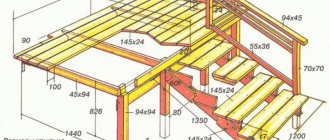

Elements of stairs

The staircase structure consists of supporting elements, steps and railings (see). They are best made from oak, larch or beech.

These wood species have excellent strength and resistance to the vagaries of nature. However, the price of these materials is not always affordable.

More often you have to be content with budget pine or spruce. It is recommended to make outdoor stairs only from coniferous trees, as their increased resin content will help protect the wood from moisture.

Staircase supports are made from debarked or rounded logs.

Here's the second option.

steps

Log steps can be made from debarked or rounded material in the following ways:

cutting the log lengthwise into two halves;

In this option, the role of the tread will be played by a flat surface, and the roundness will act as a riser.

by hollowing out treads in a solid log;

sawing logs into separate blocks;

sawing wood into elements across its length.

Fencing

For log structures, ordinary standard posts, handrails and balusters are also suitable. However, they will look quite simple and ridiculous in combination with the main components of the staircase. It is best to use elements made from tree trunks or branches.

The assembled staircase structure must have the following parameters:

- The angle of inclination of the ladder to the surface on which it is installed: 30-45 degrees.

- Staircase width (minimum): 900-1000 mm (internal structure can be 800 mm wide).

- Step depth: 260-320 mm.

- Height between steps: no more than 200 mm.

- Fence height: from 900 mm.

A staircase with such parameters will be convenient and safe to use.

Design features

Porch protected by a layer of varnish from precipitation

In accordance with the structural design, there are two types of porches - closed and open.

The complete set of the porch may vary significantly depending on the design.

A traditional open structure consists of:

- stairs;

- sites;

- supporting fence consisting of balusters and railings.

As already mentioned, an optional light canopy can be installed - a visor.

A closed porch consists of the same elements as its open counterpart, but the canopy turns into closed side railings - either solid or with glazing elements.

So, we have decided on the design features, all that remains is to find out what the instructions are for assembling the porch. But before we begin to describe the assembly, let’s decide on the choice of production material and its preparation.

Selection and preparation of lumber

On a photo-rounded log, stacked

Wood used as a building material is characterized by a number of advantages, including ease of processing using simple carpentry tools, low price, excellent appearance, etc.

But, along with numerous advantages, wood has disadvantages. First of all, it is low resistance to precipitation and biological factors. That is why it is so important to choose those lumber that are characterized by the greatest strength and, as a result, durability.

Optimal results in terms of strength are demonstrated by rocks with low porosity and high structural density. Unfortunately, hardwoods are rarely found on sale and their prices are high.

The solution to this problem is strengthening and disinfecting preparation of lumber. In our case, it is necessary to select debarked or rounded logs of the required diameter and apply special deep penetration impregnations containing antiseptics and fire retardants to their surface.

The finished structure will need to be covered with several layers of paint and varnish materials intended for external work. As a result, a porch used outdoors will not rot, mold or dry out in direct sunlight.

Construction Features

A porch made of rounded logs, unlike similar structures assembled from edged boards, is not just a functional structure, but also a design element. Therefore, before planning the construction of such a porch, think about whether it will harmoniously combine with the main building and the garden plot.

A porch assembled from logs is an excellent solution for arranging wooden and brick cottages built in a traditional manner. At the same time, modern buildings made in a minimalist style will not be combined with such structures.

The use of rounded lumber in the construction of a porch is limited to the installation of supports, stringers and the installation of steps. To make stringers, the wood can be used entirely, cutting out shelves for installing steps. To make steps, a whole log will have to be halved.

Tree trunk slitting device

Longitudinal cutting is performed on a circular saw with a disc of the appropriate size. If you don’t have a circular saw, you can prepare the lumber using a chainsaw.

Important: The only condition for successful cutting is high-quality sharpening of the chain. If the chain is not sharp enough, the saw will move to the side and it will most likely not be possible to ensure an even cut. Moreover, during the cutting process, the two halves of the log must be hooked with brackets and gradually moved apart so that the saw does not jam.

So, we have decided on the features of preparing materials, now we will look at specific examples of structures built with our own hands.

Log steps

Steps attached to the house

Perhaps, let's start with the simplest design with steps without railings and auxiliary supports.

As you can see in the photo, the main material for assembling this structure is halved rounded lumber. We will not indicate the exact dimensions, since these parameters can be selected individually for each individual house to which the structure will be attached.

“Bowl” connection

The installation instructions are as follows:

- We cut the halved logs into pieces from which we make supports for the steps.

- We place the blanks on a concrete or asphalt base and attach them to it with anchor bolts.

Tip: In order for the structures to last longer, the concrete surface on which the wooden parts will be mounted must be covered with a layer of waterproofing.

- We prepare steps, in the lower part of which we make technological recesses (cups).

- Next, the steps are laid in cups on supports and fixed with hardware.

- Upon completion of assembly, the structure is varnished or painted with enamels that are resistant to precipitation.

Other examples of building a log porch

Let's take a general look at other examples of constructing a porch at a country house or dacha.

- Steps on a concrete base are a good solution if the amount of suitable lumber is limited and you need a strong and durable porch.

Steps laid on a concrete base

As we see in the photo, a monolithic or prefabricated concrete base was erected under the wooden steps. That is, the steps in this case are only a decorative element and nothing more.

- In the next photo we can see a partially enclosed porch attached to a log house. The structure is made entirely of solid logs, with the exception of the canopy, for the manufacture of which edged boards were also used.

House and porch as one

As we can see, the steps, stringers and railings fit harmoniously into the design of the main building and are perceived not as isolated alien elements, but as a single whole.

- Finally, another interesting example of the construction of a porch, where logs are combined with planed timber, which is specially shaped into raw lumber.

Terrace with log steps

Due to this approach to the manufacture of balusters, railings and other structural elements, the structure looks integral and harmonious.

