For the construction of roofs of country houses and dachas, they are increasingly resorting to the use of alternative materials. Instead of a standard rafter system made of wooden beams and boards, you can install an iron frame made of a profile pipe. Such structures have a service life of tens of years. They can withstand enormous loads, which is why they are promising in the development of residential housing construction. How to make a roof from a profile pipe - we tell you in the article.

What is a crossbar and how does it differ from a beam?

Few people today outsource the construction of a house entirely to a team or organization. To be sure of the result, it is necessary to control the work. To do this, you have to understand the terminology, technical processes and design features. Transoms are common in building construction, but they are very similar to beams. And so much so that not even all professional builders can explain the difference. Let’s look into what a crossbar is in construction and how it differs from a beam. Let's also consider the types and types of concrete crossbars.

What is a crossbar: definition and purpose

In general, the word “crossbar” itself has many meanings. This is a German surname, a community in Germany, the name of a star, and much more. There are also crossbars in the design of the house. But many often find it difficult to answer what exactly it is. In construction, a crossbar is a part of the supporting structure of a building. It is a horizontal element connecting vertical posts. The remaining structural elements are already connected to the crossbar. That is, the construction crossbar is always located horizontally between two posts (if it is long, it may have support posts). They can be vertical or inclined.

A crossbar in construction is a horizontal element connecting racks

The purpose of the crossbar is to mechanically connect the racks, linking them into a single system, and impart stability to the structure. Also, by connecting parts of the structure, it redistributes the load from different parts of the building, evenly transferring it to the racks.

All horizontal lintels in this picture are crossbars

It can be found in any part of the building. There are crossbars in some types of foundations (pile-grillage, columnar and others where there are separate supports), wall frames, ceilings, and pitched roofing systems.

How is it different from a beam?

We figured out what a crossbar is in construction. But there is another element found in floors and roofing systems, which is often confused with a crossbar - these are beams. Beams are a load-bearing element in a structure that usually absorbs bending loads. Here's the difference - the crossbar is part of the supporting structure. This is the frame on which the beams rest.

The easiest way to figure out where the beam is and where the crossbar is is to see what load is on the element

Beams can be inclined or horizontal. But they almost always work in bending, so they must be designed to withstand long-term loads. Crossbars are strictly horizontal elements and serve to mechanically connect the racks, and do not bear bending loads. Therefore they are usually not calculated. Standard solutions are laid down, with a certain margin of safety.

What is the difference between a crossbar and a beam: often in shape, but in general, in purpose and function

Another difference between a crossbar and a beam is the materials and shape. The beam is always rectangular or square in cross-section. Crossbars often have a more complex shape, but can be square or rectangular. The beam can be wooden or metal. The crossbar is also made from these materials, but it can also be reinforced concrete. So, if you see a reinforced concrete horizontal part of the structure that rests on racks, you have a crossbar in front of you. There are no other options.

With horizontal wooden and metal elements it is a little more difficult. It is necessary to look to see if there is a bending load on them. If not, it's a deadbolt. Otherwise - a beam. And if the element is installed at an angle, it is definitely a beam.

Why choose metal?

Based on what types of loads they want and what fire standards are, the frame is made from a variety of materials. And now let’s dwell as long as possible on the distinctive features of the materials used for raftering the frame. Let's consider the main advantages of wooden rafters. For most, building a frame seems like working with a wooden board that needs to be sawed in the required place. Dried wood is mainly used as wood. However, working with wood is actually no easier than working with metal, although most people think so. Thus, in the production of wooden rafters, only high-grade wood is indispensable. In addition, they carefully ensure that such types of boards and beams do not contain large knots, wane, cracks, or the necessary slope of the fiber. What's the point? Each important flaw can lead to the fact that the rafter leg will simply crack under load. If it is not possible to purchase high-quality dry lumber, then it is dried directly onto the lenses in a special ventilated stack. For this reason, it is worth buying ready-made boards for the production of rafter systems, moreover, with a margin of width. And that is not all.

