Until recently, the main area of application of triangular windows was considered technical - they were equipped with attics and non-residential attics in apartment buildings or private country houses. As a rule, such non-standard windows were small in size and were used for ventilation and at least some lighting in the technical area.

Today, the role of attics and attics in residential buildings is changing dramatically, and, accordingly, the attitude towards the windows installed in them is changing. As before, due to the design features, these rooms are equipped with triangular windows, but their sizes have increased significantly, and the range of functions has expanded significantly. For many years now, light-transmitting plastic systems have remained the most popular.

It should be noted that the production of such triangular products is very labor-intensive, requiring non-standard equipment and the use of special technologies. During production, quite a lot of waste is generated. For this reason, such windows are always more expensive than standard designs of similar sizes.

Types of triangular windows

When selected correctly, triangular PVC windows will highlight the features of your home, make it expressive and stand out from other buildings. For installation, you can choose one of two types of windows:

- with right angles (rectangular).

- with two equal sides (isosceles).

Rectangular windows are mainly located closer to the edges of the pitched roof. They can be opened in the usual way and tilted back for ventilation. Their opening handle is located on the inclined part of the sash profile.

Windows in the form of an isosceles triangle can be solid or consist of several individual elements. Most of them open in a transom way using a handle located on the side profile of the sash.

Sheathing material

According to the work technology, the installation of pediments can be made with cladding of wall posts or the solid wall itself.

Sheathing the gable of a house involves the use of various types of materials: moisture-resistant plywood, paintable plasterboard, polymer panels, corrugated sheets and even colored polycarbonate. But still, natural wood and vinyl siding are always popular.

Combined house gable cladding

Wood for cladding is used in the form of lining (processed boards) or decorative carved elements. If the material is treated with special compounds, it will last a long time without deformation.

As for siding, this is a more economical and easier way to arrange a pediment. To cover the gable of a house with siding, no special preparatory work is required. It comes in a variety of colors and can be installed in a variety of ways.

Metal sheets are used less frequently due to their relatively high cost. These panels are covered with a special protective layer, which provides reliable protection against various types of damage and corrosion.

Red tile house pediment

Naturally, the choice of materials will be determined by the material of the structure itself. For example, the arrangement of the roof of a log house requires the presence of wooden cladding, while a brick structure may require other facing materials.

Brick and oak house pediment

Options for opening triangular windows

Options for opening triangular windows:

Window with two blind (non-opening) sashes

System with one blind leaf

Design with vertical blind sash

Single opening sash system (tilt and turn)

Design with two opening doors. On the left there is a swivel and tilt position, on the right there is only a swivel position

A window with a complex triangular shape, with the sash opening in a rotary or tilting position

At the corners of the system the doors are blind, in the center - opening to the side and in a folding position

Isosceles triangular plastic windows that open in different ways are divided into the following categories:

- Deaf - do not open at all. The simplest and cheapest designs. They do not allow the room to be ventilated. They serve only to let light into the room, and can also serve a decorative role.

- Hinged - the doors (or sash) open in the usual way.

- Transom windows - the window opens only in the “ventilation” mode. The window sash can open from the top or bottom, rotating around a horizontal axis.

- Tilt and turn - windows that open in both normal and tilt modes. Rotation of the valves is possible in both horizontal and vertical planes.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

Window handles, which control the fittings, are usually installed on the beveled side of the sash.

Light touches for an eye-catching design

All that remains is to give the pediment a small touch of individuality so that the soul of the master can be felt. For example, here is a simple decorative element for the pediment, which is especially loved overseas:

You will get a nice dormer window if you follow this master class:

You can also make an elegant and very beautiful decoration in the style of Russian architecture that will transform any home.

Got some ideas for yourself? Share your impressions and ideas in the comments!

Advantages of triangular windows

pros

original and aesthetic appearance

let in a lot of light

a full-wall model will give the illusion of panoramic glazing

this shape fits perfectly under the roof of the house

You can choose many window decoration options

If previously the windows under the roof were small and hardly illuminated the room, and therefore the attic was used only as an attic, now the situation has changed dramatically. Most often, in house construction projects, large roof windows of unusual shapes are initially installed.

Requirements for roof windows

Dormer windows are part of the roof structure, so their task is not limited to lighting. They must provide good thermal insulation, prevent precipitation from entering the room and resist negative environmental influences.

Conventional double-glazed windows are not suitable for roof installation ; installation of special roof windows is required. The design must have the following mandatory characteristics:

- thermal efficiency - models with a thermal insulation coefficient of about 2-2.6 W/sq. m;

- noise absorption – high-quality products suppress up to 35 dB;

- strength - window panels must withstand direct impacts from hail and snow deposits, so they are covered with a special film or made of tempered glass;

- exceptional tightness - the design includes sealing linings.