Types of log structures

The main idea of a log staircase design is semicircular steps. They are made by longitudinally cutting logs that are similar in diameter. When the cutting plane is facing upward, it is perfect for a tread, and the lower hemisphere will serve as a riser. The result is an ideal staircase that meets regulatory requirements.

Judge for yourself: the height of a log riser is half the depth of the tread. If we take a 30 cm log as a basis, then after sawing the height of the step will be exactly 15 cm.

There are many designs of staircases built from logs; when working with this material, the imagination of developers knows no bounds. Conventionally, they can be divided into several groups:

- An ordinary staircase on 2 log strings with the same steps. It is complemented by balusters and railings made of round timber, and can be rotated 90 and 180°. This is one of the most common options.

- The same with steps in the form of blocks (from the end they look like a truncated hemisphere).

- A flight of stairs made of half-logs or blocks mounted into the wall in the form of consoles (1 end of the step is fixed).

- The same, but with a bowstring to support the second end of each tread.

- Spiral cantilever structure, where the end of each step penetrates through a support column made of large diameter logs. The structure is a spiral staircase, only made from solid processed wood.

The spans are particularly original, where treads with ends bent upward are hollowed out in the steps made of half-logs. Bowstrings in such structures can be located both on the sides of the steps and below, depending on the material.

Kinds

Metal porches can be divided into many types depending on the shape of the stairs and canopy, as well as the size of the platform. Such diversity opens up great opportunities for numerous design and functional solutions for this component of the entrance group.

The upper landing of a street staircase can be:

- terrace, that is, a large open area fenced with railings;

- veranda - closed terrace;

- patio - an area most often without fencing, but with a canopy.

Unlike facade metal staircases that stretch all the way to the roof, and also have a purely technical purpose and a corresponding “industrial” design, even if they are spiral, such structures for the porch can approach the site in different ways and look much more elegant.

This is a perpendicular location with respect to the entrance, and a location on the side or on both sides at once. And also the staircase can have several flights and encircle the central platform. Typically, these types of designs are part of luxury, expensive homes.

MARCHING

The most common type. A distinctive feature is easy and quick installation. Such a staircase consists of one or more flights. It has not only steps and handrails, but also a base. This can be like a stringer (in the form of a beam with a comb on top), a bowstring, or a support post.

Many people believe that a flight of stairs is too simple and primitive a structure. However, it is not. After all, the structure is made not only straight, but also rotary, as well as curved in the form of the letter “P” or “G”. In addition, such stairs are convenient for moving people and moving large objects.

Marching stringer stairs are in demand among MariSrub clients. This performance looks solid and majestic. However, such stairs are massive and require a lot of space, so they are not suitable for a small room.

Advantages of a log porch

Making a porch from rounded logs is easier than building a regular platform from timber and boards with steps on stringers or strings: calculations will take less time, and you can do the assembly yourself. In addition, this design has several other advantages:

- Strength and durability. Such a porch does not require additional fastening elements: the base logs and steps are pressed tightly against each other simply due to gravity, so such a structure will not become loose even after many years.

- If assembled correctly, the steps will not begin to creak. If the half-logs are tightly packed into the mounting bowls, friction will not occur. For assembly, it is better to order a rounded log at the enterprise: machine processing will allow you to obtain mounting bowls of an ideal semicircular shape.

- Solid and aesthetic appearance. The structure is massive, it is in perfect harmony with the appearance of the house made of cylinders. In this case, you can use the same finishing option as for the main walls, or, on the contrary, paint them in contrasting colors to attract attention.

A log porch is ideal for houses decorated in the “Russian hut” style. The porch canopy can be decorated with wooden carvings or ornaments. Also, not only turned balusters, but also forged metal parts are often used for decoration.

This is not just an entrance to the house, but a full-fledged decorative element that will earn the praise of guests. It is erected from rounded logs very quickly; it is a simple and at the same time very reliable solution.

This is interesting: Making a porch from concrete - a generalized view

Construction process

The creation of a porch from logs occurs as follows:

- Compacting the area in front of the house. To do this, a cushion is created from crushed stone and sand. If you plan to build a large and massive porch, you need to make a concrete base. Often the porch is designed at the stage of building a house, so the foundation for it is created along with the foundation for the entire structure.

- Creation of the foundation and preparation of structural elements. Stringers can be made from logs with your own hands by making mounting bowls for the steps in them. If the porch is large, it is best to create a concrete base for it that can withstand heavy loads.

- Connection of elements. After the beds are cut in the stringers and logs acting as beams, the half-logs are laid. The result is a massive porch that consists entirely of logs. Whole logs or scraps can be used as supports for the canopy so that they resemble the corners of a log house.

- Treating the material with an antiseptic. This is necessary to prevent rotting and increase the service life of the structure. It is also worth using fire retardants.

- Finishing. At this stage, varnish and paint are used. To preserve the beauty of wood, it is worth using water-based varnish. It is best to purchase acrylic or latex based paint. Such compositions make the surface shiny and do not fade over a long period of time. If you purchase a rounded log, you do not need to use protective compounds.

- Do-it-yourself fencing installation. Either whole logs or timber with balusters attached underneath are used as fencing.

If this is your first time doing this kind of work, carefully look at the photos that show the construction process.

Positive and negative sides

The strength of log staircases is their unique appearance, and such a staircase will look great not only in a log or log house, but also in cottages built from other materials. There are other advantages:

- an obvious plus is environmental friendliness;

- durability;

- safety during operation;

- wide scope of application; from round timber you can build a large interfloor staircase, a rise for a porch or a slope on a site.

The main negative side of log structures is the high cost, based on the price of high-quality material, the cost of its processing and installation work. Not everyone can build a beautiful log flight inside a house with their own hands; it requires skills and knowledge of techniques for hidden fastening of wooden elements.

The structure made of round timber is quite massive, which is why it requires installation on a reliable foundation. The exception is cantilever options, in which the steps are built into the wall. Wood also requires care and careful handling. For example, walking up such a good staircase in dirty boots is unacceptable; dirt is difficult to remove from wooden surfaces.