Basically, lumber looks very smooth only to the eye, and for rafter systems geometry is a fairly important characteristic. And just having a margin of width, craftsmen have the opportunity to straighten the rafters themselves using planing equipment. Only in this way are the slopes actually level, and completely different roofing coverings can be comfortably installed on them.

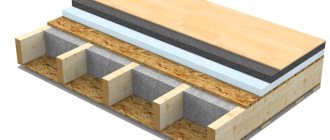

Now let’s look at the features of choosing steel beams. Today, the rafter system is quite often selected from galvanized steel beams. You have most likely seen their names: I-beams, channels or brands. Such parts are very expensive than wooden or ordinary metal ones, but they are worth it. Yes, they are very difficult for installation work, but they are preferred for one important advantage - increased reliability against bending load. With the help of this, in the construction of the frame it is possible to do without any vertical supports and other parts. However, beams are not often used in residential building construction today, although a similar practice exists, and today we will explain why. For example, the complexity of rafter systems and the presence of internal parts immediately affects the planning decisions of the attic. Because the more varied the lintels are among builders, the less the attic ceiling will turn out. In addition, all this is important not only for installing another living room under the frame. The fact is that today the so-called attic frames are in demand, under which there are ordinary rooms of the house. And various additional parts will not fit there at all. However, there is a fly in the ointment: metal beams will continue to act as cold bridges, and because of this, a roofing pie will certainly be installed for them. The main filling here is oriented strand board. This is an excellent alternative to ordinary different rafters.

Where is it used?

So, a crossbar in construction is a horizontal part of a structure that connects the vertical or inclined parts of the system:

This is how you need to store them

This element is present in almost any part of the building. It can have different shapes to perform different tasks. In the simplest cases, it is a beam of rectangular or square cross-section. These are the types of crossbars used in rafter systems. Rafter systems are assembled mainly from wood and the crossbars for them are also made from this material. In general, wooden crossbars are ordinary timber, the edges of which can be shaped into a quarter or a tenon.

Disadvantages of using metal structures

Despite the huge number of advantages, a metal roof frame is rarely used, compared with a wooden one. Metal rafters for a pitched roof have the following disadvantages:

- The complexity of installation work, when you basically need to connect a special type of equipment to lift massive elements.

- Necessary plumbing skills to carry out the work.

- The price for metal rafters is higher compared to wood.

- Inconvenient transportation.

- Huge thermal conductivity.

- At elevated temperatures, the metal undergoes deformation. This poses a risk of collapse if it catches fire.

- Possible freezing at low temperatures.

Buy metal rafters in a variety of shapes and designs, differing from one another in quality properties:

- The applied scheme;

- the shape of the span and belt;

- sizes.

Rafters are usually divided into the following types:

- arched (they have increased aesthetic qualities; with them you can create complex shapes, which increases the cost of materials);

- screw;

- beam (they are light in weight and require minimal consumption of materials);

- framed

There is a certain list of structural parts of rafter systems.

The roof structure of metal rafters of a public building is made from the following parts:

- brands;

- rectangular and round pipes;

- corners.

All parts must fit perfectly together. The grille is attached to the belt with special elements. Rafter parts are used to support the load-bearing structure. They are used when beams have uneven pitch.

According to the shape of the belts, trusses are distinguished:

- Triangular. This is the optimal choice for large angles. Needs a lot of material.

- Polygonal. Designed for powerful buildings. For a small building, such a decision will be very complicated.

- Single-pitch. They are distinguished by high reliability indicators with frame units of increased rigidity.

- Parallel installed. This type is indispensable for soft roofs as universal options that include the same components.

What can a concrete crossbar look like?

Most often, reinforced concrete crossbars connect the pillars of the building frame. They serve as support for the floors. In this case, high grade concrete is used - from B22 to B60. The choice depends on the number of storeys of the building, and also on the required structural strength. To increase reliability and strength, two reinforcement belts are made. High-strength reinforcement is used. All standards are specified in GOST 13015.3. Technical specifications and standard sizes are specified in GOST 18980-2015.

