The most reliable (but not always appropriate) option for interfloor slabs is a monolithic slab. It is made of concrete and reinforcement. Read about the rules for installing monolithic floors in this article. Analysis of the characteristics of types and applications, installation of monolithic floors.

Floor slab reinforcement: main advantages

Modern techniques, which open up new possibilities in construction, have important advantages.

- There is no need to search for heavy equipment, or rather cranes.

- There is an opportunity for the successful construction of a structure of any shape.

- The ceiling can please you with its high level of strength and resistance to any external factors.

- For a reinforced slab, additional structures, such as walls and columns, can be used as supports.

- It is possible to reinforce a monolithic slab for buildings where humidity reaches 60%. If there is a vapor barrier on the internal walls, the humidity in the room can be 75%.

- An optimal level of sound insulation is guaranteed.

What are the requirements?

PNO slabs have different sizes and characteristics. But all products must meet certain requirements, which will guarantee the quality and reliability of the future building.

Basic requirements for slabs:

- Exact compliance with all GOST standards

- Strict adherence to the dimensions and dimensions established in the documentation, absence of chips and visible damage

- Strength and fire resistance limit, optimal for a specific type of slab, corresponding to the calculations performed in the project

- Reinforcing the slab with reinforcement of the required class, in the volumes specified by GOST

- For ribbed slabs - the distance between adjacent ribs should be equal to 150 centimeters

- Optimal level of rigidity, resistance to various types of deformation

- Weight – affects ease of use and the total weight of the entire building

- Cost - must be justified and suitable for the developer

- Heat, sound, waterproofing - according to established standards

How to calculate the load correctly

The construction of any house cannot be done without correctly calculating the load that the floor slab can support. The rigidity of the entire building depends on it. Therefore, these calculations are the key to safe construction, this is a guarantee of the safety of people’s lives.

In each house, the floors have two structural parts:

- top;

- lower

The upper part transfers the load to the lower structure

Therefore, it is very important to accurately calculate the permissible value

Basically, the calculation of any building structure is simply necessary so that the building does not subsequently collapse. If the calculation is incorrect, the walls will begin to crack very quickly. The building will quickly collapse.

- dynamic;

- static.

Static calculation takes into account all objects that load the slab. All moving objects carry dynamic magnitude.

To perform the calculation, you must have:

- calculator;

- roulette;

- level.

The size of the slab determines its resistance to various loads.

To determine the load that the future floor slab can withstand, a detailed drawing is first made. The area of the house and everything that can create a load are taken into account. These elements include:

- partitions;

- insulation;

- cement screeds;

- flooring.

The main support system of the roof is located at the ends of the slab. When slabs are made, the reinforcement is positioned so that the maximum load falls on the ends.

Therefore, the middle of the structure will not hold up, even if it is reinforced with main walls.

To understand how the calculation is done, let’s take as an example a design like “PK-50-15-8”. According to GOST 9561-91, the mass of this system is 2850 kg.

- First, the area of the entire load-bearing surface is calculated: 5 m × 1.5 m = 7.5 sq.m.

- Then the weight that the stove can hold is calculated: 7.5 square meters. m × 800 kg/sq.cm = 6000 kg.

- After this, the mass is determined: 6000 kg – 2850 kg = 3150 kg.

At the last step, it is calculated how much of the load will remain after insulation, screed laying and floor covering. Professionals try to choose flooring so that it and the screed do not exceed 150 kg/sq.cm.

Then 7.5 sq. m is multiplied by the value of 150 kg/sq.cm, the result is 1125 kg. From the mass of the slab equal to 3150 kg, 1125 kg is subtracted, resulting in 3000 kg. Thus, 1 sq. m can withstand 300 kg/sq. cm.

Permissible load on the floor slab

Calculation of loads on the floor slab is done for each linear meter of it

Calculation of loads on floor slabs is a factor that must be taken into account in order to avoid subsequent destruction and cracks. That is why the calculation must be made.

The permissible load can be:

- Static

- Dynamic

Static are considered to be those that are distributed horizontally in relation to the wall, i.e. are pumped by objects hanging, lying or nailed to the wall.