Conclusion

So, we looked at examples of constructing a log porch. Now you can try to recreate the listed solutions when arranging your home or cottage.

Ksenia Skvortsova. Chief Editor. Author. Planning and distribution of responsibilities in the content production team, working with texts. Education: Kharkov State Academy of Culture, specialty “Culturologist.” Teacher of history and cultural theory." Experience in copywriting: From 2010 to present. Editor: from 2021.

Porch materials

It seems that everything is simple - the porch of a wooden house should also be made of wood and the most appropriate thing is to finish the porch with boards. However, not everything is so simple, because it is located on the same level as the base. Then wouldn’t it be better to finish the porch “to match” it? Next, be careful - there must be an appropriate base for different finishing materials.

Quite often the base is lined with natural stone - “cheap and cheerful”. It would be a good idea to continue to maintain the natural style, so finishing the porch with stone would be quite appropriate for the side walls. It is even preferable to lay these walls out of stone - it will be even more reliable and less concrete work will be required.

It’s a completely different matter if you plan to lay tiles on the steps and area near the house. Most likely, not many people will consider it appropriate to create a three-dimensional reinforced concrete structure near a wooden house. You will have to put together a deck on poles, fence it, attach reinforcement and concrete it. In addition, you will need to make metal steps for the porch and cast a screed in them. It turns out that finishing a porch with tiles is a relatively expensive pleasure, but it’s worth it - tiles are many times stronger than wooden flooring.

DIY log porch. Do-it-yourself porch - step-by-step instructions

As you can see, building a porch for a wooden house with your own hands is not so difficult. Moreover, the house itself is already ready, and if you take its style as a basis, then all that remains is to apply the skills you have already acquired. To do this, it is advisable to choose a project that is within your capabilities, but always with a twist. And if you don’t mind that you will have to learn something in the process, you can take on a relatively complex construction. After all, most often this concerns only the decor - the basic part is almost always the same.

Porch foundation

If the entire building is small or as a temporary solution, you can always make a porch without a foundation. However, if everything is planned “seriously and for a long time,” then it is simply necessary. Moreover, you need to realize in advance that this will be an extension to the main building. This means that every effort must be made to ensure its stability in relation to the house. This is clearly expressed during the change of season, when the soil freezes and thaws repeatedly, and is especially noticeable after complete thawing of the most frozen soil. Often hastily made extensions tilt and gradually “float” away from the building. This is due to the misconception that light buildings do not need a reliable foundation. And if the area is large, then sometimes they warp so much that their operation becomes dangerous.

At the same time, even a small porch should have a platform in order to be able to open the door without hindrance, or to calmly disperse in the passage. And a serious porch is always planned with an enlarged area near the house. At this point, it is important to correctly assess the possibility of using the main wall of the house as a support for the porch. That is, it will “attach”, or in a specific situation it is better to make an attached porch to a wooden house.

Also, in order to save money, it is quite possible to use a columnar foundation, and only add a grillage in the right places, and if necessary, cast a slab, but of a much smaller size. Everything happens in several stages:

- In place of the porch, markings are made for the piles. If the porch is much narrower than the facade of the house, we take a “straight” angle from it, according to the principle of a triangle of 3-4-5 m and mark the dimensions of the porch, check the diagonals, and adjust. If the porch is planned to be the same width as the facade, use a lace to mark the continuation of the side walls of the house, mark the width of the porch, check and adjust the diagonal. In both cases, in continuation of the axes, we hit wedges into the ground so that the markings can be restored and checked at any time.

- We drill holes for pouring piles. It is clear that the depth of the foundation under the porch is assumed to be below the depth of soil freezing - this is 1.5-2 m. At the very bottom of each hole we make a significant expansion - we increase the support area of the pile.

- We roll up cylinders from roofing material - waterproofing for the pile, and place them in the pits along with the reinforcement.

- We make the final decision - what the porch frame will be made of. You can weld it from a metal pipe, and decorate its visible parts with wood. If the frame is assembled from timber, then we will prepare mortgages. We will weld the channel pieces with reinforcement, later we will concrete them into piles, and install pillars in them. Immediately pouring concrete with wooden pillars is deliberately spoiling the new material.

- We fill the holes with concrete; it is useful to do this slightly above the soil level. However, if the side walls are planned from stone or brick, then you cannot do without a grillage. There will be no special loads, so a powerful grillage is not required. And to prevent the grillage from being lifted by frozen soil, you should make it above the ground in advance - either make a formwork with a bottom, or fill the formwork placed on the ground 10-15 cm deep with soil. Next, tie reinforcement into it and lay concrete. If you need to immediately install embeds in concrete.

Requirements of building codes and regulations for structures

Before starting work, it is recommended to make a sketch of the structure, taking into account the following provisions

- Site requirements.

The porch area should be spacious enough

It can be located on separate vertical supports or fixed to the façade wall on one side. There is one recommendation regarding the size - the width should allow at least two people to separate without any problems, in most cases 1.5 meters is enough. In addition, the platform must allow the door to be opened by a person entering from outside.

The bottom edge of the door should be 5 cm above the porch floor

There is one limitation in height - the level of the platform must be three to five centimeters below the level of the bottom plane of the doors. This is explained by the fact that the porch will rise in the winter, if you do not make a gap, the doors may jam. For safety reasons, the entrance doors must be opened outwards, and the difference in height eliminates the negative consequences of heaving of the earth during freezing/unfreezing.

- Requirements for steps.

Width of stair steps

The width of the staircase is at least a meter, the height is approximately 16–18 cm, the length of the steps is 25–32 cm. How to calculate the parameters of the steps? For example, the height of the platform is 120 cm, divide this value by 18 cm and get 120:18 = 6.66. We round to the nearest whole number, in the end we should have 7 steps. The distance between them is 120:7 = 17.14 cm. You can make six steps 17 cm high, and the last or first 17 + (0.14 × 6) = 17.8 cm. This makes it much easier to make porch parts. If you have chosen the length and width of the steps to be 30 cm, then the lower support point of the stairs should be at a distance of 7 × 30 cm = 210 cm from the edge of the platform. That's all the calculations, simple and accessible, there is no need to study complex formulas.