Excerpt from GOST 18980-2015

Forms and types

Lintels that serve as supports for floors are often called floor crossbars. They come in three types in shape: with one and two shelves or without shelves. Those with one shelf are used along the edges of the structure. Only the edge of one slab can be laid on them. With two - placed in the center. On two shelves you can lay the ceiling on both sides.

As you can see, there are crossbars for ribbed and hollow-core slabs. They differ in the strength of concrete, size and strength of reinforcement. The shape matches.

Explanation of markings

The marking contains complete information about the reinforced concrete element. It consists of numbers, Latin letters and Cyrillic alphabet. The designation is divided into blocks using a dash. There can be three blocks in total:

In general, this topic is extensive, you need to have a lot of tables at hand, since it is unrealistic for a non-specialist to remember all the encodings. Let's look at a few examples - RDP 6.56-110AIV-Na.

Reinforced concrete crossbars must have sling holes or mounting loops for lifting using machinery. Products with unstressed reinforcement can be sold if the concrete strength is at least 70% in warm weather and 85% in winter. Crossbars for interfloor slabs must have a tempering strength of at least 90%. There should be no cracks in the concrete. Small transverse shrinkage hairline cracks with a thickness of no more than 0.1 mm are allowed.

Source

The variety of roof elements and their meaning

All parts of a house, bathhouse or outbuilding are of utmost importance for their operation and peace of mind of the owners. The roof plays an important role in the safety of buildings. The safety of the entire building largely depends on the quality of its manufacture. What roof elements form this important structure, what functions they perform - this will be discussed later.

Where does the choice begin?

When choosing the shape of the roof, you should take into account the direction and strength of wind flows, the level of precipitation, and it would also not hurt to determine the functional load of the roof itself and the attic space.

Before starting construction you need to choose:

- type

and

slope angle - what

exactly

to cover

the roof with: what kind of frame needs to be built depends on the material and its weight; - rafters

, determine their cross-section and length; - what the distance

between the sheathing strips; - what

and how

to insulate

the roof.

Ridges and valleys as slope joints

It is very difficult to tightly connect the slopes to each other. In this regard, ridges and valleys are used to join them at the corners. They help to isolate longitudinal joints and prevent moisture from penetrating into the under-roof space.

The construction of skates is less complicated. To make them, it is enough to bring the roofing materials as close as possible to the slopes and cover them with special ridge elements, which are made from all materials used to cover roofs. A more complex element is the internal angle between the slopes of broken roofs, called the valley. The difficulty in installing it is due to the large volume of moisture flowing from the slopes.

Depending on the shape and angle of inclination of the flat parts of the roof, moisture can flow down them into drains and, partially, into valleys. Despite its small volume, the penetration of water under the roof is fraught with negative consequences for its entire structure.

Internal structure

From the under-roof space, the roof is a rather complex load-bearing structure, having inclined, vertical and horizontal roof elements. For their manufacture, they mainly use well-dried wooden beams or boards, connecting them in a certain way. Instead of processed parts, natural poles of small diameter can be used.

The traditional gable roof is based on an isosceles triangle, the length of the base of which is greater than the length of each of the sides. The use of geometric laws makes it possible to obtain high-strength trusses that can easily cope with the load on the roof from roofing material, precipitation and wind.

Rafter system

The main part of the roof is the rafters - long thick pillars, beams or boards knocked together in pairs, connected at their ends at a certain obtuse angle. Depending on the length of these parts, determined primarily by the dimensions of the building over which the roof is built, their minimum cross-section is determined. It is convenient to use a table for this:

Please note that the cross-section of the rafters or boards depends on the distance at which they are spaced from each other. An increase in the installation step of the pillars leads to an increase in the load on each leg, which requires an increase in its cross-sectional size.

The supporting ends of the rafter beams must rest securely on the walls of the pre-built box. There is also a certain complexity of installation here. Excessive load on the walls can lead to their destruction, so it is necessary to carry out preliminary calculations of this parameter and compensate for them.

