Electric and water underfloor heating systems are unable to independently maintain the set temperature in the premises of a private home. The owner adapts to adjust the power of the boiler or heating circuits manually, achieving a comfortable air temperature. To organize automatic microclimate control, you need thermostats for underfloor heating (TP), installed in each room. The purpose of the publication is to describe existing types of thermostats, installation methods and connection diagrams for control devices.

How does a thermostat work?

A remote underfloor heating thermostat is an automatic switch that opens or closes the electrical circuit after reaching the temperature set by the user. As a result, heating stops or resumes. According to the principle of operation, underfloor heating regulators are divided into 2 types:

- Mechanical with a temperature sensor in the form of a bimetallic plate. When heated, this element bends and at a certain moment breaks the circuit. The plate then cools, straightens and closes the contacts again.

- In electronic (relay) regulators, the temperature sensor is a thermistor that changes the resistance to the electric current depending on the heating. The controller microcircuit detects this change and issues a command to the relay, the winding opens the contacts, and the circuit is broken.

The device of the simplest thermostat with a bimetallic plate

Reference. Electronic devices are equipped with their own source (batteries) or are connected to the home network. The simplest mechanical thermostats operate without external power supply. This is not an advantage, since water transformers still require electricity to operate.

Now let us explain how automatic control of a heated floor is realized using room thermostats. Electric heating circuits (cable sections, infrared film) work like this:

- The thermostat installed in the room is connected to the main power supply line. While the room is cold, the circuit is closed.

- The homeowner sets the device to the desired temperature, and the heating turns on. When it reaches the required value, the temperature sensor is triggered, the circuit is opened, and the power line is de-energized.

- After cooling by 0.5–1 degree, the power supply is restored and heating continues. By the way, the difference between on/off temperatures is called hysteresis.

Thermoelectric actuators that work with room thermostats are screwed onto the valves of the distribution manifold.

The operating principle of the thermostat for water heated floors is the same. Only the relay opens the power supply circuit of the thermoelectric drive (otherwise known as the servo drive). It stands on the distribution manifold of the TP and closes/opens the coolant supply to the heating circuit.

Servo drives are placed on each loop and connected to separate regulators located in different rooms. How the automated water floor heating system works, look at the video:

Comparison

Firstly, the difference between a thermostat and a thermostat can be discovered by ensuring that the terms in question are not used as synonyms.

In this case, the thermostat can be considered as one of the hardware modules of the thermostat, and one of the key ones. The thermostat installed in the thermostat records the set critical temperature and transmits a signal about the need to maintain it at the current level to other hardware modules of the device. Which activate heating or, conversely, cool the device or elements that affect the ambient temperature.

In turn, the term “thermostat” can be used to designate a hardware component of devices whose main function is not climate control. For example, when it comes to automotive cooling systems.

Secondly, the difference between the terms in question can be traced even if it is agreed that they are used as synonyms.

The fact is that among technical specialists it is customary to consider any device designed to maintain a constant air temperature as a thermostat. In any case, it will be a thermostat in the sense of an “independent device”.

However, if the thermostat is designed to control the ambient temperature according to a schedule or in correlation with air humidity, then it would not be very correct to call it a thermostat. In this sense, the thermostat may differ from the thermostat in terms of functionality.

A small table will help us understand the difference between a thermostat and a thermostat.

To maintain the required temperature level, heating systems use electrical devices called thermostats. All devices containing electric heating elements are equipped with electric thermostats.

The need and features of thermostats

A thermostat is an electrical device necessary for automatic temperature control in cooling and heating equipment. They are installed in heating, artificial climate, cooling or freezing systems. Widely used in households in the arrangement of greenhouses.

The purpose of the thermostat is determined by turning on or off the heating elements of any device at temperatures below or above those specified, respectively. Thanks to the operation of temperature control devices, the air in the room, water, surfaces of devices, etc. I have a stable temperature.

All thermostats, no matter what device they are in, operate on the same principle. The automatic controller receives temperature data from its environment, thanks to the fact that it is equipped with a built-in or remote temperature sensor. Based on the information received, the thermostat determines when to turn on and off. To avoid malfunctions in the operation of the device, the temperature sensor should be installed in a room away from the direct influence of various heating equipment, otherwise distortion of the indicators may occur and, naturally, the regulator will operate incorrectly.

Classification of thermostats

The operating principle of all devices that regulate temperature is the same, but there are many types of thermostats, and they differ in:

- Purpose: - indoor; - weather.

- Installation method: - wall; - wall-mounted; — mounted on a DIN rail.

- Functionality: - central regulation; — wireless regulation.

- Control method: — mechanical; — electromechanical; — digital (electronic).

Thermostats for electric and water transformer stations - what is the difference

In fact, there is no difference; in both cases, the thermostat performs one function - it turns the heating on or off, interrupting the supply of voltage to the actuator - the heating cable or servo drive. But not every device is suitable for working with electric floors; for example, a purely mechanical device cannot be used. Let's explain why:

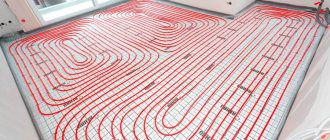

- The heating of the electrical transformer is controlled by a remote sensor located in the floor between the loops of the resistive cable. It allows you to limit the maximum temperature of the floor covering and protect the cable section from overheating.