In addition, the type of loads depends on the way they are distributed:

- Uniform

- Focused

- Uneven

Any loads are calculated in kilogram-forces or Newtons per meter (kgf/m), in the standard design they are considered equal to 400 kg per square meter. meter, taking into account the mass of the slab itself, approximately 2.5 centners, and finishing materials. As a result, the calculation comes down to a few numbers:

the total permissible load (weight) that must be distributed over the supports is 750 kg * K = 1.2 (strength coefficient) = 900 kg per square meter. meter.

Before you begin any calculations, you will need a competent drawing, made in full compliance with norms and standards. To carry out construction work, it is recommended to contact highly professional specialists for drawings, who can then make calculations.

Afterwards, it is necessary to calculate the weight of everything that will create a load for the floor, for example, possible partitions, material for floor insulation, screeds, decorative finishes. All additional materials and finishing are also usually counted in kilograms. The resulting figure will need to be divided by the number of slabs that will be laid on the floor.

Often they try to bring calculations and selected materials to the “golden mean”, so that the load of all materials is no more than 150 kg per square meter. meter. It is worth noting that the most common slab, which is chosen by almost all construction contractors, for the construction of residential buildings is PK-60-15-8, the total weight of which is 2850 kg.

All calculation standards and their necessity for each type of floors and structures (buildings) are regulated by special SPiP documents. Calculation based on the example can be easily found in reference literature.

Installation of homemade formwork

The technology for installing formwork from forest and lumber largely depends on the experience of the master. There is no specific technology here, since the method is considered artisanal. Often, lumber intended for the rafter system or floors of a building is used for table posts and beams.

There are a number of requirements that must be observed when assembling formwork yourself.

The racks must be made of solid wood - timber or boards. Overlay splicing is not allowed. End-to-end extensions on intermediate racks are allowed.

Section and pitch of racks:

- 75x75 mm - 800 mm

- 100x100 - 1000 mm

- 120x120 - 120 mm

- 150x150 - 1600 mm

- 180x180 - 1800 mm

- 200x200 - up to 2000 mm

Thickness and pitch of the crossbar*:

- 75 mm - 600 mm

- 100 mm - 800 mm

- 120 mm - 1000 mm

- 150 mm - 1400 mm

- 200 mm - 1800 mm

Thickness and pitch of formwork beams:

- 40 mm - 400 mm

- 50 mm - 500 mm

- 60 mm - 600 mm

And so on at the rate of 1 to 10.

* A reasonable width of the crossbar board or beam is assumed to be 100–200 mm.

Operating procedure

1. Carefully measure the height from the floor to the top of the wall.

2. Make U-shaped elements (“frames”) from material for racks and crossbars. The racks must be fixed 300 mm from the edge of the crossbar.

3. Install them with a given step (see above), securing them with temporary slopes.

4. Check for correct installation and compliance with the horizon.

5. Install additional posts and secure the structure with permanent slopes.

6. Lay out the formwork beams with a given step (see above).

7. Make the flooring from the selected material (plywood or board). If the flooring is supposed to be plank, lay polyethylene on it.

Note. All other things being equal, the quality of the ceiling (marks, plane) made using homemade formwork will always be lower compared to inventory. However, this is not so important, since the ceiling is usually made suspended.

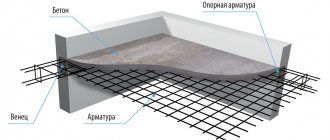

How to reinforce a monolithic slab: basic rules

Important rules must be taken into account before carrying out planned activities. It is imperative to be guided by the technological plan, which determines the final result

- It is assumed that it is possible to use a tense mesh that includes high-strength ropes. It is assumed that the mesh can be used to reinforce structures that span spans and are longer than 8 meters.

- For reinforcement, you can use conventional welding mesh, which includes rods with a diameter of over 6 millimeters. The distance between such rods should not exceed 60 centimeters.

- The thickness of the platform and the width of the created overlap are interrelated. Reinforcement of a monolithic slab should be carried out using rods only if the thickness of the platform is less than the width of the floors. For this reason, before carrying out construction activities, it is necessary to carry out calculations.

- The thickness of the platform is less than fifteen centimeters allowing the use of only single-layer reinforcement of the floor slab. With a greater thickness, it is possible to create two layers, thanks to which the structure will acquire optimal technical characteristics.

- To fill the reinforcement, you need to use liquid concrete. The ideal option is M200 concrete. Otherwise, the materials used will not be able to achieve optimal strength.