Tightening, rack and struts

A simple way to reduce the pressure of the supporting ends of the rafters is to install a special tie between them - a tie, which is a long beam, post or boards nailed together, to which the lower parts of the beveled parts are attached. This option is possible only in one case - in the manufacture of an unused under-roof space - an attic.

Strengthening the triangle of rafter posts and tie beams is achieved by installing internal vertical and inclined parts. The short insert connecting the junction point of the rafters and the horizontal part of the truss is called a post. Small-diameter posts or cuttings of boards resting on inclined boards are called struts.

Rigel and Mauerlat

More often, when constructing residential buildings, they try to make maximum use of all parts of the building. Residential or utility rooms called attics are made under the roofs. The presence of ties between the supporting ends of the rafter pairs will complicate their use. In this case, another element – a crossbar – helps to strengthen the strength of trusses made of timber or boards.

It is a tie that has smaller dimensions compared to the tie and is installed in the upper part of the trusses. Crossbars are made from scraps of boards or timber with a thickness of at least 50 mm, nailing them in pairs on each side of the rafters. The use of through threaded rods or long bolts helps ensure high strength of the connection between parts.

Sometimes the process of attaching the lower ends of the rafter poles is problematic. In this case, another roof element is used, called a Mauerlat.

Attaching the rafters to the mauerlat

It consists of pillars, boards or timber, laid and secured at the top of the walls. The Mauerlat plays the role of a support and can be located along the entire length of the walls or placed only under the rafters. In this case, the dimensions of the pillars do not exceed 500 mm.

In general, roof installation is a complex and responsible process. A well-made roof can protect the entire structure; errors during its installation can lead to the destruction of the entire structure and significant costs.

Source

Types of roofing structures manufactured at our plant:

We produce roofing at our factory and offer the following structures for sale:

Pitched and flat metal roofing for industrial buildings

The design and manufacture of roofing for industrial facilities in Russia has been well studied. Valuable practical experience has been accumulated. The MK Monteco company widely uses it in its developments, using standard series of steel columns and trusses. When installing a roof and making turnkey repairs, it is important to consider several things. For pitched roofs, trusses with inclined upper chords, metal purlins from rolled profiles and profiled sheets are used. When producing a roof for insulation, a layer of insulation, waterproofing, and then various types of materials are laid on the sheet in accordance with the project.

In flat metal structures, trusses with parallel chords or beams of constant or variable cross-section are used, and the flooring is also mounted. When installing the roof, a roofing pie of soft roll roofing is laid on top of it. The scheme is rarely used; usually PC floor slabs or PKZh roofing slabs are laid on load-bearing metal products, and then layers of soft roofing are formed.

Pitched roofs for apartment buildings

The manufacture of roofs using such structures is used in complex and original projects. They make it possible to organize additional living spaces using additional elements for the roof and facade, and give the building an interesting architectural appearance.

For such projects, the company develops and manufactures steel structures and elements that will provide the required roof configuration during roof installation with simultaneous reliable protection and insulation of premises from external environmental conditions. The coating parameters are set taking into account the roofing material used. This can be any type of ceramic and composite tiles, as well as metal tiles, ridges, corrugated sheets, in addition, the company can produce standing seam roofing that is effective in complex solutions.

Pitched roofs for individual construction

According to marketing research, roofing production is in demand mainly for pitched roofs in individual construction. This market segment is targeted by foreign industry leaders RUUKKI, BRAAS, TEGOLA and domestic ones - Metal Profile, TECHNONICOL, Ruflex, which produce millions of square meters of flexible, composite, metal and ceramic tiles at a low cost. Accordingly, a significant number of structures are required for roof installation. The metal roofing plant MK Monteko offers modern solutions from rolled metal, as well as light steel roofs from LSTK.

Steel products are distinguished by greater strength and durability, high fire safety and a relatively low price per m2. At the same time, the manufacture of roofs using high-quality materials allows you to implement any architectural solutions and have many advantages over wooden ones.

