TYPES AND TYPES OF PIPES INSTALLATION RULES

When laying cable lines, as well as installing electrical wiring, various support and protective structures are usually used. One of the cable installation options is to lay it inside the pipe.

The main function performed by pipe products is to protect the cable from mechanical damage.

In-pipe installation provides a high level of protection of conductors from various external influences. However, this type of protection has its downsides.

Thus, if the cable is damaged, it becomes difficult to find the location of the insulation breakdown. When a pipe route is firmly embedded in building structures, it is not always possible to replace the cable.

There are often cases when, when renovating a room, hidden wiring laid in pipes has to be “buried” by installing new wiring.

At energy facilities, cabling is installed in special cable channels or trays.

At the same time, cable lines are available for inspection, repair or replacement along their entire length.

Pipelines, as protection, are used only at the points where the cable exits the channel and where it enters the terminal cabinets or drive cabinets of switching devices.

Pipe products made from various materials are used when laying power cables in the ground. The Electrical Installation Rules require the installation of single-phase low-pressure oil-filled cables in pipes made of non-magnetic material; usually asbestos-cement products are used for this.

Each phase of these cables must be in a separate pipe channel.

Pipes can be used when installing all types of electrical wiring:

- external and internal wiring;

- open and hidden laying of conductors.

What is corrugation

Installation of cables in corrugated cables

Corrugated cables, despite their simple design, are considered one of the most useful and sought-after inventions of mankind. Visually, it is a pipe with a ribbed surface, which simultaneously gives it rigidity and flexibility. Corrugated pipes are made from various materials, the most popular being metal, aluminum, and plastic pipes.

Corrugation comes in different diameters, the indicators range from 10 mm to 2 m. This product has a wide range of applications.

Main points of requirements and rules

Table of cable cross-sections by power

Rules for laying electrical wiring cover a wide range of aspects of installation, from the selection of materials to the procedure for putting the structure into operation.

Minimum cross-section of cable cores:

- introductory - 4 mm;

- sockets - 2.5 mm;

- lighting group - 1 mm.

Number of conductor cores:

- single-phase line - 2;

- single-phase network with grounding - 3;

- two-phase supply - 3;

- two-phase network with grounding - 4.

Placing sockets, switches and electrical wiring at a distance from surfaces and objects:

- floor - 30-120 cm;

- panel joints - 20 cm;

- window and door openings - 10 cm;

- sewer and water pipes - 30 cm;

- sinks, bathtubs - 50 cm;

- heating devices - 20 cm;

- electric stoves - 15 cm;

- gas lines - 40 cm.

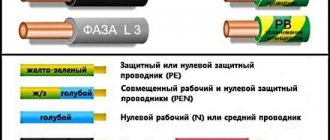

Types of wiring:

- with insulation of one or several colors;

- copper and aluminum;

- with regular and non-flammable coating.

Circuit breakers that are installed in the electrical panel:

- batch type;

- relay;

- fusible;

- electronic.

Line layout diagrams:

- sequential;

- parallel;

- combined.

Requirements for the installation of electrical wiring apply to residential and auxiliary premises, including loggias, balconies and vestibules.

Scope of application of corrugated pipes

Corrugated pipes provide the opportunity to lay air ducts of any complexity and length with the least number of turns and connecting nodes.

Corrugated pipes are widely used in various fields of industry, as well as for domestic purposes. In demand when performing the following installation work:

- installation of exhaust duct and ventilation system;

- for drainage of condensate they are equipped with air conditioners and split systems;

- used for connections in plumbing, for example, to connect a drain siphon to a sewer system;

- in the automotive industry to drain condensate and protect wires from thermal and chemical influences;

- for connecting boilers, ovens and stoves;

- for connecting heating systems.

For electrical cables, special electrical corrugations made of polyvinyl chloride are most often used.

Compliance with standards

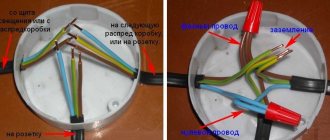

Safe connection of wires

When carrying out electrical work in residential premises, it is necessary to comply with the standards established for them regarding the following parameters:

- Section of veins. You need to select conductors with a calculation of the maximum load that will affect them. If the permissible power is exceeded, the metal heats up, which leads to the formation of smoke, melting of the insulation and the risk of fire.

- Laying lines. Network fragments can only be located in the vertical and horizontal directions; they should not intersect each other during internal installation. Groups of sockets should be located at the same distance from the floor.

- Switching. The main rule is the prohibition on directly connecting copper and aluminum conductors. To do this, you need to use an indirect connection in a bolt and nut, tires or spring terminals. Wires made of the same metal can be twisted and then insulated.

