Electrics in an aerated concrete house are perhaps the only type of communications that can be installed after the box has been erected - and even after finishing work has been completed. Installation must be carried out in accordance with the requirements of the PUE, which will definitely be taken into account in today's material.

Electrical wiring in a house made of aerated concrete is not much different from similar work in other buildings, but there are still some peculiarities. Let's talk about this in more detail.

Calculation of power consumption and cable selection

To determine the characteristics of the required electrical cable, it is necessary to calculate the power consumption of all possible electrical appliances in the house. Let us immediately note that it is necessary to use copper wires.

For a socket group, the cable cross-section should be from 2.5 mm. Sq., for lighting – from 1.5 mm. sq. To connect powerful electrical appliances, such as a boiler, electric stove, fireplaces, etc., the cable cross-section should be from 4 mm. Sq.

Place of electrical panel in a private house made of aerated concrete

Installation of an electrical panel is an important point when installing electrical wiring. All cable lines will be laid from it. The location for the shield should be chosen so that it is located close to the exit from the house. This is necessary so that it is easy to completely de-energize all circuits that will not be used if the owners are absent from the house for a long time.

Another requirement is that the electrical panel must be easily accessible in case the protective devices . If the lighting goes out at night, you will have to get to the switchboard by touch.

Possible options for a successful location of the electrical panel:

- in a garage, if it is located under the same roof as the living quarters and communicates with them;

- on the veranda located at the entrance to the house;

- in the hallway, if its area allows you to successfully arrange all the pieces of furniture without covering the shield;

- in the boiler room (for gas boiler rooms, it is better to coordinate the location of the electrical panel in advance with the services that supervise the use of gas equipment).

When choosing a housing for an electrical panel, it is necessary that it can accommodate the required number of circuit breakers and RCDs. Residual current devices must protect all lines in wet rooms, children's rooms, rooms where animals can be freely present, as well as all sockets for electric water heaters, washing machines, water supply and heating pumps from leakage currents.

The location of the shield on the wall should ensure free routing of cable lines. In this case, it is advisable to hang the shield on internal walls or partitions.

Single-wire or multi-wire conductor

The single-wire cable core is more rigid and breaks if it is bent frequently. It is used specifically for stationary electrical wiring, since it is cheaper than multi-wire and easier to install.

The stranded core is very flexible, used for hard-to-reach places and for connecting portable equipment.

Single-phase input or three-phase - which is better?

Currently, electricity consumption in private homes is constantly increasing. Back in the mid-twentieth century, the number of electrical appliances was limited to an electric stove, a couple of household appliances, and a few incandescent lamps.

Today, in any room there is a huge abundance of household electrical appliances, therefore, in private properties they often began to resort to three-phase cable inputs, abandoning single-phase ones.

Three-phase or single-phase current - the choice is yours

Many believe that a three-phase network will allow the use of power more than usual, in fact, turning on many devices at the same time. But this is not at all true, because the maximum permitted power is indicated in the technical conditions for connection.

For a three-phase connection, this is usually 15 kW for household needs, for a single-phase network - 10-15 kW. As you can see, the benefit is insignificant or completely absent. In addition, the meter for the three-phase input has bulky dimensions - and this is a minus.

However, the fact that it becomes possible to directly connect three-phase electrical receivers to the network:

- electric boilers;

- asynchronous electric drives, etc.

This is definitely an advantage. The fact is that for the operation of the same asynchronous motors connected to a three-phase network, the energy and mechanical parameters are improved. And when operating powerful electrical consumers, such as boilers and stoves, “phase imbalance” is not observed.

The operating voltage in a three-phase network is close to 380 volts, which will require you to take a more careful approach to electrical safety issues! especially if the electrical wiring is in a wooden house.

Disadvantages of three-phase input

- It is necessary to obtain permission to connect from local authorities.

- Increased risk of electric shock, as well as the risk of fire and fire, due to high voltage.

- Cumbersome dimensions of distribution input panels.

- The need to install a modular surge suppressor in the switchboard.

Advantages of three-phase input

- The ability to avoid “phase imbalance” by redistributing workload between phases.

- Direct connection to the network of powerful three-phase electrical consumers.

- Reduction of current ratings in input protection equipment and cable cross-section.

- Sometimes, the possibility of increasing the maximum permitted power consumption of electricity.