The main indicator when calculating a flight of stairs is its slope (steepness), which depends on the width and height of the stairs

Select only high-quality lumber for making a porch; avoid damage from pests, diseases, rotten knots and through cracks. Only moisture-resistant species: coniferous or hard trees. It is also not recommended to use boards with significant natural developmental defects.

Buy only high-quality lumber

It is advisable to treat the materials several times with antiseptics.

Bioprotective wood treatment

Take all possible measures to prevent water from accumulating on steps and landings. You can make them with a slight slope or leave gaps of 2–3 mm between individual boards.

Wooden porch construction diagram

For the final paint coating, use only high-quality paints. They must be wear-resistant, resistant to moisture and harsh ultraviolet radiation. Another requirement is that when painting surfaces, strictly follow the manufacturers’ recommendations; do not try to simplify the technology by skipping some steps. Remember that there are no wooden structures in the house that are used in such difficult conditions. It is very difficult to restore the original appearance of the paint; you will have to completely remove the old coating. Such work requires a lot of effort and time, and it is rarely possible to completely get rid of traces of old paint.

This is interesting: How to paint a wooden porch on the street - we present it in order

Device instructions

Installation must be performed in the following order:

- Drawing up a plan and performing the necessary calculations;

- Drawings and necessary materials;

- Frame structure;

- Construction of the upper platform.

Designing a carved porch

The porch is a kind of platform in front of the entrance to a building with a staircase. The building can have any design, which depends on the architecture of the overall structure, the location of the base, landscape design, as well as the preferences of the owners. They come with 1 or two platforms and stairs.

Dimensions

Depending on the height of the first floor, the porch of a wooden house can be high or have only a couple of steps. A very important point is maintaining proportions.

The porch is a horizontal platform with steps leading to it (sloping flights). The size of a standard step ranges from fifteen to twenty centimeters, and the depth is thirty centimeters. Steps are usually designed with an inclination of two to three degrees.

The average width of a march is considered to be 120*145 cm. The steps consist of inclined bars - bowstrings, the steps themselves and the fence. The width of the string is equal to the width of the step, and the thickness can be from 60 to 70 mm. The steps, in turn, consist of risers, treads and overhang.

The most convenient prostrupa (step depth) is considered to be from 270 to 320 millimeters, the rise (riser) is from one hundred and forty to one hundred and eighty millimeters, and the overhang is from twenty to twenty-five millimeters.

Note: The overhang of a step is the edge of the tread that protrudes forward.

The top landing of a wooden staircase can be of any size. The minimum width of the stairs is six hundred millimeters, and the optimal width is from 800 to 900 mm. If the planned extension is planned to be larger, then additional support will be needed.

The average size of a front door is nine hundred millimeters in width, which means that the door area should not be smaller in depth. According to established standards, it is built 1.5 times wider than the size of the door. This is how we get the minimum porch size of 900*600 mm, and the maximum can be anything.

Important: In the middle zone, doors are made to open outward, and only in the northern snowy regions do doors to the house open inward.

Basic moments

All wooden elements are attached with screws, nails, staples, and the balusters are fixed with a waterproof adhesive.

The staircase is secured with internal and external supports. A wooden beam fixed at the crown of the log house can represent an internal support, and for the external one the foundation is expanded. The platform itself should be made at a slight angle towards the street, so that rainwater does not accumulate on the porch. Also, when laying the floor, you should not lay the boards too tightly, in order to also prevent liquid from stagnating on the threshold.

Note: For a small staircase with several steps, there is no need for railings, but if it is large, then a railing will be necessary.

To protect the porch from precipitation, a canopy is built. It can be attached to the slope of a common roof and covered with the same roof.

Important: So that the door can open unhindered, the platform is made on the front side in the range from 120 to 180 cm.

As for the shape of the extension, there are no frames. The main thing is that it fulfills its main purpose and fits into the overall style of the building. For example, semicircular or angular.

The size of the canopy is not made very narrow, because it will not be able to provide protection to the door. The optimal length is considered to be from 80 to 85 cm, and the width exceeds the size of the door by half a meter. As with the platform, the visor is made slightly sloping.

Choosing wood for a carved terrace

There are no special restrictions on the material when constructing porches. For a more budget-friendly option, birch or spruce are quite suitable. However, they are considered not durable, because when exposed to damp conditions they can rot. Material made from cedar or oak is considered more stable, but the price will be much higher. The ideal option is timber and boards made of pine or larch. They are relatively inexpensive and have increased resistance to external factors.

Important: When building a carved porch, you must use only dry wood treated with antiseptic and fire-retardant impregnation. The part of the post with which it will be buried in the soil is wrapped in two layers of roofing material or covered with bitumen mastic.

Foundation

The basis of any structure is the foundation. The foundation can be laid in the initial design of the house itself or designed separately.

There are the following types of foundations: slab, pile and strip.

If you plan to build a large-scale porch, you can use a slab or pile foundation. But for a small extension, pillars are quite suitable for the base.

The best option for a wooden platform would be a pile foundation. Its design is quite simple and not expensive. This foundation can easily be done independently. The durability of wooden buildings will depend on properly prepared wood. It must be well dried and treated with special protective agents.

First, holes for piles more than eighty centimeters deep are dug. A gravel-sand cushion is made at the bottom of the recesses. Supports are placed in the pits, the top is filled with soil and thoroughly compacted. For a stronger base, the supports can be concreted.

Important: Driving piles must be carried out two hundred millimeters below the freezing ground level. This is necessary to prevent them from being pushed out when the soil swells in spring. Then the pillars are aligned and the cuts are prepared. For this purpose, nests are hollowed out in the joists and the base strapping is secured to the spikes.

Next comes the preparation of the base of the lower step. To do this, a trench is dug from 500 to 700 mm in depth, three hundred millimeters wide. And the length of the trench will be equal to the stairs plus one hundred millimeters. A sand cushion is compacted at the bottom, reinforcement is placed on it and filled with concrete mortar.