- Calculations are expected to be carried out to ensure that the correct design is created with optimal reinforcement zones. Special treatment is required for places that touch the structure's supports, holes, the middle of the slab, and suggest the presence of an accumulation of loads.

- Auxiliary reinforcement of floors is used, first of all, only for holes, the main one - on a full basis. Despite this, formwork calculations must be performed for the entire length of the structure.

Technology of work execution

To fill a monolithic floor with your own hands, you need to prepare boards for formwork and sheets of plywood

To fill a monolithic floor with your own hands, you need to prepare the following tools and raw materials:

- Boards for formwork and plywood sheets (preferably glossy so that the concrete has minimal adhesion to the wood when drying);

- Supports for the monolith at the rate of 1 piece/1 m2 of floor slab;

- Rods for knitting reinforcing mesh with a cross section of 8-12 mm;

- Plastic clamps-stands for fittings;

- Concrete grade M-350 and higher (it is better to order ready-made in the required volume);

- Tool for bending reinforcement.

Various types of loads

Any overlap consists of three parts:

- the upper part, which includes the flooring, screeds and insulation, if there is a residential floor on top;

- the lower part, consisting of ceiling finishing and hanging elements, if there is also a living space below;

- the structural part that holds it all in the air.

Floor slabs weigh a lot, so they need to be installed only with the help of a crane.

The floor slab is a structural part. The upper and lower parts, that is, the finishing of the floor and ceiling, creates a load that is called constant static. This load includes all elements suspended from the ceiling - suspended ceilings, chandeliers, punching bags, swings. This also includes what will be placed on the ceiling - partitions, columns, bathtubs and Jacuzzis.

There is also the so-called dynamic load, that is, the load from objects moving across the floor. These are not only people, but also their pets, because today some people acquire exotic pets, for example, boars, lynxes or even deer. Therefore, the issue of dynamic loading is more important than ever.

In addition, loads can be distributed and point. For example, if you hang a 200 kg punching bag from the ceiling, then this will be a point load. And if you mount a suspended ceiling, the frame of which is attached to the ceiling with hangers every 50 cm, then this is already a distributed load.

When calculating point and distributed loads, more complex cases are also encountered. For example, when installing a bathtub with a capacity of 500 liters, you need to take into account not only the distributed load that the weight of the filled bathtub will create over the entire support area (that is, the area between the legs of the bathtub), but also the point load that each leg will create on the floor.

About prefabricated slabs according to the PC and PB series

PC slabs are often used to create interfloor floors, but they are gradually being replaced by PB from the market. The main difference and advantage of PB slabs is the technology of formless production, thanks to which panels can be made of almost any length (the product comes from the conveyor belt and is cut into the required pieces).

The thickness of the slabs is standard and equal to 22 centimeters. When calculating the thickness of floors, the following parameters are additionally taken into account: the thickness of the concrete screed up to 5 centimeters, the insulation layer (if any), the floor covering layer, the ceiling itself. All this affects the installation features of the slab, so it is calculated in advance.

All slabs are used to create a reliable and durable floor. In individual low-rise construction, slabs are used for: laying floors, dividing attics and floors, creating pitched roofs in outbuildings, enclosing structures, and platforms.

The standard load-bearing capacity of slabs with the weight of furniture and people is 150 kg/m2; sound and heat insulation characteristics guarantee reliable protection from noise and cold, even where single-layer floors are installed.

Long slabs (up to 9 meters for a PC, 12 for 4-6 PCs, PG) are relevant for the installation of industrial and public buildings, they are universal and can be used anywhere. When choosing a size, be sure to take into account the importance of observing the norm for laying on supports - 7-15 centimeters in accordance with the material of the walls.

PC reinforcement is carried out with steel grade A4-A5, as well as transverse wire mesh of small diameter. The PB series assumes only longitudinal reinforcement made of durable steel rods class K-7. Due to the absence of a transverse frame, the slabs can be cut at any angle, using unusual configurations in the construction of buildings.

All slabs are sanded, so their surface requires virtually no preparatory finishing work. As for the cost, usually PB series plates are cheaper than PC. In general, when recalculated into squares of the price per square meter, a 1 meter wide floor is more expensive than using products 1.2-1.5 meters wide.

Load on a floor slab in an old panel house

When determining how much weight a floor slab can withstand in an apartment of an old house, a number of factors should be taken into account:

- load capacity of walls;

- condition of building structures;

- integrity of the reinforcement.