As you can see, the use of three-phase input is most appropriate for houses with a usable area of 100 sq.m. and more. When there are many single-phase current consumers, it is easy to distribute the load more symmetrically. Moreover, three-phase input is ideal for heavy-duty three-phase electrical appliances.

In other cases, the transition to “three-phase” is not particularly necessary.

Use of transformers and stabilizers

Unstable voltage in the network is a common problem in homes, and this can cause not only breakdown of electrical appliances, but even damage to electrical wiring.

Such problems can be solved by using a voltage transformer, which is a statistical electrical device that converts voltage. You can order such a device on the website newet.ru. The principle of a transformer is that it levels out and smoothes out power surges, protecting the entire electrical system of the home.

Electrical panel

This is the main element of the home's power supply circuit. An external cable comes to it, and all wiring throughout the premises is carried out from it. On the panel there are automatic circuit breakers (RCDs) for all phases supplied to the house.

It is necessary to place the shield so that it is always freely accessible. There are often tips for placing a panel in a garage or boiler room, but they look quite dubious - if the machine turns off the lighting, you will have to somehow get to these rooms in the dark. You will always have to have a flashlight on hand.

Wiring diagrams

The reliability of electrical wiring, ease of use, and the consumption of wires and components depend on the connection diagram.

The following types (schemes) of connection are distinguished:

- All sockets and light bulbs are connected through one machine.

- All sockets are connected through one circuit breaker, all light bulbs through another.

- In each separate room there is a machine with sockets, and all the lighting is connected to another machine.

Selecting a wiring diagram

The electrical wiring diagram should not only be convenient, but also comply with the current SP 76.13330.2016 and SNiP 31-110-2003. Basic rules that must be followed when developing a wiring diagram for a house made of aerated concrete blocks:

- Cables and wires must be positioned strictly vertically or horizontally. Cable laying at an angle or rounded bends is not allowed. Rotation is only possible at an angle of 90 degrees. Straight wires are easy to find for repair.

- The distance of switches, sockets and other elements from door and window openings must be at least 0.2 meters, from the floor level - at least 0.8 meters, from gas pipes - at least 0.5 meters.

- Separate circuits must be provided for powerful household appliances. Such devices include: washing machines, water heaters (boilers), gas and electric boilers, pumps, air conditioners.

All electrical wiring diagrams for private houses are built according to the same principle and differ only in the number of sockets, switches, and circuits. The diagram indicates the location of all energy consumers: high-power and low-power household appliances, lamps, sockets, switches. Using the diagram, you can calculate the required number of machines, panels, RCDs and the required length of wires.

In a small one-story house made of aerated concrete there may be only one electrical panel. For two- and three-story cottages, it is advisable to install electrical panels separately for each floor. If you have a backup power source - a generator, it is better to place the electrical panel in a utility room or garage. An input switch, voltage stabilizers and electricity meters are also installed here. If you plan to install a powerful device with a separate circuit and many small energy consumers in a room, for example, in the kitchen, then you need to install a distribution box at the entrance. For living rooms, the box can be for several rooms.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

When drawing up an electrical wiring diagram for a house made of aerated concrete with three-phase voltage, do not forget about the extensions. Bathhouse, garage, gazebo - all this should also be illuminated and taken into account when calculating power and choosing the cross-section of electrical wires.

House wiring and wiring plan

The electrical wiring plan is a very important and responsible step, which you need to understand very well yourself, or resort to the services of specialists.

At the planning stage, you need to schematically indicate the following elements:

- Shield.

- Wires.

- Sockets.

- Lamps (light bulbs).

- Switches.

- Automatic machines.

- Distribution boxes.

Installation

Installation work is carried out in accordance with pre-drawn diagrams and plans for the placement of wires, sockets and switches, etc. The first step is to lay grooves along all walls and ceilings. Its depth is 203 cm, the width depends on the number of circuit elements, lighting and power sources. According to the rules of installation work, channels for laying electrical wiring must be located either strictly vertically or horizontally. This point is taken into account at the marking stage, but you need to remember it throughout the entire work.

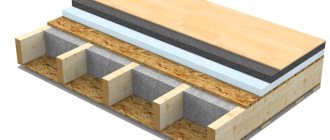

Lay the wires and fix them in the groove with nylon dowel clamps. There is no need to specially seal the groove, since after the completion of the installation, the electricians will begin finishing work, during which everything will be sealed.

Wiring can be laid in grooves on the walls without corrugation, since no mechanical effects on the wires are expected. However, a cable laid on the floor must be installed in a nylon or metal corrugated tube.

