Self-installation electrical wiring in a frame house – the occupation is very responsible and tiring, as it is associated with large labor costs. This will require experience in installation work and certain construction skills. In addition, before installing electrical wiring in your home, you need to familiarize yourself with some of the features of this procedure.

Features of electrical wiring in frame houses

Frame houses are characterized by numerous advantages, but they have a number of specific properties that affect the electrification process. The main nuance is the use of flammable building materials when arranging walls and ceilings. The tree is coated with special substances, fire retardants, which reduce the risk of fire and the release of toxic substances, but such protection cannot be called sufficient. The slightest spark or significant temperature jump can cause ignition.

In a frame house, the installation of wires is carried out on a combustible base

Another negative point is the low thickness and low strength of the load-bearing surfaces. It will be difficult to secure power lines to thin sheets of plywood or drywall. These building materials are mainly used for interior decoration.

There are several ways to route the cable. Depending on the specific decision, you need to follow a certain order. Electrical wires can be installed before installing the load-bearing parts of the building or after completing the interior decoration.

Organization of hidden wiring during the construction of the frame

Set of tools

Installation of electrical wiring requires special tools. If a couple of wires can still be cleaned with a knife, then for large-scale work you need to purchase:

- Grinder (angle grinder).

- Hammer (they make through holes and mounting grooves).

- Wall chaser (forms grooves in brick, concrete and block walls).

- Insulation stripper (to strip the ends of wires and cables).

- Pliers (crimp wires).

- Wire cutter.

- Pliers, hammer, side cutters, screwdrivers.

As auxiliary and protective equipment you need: a good stepladder to easily mount electrical appliances on the ceiling or lay cables, a respirator, and gloves.

Standards and rules

There are two main documents containing rules and regulations for installing electrical wiring in a frame house:

- PUE, or “Electrical Installation Plan”. "ABC" for electricians.

- SP, or “Code of Rules,” which describes in detail the electrical wiring in a frame house.

When studying these documents, you may come across several inconsistencies and conflicting advice. For example, the PUE assures that hidden wiring in frame houses must be hidden in metal pipes, since corrugations and metal hoses do not provide the required level of safety. But the authors of the joint venture were not so categorical, allowing the cable to be pulled directly inside walls and partitions without the need to hide it in pipes. However, the “Code of Rules” states that the wire must have high-quality insulation made from materials that do not support combustion. These are NYM and VVGng.

Laying cables in metal pipes

It is precisely because of such disagreements that at the beginning of the article we recommended that you turn to professional specialists. At least take advantage of their advice. It would be a good idea to talk to a representative of the Ministry of Emergency Situations.

Wiring and Safety

Most fires in wooden houses occur due to problems in the electrical wiring. Many mistakes are associated with ignoring fire safety, lack of protection from external mechanical influences, incorrect calculations of the total load and the subsequent purchase of small-section wires.

When going to an electrical store, make sure you purchase certified products. Wires must have high-quality insulation. Try to buy products from well-known manufacturers. Cheap Chinese cables may actually have lower physical parameters and properties. Poor insulation will quickly deteriorate, increasing the risk of short circuits, overheating and fire.

Cable VVGng 3*2.5 with non-flammable insulation

Is it necessary to use corrugation or metal hose?

There is no need to use corrugations and metal hoses if certified products are used, and installation is carried out in strict compliance with the rules and recommendations. The presence of such components increases protection, but is optional if all other conditions are met.

Proper organization of electrical wiring in a frame house reduces the likelihood of fire. As for mechanical influences, neither the corrugation nor the metal sleeve will protect the cable if you thoughtlessly drive self-tapping screws into the wall. Be sure to make a schematic representation of the places where power lines were laid.

Using a metal hose for wiring in a wooden house

Many articles write about rodents in a wooden house. In fact, with proper sanitization of wood, you will eliminate their occurrence and prevent a scenario where mice chew through wiring.

Another negative aspect of using corrugation or metal hose is the increase in the total cost of wiring. What's the point of paying more if the level of security is already high?