When placing heavy furniture and bathtubs of increased volume in old buildings, it is necessary to calculate what maximum force the slabs and walls of the building can withstand. Use the services of specialists. They will perform calculations and determine the magnitude of the maximum permissible and permanent forces. Professionally performed calculations will help you avoid problematic situations.

Originally posted 2018-03-05 17:23:17.

Characteristics are taken into account when calculating the slab base

When entering initial data into the floor slab calculator, the user, in addition to linear dimensions, must first correctly select such characteristics of the future reinforced concrete slab as thickness and laying depth.

Foundation thickness

The thickness of the foundation slab ranges from 15 to 30-50 cm and depends on factors such as:

The weight of the structure is light wooden houses; buildings made of foam concrete should be erected on slabs with a thickness of 15 cm. Heavy brick buildings, houses with two or more floors, are erected on reinforced concrete slabs with a thickness of at least 30 cm.

A massive house needs a strong foundationSource innovus.biz

Soil properties - for non-heaving sedimentary (coarse-grained sands) and hard rocky soils, a slab 20 cm thick is sufficient. When erecting a building on mobile soils subject to winter heaving (silty sands, clays, sandy loams), the slab must have a thickness of at least 30 cm.

Laying depth

This characteristic of a monolithic foundation slab reflects the depth of the latter relative to the soil level. There are monolithic foundations of shallow and deep foundations. The former are located completely above the soil surface, resting on a sand cushion, while the latter are located below the soil freezing level.

Depends on factors such as:

- Structure weight

– for heavy brick houses, buried monolithic foundations are used, while for lighter ones, shallow slab foundations are used.

- Soil freezing depth

and groundwater level - if groundwater lies close to the surface and the soil is susceptible to swelling, use deep slab foundations, poured below the freezing mark. If the groundwater is deep, shallow monolithic reinforced concrete slabs are poured.

The approximate depth of soil freezing can be found from reference books, and a geological examination will give the exact answer for a specific area. Source shallot.ru

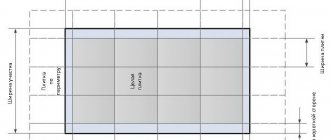

First stage: determining the estimated length of the slab

The floor slab can be of absolutely any length, but the length of the beam span must be calculated separately.

The actual length can be absolutely any, but the calculated length, in other words, the span of the beam (in this case, the floor slab) is a completely different matter. The span is the clear distance between load-bearing walls. This is the length and width of the room from wall to wall, therefore, determining the span is quite simple. This distance should be measured with a tape measure or other available means. The actual length will be greater in all cases.

A reinforced concrete monolithic floor slab can be supported by load-bearing walls, which are made of brick, stone, cinder blocks, expanded clay concrete, foam or aerated concrete

In such a case, this is not very important, however, if the load-bearing walls are laid out from materials that have insufficient strength (aerated concrete, foam concrete, cinder block, expanded clay concrete), it will also be necessary to collect some additional loads

This example contains a calculation for a single-span floor slab supported by 2 load-bearing walls. The calculation of a reinforced concrete slab that rests along the contour, that is, on 4 load-bearing walls, or for multi-span slabs will not be considered in this material.

In order for what was said above to be better understood, the calculated length of the slab should be taken as l = 4 m.

Structural solutions

When choosing a monolithic floor design, you should focus not only on the properties and characteristics of the material used or the layout of the house being built. A slab made of monolithic concrete must withstand loads that must be taken into account and calculated.

Monolithic floors can be constructed in various ways:

- using beams;

- without beams;

- with a removable formwork device;

- on corrugated sheets.

For small residential buildings, the most acceptable option is to install prefabricated formwork.

Why do you need a monolithic floor calculation?

The reliability of the entire building structure depends on the strength of the walls, and this fact is undeniable, but floors are no less important for the safety of those living in a private house (as well as in an apartment building).

A strong floor underfoot is very important in order to feel comfortable in the premises. But, if concrete slabs at the design stage are forced to adhere to certain frameworks, since their parameters are constant, then the calculation of a monolithic floor, on the contrary, has to be done based on the desired layout of the house

And mistakes are extremely undesirable.