Then they drill sockets for distribution boxes, sockets and switches, and install socket boxes. It is not necessary to install sockets and other elements right away, since during the finishing work they can be dirty or filled with plaster mixtures. It is more correct to leave loops of wire, to which the necessary elements of the electrical circuit will subsequently be connected.

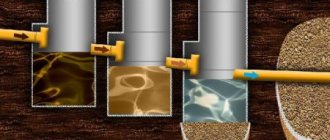

Hidden and exposed wiring

Hidden wiring is an option when wires are hidden in the walls, ceiling and floor. Grooves are made in the walls, cables are laid in them and covered with plaster. Corrugated wiring in floors is filled with concrete screed. On ceilings, corrugated cables are covered with suspended ceilings, plastic panels and other hanging materials.

The main purpose of hidden wiring is visual perception and additional decorative options.

Open wiring is an option when corrugated cables are laid outside the walls in special cable channels. Cables along the floor and ceiling are laid in plinths. In appearance, such wiring does not look very nice, my subjective opinion.

And it is more susceptible to mechanical damage, for example, if it is accidentally hit by moving furniture. The advantage of open wiring is quick replacement and simple repairs.

Installation of branch boxes, sockets, switches in aerated concrete

Branch boxes should be located on cable routes in places where cables branch and connect. When installing hidden wiring, they are buried in the structural material and firmly fixed. Due to the high porosity of aerated concrete, not every fastener can reliably fix the body of the junction box, so it is better to use building mixtures. They can be used to attach the box to aerated concrete.

You can quickly prepare such a solution by mixing alabaster and glue for gluing ceramic tiles.

When installing open wiring, the installation fittings of sockets or switches are attached to aerated concrete using special fasteners. It consists of self-tapping screws, polypropylene dowels for aerated concrete or chemical anchors that prevent sockets from being pulled out of the walls. This sometimes happens when there are large mechanical forces on the spring-loaded contacts of the sockets, if the fasteners are applied incorrectly.

Compliance with the rules for laying electrical wiring is the key to the safety and reliable operation of electrical appliances and equipment used in the house.

You might be interested

Choosing a cable cross-section for electrical wiring in a private house or apartment

How to choose a cable for electrical wiring in a wooden house

Using corrugation

Corrugation is an additional cable protection and is used in electrical wiring quite often. But is its use always justified? Let's figure it out. Many electricians insist on the widespread use of corrugation in order to increase the amount of work and the overall cost. But let's approach this issue logically.

Think about it, if you use a good VVGng-Ls cable, which is hidden in an aerated concrete groove and plastered, does it need corrugation? From a fire safety point of view, corrugation is not needed in this case, but it can be justified if the cable is replaced when it is pulled out of the groove with wire. But it is far from certain that this will work out.

Corrugation must be used if part of the cable is laid in a concrete screed.

The use of corrugation is mandatory for open wiring, and especially when using flammable facing materials such as plastic and wood.

We calculate the total power of electrical appliances

The main task that craftsmen have to face when installing new wiring is the choice of materials, wire cross-section, and characteristics of the machines. The reliability and safety of electrical appliances depends on this.

For lighting, the total power is usually 10 or 16 A. For a group of sockets, it is taken from 16 to 40 A. Taking this into account, electrical installation of a house begins with calculating the power of consumers connected to one line. The resulting value is divided by the network power, which is 220 W. For example, if a total of consumers require 4 kW, then the required network power is 4000/220 = 18.2 A.

When making calculations, it should be taken into account that it is practically impossible to turn on all electrical appliances at the same time. Therefore, a correction factor is introduced, which depends on the total power:

- up to 14 kW it is taken 0.8;

- up to 20 kW – 0.65;

- up to 50 – 0.5.

Using the coefficient will help you avoid unnecessary expenses on purchasing expensive equipment. At the same time, network security remains at the proper level. It is better to dispel any doubts about installation in a panel house or any other house by consulting with specialists.

For many craftsmen, electrical installation in a private building becomes a difficult task. A program for developing an electrical part project allows you to simplify it and avoid many mistakes. She will handle the following questions:

- calculation of power supply capacity;

- voltage loss calculation;

- determining the length and cross-section of the cable;

- selection of materials.

Another important bonus: using the program for installing any type of wiring will ensure an accurate calculation of the required number of lighting devices and selection of their optimal installation location. It will become a reliable assistant to a person who has minimal knowledge of electrical engineering. In addition, the program makes it possible to consider options without financial investments, study the features, advantages, and disadvantages of connections. This minimizes the likelihood of error.