- Mechanical thermostats contain a plate that responds to changes in air temperature. The device is not designed to connect an external temperature sensor, so it does not “see” the degree of heating of the floor screed.

- Film heated floors work in a similar way. When it is necessary to regulate the air temperature, a relay thermostat is selected, equipped with an internal sensor and terminals for connecting an external one.

Electric heating transformers are always installed with a thermistor sensor that measures the floor temperature

Note. The thermostat controller simultaneously processes signals from the floor and built-in sensor. When 1 of the 2 thermistors indicates that the set temperature threshold has been reached, the electric heating is turned off.

To adjust the water heating circuits, an air-heated floor sensor is used; a remote meter is installed at will or if necessary. For example, to control edge zones that are very cold. The coolant temperature is limited by control valves on the manifold - RTL thermal heads or a mixing valve with a surface-mounted/submersible sensor.

Good quality electronic heat controllers

The use of electronic thermostatic valves and external water thermostats provides very big advantages:

- Possibility to coordinate the operation of several furnaces simultaneously.

- Mount sensors wherever it is convenient.

- Remote control from a computer or smartphone.

- Receive an alert signal to your phone in case of breakdowns.

Some devices are equipped with the ability to send electronic reports. Most models allow control using voice control

Not a single heating device, in this case a muffle furnace, can do without a thermostat or thermostat. As you can see, although these devices have design differences, it would not be a big mistake to use any of these names.

Tips for choosing a device

We believe that installing mechanical thermostats on heated floors is pointless. These devices are somewhat outdated, the number of functions is limited, and the accuracy of the maintained temperature leaves much to be desired. The devices can be used in utility or technical rooms, where it is necessary to maintain +15...18 °C around the clock.

We select the type of microprocessor thermostat depending on the heating method, operating conditions and our own wishes:

- It is better to buy a regulator for an electric floor together with a heating cable (film) and sensors from one manufacturer. For example, Devi, Caleo and Teplolux companies sell their own control devices.

- If you have to buy a thermostat for electric TP separately, you should choose any two-pin device equipped with terminals for connecting an external sensor. Pay attention to the maximum power indicator that the regulator is capable of switching (usually within 2...4 kW).

An example of technical characteristics of Teplolux brand regulators - For water heated floors, it is better to take a universal (3-pin) thermostat, an external temperature sensor - if necessary. Switching power does not matter, since servos consume 1...3 W of electricity.

- The number of additional bells and whistles depends on your needs and wallet. But if you need real energy savings, consider programmable models that turn on heating on a schedule. During working hours or at night, the temperature in the house can be lowered to 18...20 °C.

Installation of thermostats is provided in each room. This means that you will have to pull the wires from there to the TP comb, where the servos of the water circuits are located. Such “electrification” is inappropriate in apartments with fresh designer renovations. Solution: install a switching unit with a receiver near the collector, and wireless battery-powered thermostats in the rooms.

Reference. Typically, switch units have 1–2 relay outputs for connecting a circulation pump or boiler burner. A Danfoss switching device costs about 100 euros, a TP5001A-RF wireless controller costs 82 €, an RX type receiver for 3 thermostats costs 95 €.

Heating/cooling.

The easiest way to turn a heating thermostat into a cooling thermostat is a changeover contact.

Some thermostats have an option in the settings that clearly indicates that cooling work is required.

There are thermostats with separate control channels for the heater and air conditioner.

Multi-output cooling thermostats are designed for central air conditioning systems where it is necessary to control the air conditioner fan and the coolant valve of a split system.

Installation and connection of the thermostat

Before installation, carefully read the operating instructions for the device. Typically it contains the following installation instructions:

- thermostat height above floor level – 1.5…1.7 m;

- do not place the regulator with an air sensor near sources of heat or cold - heating radiators, air conditioners, ventilation openings;

- technological distance from window and door openings – 1 m (minimum);

- maintain the maximum distance between the thermostat and the distribution manifold of water transformer substations (the cable length is indicated in the instructions);

- the external sensor is located exactly in the middle between the underfloor heating loops at a distance of 500 mm from the wall;

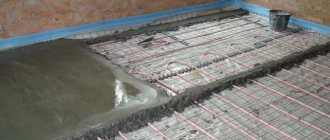

- The floor temperature sensor is mounted inside the corrugated pipe; it should be easily pulled out after pouring the screed.

Surface-mounted devices are screwed directly to the wall, the wiring is laid in grooves. A recess is made under the built-in thermostats, and a regular socket box is installed.

Advice. To connect the regulator, use a two-core copper cable with a cross-section of 0.75 mm². The connection diagram for an electric heated floor circuit with an external sensor looks like this:

If the cable heating section consumes more power than the thermostat can switch, you need to use a modular contactor in the circuit. The specified actuator is mounted on a standard DIN rail.