Metal roof fencing

The safety of people depends on the quality of roof fencing, so the roof is installed in strict accordance with the requirements of the GOST 25772-83 standard. The MK Monteko company designs and manufactures metal roof fencing for any structures of all categories of responsibility at a low cost. You can order turnkey metal structures from sheet and galvanized steel, from corrugated sheets, choose a flat metal roof, and, if necessary, order additional roofing and facade elements for a private home with delivery throughout Russia.

How are the crossbars of the roof structure located?

What location options are there?

The roof of the roof is one of the main elements of the house and the construction of the roof is determined by the construction of the main elements. The main element of the roof is the roof truss, which consists of:

Rafter legs are boards or beams that form the outline of the roof;

Tights or crossbars are horizontal elements, they tighten two rafter legs;

Struts or supports are placed at an angle and support the rafter legs;

This picture shows very well where the crossbar is located:

These elements are usually made of timber or boards; it all depends on the roof structure and its size. Before installing all elements, they must be impregnated with various antiseptics, after which installation is carried out.

And this is how the installation of crossbars to the rafters takes place; it is best to fasten them with bolts, but you can also use ordinary nails.

The crossbar is located horizontally.

The crossbar is a rather broad concept, but in the case of roofs (if we are talking about a hanging roof truss system), the purpose is specific, the crossbar is a horizontal beam connecting the rafter legs (rafters).

The crossbar prevents the roof from “expanding.”

It is attached in different places between the rafter legs (above, below). There is a direct pattern here: the higher the crossbar is attached, the larger the cross-section of the beam is selected for its manufacture.

There are quite a few options for fastening the crossbar to the rafters, these include bolt fastening (or fastening using studs with washers and nuts) and fastening using special fasteners, fastening with nails, or a combined fastening option in which several types of fasteners are used simultaneously.

The fastening can be overhead, or with a “lock” insert.

In general, this unit is calculated, like the entire roof rafter system.

Source

Fastening methods

Metal rafters are assembled into triangular, trapezoidal or arched trusses. Internal stiffeners are attached to the frame beams, which form corners that significantly increase the load-bearing capacity of the frame. This system allows you to make the pitch between the rafters larger, taking into account the support capabilities of each truss. Fastening the metal elements of the roof frame is performed using one of the following methods:

- Fastening by welding. If you weld the parts of the rafter system using a welding machine, you can get a rigid structure with high strength and load-bearing capacity. If you correctly calculate the roof, you can lighten the frame and reduce the load on the foundation of the structure. The disadvantage of this method is that only a professional can perform welding using special equipment.

- Fastening with bolts. Fixing the rafters with fasteners allows for a less rigid fastening. This method of assembling a rafter frame based on a metal profile is used in private housing construction, where the length of the slopes does not exceed 10 meters. Eliminating welding allows for faster roof installation.

Experienced craftsmen rely on the fact that metal sheathing and rafters can withstand more weight than wooden ones, so you can increase the step between them and reduce the thickness of the cross-section of the elements. Moreover, construction stores sell ready-made trusses, fastened by welding, suitable for covering buildings of standard width.

What is a deadbolt

These structures are load-bearing in the building frame, usually located horizontally.

The two vertical supports are well connected to each other, and this connecting element distributes the weight of the slabs or floors onto the columns, which are installed under the edges of the transom.

A crossbar is also used to describe many parts used in different areas.

For example, this is called:

Crossbar in jewelry

In jewelry, crossbars are used to straighten or reduce the size of bracelets and rings. The tool is made of steel and has a measuring scale.

Roof trusses and its types

The rafter system is the basis of the roof, which focuses on the load-bearing elements of the structure and also serves as a frame for various types of roofing materials: insulation, waterproofing, various coatings.

The dimensions and design of the rafters depend on:

The rafter system has:

Each of the above factors is very important, since it is necessary to understand what type of rafter system will be optimally suited for a particular situation.

When it comes to low-rise buildings, wood structures are the most common. In many cases, three types of rafter trusses are used: hanging rafters, layered rafters and a mixed rafter system.

Characteristics of hanging rafters

Hanging rafters are the most elementary type of rafter systems, their characteristics:

If the roof of the house has a complex structure, the types of rafters can be alternated. For example, if there are supports or a middle main wall, layered rafters are installed, and if there are no such elements, hanging rafters are installed.