If you read European sites and try to find articles about wiring in a frame house, the strict need for the use of additional means of protection - corrugation or metal sleeves - will rarely be mentioned. But the checks there are much stricter.

You are mistaken if you believe that the presence of corrugation in the wall will allow you to re-stretch the cable without destroying the finishing layer. Cable lines have many bends, so it is difficult to imagine this process. You will have to place a corrugation, the diameter of which will be several times larger than the total cross-section of the wires being laid. But this is not economically profitable and takes up a lot of space in the wall or partition.

It is allowed to organize electrical wiring without using corrugations

Wiring and vapor barrier: how to run wires in a frame house

Electrical wiring in a wooden frame house must contain the most airtight insulation circuit possible. This is especially true for external walls, because hiding an entire line only in partitions will not work.

One of the best options is to hide the wiring inside the insulation materials installed in front of the vapor barrier on the living space side. The likelihood of damage to the circuit is minimized, and this gap makes it easy to install socket boxes.

Installation of cable in the insulation layer

The second option is to place the electrical cable behind the vapor barrier loop. This is much more difficult to accomplish and will require more financial resources. You will have to drill racks along the entire length of the cable line and stretch the wires. If communications consist of several cables, then the rack will turn into a sieve, which will reduce its strength. The vapor barrier is damaged and you have to reseal it.

Laying methods

Let's consider the main methods of laying an electrical cable in a frame house.

Outdoor

External installation of an electrical cable in a frame house can be done independently. There are several options.

Open cable

When arranging this wiring, a rigid wire with double/triple insulation made of materials that do not support combustion is used. To secure the line to the walls, install special brackets. To reduce the risk of fire, an asbestos or metal backing should be placed between the cable and the wooden wall. Its width directly depends on the thickness of the cable and is made 20 mm larger (the line is laid right in the middle).

External wiring in a frame house

This method is the cheapest and most reliable, but the electrical wiring does not look aesthetically pleasing. The system looks even worse if there are several wires nearby. On the other hand, this option is suitable for houses in retro design or loft style.

Electrical pipes

Electrical wires can be hidden in special corrugated pipes made of non-flammable materials. They can withstand high temperatures and have a diameter that allows multiple cables to be accommodated inside. Using special clips, the pipe is fixed to the wooden walls of the building.

Wiring takes up a minimum of free space, increases electrical and fire safety, and reduces the risk of mechanical damage during operation. However, we can again talk about unaesthetics associated with the untidy appearance of metal pipes. They will attract dust and dirt from the street.

Laying wires in electrical pipes

Cable channels

Such protective devices for electrical wiring have a more laconic and thoughtful design, which is what makes them better than corrugated pipes. The products are available in different colors, so they fit into any interior or exterior. Ideally straight cable channels can reveal a potential drawback of a frame house - the curvature of the walls. But if the house is built to last, then this will not happen.

Cable channel is a plastic box installed on walls or ceilings. Self-tapping screws or glue are used for fixation. The plastic from which the products are made does not support combustion and retains its properties when exposed to high temperatures.

Cable channels are available in different colors and dimensions. The specific width is selected depending on the communications. After fixing the box on the wall, lay the cable inside and then hide it under the cover.

Open wiring in cable channels

The main disadvantage of cable channels is associated with the potential shrinkage of the frame house, due to which the products will begin to crack. As a result, you will have to re-do the electrical wiring and change various components. To the advantages listed above we add the moderate cost of the products and ease of installation.

Wiring hidden in the casing

The PUE lists the basic rules and recommendations that should be followed when laying cables inside walls or ceilings. We wrote above that hidden wiring must be additionally protected by metal pipes. You will have to buy a lot of pipes, so the total cost of electrifying the house increases significantly. In accordance with the joint venture, you can get by with a more budget-friendly option by replacing the pipes with corrugated or metal hose. However, if finances allow, it is better not to save.

