with a neat appearance, elegant design and decor. But their cost is much less than other samples. You should not buy Chinese batteries for houses with central heating; they may not withstand pressure testing and unstable pressure in the main line.

It is worth buying Chinese batteries only if you have a limited budget and expect that they can withstand lower operating pressure.

The following table presents the technical characteristics of bimetallic radiators from various manufacturers.

| A country | Model | Maximum operating pressure, bar | Maximum coolant temperature | Thermal power, watt | Weight, kg |

| Italy | STYLE 500 Gladiator 350 | 35 30 | 110 110 | 168 140 | 1,97 0,85 |

| Germany | TENRAD 500 | 24 | 120 | 161 | 1,44 |

| Russia | RIFAR Forza 500 RIFAR MONOLIT 350 | 20 100 | 135 135 | 202 136 | 1,84 1,5 |

| China | Gordi 500 | 30 | 110 | 181 | 1,7 |

Materials used

The core of the bimetallic radiator section is made of steel pipes. For batteries of normal strength (working pressure 16 - 20 atm), the core is made of carbon steel grade St.3 or its foreign analogues (for example, Tenrad radiators). The core (frame) of high-strength models is welded from stainless steel pipes. High-strength devices with a stainless steel core (for example, Biliner from Royal Thermo) can withstand burst pressures of more than 100 atm.

The outer part of bimetallic radiators is made of aluminum by injection molding. The extrusion method used in the production of some aluminum models cannot be used in this case, since a core must be placed inside the workpiece before forming begins. O-rings are made from heat-resistant silicone rubber.

Profiled fins.

Installation of bimetallic batteries

As a rule, installing bimetallic batteries does not cause any particular difficulties. The main thing is not to miss the point that during installation both right-hand and left-hand threads are used. If you tighten the nuts in the wrong direction, leaks may occur. Typically, the battery kit includes nuts with both types of threads.

Step-by-step instructions for installing bimetallic batteries:

installation

- Assembly. As a rule, it is performed at the place where the radiator is sold or at the production site itself. If you purchased a disassembled battery, it is better to invite experienced plumbers to assemble it.

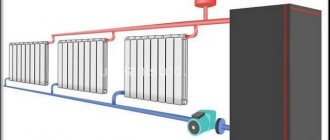

- Connection diagram. When thinking through it, it is necessary to take into account the location of the pipes, the need to connect new taps, etc. As practice shows, the best option for the connection diagram is diagonal.

- Selection of material for installation. When connecting plumbing fittings, flax with sealant or special tapes can be used. Threaded connections must be made with precisely measured force - that is, it is important to tighten them firmly, but not overtighten (to avoid stripping the thread).

- Direct installation of batteries. It should be noted that certain indentations are required: from the wall - 3-4 cm, from the window sill - 8-12 cm, from the floor -11-20 cm. Radiators are usually sold in a protective polyethylene film. It is best to remove it after installation is complete, so as not to cause damage to the surface.

- Opening taps. This must be done as smoothly as possible to prevent clogging of the flow pipes. You should also bleed air from the radiator through the vents. The absence of leaks is an ideal option, although usually few people manage to avoid them when they are turned on for the first time. If a leak is detected, it should be repaired and the system restarted.

For safe and proper operation of bimetallic radiators:

- It is not recommended to block them with screens;

- be sure to put a jumper on the pipes, and between them and the battery - two taps and a regulator;

- Keep in mind that leaks rarely appear, but if this suddenly happens, then most likely the problem is in the fitting connection to the battery.

Temperature and pressure requirements

When creating a heating system, parameters such as the temperature of the working medium and the pressure in the system are important.

The presence of a stainless steel insert does not have any effect on the appearance and dimensions of the heating device. But their use allows them to withstand significant pressure (up to forty atm.). It should be noted that testing of the heating network is carried out at a pressure of one and a half to two times higher than standard parameters.

Heating temperature chart

By the way, the maximum permissible temperature of the thermal environment can reach 100-110 degrees Celsius. This value is close to the parameters of the heat carrier entering the building from the centralized network. But it loses some of the energy when passing the point where the working environment circulating in the home network is heated.

Important! Before purchasing new heating devices, it is advisable to contact the office of the management company and request data on the operating and test parameters of pressure and temperature. This will help you make the right choice.

Sectional bimetallic heating radiators

Selecting the distance between the axes

The functionality of different models of bimetal radiators is usually equivalent. But they differ in the distance between the axes of the collectors.

There are models with both standard values (50 and 35 centimeters) and non-standard ones. For example, if radiators of minimum or maximum height are suitable for your purposes, then keep in mind the following points:

- A small distance between the axles (20 centimeters) is found only in models from BiLUX, RIFAR and Sira.

- A large distance between the axles (about 80 centimeters) occurs only in models made by the Italian company Sira.

We can note some advantages of the products of our manufacturer – RIFAR. He makes a line of RIFAR MONOLIT radiators, which have a solid core. Another line - RIFAR FLEX - can be rounded in accordance with the wishes of the customer.

This is convenient in an apartment where the corners are not straight, but rounded. Such a radiator will fit into the design most optimally and will fit perfectly into the wiring.

Design of bimetallic heaters

The body of these radiators is figured-ribbed, made of aluminum alloy, which is distinguished by excellent heat transfer. Under the housing there is a heating circuit made of pipes (copper or steel).

This “filling” helps the battery adequately withstand the attack of chemical and mechanical impurities present in hot water for heating.

The steel from which the core tubes are made is very strong. Therefore, the radiator will withstand even under high pressure. This can be 20, or even 40 atmospheres (some models up to 100 atmospheres). And the temperature of the coolant can rise to 110 or 130 degrees. If you need more specific numbers, you need to look at the passport of a specific radiator. Aluminum not only increases heat transfer, but also significantly makes the device lighter. In addition, the complex shaped housing has a very attractive design, giving the radiators an excellent appearance.

According to their characteristics, these radiators are quite suitable both for apartments in buildings of various heights, and for individual cottages with autonomous heating systems. But don’t rush to the store right away - first we’ll tell you how to intelligently approach the issue of choosing them.