After the concrete has dried, the vertical supports are aligned to the required size and tightened using a grillage around the perimeter. Note: A grillage is boards installed at the top of the foundation, which serve as a distribution of load from the load-bearing walls of the house. The grillage beam near the entrance is attracted by iron corners and anchors to the wall of the building. Perpendicular logs are attached. A bed is laid on the base.

Note: A grillage is wooden edged boards installed at the top of the foundation, which serve as a distribution of load from the load-bearing walls of the house.

The grillage beam near the entrance is attracted by metal corners and anchors to the load-bearing wall of the building. Perpendicular logs are attached. A bed is laid on the lower foundation.

Note: Wooden logs or beams lying horizontally in different buildings are called logs.

Forming the bowstring

The bowstring and stringer are load-bearing boards for attaching the steps. They differ only in the position of the steps: in the bowstring they are hidden, but in the stringer they are left visible. How many of them will need to be made is determined by the width of the stairs. For example, for a standard 700 mm staircase, it is enough to install 4 load-bearing beams.

The bowstring can be of the following types: having cut out ledges, having inserted or embedded wooden steps. To form identical recesses, a cardboard pattern is made. As a rule, this is a triangle with right angles; on one side it will be equal to the size of the tread, and on the other the riser. Next, markings are made on the boards using the template. The parts are cut out using a jigsaw or hacksaw and attached to the support posts.

Note: This design can also be metal, reinforced with additional metal brackets.

Upper platform arrangement

The site installation work can be divided into several stages:

- The boards are prepared and cut.

- Lay the boards, securing them to the stringers on one edge and to the wall on the other. Here they use a tongue-and-groove connection without using nails.

- The boards are laid tightly so that very large gaps do not form when they dry out.

- At each stage of work it is necessary to check the surfaces for level.

- Installation of steps. First, lay the lower risers, attaching them to the bowstring. This can be done using a tongue-and-groove connection or self-tapping screws. The tread is attached to the risers and string. According to this scheme, all the steps to the top are arranged. Important: If the base of the staircase is a stringer, then the steps are laid from bottom to top. And with a bowstring as a base, laying occurs from top to bottom.

An important point when building a site with your own hands is to ensure that the boards are laid tightly enough. Since when the wood dries out, the structural elements will become loose, which will lead to the repair and reconstruction of the porch. Special glue can be used if necessary. If this is possible according to the planned width of the step, then one wide board can be installed.

Installation of fencing and fastening of the canopy

By adding carved railings to the staircase you can create a harmonious and complete look. They must be installed if the staircase has more than 3 steps

Balusters are cut from wooden blocks. This will serve as the main vertical support for attaching the railing. A small hole of about 12 mm in diameter is drilled in the lower part of the end. Metal pins coated with glue are inserted into the drilled holes. The other end of the pins protrude from the boards by about seventy centimeters. In the outermost step, 8 cm from the edge, a hole with a diameter of 14 mm is drilled. The protruding part of the baluster pin, coated with glue, is installed in the hole in the step. First, the outer balusters are fastened, and then the intermediate ones.

Places for installation are marked on the strings. The upper ends of the balusters are trimmed to fit the railings. Boards for the railings are being prepared. They are installed using metal pins.

Important: It is not recommended to use nails and screws for this because there is a risk of injury when using the railing further. The canopy consists of two components - the frame and the roof. Depending on the type of device, it can be suspended or supported. The suspended one is represented by a small structure and is attached to the facade wall of the building. Supporting involves the arrangement of supports. Load-bearing supports are installed on the extension site.

Important: All wooden surfaces must be treated with special antiseptics before direct installation.

If the canopy is very long, additional supports will be required. When they go beyond the perimeter of the site and land on open ground, their base must be filled with concrete mortar for greater strength. Guides located in a perpendicular position to the pillars are attached to the supporting posts. They are fixed using anchors. The sheathing boards of the canopy are nailed to the guides. The finished frame is lined with corrugated sheets or roofing felt.

Wood preparation

The logs from which the stairs will be made should be thoroughly dried beforehand, because excess moisture will affect the premature formation of rotting or drying out. Such an error in preparing the material can lead to cracking and rapid loss of strength, as well as rapid loss of its shape.

Sometimes there is an option to use logs from a disassembled log house, but special care will be required here, because during the cutting process old fasteners, such as nails, may come across, which will lead to damage to the saw.

Elements of the staircase structure must be prepared before starting work

To do this, you will not only have to clean the knots, but also pay attention to the following steps:

- processing wood using an antiseptic. This measure will eliminate the possibility of the formation of small pests that will cause the material to become unusable.

- necessary coating of ends with resin. It will also be necessary to treat the surfaces of the logs that will come into contact with the ground to avoid their destruction over time.

The choice of wood depends on the owner's preferences and expected costs. But it is worth noting that the most suitable options would be to use oak, beech or larch

. True, material of such quality may increase the cost of the structure. Among the more economical types of wood, which are also often used to create staircase structures from logs, are soft pine and spruce. It is worth noting that significant budget savings can be achieved if you use steps made of half-logs, in which the cut will act as a tread. The rounded lower part in this case is used as a riser.

How to do it?

The process of creating a log porch must be given close attention, since the quality and reliability of the future structure depends on this. First of all, you need to choose high-quality materials that can last for many years and will not deteriorate under the influence of external factors. It is worth understanding that the porch will constantly be exposed to precipitation and other loads, so all work must be carefully checked, and the quality of the materials should not be in doubt. So, to create a porch from a log, you need to do the following work.

- A small square-shaped hole is dug, the depth of which does not exceed 40 cm. In addition, it is necessary to get rid of the fertile top layer.

- A mixture of sand and gravel is placed at the bottom of the pit, and the thickness of this layer should be about 10 cm. Thanks to this, it will be possible to create a sand cushion, which should be compacted using a special vibrating plate.

