Traditionally, construction tools are used independently without additional devices, but wall gating is an exception. And in addition to the main tool, a vacuum cleaner for a wall chaser is used. It significantly increases the comfort of performing operations, speeds them up and increases accuracy. In addition to this, there is no need to clean the workspace after such gating. We will try to understand in this material how to choose a vacuum cleaner for a wall chaser, and the choice will be yours.

Basic Rules

Chasing walls for wiring refers to the rough work of major repairs, therefore, such work must be subject to certain rules:

- You can only dab vertically.

All wiring is carried out along the ceiling, so even if there are several sockets or switches on one wall, a separate outlet is connected to each of them. Neither horizontal nor diagonal grooves are allowed. It is important to know. If you follow this rule, you will always know in which place on the wall you cannot drill a hole so as not to get into the wire. - The cable or wire in the wall is laid only in a pipe or corrugated pipe; the width of the groove must ensure installation of pipe fasteners inside, and the depth is 10 mm greater than the diameter of the tube.

This will ensure reliable fixation of the plaster layer on top. Laying the wire inside a PVC or corrugated pipe provides the possibility of replacing the cable in the future without dismantling the walls. It is important to know. The minimum Ø of a corrugated pipe is 16 mm, therefore the minimum depth of the groove should be 26 mm. - If there is a need for several pipes, the groove can become wider, but not deeper.

- Coordination with the management company for gating walls for wiring is required only if work is carried out in a panel house on a load-bearing wall without plaster. If a layer of plaster allows you to make a groove in it without touching the slab itself, approval is not necessary.

Criterias of choice

When purchasing a tool, you should pay attention to such parameters as:

- Power . The most important factor that determines the performance of a device. Varies from 900 W to 3 kW. The main rule is that the power must correspond to the diameter of the disk and the work performed. It is advisable that the device have a power reserve - this will protect the motor from overheating.

- Disc diameter . Determines the maximum depth of the groove to be made.

- Disk rotation speed . It determines how high quality the cut will be.

- Adjusting the distance between discs. For laying wires, a groove 1-2 cm wide is enough. If the task is to install a pipe into the wall, this figure should be much larger. Therefore, the adjustment range must be selected according to the purpose of the work.

- Weight. The lighter the device, the less your hand gets tired (it is especially important to take into account the weight when working on ceilings). At the same time, it is possible to reduce the weight of the tool only simultaneously with a decrease in power.

- Noise level. The sound of discs cutting concrete is usually very loud. It is advisable that the overall volume is not increased too much by the noise of the electric motor. You can check this indicator by starting the engine at idle speed.

- Vibration. There is no information about this characteristic in the instructions. The degree of vibration can only be assessed experimentally or based on feedback from tool owners.

- Auxiliary functionality: smooth start;

- protection against overload, jamming, accidental activation;

- automatic rotation speed control;

- vibration damping system;

- maintaining cut depth.

Tool

To ensure that the work of wall grooves is completed as efficiently and quickly as possible, use only professional tools. If electrical wiring is your profession, purchase one; if you are doing repairs only for yourself, rent a professional tool.

- Wall chaser + construction vacuum cleaner. Use only in pairs. If you use a wall chaser without a vacuum cleaner, you will not only not be able to breathe, you won’t even be able to see where you need to cut.

Do not use the wall chaser without a vacuum cleaner! - If you don’t have a wall chaser with a vacuum cleaner, you can use a hammer drill with an 8-10mm drill, a chisel and a channel chisel.

Drill, chisel and channel chisel for hammer drill

We will not consider perversions of the type “you can also cut out a groove with a hammer and chisel” within the framework of this article. It's unprofessional, ugly, time-consuming and expensive.

Which vacuum cleaner to use for a wall chaser?

The most important criterion for choosing such a device is model compatibility. First of all, this concerns adapters that allow you to connect the operation of two devices. The diameter of the mounting hole in the wall chaser must match the adapter of the hose or pipe of the vacuum cleaner. The same applies to the power of devices. Thus, the rate of absorption of debris that a vacuum cleaner for a wall chaser has must be no less than the rate of its formation. Otherwise, additional cleaning of the room or cleaning of the tank will be required at the most inopportune moment.