- Location. The slightest possibility of mechanical damage, melting of wiring elements and water getting into them must be excluded.

Compliance with standards is the basis for the safety and durability of the structure.

How to insert a wire into a hose

Correct connection of the string with the wire installed in the corrugation.

It is recommended that two people perform the work. This is due to the algorithm of actions.

- Remove the end of the wire (a kind of cable or string) from the hose and connect it to the cable being installed. A hole is made in the wire winding, a thin wire is pushed through it and securely fixed by twisting.

- The hose is leveled along its entire length, only after this can you begin to wind the cable into the corrugation.

- One worker firmly holds the end of the pipe from which the cable is wound, and the second pulls the wire from the other side. This approach allows the wire to be pushed through efficiently.

- The fully extended wire must be wound to the pipe to prevent the structures from moving relative to each other.

There are common cases when the wire gets stuck inside the corrugation. This is due to the weakening of its tension or the formation of bends. Until the end of the pulling process, it is important to monitor the condition of the hose.

Number of cables in trench

From my experience I can say that most often the number of cables in one trench does not exceed 4. But, cases are different, so let’s consider what is the maximum number of cables that can be laid in one trench and how this will affect the cross-section of the cables.

Of course, we will be based on the requirements of regulatory documents.

Many of us probably still believe that the number of cables in a trench should not exceed six based on the PUE:

1 When laying cables in the ground, it is recommended to lay no more than six power cables in one trench. If there are a larger number of cables, it is recommended to lay them in separate trenches with a distance between groups of cables of at least 0.5 m or in channels, tunnels, overpasses and galleries.

Quite recently, in one article I drew your attention to one GOST:

There are two very interesting tables in this document:

1 Reduction factors when laying cables directly in the ground.

Reduction factors when laying cables directly in the ground

2 Reduction factors when laying cables in pipes in the ground.

Reduction factors when laying cables in pipes in the ground

As you can see, there can be 20 cables in one trench.

However, the most interesting thing that you should pay attention to is the correction factors, which are lower than the coefficients proposed in the PUE (Table 1.3.26):

Correction factor for the number of working cables lying nearby in the ground (in pipes or without pipes):

| Clear distance between cables, mm2 | Coefficient for the number of cables | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |

| 100 | 1,00 | 0,90 | 0,85 | 0,80 | 0,78 | 0,75 |

| 200 | 1,00 | 0,92 | 0,87 | 0,84 | 0,82 | 0,81 |

| 300 | 1,00 | 0,93 | 0,90 | 0,87 | 0,86 | 0,85 |

Even a coefficient of 0.75 (for 6 cables according to the PUE) is quite low, not to mention a coefficient of 0.44 (for 20 cables). I don’t see any particular problems for cables with small cross-sections, but if you transmit enormous power, this will lead to an increase in the cross-section of the cable line and, accordingly, to a significant increase in the cost of the cable line.

If previously power cables in the trench were placed at a distance of at least 100 mm, then GOST R 50571.5.52-2011 allows cables to be placed touching each other. I still do not recommend you use this method. Under certain circumstances, you can refer to this GOST.

Of course, all this applies only to design in Russia. In Belarus, I still focus on the PUE and standard projects.

Source

How to stretch a wire

Scheme for pulling wires into the corrugation

You can route electrical cables along the walls or ceiling using special clips. Their diameter is selected in accordance with the cross-section of the corrugation. This method is more common because it securely fixes the pipes and has an attractive appearance. In hidden places it is preferable to use dowel screws or metal staples.

When laying pipes, the joints are connected using a low-cost connecting element - a coupling. If the wires in this section are not insulated, the place of attachment to the pipe coupling can be sealed with sealant. To pass through the walls, special perforated sleeves are used, which, if necessary, are also treated with sealant.

When pulling cables through corrugations, it is important to avoid bends that exceed the permissible radius.

Pros and cons

When laying electrical wiring, in practice several options for solving this problem, at least comparable in popularity, are used. The very absence of a clearly defined leader among them clearly indicates that each of the available options has its own advantages and disadvantages. Thus, each specific wiring installation is based on the one that provides the greatest benefit for the given local conditions. The inevitable disadvantages of the chosen method should be of secondary importance.

Advantages.

- the use of concrete screed as the basis for cable ducts ensures high electrical and fire safety; the wire in such a channel is surrounded by fireproof materials, and most varieties of modern floor coverings are an excellent additional insulator;

- the risk of insulation damage is minimized;

- the ability to select the optimal route reduces cable consumption, i.e. reduces the cost of repairs;

- turning to underground laying allows you to avoid labor-intensive wall slitting;

- comparative simplicity of channel formation;

- permissibility of movement of metal corrugation when pouring concrete.