Disadvantages of triangular window systems

Minuses

it is important to take into account the load-bearing capacity of the floors of the house, since large solid windows can cause them to collapse

Most often, windows need to be made to order - with measurements of dimensions, roof angle, etc.

triangular windows are more expensive than standard ones

for them you need to use special cornices, window sills, fittings and other elements

the maximum number of chambers in a double-glazed window for such windows is three, since a larger number is problematic for manufacturing

The main problem is the high price of custom designs. Therefore, even at the stage of building a house, it is important to include their cost in the estimate. When repairing and replacing old windows with new ones, simply calculate your available budget in advance.

In general, triangular windows have many more advantages than disadvantages. If you decide to create a truly cozy place on the top floor, this glazing option will definitely help in this matter.

Limit dimensions of the corners of the structure

Another interesting nuance associated with triangular windows is restrictions on the degree of their corners. The most successful project from an aesthetic point of view includes a roof window, the side edges of which are parallel to the roof slopes. But is it possible to achieve such a result in all cases?

First, let's define what triangles are:

rectangular - one of the angles has a value of 90°. Such windows are located in the wall so that a right angle serves as the base. To create symmetry, two mirrored windows are installed at right angles to each other;

isosceles - two angles have the same size. In this version, the base is the side that connects the same corners. The design looks symmetrical in any case, but it is for it that there are restrictions on the size of the base angles

equilateral - all angles are equal to 60°. In this case, the window already meets the requirement for the size of the angles.

Blitz survey: When choosing a plastic window, what is important to pay attention to? From the articles you can learn how to choose plastic windows depending on the design and heat and sound insulation characteristics.

So, after choosing a window design, you should consider the size of its corners in such a way that this is feasible in the project, and so that the window fits well under the roof slope.

The corners of a triangular window should be:

- in the case of a fixed window - at least 30°;

- in the case of an openable one - at least 45°.

If these values are not taken into account, the window may collapse either during installation into the wall or during operation. At the same time, for different profiles and different numbers of chambers in double-glazed windows, these values may deviate, so the exact data must be obtained from the manufacturer.

The most successful and problem-free option is to think through the design of the window when drawing up the attic construction project.

But if you are installing a window in an already finished room, most likely there will be no problems, since most houses have standard roofs with certain angles, at which specialists will be able to select a safe window model.

Related articles:

◾Arched windows

◾Fixed plastic windows

◾Corner windows

What should be the height of the roof gable?

The height of this structure depends on what it will be used for. That is, it will affect the functionality and degree of comfort of the interior.

To do this, it would be necessary to consider various options for gable walls.

Non-residential premises

In this case, a height of 80 centimeters may be sufficient. If there are identical four slopes, the roof will look proportional and beautiful. If the height is from 80 to 100 centimeters, then this is already some kind of attic space, where you can equip at least a summer recreation room. The height of the walls, reaching 1.3 -1.5 meters, allows you to create a fully insulated rest room with minimal furniture: a table, chairs, a buffet, a TV.

Living space

Living space is possible at a height of two meters. Here you must strictly adhere to the project plan and strictly fulfill all the necessary construction requirements.

Layout on glass

As a decorative element, complex triangular plastic windows are decorated with a grid of false frames or a layout located inside or outside the glass unit. Triangular windows are beautiful in themselves - they give an original look to the house, make it more modern and elegant, and are also able to emphasize the chosen architectural style of the building.

We install plastic windows in a wooden house with our own hands

Windows made of strong and durable plastic can be found today not only in stone, but also in wooden buildings.

However, their installation in a wooden wall differs significantly from installation in stone structures. The reason for this is the significant shrinkage of wood during the drying period.

For raw material it can reach 6-8% (1.2-1.6 cm per 1 meter of log height).

Drying wood turns into a powerful press that easily deforms the window block. The doors do not open after such an impact, and the frame is severely warped.

It turns out that high-quality installation of plastic windows in a wooden house is not possible - you ask? No, it is quite real, but only if special technology is followed. We will consider this in our article.

How to properly install a plastic window in a wooden wall?

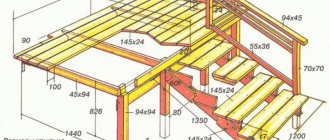

In order to eliminate the pressure of the wall on the window block, the craftsmen came up with special “sleds”, popularly called frames or casings. The idea of this technology is very simple: a vertical protrusion-ridge is made with a chainsaw on the end part of the window opening logs.

A window carriage is placed on it - a wooden beam with a vertical groove cut into it. There is no rigid connection with screws or nails between the opening and the carriage. As a result, due to the sliding tongue-and-groove connection, we get a frame that moves freely along with the drying wall.