Table of cross-sections of copper and aluminum cables by power and current

Installation of distribution boxes and sockets

Distribution boxes, like sockets, can be recessed into the thickness of aerated concrete, or they can completely protrude on the surface. The recessed version in aerated concrete is more preferable, as it is both more fireproof and more practical.

A large hole in aerated concrete for a socket or distribution box can be made using a screwdriver with a crown. The circles are drilled out and the inside is chopped off with a hammer.

Cable line layout

According to the current rules, electrical wiring in a private house made of aerated concrete must be made of wires or cables with copper conductors. It is unacceptable to use aluminum conductors for permanent wiring indoors.

Wires and cables for electrical wiring are laid either directly on the surface of aerated concrete or in grooves. In order not to confuse cables from different groups of electrical wiring with each other during wiring, it is recommended to first draw the routes on the walls with chalk, using different colors.

To ensure the possibility of replacing wiring during repairs, cables are laid in pipes made of self-extinguishing materials - polyethylene, ABS plastic. The pipes are walled up in grooves so that the layer of mortar above them is at least 10 mm. In places where the direction of the cable line changes, special bends or branch boxes are installed.

Grooves in aerated concrete are made using a wall chaser, a hammer drill or a “grinder” - an angle grinder. Since this material is malleable to mechanical processing, such work is carried out without much difficulty.

Outdoor wiring

Laying open electrical wiring in a house made of aerated concrete is carried out if there is a time limit and there is no desire to create dust. This type of work is much simpler and can be used for both aerated and wooden walls, in accordance with the requirements of the PUE. All components are purchased for open wiring; the wires must be designed for the maximum rated load and have double insulation made of non-flammable material. All sockets, switches, junction boxes are installed on the wall surface and secured. Gaskets made of asbestos, metal or other fireproof material are installed under them. Although modern products are made from flame-retardant or non-combustible materials and require installation without gaskets (pay attention to the instructions or consult a specialist).

We recommend choosing VVGng-LS cable, it is non-flammable. All wiring and installation is carried out similarly to the installation of hidden electrical wiring in aerated concrete, with the exception that the wire is laid along the surface of the wall in a plinth, gutters, corrugation or on dielectric insulators.

The conductors are connected using terminal blocks, welding, soldering or crimping. Twisting is unacceptable (Chapter 2.1. PUE clause 2.1.21).

Work on installing wiring in a house made of aerated concrete must be carried out by specially trained personnel - an electrician, in order to avoid possible malfunctions during operation. The video examples below clearly describe all the stages of installing electrical wiring in an aerated concrete house:

That's all I wanted to tell you regarding this issue. We hope you now know how to do electrical wiring in a house made of aerated concrete with your own hands!

It will be interesting to read:

Outdoor wiring

Laying open electrical wiring in a house made of aerated concrete is carried out if there is a time limit and there is no desire to create dust. This type of work is much simpler and can be used for both aerated and wooden walls, in accordance with the requirements of the PUE. All components are purchased for open wiring; the wires must be designed for the maximum rated load and have double insulation. All sockets, switches, junction boxes are installed on the wall surface and secured. Under them, wooden planks are installed, with a lining made of asbestos or a similar non-combustible material (asbestos, fluoroplastic), or ready-made segments of non-combustible material. We recommend choosing VVGng for the cable; it is non-flammable, which will additionally protect your residential building from fire. All wiring and installation is carried out similarly to the installation of hidden electrical wiring in aerated concrete, with the exception that the wire is laid along the surface of the wall in a plinth, gutters, corrugation or on dielectric insulators. The connection of conductors is carried out by an electrician using terminal blocks, welding or crimping.

Work on installing wiring in a house made of aerated concrete must be carried out by specially trained personnel - an electrician, in order to avoid possible malfunctions during operation. The video examples below clearly describe all the stages of installing electrical wiring in an aerated concrete house:

That's all I wanted to tell you regarding this issue. We hope you now know how to do electrical wiring in a house made of aerated concrete with your own hands!

Grooves for cables in aerated concrete

Grooves are also made in aerated concrete very simply, using a wall chaser or a screwdriver with a cutter. Remember that the grooves must run strictly vertically and strictly horizontally so as not to get tangled during further finishing.

When cutting out the grooves, we recommend screwing the guides from a metal profile, this will make the grooves perfectly even.