Any ceiling can withstand only a strictly defined (expressed in kilograms) load per square meter. Not knowing this value, and exceeding it, for example, by changing the layout by installing partitions, can provoke the appearance of cracks in the concrete structure. As a result, the poured monolithic base of the floor will be weakened and may subsequently collapse

To avoid this, the calculation must be done in such a way as to have a margin of safety for the floor, taking into account the characteristics of the concrete grade used, the diameter and number of bars for the reinforcement, and their total weight

In some cases, to strengthen a monolithic self-leveling base, horizontal reinforced concrete beams under the ceiling can be made in a similar way, which will act as stiffeners. To calculate them, you only need to determine in advance the dimensions, which consist of height, width and length. This is the main difference between a beam and a floor, for the calculation of which you need to use parameters such as the area and thickness of the concrete pour. Next, we will look at the basic standards that should be followed when pouring slabs so that their strength is high enough.

Formwork

To form a semi-liquid concrete mixture into the future floor, it is necessary to make formwork. Only construction organizations can afford to buy inventory formwork for ceilings. For a private developer, these expenses are completely unacceptable, so the formwork was made with their own hands for the ceiling.

To reduce the cost of flooring, the formwork can be made removable by pouring individual areas of the floor, and after the concrete has hardened, it can be moved to a new area. But this process is very long, since it is recommended to remove the formwork after about a week, when the concrete has gained 50% strength.

Permanent formwork made of profiled steel sheets, laid on purlins made of metal or wooden beams, will help speed up the process. But, with a large area, a lot of sheets will be required, and their cost will have to be included in the cost of the ceiling, since it will be almost impossible to remove them.

Read also: How to make new lipsticks out of leftover lipsticks

For a house under construction, it was decided how to make formwork inexpensive, and at the same time, not delay the process of installing the floor:

- for the formwork runs, installed in increments of 500-600 mm, a 200 x 50 mm edged board was used, which was later used to construct gable roof rafters;

- the racks for the purlins were made of a 100 x 50 mm bar, which I later used to install lathing under the metal tile roof;

- the flooring was made of boards 150 x 25 mm, which were securely covered with dense polyethylene sheets left over from the packaging of aerated concrete blocks; subsequently, the boards were used to construct the upper floor in some attic rooms.

Since it was necessary to cover a span of 9,400 mm, even at the design stage it was decided to pour a reinforced concrete beam lying on two columns in the middle of the span simultaneously with the ceiling. The permanent formwork for the beam was two channels 200 mm high, which added strength to it. The result was two spans of 4,600 mm, separate floor formwork, with common reinforcement.

The racks and purlins must be fastened with metal connecting plates on self-tapping screws. If you use nails, removing the formwork will be very difficult. The flooring, on the contrary, is sewn on with 60 mm nails, since they will ensure the necessary movements of the boards during pouring if the latter are not tightly pressed to the purlins.

After installing the flooring, vertical formwork parts are installed, consisting of ready-made panels, the width of which is approximately 100 mm greater than the thickness of the ceiling. They can simply be screwed to the walls with self-tapping screws. These elements should keep the concrete mixture from spreading. Sheets of extruded polystyrene foam are subsequently installed along the vertical panels. They will serve as insulation for the ends of the floor.

The duration of this stage turned out to be short, since I used the panels that were used when constructing the strip foundation and the ceiling of the first floor.

Future openings for ventilation duct shafts, as well as for the flight of stairs, must be carefully marked and limited by vertical formwork elements made from 100 x 50 mm bars.

Formwork for monolithic reinforced concrete floors

I covered the flooring with polyethylene, which I attached to the boards using a construction stapler. I taped the joints with office adhesive tape. You need to cover the boards carefully for two reasons:

- to prevent water loss and changes in the water-cement ratio of the concrete mixture;

- in order to keep the flooring boards clean and suitable for further use.

The surface of the formwork for a monolithic ceiling must be carefully insulated.

I fenced the ventilation ducts made in the load-bearing wall with boxes made of boards and bars. All cracks and leaks were filled with polyurethane foam.

The installation of the formwork took five full days, and I did almost all the work myself. Sometimes I needed the help of my eldest son.

Estimated slab length

The dimensions of the slab are the distance from wall to wall.