Features of layered rafters

For a layered rafter system, the house must be additionally equipped with a load-bearing wall located in the middle. Layered rafters are distinguished according to the following characteristics:

Mixed rafter system

The design of the combined system is the most complex, since it includes parts of two other types of rafters - hanging and layered. It is used for attic roofing. The walls of the rooms, which are located on the second floor, are formed by vertical supports; these supports also serve as intermediate supports for the rafter beams.

The part of the rafters that connect one end of the racks functions as a crossbar for the slopes located on the side, and for the upper part of the structure they are a tie.

At the same time, the horizontal beams perform the following functions: for the upper slopes - the Mauerlat, for the side slopes - the ridge beam. To increase the strength of the roof, struts are installed that connect the side slopes and vertical posts.

The combined sling system is the most complex and time-consuming to manufacture, but these shortcomings are fully compensated by the increase in the load-bearing qualities of the roof in the absence of unnecessary supports, especially when there is a need to cover significant spans in the building.

Flaws

Despite the obvious advantages, metal rafter systems are not the most popular design solution in private housing construction. Even a large step between the rafters and sparse lathing with the high cost of metal cannot make the structure cheaper than a wooden one. The disadvantages of metal rafters are:

- High thermal conductivity. Metal has a high thermal conductivity coefficient, so the rafters and roof sheathing form cold bridges. From the point of view of energy efficiency, a frame made of metal profiles is not the best solution.

- Problematic transportation and installation. When choosing a metal rafter system, take into account that transporting, lifting and fastening long and heavy elements is more difficult than standard-length lumber rafters.

- Difficult to install. To lift the trusses to a height and fix them, special equipment is used, the rental or purchase of which is expensive.

- Deformation under high temperature. Although metal is considered a non-combustible material, during a fire it is greatly deformed, which usually leads to the collapse of the roof.

To determine whether it makes sense to use more expensive rafter elements made of metal profiles, you need to calculate the roof frame. If the length of the slope exceeds 10 meters and the load is more than 450-600 kg, then installing a metal frame is economically feasible.

Roof trusses for various roof types

When constructing a certain building, rafter systems of one type or another are necessarily used, and the type of roof will completely depend on the design of the future structure.

Rafter truss for gable roof

Gable roofing is a common roof construction for residential buildings that have no more than three floors. Preference is given to this particular design due to the technical characteristics of the inclined shape of the rafter system, as well as due to the fact that installation work is carried out easily and simply.

The rafter system of a gable roof includes two rectangular inclined planes. The upper part of the building from the end side resembles a triangle. The main components of a gable roof are the mauerlat and rafters. In order to correctly distribute the load across the rafters and walls, struts, crossbars and racks are installed, thanks to which you can create a durable, rigid, elementary and lightweight structure for installing a structure for a gable roof.

You can install sparse or solid sheathing on top of the rafters, and then attach bitumen coating, tiles or some other type of material to it. The rafters and the sheathing itself are usually made of beams or boards, which are fastened with nails, bolts or metal fasteners. Metal profiles can be used as rafters, thereby covering significant spans. There is no need to use extra racks and struts.

The installation of a rafter system for a gable roof allows you to evenly distribute the entire existing load along the perimeter of the building. The lower ends of the system place emphasis on the Mauerlat. They are fixed with fasteners or metal brackets. By the angle of inclination of the rafter bars, you can determine at what angle the roof slopes will be inclined.

Rafter system for hip roof

When arranging a system for a hip roof, you will need to install different types of rafters:

Functions of rafters

The roof truss frame structure consists of many interconnected elements that form trusses. The pitch, the cross-sectional size between the rafters and other supports is determined by the calculation of the loads to which they are subjected during operation. The roof frame performs the following functions:

- Load distribution. Interconnected nodes, reinforced with corners, evenly distribute the weight of the roof, which can reach up to 500-600 kg, taking into account the snow load. The larger the cross-section of the rafters and the smaller the pitch between them, the greater the load-bearing capacity of the structure.