- Time to install a small reinforcement cage. Despite the fact that a wooden staircase does not have any load, such a frame will have to strengthen the concrete and also prevent cracks and deformation in the future. Formworks, which are made of ordinary boards, are mounted along the edges. The upper edge of these formworks should protrude several centimeters above the soil surface.

- Once the supporting structure is installed, you can proceed to assembling the march. To do this, you will need to fasten several stringers using a self-tapping screw, starting from the first and ending with the highest. During the fastening process, it is necessary to pay close attention to this so that no moisture remains on the porch, as this can negatively affect the strength of the structure in the future and cause squeaks when using the porch. Once all the steps are securely fixed, you can install the steps.

When the work on installing the porch is completed, you can move on to creating the canopy. At this stage it is necessary to be as careful as possible, since the safety of the entire structure depends on this. It is best to use lightweight materials and use high-strength self-tapping screws for fixation.

Thus, to create a porch from a half-log or rounded log with your own hands, you need to follow step-by-step instructions and use high-quality materials.

Watch a master class on building a log porch.

Calculations required to build a wooden porch

You can easily calculate and build a wooden porch yourself. You will not need any special knowledge of geometry and construction, just a small amount of free time. Next, we will present the basic calculations and construction nuances that you may need.

Sizes and shape of the site

You can choose the shape and size of the platform that you like and will be comfortable. The main thing is that the width of the structure is no less than 90 cm. If it is smaller, then inconvenience may arise when opening the door outward. Also, if the platform will pass under the window of the house, it should end at least 20 cm beyond the border of the window frame.

The height of the porch platform is determined by the height of the entrance door threshold: we measure from the ground to the upper limit of the threshold and subtract 3-5 cm. This is especially critical if the front door opens outward, since in winter, due to the formation of ice or snow drifts on the platform, problems with by opening it.

A few words about ice: the steps and the platform itself should be made with a slight slope outward, 1-1.5 degrees. When walking, such a slope will not be noticeable, but it will ensure the outflow of rainwater and other water that will reduce the formation of ice on the wooden surface.

We calculate stringers and steps

Counting the height and number of steps. As a rule, risers are made about 18 cm high, so to start calculating we take this figure. We divide the height of the platform by 18, the resulting number is the number of steps. If the output is a fraction, then round it up. For example: 150:18=8.33 pcs. We round 8.33 to 8, count: 150:8 = 18.75 cm. So we got 8 steps with a height of 18.75 cm.

You can calculate the length of the stringers in the following way: a 2 + b 2 √22.65. Here a is the height of the porch platform, b is the distance from the lower support to the front landing beam. The width of the stringer is the height of the riser multiplied by two. The figure is rounded up only. Based on these calculations, you can draw up a project for the porch of a wooden house.

How to make a wooden porch: we take the necessary measurements

Important: if you are designing a porch on two sides, then the stringer calculations are made twice, with the measurements repeated on both sides. The height of the platform may not be the same, and a stringer prepared according to measurements on one side may not be suitable for installation on the other side

Useful tips for building a porch

Usually, a canopy is created over the porch to protect against moisture. But even this does not always completely protect the surface from snow and rain. To prevent moisture from remaining on the boards, it is enough to make small gaps between them. But this option is not suitable for everyone, since cracks in the floor can look unsightly. To avoid the problem, it is enough to make a slope of about 2 degrees. Such a slope will be invisible, and water will not accumulate on the surface of the porch.

The canopy should be fixed at a height of about 30 cm above the front door. If you install it higher, the structure will look too elongated upward. Precipitation, which will not be stopped by a high canopy, can also become a problem. By looking at photos of various log buildings, you can easily determine which option is right for you.

If the porch attached to the house is less than one meter high, you don’t have to make a railing, leaving the area with a canopy.

street staircase

Designs made from half-logs are widely used by designers when decorating suburban areas, gardens and park ensembles. They blend perfectly with the surrounding natural landscape. In particular, such stairs will be appropriate in areas with sloping areas where buildings made of logs or wooden beams are erected.

Steps made from half-logs are often laid directly on the ground, treated on the bottom with resin, and on the top with moisture-resistant paint and varnish compounds intended for outdoor use. The logs, in this case, can be placed along the steps or across them, and something like a wooden fence is placed on the sides as a fence.

There are quite a lot of design solutions for half-log staircases; you just have to dream or look at the options offered by manufacturers. But in any case, the design will be distinguished by its individuality!

A staircase in a house made of rounded logs is not only a structure for going up or down to another floor of the house, but also an important design element, so any staircase will not work in this case - it is necessary that it fits organically into the interior of the house.

As part of the article, we will look at stairs, which are usually installed in wooden houses made of logs, since in houses with false walls the design can be very diverse, and therefore the choice of stairs too.

But first, let’s look at what kind of stairs there can be in a log house.

- Firstly, these can be flight stairs - stairs that are separate flights, connected by stringers, or separated by a landing.

- Secondly, screw or spiral.

- Thirdly, bolt ladders - they do not have supporting elements (stringers or bowstrings), so they give the impression of being suspended in the air.

To preserve the classic style of a wooden house, it is advisable to make the stairs in it from the same material. Often in houses made of rounded logs you can find a staircase, the role of steps in which is performed by blocks also made of rounded logs, sawn along the diameter. Such stairs are reliable and safe, and blend very organically with the walls of the house. They are often used on the street at the entrance to the house.

There are several suitable options for log stairs:

- with fastening steps-block on a bowstring or stringers made of logs;

- with a through cantilever arrangement of scaffold steps;

- staircase with two strings of logs with flat steps;

- corkscrew cantilevered staircase with flat steps-blocks and a turn of a third or a quarter.

Railings and handrails for such stairs are usually made of wood. Metal can also be used in the design of railings, but some craftsmen consider the use of metal undesirable due to its poor interaction with wood.

Stairs made of logs usually look monumental and heavy. A staircase with steps made of boards and a string made of laminated veneer lumber will be lighter.