Thanks to this original solution, the plastic window installed in the casing is not subject to the destructive forces of deformation of the log house.

- prevents logs from moving from the vertical; does not interfere with the vertical shrinkage of the log house; strengthens the wall in the window opening area.

Now let's take a closer look at how to install plastic windows in a wooden house with your own hands using a casing box.

Features of installing plastic windows in wooden walls

You need to be very careful when cutting the ridge at the ends of the window opening, marking it using a level. Any deviation from the vertical and any inaccuracies in the tongue-groove joint will negatively affect the operation of the socket, disrupting its free movement along the wall.

Having made the ridge cutouts, you can begin making window carriages. These are planed wooden blocks with a cross section of 150x100 mm. At their ends it is necessary to make cutouts measuring 5x5 cm for inserting horizontal jumpers (150x50 mm board with two tenons at the ends).

Casing box assembly

When making a casing, keep in mind that its assembled height should be 7-8 cm less than the height of the window opening. If you make a casing without such a gap, then the upper crowns, when the wall shrinks, will put pressure on the box, deforming it.

In order to correctly insert a plastic window in a wooden house , you need to follow the sequence of operations established by experienced craftsmen.

First you need to cover the ridges of the window opening with tow and secure it with a stapler or small nails. This is necessary to insulate the joint and eliminate squeaks. After this, the lower lintel of the frame is placed in the window opening.

Then carriages (side bars of the casing) are stuffed onto the ridges. The second jumper is inserted into the upper cutout of the carriage and lowered to a horizontal position. Having assembled the box, you need to carefully fasten it with self-tapping screws so that they do not go into the ridges of the log house. Otherwise, the casing will not “work” because the screws will not allow it to slide along the wall.

All cracks remaining in the window opening after installing the frame are tightly clogged with tow. Next, using standard technology, the installation of a plastic window is carried out with all the accompanying operations to ensure protection of the junction area with the casing from moisture, heat loss and noise penetration.

The gap between the frame and the wall of the log house is filled with thin boards wrapped in rolled tow. As the walls shrink, they are knocked out one by one. To do this, remove the top trim (it is attached only to the frame) and, removing the unnecessary “compensation” board, put it back in place.

The finishing of a plastic window in a wooden house is no different from the decorative cladding of a regular frame.

It is highly advisable to order not standard white plastic windows, but those covered with a special film that imitates the color and texture of natural wood.

They will look natural against the background of a chopped wall. Having completed the insulation and sealing of the joints, the window block with the frame is sheathed inside and outside with wooden casing.

A plastic window of brown “wood color” looks natural in a log wall. A timber house with a white plastic window and wooden trim (the color dissonance between white plastic and natural wood is striking)

Features of attic glazing

A triangular window in the attic can be used as part of a complex system, organically complementing rectangular or trapezoidal models, or as an independent structure that occupies virtually the entire opening in the under-roof space. Various methods of integrating such models expand the capabilities of designers and architects, and also make it possible to perform glazing, including on objects with complex roofs.

Blitz survey: Which window is best for the kitchen? From the article you can learn how to make ventilation for plastic windows.

The procedure for assembling gable walls

In conclusion, we can add that there is no difference in what order the pediment is made - before the roof is made or after.

Assembly done “before” is convenient in that the finished roof does not interfere with the work. In this case, measurements must be taken and executed accurately . In any case, installation on the rafters is done first. The construction of gables “after” is often used, which is quite difficult, especially if the attic is small.

The work done correctly will guarantee a presentable appearance of the house.

Accessories for triangular windows

The selection of the main elements for the manufacture of triangular-shaped products is carried out on a general basis. Window blocks are traditionally made from PVC profiles with different numbers of internal chambers or euro-beams if the structures are wooden.

To complete them you can use:

- any double-glazed windows, including energy-efficient and shockproof;

- laminated or body-painted profiles;

- Mosquito nets;

- supply ventilation valves.

When it comes to blinds for triangular windows, it is best to use pleated blinds, although other shading methods are available.

For example, you can install reflective double-glazed windows or a more economical option - sun protection films. Related articles:

◾Round windows

◾Folding windows

◾Non-standard windows

Installation of a roof window

Due to special operating conditions, roof windows have a more complex structure than conventional wall models. The delivery set, in addition to the traditional double-glazed window, frame and fittings, includes additional elements:

- insulating protective flashing - responsible for sealing the gap between the roofing and the window frame; the profile of the lower part is selected taking into account the topography of the roof surface;

- waterproofing sealant; the flashing redirects moisture to the drain;

- drainage gutter to protect against leaks;

- insulating insert;

- internal slopes.

Some models have built-in blinds or a roller blind.