- Giving slope and shape. The rafters, located at an angle to the base of the roof, form an inclined plane of the slopes, so that snow and water do not accumulate on the roof surface.

- Forming a base for fixing the roofing material. The finishing coating of the roofing pie is attached to the roof frame. The sheathing acts as a basis for fixing the covering, distributing its weight evenly across the rafters.

Note! What all components, rafters and sheathing of the roof structure should be like is determined by engineering calculations. To determine the required load-bearing capacity of the frame, it is necessary to calculate the total load to which it will be subjected. To do this, add the weight of the roofing material, insulation, waterproofing, maximum snow load with the weight of the rafter system.

Self-production of the rafter system

Before the installation of the rafter system begins, the mauerlat must be secured to the longitudinal walls with anchors. Next you need to decide on the required leg section for the rafters, depending on the distance and their length. If there is a need to increase the length of the rafters, then connect them with various fasteners.

When using different insulation, you need to choose the ideal distance between rafter elements in order to reduce the number of thermal insulation scraps.

Installation of the rafter system must be done in the following order:

Typical components of a standard rafter system

The strength of the rafter structure depends on the ideally selected section of the boards, as well as on the high quality of the rafter assemblies. The connection of parts for the roof structure is done according to established rules.

The main typical units in the rafter system:

After the design of the rafter system has been chosen, it is necessary to draw up a plan in which to highlight all the nodes. In each design they are made differently, since it depends on various nuances: the type of roof, its size, angle of inclination.

Rafters from a profile pipe

Rafters made from a profile pipe are a metal structure that is assembled using lattice rods. The production of such farms itself is a very labor-intensive process, but also more economical. To make rafters, paired material is used, and gussets are connecting elements. The structure of the rafters from profile pipes is assembled on the ground, using riveting or welding.

Thanks to such systems, any spans are blocked, but the correct calculation must be made. Provided that all welding work is done efficiently, in the future all that remains is to transfer the structural elements to the top of the building and assemble them. Load-bearing rafters made from profile pipes have many advantages, such as:

Crossbar in the rafter system

Crossbar is a fairly broad concept, but in the case of roofs it has a certain meaning. The crossbar is a horizontal beam that connects the rafters. This element prevents the roof from “expanding.” It is made of wood, reinforced concrete, and also metal - it all depends on the type of structure. And the crossbar serves to distribute the load exerted by the rafter system.

It can be fixed in various places between the legs of the slings. There is a direct pattern here - if the crossbar is fixed higher, then the timber for its installation must be selected with a large cross-section.

There are many ways to fix the crossbar to the rafter system:

The fastening is available with a mortise or overhead. In general, the crossbar is a design unit, as is the entire system of roof slings.

Fastening the rafter system

To ensure the reliability of the rafter system, you must first find out how they are attached to the supporting roof and ridge. If a fastening is made to prevent deformation of the roof when the house shrinks, then the rafters are secured on top with a hinge plate or a nut and bolt, and below with a sliding support.

Hanging rafters need a tighter and more reliable fastening in the ridge, so in this case you can use:

In the layered system, the rafter legs are not connected to each other, since they are attached to the ridge girder.

The rafters are attached to the mauerlat using the cutting method, which is made in the rafter leg. Thanks to this fastening method, the roof support will not weaken. Cutting is also done when installing rafters on floor beams. In this case, a cut is also made in the support beam.

pros

Metal roof rafters have the following advantages:

- Huge operational period. If you choose the right material, everything will last for about a century.

- Fire safety. Production is carried out using non-flammable material.

- In case of local fires, it lasts longer.

- Minimum waste during installation of such a unique structure as rafters made of metal profiles.

- Easy maintenance. A special coating of metal fasteners for rafters began to provide a protective option, which prevents the destruction of raw materials, and becomes the reason for the absence of the need for annual treatments.

- There is no serious load on the load-bearing walls and the foundation of the building.

- Environmentally friendly construction, no need for treatments with chemicals.