When purchasing metal pipes, try to select products with a wall thickness of 2–4 mm. This value will allow the products to withstand high temperatures resulting from short circuits. To avoid rust, paint the pipes inside or outside, or purchase galvanized elements.

Metal pipes for cable laying

Any electrical wiring has numerous bends and other route features, so the pipes will have to be welded together or secured with threads. To simplify the installation process, preference should be given to copper products, but they are more expensive than galvanized steel. To protect the plastic insulation layer, place protective sleeves on the ends of the cut pipes.

Pipes are installed at the initial stages of construction. You are guaranteed to need physical assistance. This type of wiring in a frame house requires a lot of time and serious investment, and therefore is extremely irrational.

Selection of materials

It is strictly not recommended to save on the purchase of tools, cables and other materials. It is better to buy high-quality, certified products from trusted manufacturers, which will significantly increase the durability of the system and the safety of network users.

Electricity must be supplied to the house using a thick cable with aluminum conductors; the wiring inside the building is made of copper products. Preference should be given to three-wire wires in order to ground powerful electrical appliances without any problems in the future. When connecting lines, copper or brass bars are used.

Permanent connection of wires

In some cases, when it is not intended to connect the wires in the future, they can be connected in a permanent way. This type of connection is highly reliable and is advisable in hard-to-reach places, for example, connecting the ends of a nichrome spiral with copper current-carrying conductors in a soldering iron.

We will not consider such connections, since they require special equipment, and in ordinary life you are unlikely to use devices that allow you to crimp wires with pliers.

So, what connection options exist:

- The wires must be connected to each other.

- wires must be connected to terminal devices

Preparatory work

Design is the first stage of building electrification. You should decide where the sockets, switches, distribution boxes will be located, how the cable lines will run, and so on.

Installation tools

A man who considers himself a master must have all the tools necessary to install electrical wiring. If they are not there, then you are unlikely to install cables in the house yourself.

Let's list the main tools:

- drill and/or screwdriver;

- wire cutters;

- Screwdriver Set;

- screwdriver with indicator;

- stationery knife;

- tape measure and pencil;

- level;

- ladder or other devices to reach high points.

Tools for electrical work

Pliers, a saw and a hammer may also come in handy.

Consumables

In addition to the electrical cable, to supply electricity to the house and lay communications inside the building you will need:

- protective devices: corrugations, metal hoses or pipes;

- distribution boxes;

- socket boxes;

- mounting boxes;

- sockets and switches;

- clips or other fasteners to secure the protective devices and cable inside;

- clamps for fastening the input cable;

- self-tapping screws;

- electrical insulating tape.

Wiring materials

Drafting

Next, you need to draw up an electrical wiring diagram, which displays all electrical points (switches, sockets and lamps, heaters), distribution boxes, panels and the cable line itself. Switches should be installed near the doors, sockets should be installed closer to the places where electrical appliances will be located. Otherwise you will have to use extension cords.

When drawing up a diagram, you need to take into account all the objects located in the room: doors, windows, pipes and heaters.

Calculate the total load of appliances used in each room. In accordance with the obtained value, select the correct cable cross-section, which should be 15–20% larger than the recommended one. The total load in the house will allow you to decide on the differential circuit breakers used.

Layout of electrical wiring in the house

After drawing up the diagram, mark the interior using a building level, a pencil (marker), a tape measure and a ladder. Display “crosses” at the locations of the electrical points. The distance between the floor and the socket must be at least 300 mm, between the floor and the switch - 900 mm.

Layout

As with any other building, first you need to carefully plan everything and diagram it on paper. Consider where the distribution panel and entrance doors to the rooms will be located, since switches must be installed near them. Decide on the location of lighting fixtures and household appliances so that the sockets are nearby, and you don’t have to throw carriers across the entire room.

Calculate the loads to correctly select conductors by cross-section and switching devices by rated current. Also, such a layout will help you decide on the amount of materials needed.

Entering the house

Connecting the house to power lines is done using a thick cable with aluminum conductors. It is laid through the air or in the ground. Accordingly, holes should be made in the ceiling slab or plinth.