If there is little space in the house, you can install a spiral staircase. These stairs are not very convenient for the elderly and children, but they can significantly optimize the interior space of the house. A rounded log can be used as a vertical post for the stairs, and the steps can be made from rounded logs or boards. A metal spiral staircase is also acceptable. Such a staircase can be located not only against the wall, but also in the middle of the room, which gives scope for design solutions.

Bolster staircases are usually used in high-tech or modern style rooms, but in some cases they look natural in houses made of rounded logs. As a handrail for such stairs, ropes attached to the ceiling will look original. The steps can be made of logs or boards.

Choosing a staircase in a house made of rounded logs is not an easy process. What complicates the task is that it is advisable to do this at the design stage of the house, because each type of staircase requires different space. Professional designers and special 3-D design programs can come to the rescue. Only being a specialist with many years of experience in wooden house construction can you design a staircase that is comfortable, beautiful and practical, the embodiment of elegant style and good taste.

Porch made of timber. Porch foundation

If the entire building is small or as a temporary solution, you can always make a porch without a foundation. However, if everything is planned “seriously and for a long time,” then it is simply necessary. Moreover, you need to realize in advance that this will be an extension to the main building. This means that every effort must be made to ensure its stability in relation to the house. This is clearly expressed during the change of season, when the soil freezes and thaws repeatedly, and is especially noticeable after complete thawing of the most frozen soil. Often hastily made extensions tilt and gradually “float” away from the building. This is due to the misconception that light buildings do not need a reliable foundation. And if the area is large, then sometimes they warp so much that their operation becomes dangerous.

At the same time, even a small porch should have a platform in order to be able to open the door without hindrance, or to calmly disperse in the passage. And a serious porch is always planned with an enlarged area near the house. At this point, it is important to correctly assess the possibility of using the main wall of the house as a support for the porch. That is, it will “attach”, or in a specific situation it is better to make an attached porch to a wooden house.

Also, in order to save money, it is quite possible to use a columnar foundation, and only add a grillage in the right places, and if necessary, cast a slab, but of a much smaller size. Everything happens in several stages:

- In place of the porch, markings are made for the piles. If the porch is much narrower than the facade of the house, we take a “straight” angle from it, according to the principle of a triangle of 3-4-5 m and mark the dimensions of the porch, check the diagonals, and adjust. If the porch is planned to be the same width as the facade, use a lace to mark the continuation of the side walls of the house, mark the width of the porch, check and adjust the diagonal. In both cases, in continuation of the axes, we hit wedges into the ground so that the markings can be restored and checked at any time.

- We drill holes for pouring piles. It is clear that the depth of the foundation under the porch is assumed to be below the depth of soil freezing - this is 1.5-2 m. At the very bottom of each hole we make a significant expansion - we increase the support area of the pile.

- We roll up cylinders from roofing material - waterproofing for the pile, and place them in the pits along with the reinforcement.

- We make the final decision - what the porch frame will be made of. You can weld it from a metal pipe, and decorate its visible parts with wood. If the frame is assembled from timber, then we will prepare mortgages. We will weld the channel pieces with reinforcement, later we will concrete them into piles, and install pillars in them. Immediately pouring concrete with wooden pillars is deliberately spoiling the new material.

- We fill the holes with concrete; it is useful to do this slightly above the soil level. However, if the side walls are planned from stone or brick, then you cannot do without a grillage. There will be no special loads, so a powerful grillage is not required. And to prevent the grillage from being lifted by frozen soil, you should make it above the ground in advance - either make a formwork with a bottom, or fill the formwork placed on the ground 10-15 cm deep with soil. Next, tie reinforcement into it and lay concrete. If you need to immediately install embeds in concrete.

Calculation and design

When starting design, you need to decide on the space that the staircase can occupy. You also need to measure the height between the floors, or between the platform and the level of the entrance to the house.

Basic design parameters

In order for wooden stairs for a log house to be comfortable and safe, when designing them you should be guided by the standard requirements:

- The width of the structure should be such that two people can pass each other on the steps. And in the case of an interfloor staircase, its width should allow furniture and other large objects to be lifted to the upper level.

- It is advisable to make the tilt angle no more than 35 0, especially for long spans.

- The optimal tread width is 25-30 cm. Therefore, the diameter of the log for the steps should be no less, otherwise walking on them will be inconvenient and dangerous.

The instructions also regulate the height of the riser, which should be 15-20 cm. In the case of structures made of logs, risers are usually not made, and the vertical distance between steps depends on the thickness of the log

It can be adjusted by laying the steps close to each other, or by making gaps between them. The optimal height of the railing is 90 cm. When designing interfloor stairs for a wooden house made of timber, it is necessary to pay attention to the size of the opening in the ceiling. It should be such that the vertical distance between the step and the edge of the opening is 20 cm greater than the height of the tallest person in the house.

What you need to know to calculate

The following data will be required for the calculation:

- Size of the staircase in plan;

- Lifting height;

- Step width and riser height.

Example:

Let's say the floor height is 270 cm and the riser height is 15 cm.

- The number of steps is 18, because 270: 15 = 18.

- If the width of the steps is 25 cm, then a single-flight staircase will require a plan distance of 25 x 18 = 450 cm.

For a room or hall in a small house, this is a lot. This means that the staircase needs to be double-flight. And in a very small space it is worth considering a screw design.

What is a finished porch and why is it so in demand?

Specialists have developed a unique C3 technology for staircase cladding, which has no analogues in the world. It is with the use of products made using this innovative technology that monolithic overlays for finished porches are made, acting as steps. The supporting structure is made of a profile metal pipe, onto which a stringer made of fiber-reinforced concrete is attached - a material made using high-quality cement and granite-composite chips.

Welding seams, made by professionals in the factory, are ideal and have no flaws, which increases the service life of products that do not allow moisture to pass through. The overlays have no gaps between the tread and the riser (the main problem of steps made using classical technologies, so the penetration of moisture into the structure is also reduced to zero. The finished porch can withstand 500 or more freeze-thaw cycles, is not afraid of temperature changes, therefore it is recommended for use in different climatic zones.