The disadvantages of hidden floor gaskets are actually an extension of the advantages. They express themselves

- the difficulty of localizing the location of cable damage;

- in a channel with a large number of turns, problems arise with removing the failed cable and then inserting a new one into it.

- Sometimes the disadvantages include the need to use rather expensive conventional or corrugated metal pipes.

Installation of electrical wiring in corrugated open method

Installation of open electrical wiring in a wooden house

Installation of corrugated pipes includes several stages. Algorithm for installing electrical wiring in a corrugated open method:

- To fix the hose, special clips made of high-quality plastic are used. They come in different sizes; the choice will depend on the diameter of the pipes used.

- Clips are attached to surfaces at intervals of 30-40 cm. This is done using dowel screws or self-tapping screws. The choice of parts depends on the material from which the surface is made, for example, wood, concrete, brick, etc.

- For reliable fixation, the corrugation is pressed into the clip until a characteristic click appears. If the clips were selected correctly, the possibility of spontaneous loss is excluded.

At the design stage, when laying out a schematic wiring path, you need to take into account the following important points:

- The maximum and permissible radius of rotation of the corrugation is 90 degrees. The smoother the angle, the better.

- Turns should not be located close to each other; the optimal distance between them is 4-5 meters. If this is not possible, for safety reasons the wiring is additionally equipped with a junction box.

- The maximum length of an individual section is 25 meters, the permissible number of turns is 4.

Calculator for calculating the permissible number of cables in a corrugated pipe

Brief explanations on the calculation

The corrugation tightly packed with wires is also an inconvenience during installation. And insufficient heat dissipation, and possible mutual interference. Therefore, it is generally accepted that for normal operation of the wiring, the cross-sectional area of all cables or wires stretched in the pipe (taking into account their insulation) should be no more than 35% of the cross-sectional area of the internal channel of the corrugation. This is what the calculation is based on.

- The user must indicate the standard diameter of the corrugation (external) - it is produced in the range from 16 to 63 mm.

- Next, it is selected what cross-sectional shape the cables will be laid. The most common are round, and for them the diameter is indicated along the outer insulation (braid), which is easy to measure with a caliper or even just a ruler.

- If a flat cable is being laid, then after selecting this calculation path, two data entry fields will appear in which the thickness and width of the outer braid are indicated.

- All you have to do is press the calculation button and get the finished result.

It happens that the calculator shows the final value equal to zero. This means that even for a single cable this corrugation diameter is too small, and it is necessary to purchase a pipe one size larger.

Which cables to choose for home wiring

This is a whole science, replete with nuances, ignoring which is a very dangerous matter. Poor quality wires and cables that do not meet operating conditions often cause very serious consequences. Which cable should be used for electrical wiring in an apartment or house - read in a special publication on our portal.

Source

Submarine lines

• Cable routes crossing and/or running along water bodies can be laid on the bottom and banks of both stable and erosion-prone soil. In the first case, the laying depth is 1 m, in the second - depending on the characteristics of the soil. • The cable must run along the bottom or along the shore of the reservoir in such a way that it does not become sagging in uneven areas. Such areas should be avoided or covered with crushed stone, pebbles or other materials. If there are obstacles along the route in the form of shallows, rock ridges, etc., the cable is laid in a previously prepared trench. • Information boards should be installed near bodies of water where cables are laid, notifying about the presence of electrical wiring under water. • Crossing cables during underwater installation is prohibited.

A large selection of electrical cables is presented on the website. After reading the product description, you can make a choice yourself or contact a company specialist who will competently advise you on issues of price and quality.

Distinctive features of modern electrical wiring

At the end of the 20th century there was a breakthrough in modern household technologies. In addition to televisions, other devices began to be used inside homes:

- Wireless connection.

- Powerful household appliances.

- Video surveillance and security systems.

- Computers.

Therefore, work with the installation of electrical networks has become more complicated. The principles of operation and arrangement remain the same. Even the first stage - design - causes difficulties. It is necessary to know the locations of household appliances and the power they absorb. The lighting system for each room is thought out at the same stage.

Now they use not only power, but also low-current systems. These are wires for TVs, telephones, and computers. This also includes acoustic and security equipment. Power and low-current systems are not separated. The power source for the devices is a classic 220 V network.

The number of devices and devices with simultaneous operation is changing upward. Previously, one chandelier was enough, now local or a system of spotlights is added to the overhead light. The total power consumed by the devices also increases.

Dividing electrical wiring into groups (lines)

It is much easier to manage and control an electrical network if it is divided into several lines. In the event of a malfunction or emergency, you can turn off one group, while the rest will function as usual.