Work order

Preparatory work:

- Select a PVC pipe (for wiring) or corrugated pipe of the required diameter. To do this, place the required amount of cable into the pipe section. The wires must enter freely, because You will insert them into the already mounted structure.

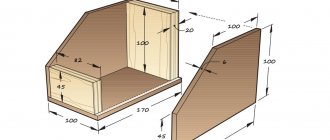

- Measure the outer Ø of the fasteners for the selected pipe.

Mounting diameter for corrugated pipe - Make markings in the required location on the wall. It is better to do this with a marker, because... the pencil may be blown away by the work of a wall chaser or hammer drill. For a hammer drill, you need to draw two lines, indicating the width of the groove. It is important to know. There is no need to remove the wallpaper before grating the wall; on the contrary, the paper will prevent the appearance of dust.

When working with a hammer drill:

- Holes are drilled along the entire marked line with a Ø 8mm drill to the depth of the groove.

- Using a chisel and channel chisel, cut out a channel of the required shape and depth.

When working with a wall chaser

- Set the required width and depth of the channel on the wall chaser.

- Cut the groove along the outlined line.

- Using a hammer drill chisel or a regular chisel, cut out the channel of the required shape.

It is important to know. Divide wide channels into several lines to make it easier to remove excess plaster, and the channel itself is neater.

Pipes are fixed to the bottom of the resulting channel with fasteners, into which the wires are subsequently drawn.

It is important to know. To fix the pipes at the bottom of the groove, it is better to use a special clamp with a “comb” - it does not add width and depth to the entire structure.

Disk saving

During operation, the wall chaser disks (only metal disks are used) quickly heat up. The heating intensity depends on the quality of the disks themselves and the material used to make the wall. When gating walls, this factor should be taken into account, because... Excessive heating of the disks leads to unnecessary consumption.

Make marks in increments of 15-20 cm along the entire length of the future channel, so that when you reach them, allow the wall chaser disks to cool. As a result, the work will be completed faster, and consumables will last longer.

Popular makes and models

Hitachi WDE3600

Today, many manufacturers produce vacuum cleaners for wall chasers. Among the most popular models are:

- Hitachi WDE3600 are universal devices, characterized by versatility, efficiency, low noise levels and convenient dust collectors. They quickly remove debris from various surfaces, suck up concrete, metal and wood debris and other complex waste. For equipment, you can take both fabric and paper and plastic disposable cleaning containers. Among the disadvantages, it can be noted that they have fragile wheel mounts and have a loose latch fixation.

- Karcher WD 7 Premium is a series of multifunctional devices with a pleated filter, thoughtful design and self-cleaning system, which has a light and spacious tank. Among the disadvantages, many users note the fact that the filter quickly becomes dirty and there are problems with suction of certain types of debris, for example, threads with wood chips and leaves. In addition, there is no mechanical wire winding.

- Karcher MV 6 P premium is a line of maneuverable and lightweight devices with many useful functions. For example, when cleaning, the filter itself shakes off dust. The user only needs to press a button. Thanks to the blow-off option, you can sweep up scraps of leaves and shavings into a pile. As for the design, the devices have good mobility thanks to five swivel wheels, long hoses and cords. In addition, consumables are available. Among the disadvantages of the Karcher MV 6 P premium are design flaws, due to which debris gets clogged in the gap, and rapid clogging of the filter.

- Makita VC 2512L is a range of devices that are distinguished by a convenient cleaning system, optimal configuration, availability of consumables for sale, light weight and high power. Among the shortcomings, users note insufficient insulation of the tubes, unreliable fastening of the filter and incompatibility with some power tools.

Safety precautions

Wall chipping is a high-risk job, so it is imperative to use:

- Protective glasses. Splinters of plaster and concrete are inevitable both when working with a wall chaser and a hammer drill. They, as well as the dust from them, can get into your eyes and cause a lot of trouble.

- Gloves. When working with power tools, they are mandatory; it is much better if the moving parts of a hammer drill or wall chaser tear out a piece of fabric than a piece of skin from your hands.