Ready steps for a porch are installed very quickly and do not require much experience, and even a special tool is not always needed. Brought, installed and go - this is the principle of delivering ready-made stairs, which is what attracts customers in the first place. Among other things, the steps do not slip in any weather, as they have an expressive relief pattern, as in the photo. It is also important that the price of ready-made steps for a porch is affordable, and you can always clarify prices and other points by contacting the company’s managers in any convenient way.

Non-slip steps C3 can be installed in kindergartens and schools, as the creators of this video claim:

Staircase made of logs on the street

Staircase made of logs on the street

This method of constructing a staircase structure will fit perfectly into the design of a suburban area, garden or park ensemble. Using logs as the main structural element will allow you to create a staircase that blends perfectly with the surrounding nature and landscape. If there is a slope on the site, as well as the construction of main buildings made of logs or wooden beams, the use of such a decorative element will be most justified.

Steps of this design can be laid on the ground using resin to treat its lower parts. A moisture-resistant paint coating intended for outdoor use is applied to the upper part of the elements. The arrangement of logs is allowed transversely or along the steps. A decorative wooden fence is perfect for decorating a fence.

Beautiful and exclusive chopped spiral staircases for cottages and houses

today they often decorate a huge proportion of suburban housing. They allow you to create original and unique interior solutions, decorated in both classic and country style. Moreover, we can talk about a small country house with an attic, or a huge country house with several floors. Because a staircase in a log country house made of wood will always help solve the problem of beautifully and competently arranging a living room or corridor, while emphasizing the high quality of materials and their safety for human life and health.

Options for using carved pillars

Carved pillars are used both outdoors and indoors. The choice of wood species depends on where they will be installed. Inside buildings, the influence of the natural environment is small, so you can save money by using cheaper types of wood, such as pine.

For external structures, it is better to choose solid and durable types - for example, oak or ash. In addition to reliability, they have an excellent structure.

For figured columns, columns, balusters, railings, you can only use solid wood; laminated wood will quickly become unusable and lose its appearance - repair or replacement will be needed.

To extend the service life of finished poles, they must be coated with protective compounds and treated with varnish, which will add shine to the wood.

Outdoor structures

In external structures you can see:

- porch supports. Their purpose is to hold the canopy and decorate the entrance area, so reliability and compatibility with other components are relevant. Sometimes a project may include columns and columns of different heights, but made in the same style;

- gazebo pillars. Wood is an ideal material for this building, which creates a natural atmosphere, and if the pillars are carved, then spending time in the gazebo will become even more pleasant;

- pillars standing separately. Such columns can become the main accent on the site, its main “attraction”. The shape and size are not limited, but they must be combined with the design of the entire territory;

- the entire load-bearing support of a gate or fence. A carved fence is very beautiful, but its creation is a costly and labor-intensive process.

Elements inside buildings

Carved supports indoors perform various functions:

- columns as load-bearing elements. They can replace walls, thereby expanding the space. When manufacturing or ordering columns, the load must be calculated;

- staircase supports. They set the general style of the structure; if desired, balusters, railings and additional decor for wooden stairs can be made in the same style.

How to build a log staircase

Let's consider, as an example, how to make a simple one-flight staircase with your own hands on two stringers (strings):

| Image | Description of the stage |

| Making a drawing on graph paper | Having made all the calculations, we transfer them to graph paper, drawing a drawing of the future staircase to scale with dimensions indicated. |

| |

| We saw the logs along and lengthwise for the steps. | |

| We clean all manufactured elements of the future staircase from bark, remove knots, grind chips and burrs. | |

| We install the stringers in place and fix them. If the house is new, then rigid fastening to the ceiling cannot be made in the upper part until the structure shrinks. | |

| We try on the steps, setting them according to the level. | |

| The steps are attached to long anchors with washers. We pre-drill a through hole in the stringer with a diameter of 8 mm, and then countersink it to a depth of 5-6 cm with a 28 mm feather drill. Before fastening, lubricate the bowl with wood glue or sealant. | |

| After installing the steps, the holes in the stringers are sealed with wood putty or closed with plugs. | |

| At the final stage, support posts, railings and balusters are installed. |

When making wooden stairs, the log must first be dried, and after cutting into elements, it must be treated with protective compounds against rotting and burning.

If the staircase is external, then the ends need to be coated especially carefully and several times. The best thing is to tar it. And those areas that will come into contact with the ground should be protected with several layers of roofing material.

After installation is completed, the structure is sanded again, after which it can be coated with decorative paints and varnishes. By deciding to make such a staircase yourself, you will save a lot, since the price of such structures and their installation by specialists is very high.

Conclusion

So, we looked at examples of constructing a log porch. Now you can try to recreate the listed solutions when arranging your home or cottage.

Still have any questions? The necessary explanations can be obtained by watching the video in this article.

| An open area with several steps (usually 1-3 steps). | |

| A half-closed extension to a house (for example, the extension is fenced on only two sides, the third side remains completely open). | |

| A completely enclosed extension in front of the house, which is a closed area (veranda). | |

| The extension is built separately after the house is built. | |

| Designed and built together with the building. | |

| An open structure with a specially equipped area. | |

| At the very beginning, the drawing is transferred to the construction site. It is necessary to make markings from the middle of the door in two directions and set marks. | |

| The choice of foundation density also depends on the structure you choose. If the front door is located low, then for the foundation you can limit yourself to crushed stone and sand. If the stairs of the house are high, then you will need a full-fledged concrete foundation. | |

| Based on the markings you have made, a small hole is dug for the foundation. The size of the pit should be no more than 50 cm deep. In this case, the bottom of the pit is filled with crushed stone and sand in proportions of 5/3, a reinforcing frame is made and concrete is poured on top. | |

| Stringers, bowstrings and frames for log steps can be made of concrete, stone, brick, timber or metal. | |

| The steps are prepared with special recesses “bowls” or rectangular grooves. | |

| The steps are laid out on supports in “bowls” and secured with bolts. |