Air laying is carried out using a powerful and elastic steel cable. First, it is pulled, and then an electrical cable is attached to it using clips. Underground entry involves digging a trench, laying a pipe and pulling a wire through it. The pipe will protect the line from ruptures due to soil heaving. A flexible steel adapter is placed at the point at which the cable enters the house.

Input of electricity into a frame house using SIP cable

Do not forget to follow SNiP. In accordance with this document, the cable is connected to a meter located outside the building. To protect the device from environmental influences, it is hidden in a sealed box and behind a transparent window. Behind the meter there is a batch switch that interrupts the power supply in the event of an emergency.

Distribution panel

The shield is installed where the cable enters the house. You can make it yourself, but ideally you should purchase a factory-made product.

The following are mounted in the shield:

- introductory machine;

- buses for switching;

- RCD;

- automatic machines;

- ventilation;

- set of fuses.

Installation of a distribution board in a wooden house

Important! A secure lock must be placed on the switchboard doors.

General recommendations

The electrical system of a private home includes a ground loop, which is installed in the ground. There are factory-made devices and home-made structures made from steel profiles. If a gas boiler is to be used in the room, then it is necessary to check the grounding resistance by a laboratory and issue a certificate.

For installation of switches or sockets, it is recommended to use sealed housings from Kopos. The products are made of elastic, non-flammable plastic and prevent sparks from hitting wooden elements. Cable breaks in junction boxes are sealed with a sealed coupling, and the ends of the metal sleeves are protected with heat-shrinkable tubing.

What type of wiring to choose

The updated collection of rules for electrifying a private home involves the use of wires with copper conductors. Aluminum wiring is a thing of the past, so if it is discovered, inspectors may simply refuse to put your house into operation.

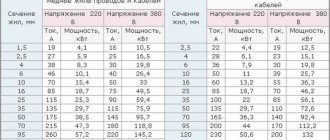

The choice in favor of a three- or five-core cable depends on the voltage supplied to the house - 220 or 380 V, respectively. And the wire cross-section is selected depending on the total load of energy consumers.

The optimal cross-section is considered:

- 1–1.5 sq. mm for lamps, luminaires, video cameras and alarms;

- 2.5 sq. mm for sockets and switches;

- 4 sq. mm for boilers, electric stoves, microwave ovens.

Wire cross-section and load

Also try to buy wires that do not change their useful properties when exposed to high temperatures and other negative factors. Choose a cable with better insulation, which will eliminate the need to install metal pipes.

Switching electrical points

To provide electricity to all rooms, we make wiring through distribution boxes. Wires branch from them to sockets, lamps and switches.

When installing, it is necessary to take into account the color of the wires:

- White wire – phase;

- Blue – zero;

- Green with blue stripes – grounding.

To ensure reliable contacts, use terminals from the German company WAGO. This is an ideal solution for those who do their own wiring. All you need to do is strip the ends of the wire from insulation, insert it into the terminal, and the spring mechanism will securely fix it. This connection is of very high quality and does not allow the contacts to overheat.

Choose sockets that are designed to be grounded. When installing such devices, first this wire is connected, then the phase and, lastly, zero.

Load distribution

To prevent overheating of the contacts and fire of the line, you should distribute the load as evenly as possible and distribute the wiring in the house. For the calculation, data obtained when the network was operating at design capacity for 20–30 minutes is used.

Group consumers according to the following principles:

- similar devices;

- summarized indicators;

- powerful devices with long operating time.

Place the installations along the lines, and upon completion of the calculations, select the number of directions, differential circuit breakers, RCDs, cross-section of cable cores and type of sockets for individual rooms.

Electrification of a wooden frame house is a complex process that requires compliance with numerous rules and recommendations prescribed in the PUE and joint venture. Without proper knowledge and experience, it is almost impossible to do it on your own. It is recommended to seek help from specialists, at least for consultation. Only competent installation of wiring and selection of high-quality materials guarantee the electrical and fire safety of the building.