Here the thermostat sends a control signal to the contactor, which opens the power line

Some versions of thermostats have a contact for connecting a timer. This solution allows you to reduce the temperature in the room by 5 degrees once a day without purchasing an expensive digital model of the device. The timer circuit is shown below.

The Latin letter L in the diagram indicates the phase wire, N - zero (neutral)

Let's move on to water heated floors. The simplest way is to connect the thermostat to the servo drive directly (in series). Just first find out the type of drive, “normally open” must be connected to the normally open contact of the device, “normally closed” - to the break contact. Often, manufacturers put the appropriate markings on the terminals - NO or NC. The COM contact is common.

To implement multi-zone underfloor heating in a private home with wireless thermostats, use the following circuit diagram. Terminal numbers and other details are not indicated here, since equipment from different manufacturers has different markings.

Reference. Patch panels, receivers and wi-fi modules are produced by many well-known manufacturers - Legrand, Danfoss and others. How the thermostat-switching unit combination functions is described in the video.

GSM controlled devices

These thermostats have a connector into which a SIM card from a telecom operator is placed. After that, it can be controlled from a smartphone remotely; it is only necessary that there is mobile coverage at a given point.

These devices are capable of combining a number of additional functions. Along with maintaining the microclimate in the room, they can take on monitoring the operation of an electric kettle, coffee maker, as well as a boiler and other household appliances.

Finally, about setting the temperature

To set up each floor heating thermostat and check the performance of the system as a whole, you should turn on the heating and set all devices to the desired temperature. Please note that the house needs to be warmed up completely. The optimal boiler operating mode is 60 °C; if the heat generator starts to “clock” (frequently switch off and start), it is better to reduce the power.

The essence of the setting is to select a comfortable temperature in all living areas. The thermostat display readings do not always correspond to our feelings, so the settings will have to be adjusted during operation. A separate issue is programming heating according to a schedule; this procedure is described in the instructions for a specific device.

What is a thermostat?

The term “ thermostat ” is commonly understood as:

- a household device (refrigerator or, for example, air conditioner), which contains a thermostat in the meaning of “hardware module”;

- a synonym for the term “thermostat” in the meaning of “independent device”, provided that the device is designed to maintain a given level of ambient temperature;

- a narrow-purpose hardware module that is part of more complex devices (for example, car cooling systems) and is used to ensure the optimal temperature of a running engine.

Wi-Fi controlled devices

This option implies increased expenses compared to all previous ones. At the same time, such a thermostat can be controlled via calls or SMS, and via the Internet.

It is only required that Wi-Fi function in the space where the device is located.

Main varieties

Thermostats are divided into several large groups, the main ones being three. They all have a similar external structure, but differ in the temperature at which the circuit opens. This value is adjusted at the factory; it is not recommended to carry out the adjustment yourself; such an impact on the device will only lead to incorrect operation.

The type of suitable thermostat can be found in the documentation for the refrigeration equipment.

Thermostats for single-chamber refrigerators

Thermostats T-110, T-111, T-112 are mounted on refrigerators with one chamber. In terms of temperature indicators, all devices are the same, turning off is done at a temperature of -14 degrees Celsius, turning on at -12 degrees.

The thermostat models of this group differ somewhat in external characteristics. First of all, this concerns the dimensions; the handle rod and the bellows tube can have different diameters. Some models have a crossbar for easy fastening. The length of the tube can be determined by the number printed on the body. For example, 0.7 is 70 centimeters. Some thermostat models may have additional numbers and letters in the designation, T-112-1M instead of T-112.

In some cases, products are interchangeable. Using a special kit, you can install TAM-112 (new model) instead of T-110; the kit includes a nylon adapter, a nut and a fastening strip.

Thermostats for two-chamber refrigerators

Most often, for refrigerators with two chambers, thermostats are used, designated by the symbols T-130, T-132, T-133, TAM-133, TAM-133-1M.

All devices in this group turn on at +4 degrees Celsius and turn off at -14 degrees. Some products have a special strip for attachment. The handle rod and bellows tube may have different diameters, so the selection of the model is carried out according to the equipment documentation.

Thermostats for freezers

Temperature regulators T-144 and T-145 are used for installation in freezer cabinets. The T-144 thermostat differs from most models in that the manufacturer did not leave room for independent temperature control. Usually there is a special rod for this. The thermostat turns on at -20 degrees Celsius and turns off at -24 degrees.

There are four terminals on the side of the thermostat body, two of them are double terminals, this is “ground”. Terminals numbered 3 and 4 are contacts through which electricity is supplied to the compressor. A special function is performed by contact number 6; it turns on a lamp indicating that the permissible temperature standards in the chamber have been exceeded. Activation of this contact is performed at -15 degrees Celsius.

Thermostats for refrigerators "Stinol"

The selection of thermostats for refrigerators of this brand is due to the fact that devices of various models can be used for them. These are not only the TAM-133-1M and TAM-145-1M produced in our country, but also the K-57 and K-59 regulators from the manufacturer RANCO.

An important difference between thermostats for Stinol refrigerators and other models is the covering of the bellows tube with a vinyl shell. The compressor is connected through contact number 6. The temperature range of various thermostats depends on the model of the refrigerator and the device itself.