- Headphones. When working with a wall chaser or hammer drill for a long time, the strain on your hearing may seem insignificant at first, but it can gradually deprive you of your hearing. Don't neglect your ear protection!

- Respirator. If you only use a hammer drill to hammer walls, then breathing protection with a high-quality respirator is mandatory. When using a wall chaser in conjunction with a vacuum cleaner, it is enough to use a “petal”

Karcher industrial vacuum cleaners for wall chasers

Karcher is an exemplary company in every sense for the production of industrial vacuum cleaners. But this company does not produce wall chasers, although this does not prevent it from producing a cleaning tool that can remove brick, concrete and other construction dust. Such a tool has enough power, both electrical and suction. Therefore, there is no need to worry about its effectiveness.

The problem with vacuum cleaners of this brand is different. The main factor that allows you to refuse to choose this technique is the relatively small volume of the garbage tank. In addition, you will have to use disposable bags for concrete dust, which is not always practical. The last difficulty that the consumer may encounter is the lack of the required adapter for the groove cutter adapter in the package. You will have to buy it for an additional fee along with another hose if the diameter of the hole and the adapter do not match.

However, such equipment provides an additional exit, which is used to remove waste into the garbage chute system or directly outside the premises. In addition, such a device will be useful after use at a construction site.

Comments:

Palych

Well, I wouldn’t completely write off the hammer and chisel. If you need to cut 10 cm grooves, you can use the old-fashioned method. For such a purpose, I would not bother with a wall chaser in combination with a vacuum cleaner or even a hammer drill. But it all depends on the wall, of course.

Lech

Palych, that’s it, it depends on the wall. In new buildings they pour such concrete now that no hand chisel can handle it. It is almost impossible to chip 5 mm deep. Not every wall chaser takes it. An ordinary grinder won't take it either. Only Hilti.

Mahmut

The article is good, but why does it say that ditching can only be done vertically? What if I need it horizontally? What if I need to make two sockets on the same level?

Lech

Mahmut, if two sockets are on the same level, then you are cutting a new groove from the ceiling to this level. Of course, you can cut a groove even diagonally, but how can you then look for wires in the wall?

Sergey

And look for wires in the wall with a regular sensor - tolerance +- 5 mm.

Oleg

What the hell is this about vertical and horizontal grooves? I pull the cable into the room, put the box down, go down to the first socket 35 cm from the floor and run the groove horizontally from the socket block to the next one. Pictures, carpets, and shelves should not be hung at such a height. And everyone knows that the cable runs in a straight line from socket to socket. Sometimes this is the best option. And they offer us to put a bunch of boxes on top.

Leave a comment Cancel reply

Similar posts

Armored copper cable for your home and site Drawing up a wiring diagram for a one-room apartment, selecting the necessary equipment

The “Elekor” cable channel from IEK will help organize the power supply of any facility. Do-it-yourself wiring in a country house - features of organization and installation sequence

Advantages

The wall chaser gives the master several advantages at once:

- Minimal dust in the working area. Unlike an angle grinder, any furrow cutter is equipped with a pipe that catches particles of concrete and plaster. This is especially important if the renovation is carried out in a room where people live.

- High performance. Thanks to two disks, the wall chaser performs work at least 2 times faster than any angle grinder.

- High furrow quality. This is ensured by rollers, target marks, good visibility and a disk rotation control system.

Comparative characteristics

The main parameters of the above models are summarized in the table:

| Brand | Power, W | Speed, rpm | Disc diameter, mm | Depth and width of the groove, mm | Weight, kg |

| Fiolent B1-30 | 1100 | 6200 | 125 | 30/30 | 3,5 |

| Fiolent B3-40 | 1600 | 9000 | 150 | 41/41 | 4,3 |

| Bison ZSh-1500 | 1500 | 7000 | 150 | 45/45 | 6 |

| Caliber Master SHTBE - 2600/230m | 2600 | 4800 | 230 | 65/40 | 10,5 |

| Makita SG 1250 | 1400 | 10000 | 125 | 30/30 | 3,9 |

| Bosch GNF 35 CA | 1400 | 9300 | 150 | 39/35 | 4,7 |

| Metabo MFE 65 | 2400 | 6500 | 230 | 65/41 | 8,2 |