The actual length of a reinforced concrete slab can have any value, while the value of the calculated length or, in technical terms, the span of the beam (floor slab) will be completely different. The span is the distance between two walls supporting the slab. That is, the span represents the length or width of the room. Determining it is quite simple: just measure this distance with a tape measure, measuring from wall to wall. The actual length of a monolithic reinforced concrete slab, of course, will be greater. The support for the floor slab can be walls made of brick, stone, cinder block, foam, gas or expanded clay concrete. Given the nature of our calculations, the material of the walls does not seem so important, but if the strength of the materials is insufficient for the slab (in the case of cinder block, expanded clay concrete, foam concrete and aerated concrete), then the walls must be designed for the corresponding loads. Below we will consider a single-span floor length, supported by two walls. The calculation of a slab resting on four load-bearing walls (along the contour) will not be considered in this part.

To better understand all the information above, let’s take a specific length value, for example, 4 m.

Calculation step by step

An online calculator will help you automatically calculate the floor slab for a residential building - you just need to enter the geometric dimensions of the structure and the grade of concrete used. The calculation is made on the basis of standard parameters and loads, which are regulated by SNiP 2.01.07-85.

We will consider the method of independently determining parameters below.

Determination of the estimated length of the slab

The basic concepts when designing the geometry of a monolithic slab are design and physical length. The concept of “calculated length” should be understood as the minimum distance between the most distant walls. From this we can conclude that the physical length will always be greater than the design length.

A monolithic floor slab can be single-span (supported along the length by only 2 load-bearing walls) or multi-span (supported by 3 or more wall structures). Support on the walls can be done rigidly (with pinching) or hinged.

Figure 3. Scheme of rigid support

Figure 4. Scheme of hinged support

Figure 5. Scheme of a multi-span monolithic floor

The thickness of the slab can be calculated according to the ratio of 1:30 to the calculated floor area. Usually it is at least 200 mm.

Preliminary determination of reinforcement class and concrete grade

The calculation of the interfloor (interfloor) floor begins with determining the class of reinforcement. This can be done manually or selected from the table in Fig. 6.

Figure 6. Formula and table for selecting a reinforcement class

The reinforcement class without calculations is selected according to the aR value, indicating the distance from the center of the cross-section of the bar to the lower level of the slab. As this distance increases (its minimum value must be no less than the diameter of the reinforcement itself, but not less than 10 mm), the adhesion strength of the rod to the concrete increases. It can also be taken by the coefficient ξR, which is calculated using the formula shown in Fig. 6.

When choosing a brand of concrete, it is necessary to take into account that this material is heterogeneous, therefore its physical and mechanical properties (even if samples are made from one batch) are characterized by a significant scatter.

It is important to know that when making calculations, you need to take into account both the grade of concrete and the class of reinforcement. In this case, the compressive resistance of concrete is not allowed to be greater than the resistance of the reinforcement - i.e.

in essence, it is the reinforcing frame that will work in tension.

As a rule, when constructing floors in residential buildings, concrete mixtures of grades M250-M350 (B20-B25) are used. For the reinforcing frame, A400 or A500 reinforcement is usually used.

Determining the load on the slab

The calculation of a concrete floor slab is always aimed at determining the distributed load. To do this, you need to sum up the dead weight of the horizontal structure and the vertical loads.

The mass of a future slab 200 mm thick is determined taking into account the density of concrete and, as a rule, is within 500 kg/m2. According to building codes, the standard loads from overlying building structures on floors in residential buildings are taken to be from 200 to 800 kg/m2 - we take the average value of 500 kg/m2. As a result, we obtain a total distributed load of 1000 kg/m2.

The basic principles of how to calculate a floor slab are discussed in the following video:

The maximum bending stress always occurs at the center of the monolithic floor, which rests on the walls along the contour. To calculate the bending moment, you need to use the formula shown in Fig. 7.

Figure 7. Effect of bending moment and formula for its calculation

An example of calculating the bending moment acting on a monolithic floor slab during a span of 6 m:

Mmax=(1000×62)/8=4500 kg/m

Selection of reinforcement section

To create a reinforcing frame, corrugated reinforcement is used. According to building codes, the diameter of the rods is selected to be at least 10 mm for double-row and 12 mm for single-row knitting, depending on the length of the overlap. The size of the mesh cells is selected to be 200x200 mm or less, but in this case the total weight of the monolithic structure will increase.