Option for dividing into 4 groups:

- Group 1 – powerful household appliances

- Group 2 – kitchen line

- Group 3 – bathroom and toilet

- Group 4 – lighting system

Below we will talk about each electric group in more detail.

Stationary household appliances

Large household appliances are usually located in the kitchen or bathroom area. Layout of sockets in the kitchen. Rules: it is prohibited to place sockets directly behind the dishwasher and washing machine; It is better to use waterproof models.

A separate connection for the kitchen area is necessary for repairs. If one of the devices breaks down, a replacement will be required. In order not to turn off the electricity in the entire apartment, it is enough to turn off one protection device responsible for stationary equipment. Unfortunately, even expensive household appliances break down from time to time. Repairs sometimes take several hours. A separate electrical group will allow you to maintain a comfortable stay in the kitchen and other rooms.

What prevents you from simply disconnecting a broken device from the network by pulling the plug from the socket? The fact is that built-in equipment has connection points to the electrical network in hard-to-reach places. In addition, the malfunction may occur not in the device itself, but in the wiring disguised in the wall. In this case, it is much easier to move the circuit breaker lever.

Dedicated line for the kitchen

The kitchen line is traditionally the busiest. Approximately 5-6 units are constantly connected to the network, even when not in use. This applies to the refrigerator, oven, hob, dishwasher, hood, microwave, toaster. Many people use a kitchen electric grill, meat grinder, bread maker, multicooker, etc.

Electrical wiring diagram for the kitchen, divided into 4 groups. For powerful household equipment, separate circuit breakers are installed in the distribution board. In this case, a separate powerful electrical cable will simply make it possible to use several devices simultaneously.

If lighting devices or a water heater are also “hanging” on the common wiring, then when the next device is turned on, the network simply cannot withstand it and an automatic shutdown will occur. A detailed analysis of diagrams and options for the location of sockets in the kitchen is given in the article, which we recommend that you read.

One or more lighting groups?

Considering the number of lighting fixtures in each room, you can make one or several lines. If there is one six-arm chandelier in the hall, and in the bedroom there is low-power overhead lighting and two chandeliers, then all the devices can be combined into one line.

However, if the living room resembles a disco hall - with chandeliers, spotlights, ceiling and wall lighting - then a separate group should be organized only for it.

Wiring diagram for 220 V spotlights or halogen lamps for one room, for example, a kitchen, children's room or hallway. If, in addition to lamps, the network of one room includes transformers or power supplies, then it is also recommended to connect it to a separate protection device.

Rooms with high humidity

Increased requirements apply to electrical appliances and cables in the bathroom, since the close proximity of water is a risk. In order for the electrical network to be safe and functional, a number of rules must be taken into account when drawing up the diagram and installing the wiring:

- The distribution box should be installed outside the bathroom - in the corridor, hall or hallway

- For each device that is used in the bathroom (washing machine, mirror lamps, hair dryer or electric razor), it is necessary to allocate a separate socket

- Regardless of the size of the bathroom, the switch is always installed on the outside. The best place is near the front door

- It is recommended to lay the electrical cable at the top of the wall, right under the ceiling, placing the lines parallel to the floor and using an insulating sleeve

The requirements also apply to the choice of fittings that will be used regularly - sockets and switches. Suppose the degree of protection of sockets should be at least IP 44, and it is even better to purchase special devices with a splash-proof cover.

It is recommended to abandon 220 V lamps in favor of 12 V analogues.

Necessary materials and tools for work

High-quality electrical wiring must meet the requirements of SNiP and safety standards. To carry out such wiring, you will need consumables and tools:

- electric meter;

- residual current device (RCD) for conducting currents under normal operating conditions or when leakage currents occur;

- power, low-current, lighting cable;

- branch boxes;

- terminal blocks (preferably screwless);

- sockets and switches;

- socket boxes;

- open type electrical wiring box;

- a mixture of alabaster for installing the cable inside the groove;

- glue;

- screws and self-tapping screws;

- baseboards;

- electrical insulating cardboard;

- tin strips for fastening.

Tools you will need: wall chaser, chisel, hammer, scissors for cutting cables. To lay the cable inside walls or boxes, you will need a spatula and an emery float. You will also need pliers, a screwdriver, a measuring tape and a knife.

Rules for different types of wiring

When choosing wiring for equipment of various types of premises, you should follow the rules set out in GOST 12.1.044. For residential buildings, you need to use three-core cables with copper cores of 1-2.5 mm. The insulation must be non-flammable and not emit smoke when heated. The brands VVG-Pngd, VVGzngd, Flame-X, N2XH, YnKY correspond to these parameters.

For the arrangement of premises made of non-combustible materials, the use of simple conductors is allowed without any restrictions. Powerful consumers operating in continuous mode must be connected to a separate line equipped with an RCD.