Photo 8. Appearance of the reinforcing frame

When connecting formwork to a stone wall, a reinforcing frame is used in several ways, shown in Fig. 9

Figure 9. Methods for connecting formwork to a stone wall

Pouring concrete

Before pouring concrete into the formwork, it is necessary to check its reliability and check the presence of all technological holes. The latter include chimneys, ventilation ducts, openings for pipes, cables - ducts, embedded parts, and other solutions are provided for all.

The concrete mixture is usually supplied through the distribution hose of a concrete pump. Before delivering concrete to the site, you need to find out whether the automixer kit includes a sleeve of sufficient length.

To accept concrete, two people are required: one delivers a hose with concrete to the desired place on the formwork, the other levels the mixture to a given level. If the plasticity of the concrete mixture is low, the operator can add a little water to it - this will not affect the quality of the concrete, and it will be much easier to level and distribute the mixture to the farthest corners.

Concrete is compacted using a deep vibrator; it can be rented; the cost is low, especially considering that it is needed for several hours.

After pouring the entire formwork, the concrete is finally leveled and smoothed.

general information

The slab foundation is a monolithic reinforced concrete slab mounted on a sand and gravel base using a waterproofing layer and insulation.

The design of such a foundation under the building ensures reliability, comfort and a long service life on any type of soil in any climatic conditions, practically without any outside intervention.

How to choose a slab foundation: calculate thickness and reinforcement correctly, and we’ll talk further in the article.

The foundation, being the support of any structure, must perform its function without any complaints throughout its operational life. This requirement is especially imposed on a slab foundation due to the impossibility of modernizing it without demolishing the main structure.

That is why, before purchasing materials and starting construction, it is necessary to make a more or less accurate calculation of the monolithic foundation slab.

The calculation is performed:

- To determine the thickness of the load-bearing slab. The calculation of the foundation slab depends on the type of soil: the thickness of the sand and gravel cushion and the thickness of the reinforced concrete layer can differ significantly.

- To determine the area of the slab. In the case of particularly mobile and unstable soils, the base area may be larger than the area of the house to achieve the necessary stability.

- To determine the amount of materials needed to build the foundation.

- To determine the load on the base.

If the decision has not yet been made and you are at the stage of choosing the type of base, you may find the pros and cons of slabs useful. In some cases, the choice is made in favor of combined types, for example, pile-slab or universal, for example, road slabs.

Calculation algorithm based on soil bearing capacity

When the dimensions of the foundation slab are determined, it is possible to calculate this structure based on the bearing capacity of the soil. The purpose of this operation is to assess the condition of the soil and its ability to withstand the total weight of all floor walls and other elements inside the building.

Example: Strong pressure on the soil will lead to excessive settlement of the foundation slab and displacement of soil layers. All this together will cause catastrophic consequences.

The foundation area is considered reliable if it exceeds the following condition:

in which S is the base of the house in sq. cm;

Kn – coefficient determining the reliability of the support (assumed equal to 1.2);

F – total mass of all floor slabs (including operational loads) on the foundation in kg;

Kр – coefficient that determines the working conditions;

R – conditional value of the calculated soil resistance in kg/sq.cm.

Reinforcement of a monolithic base

Working conditions on each soil take on different values. The type of building being constructed also affects the coefficient Kp. For example, it is necessary to build a heavy house on soil whose base is plastic clay. Kp in this case will be equal to 1. Light clay and fine sandy soils - Kp is equal to 1.2. Light construction on coarse sandy soil determines the Kp value to be 1.4. These coefficient values that determine construction conditions can be taken from special tables. The found figure is substituted into the above calculation.

Table 2. Values of coefficients that determine working conditions during the construction of a foundation on soils with organic components

Advantages and disadvantages

The main advantage of a slab foundation is its large support area, which reduces the pressure on the ground and reduces the possibility of deformation of walls and other load-bearing structures of the building. Other advantages of this type of foundation undoubtedly include long service life, safety of use, quick and easy installation, resistance to ground and surface water, as well as the possibility of building a basement and simultaneous use of slabs as the basis for the floor of the first floor. But all this is possible only if the correct calculation of the foundation slab has been made.

A monolithic foundation is also the floor of the first floor. Source domsumom72.ru

The only important drawback of a slab foundation is its high cost. However, the high price is usually justified - after all, it is a highly reliable, durable, durable design with excellent technical and operational properties.