The use of sanitary manifolds with shut-off valves increases the comfort of using water.

If the distribution is made with one pipe from the riser, then when several taps are opened, the water pressure in them weakens. As a result, for example, you can get burned in the shower if someone turns on the water in the kitchen.

A distribution manifold eliminates this problem. From the article you will learn more about what a water supply collector is and how to choose it.

What is a collector

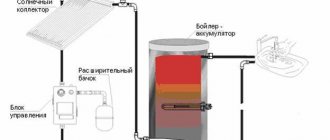

A water supply manifold, or simply a “comb”, is essentially a distributor of water flow from a source to consumers. In the case of an apartment, the source is the water supply risers, and the sources are the plumbing fixtures of the apartment.

The scheme of such a water supply system is called parallel or, based on the name of the basic device, collector. Read: Collector water supply scheme. Since the water supply manifold is the basic element of the scheme, you need to choose the manifold for the water supply of your apartment or house as correctly as possible.

Wall mounting options

Placing a polypropylene pipeline directly on the surface is a simple and fairly quick installation method. In this case, clips are used for pipes of small diameter and clamps for more massive ones, as well as a minimal set of tools.

For hidden fastening, you will need to groove the walls, use an additional grinder, special heat-insulating materials and cement.

The second option is more aesthetic and is especially relevant for small rooms. In addition, the technical characteristics of polypropylene pipes (strength, heat resistance, durability) allow you to “wall up” the pipeline without fear.

And yet, only external fixation provides constant access to all components of the system, making it possible to change its configuration and perform repairs if necessary. Each method has its own characteristics that affect the final result.

At what distance should the fasteners be placed?

The distance between clips or clamps is a determining factor in the proper functioning of the pipeline.

If you do not follow the installation recommendations and attach the supporting elements too far from each other, the structures will subsequently begin to sag. This negatively affects both the strength and throughput of the system. The step size is set in accordance with the diameter of the polypropylene pipe and temperature indicators:

| Diameter of PP pipe, mm | Distance between fasteners in centimeters at a certain temperature | |||||

| 20⁰С | 30⁰С | 40⁰С | 50⁰С | 60⁰С | 70⁰С | |

| 16 | 75 | 70 | 65 | 55 | ||

| 20 | 80 | 75 | 70 | 65 | 60 | |

| 25 | 85 | 80 | 75 | 70 | ||

| 32 | 100 | 95 | 90 | 85 | 75 | |

| 40 | 110 | 105 | 100 | 95 | 85 | |

| 50 | 125 | 120 | 115 | 110 | 105 | 90 |

| 63 | 140 | 135 | 130 | 125 | 120 | 105 |

| 75 | 155 | 150 | 145 | 135 | 130 | 115 |

| 90 | 165 | 155 | 150 | 145 | 125 | |

| 110 | 185 | 180 | 175 | 165 | 160 | 140 |

External and hidden fastening: sequence of actions

Even at the stage of drawing up a pipeline layout plan, you should try to avoid too many corners, bends and turns.

Such areas are prone to sagging and require additional reinforcement. Structures that are placed in the walls must be as monolithic as possible in order to reduce the risk of depressurization of welds (repair in this case will be quite labor-intensive).

Clip mounting

The minimum set of tools includes a drill or hammer drill (depending on the material of the walls), a screwdriver or a screwdriver for screwing in self-tapping screws, a hammer, as well as a marker, tape measure and level.

The sequence of work is as follows:

- Markings are applied to the surfaces on which the pipes will be laid. The places where the clips are attached are marked in accordance with the table data on the distance between the fixation points.

- Using a drill or hammer drill, holes are made according to the marks, into which the dowels are fixed with a hammer.

- Clips are screwed to the wall with self-tapping screws, into which welded pipes are then inserted.

It is important! Horizontal markings for sewer pipes should be made with a slight slope towards the drain. This will allow you to avoid blockages in the future, as well as freezing of the system in unheated rooms.

Mounting with clamps

External fastening of the pipeline using clamps is not fundamentally different from the clip method.

First, the fixation points are marked at recommended intervals, then holes are drilled for the dowels and the clamps are screwed to the surface until they stop.

In places where pipes bend, additional fasteners are installed (at a distance of about 15 cm from the corner).

Then the welded structure is fixed in clamps with a rigid or floating fastener.

Main differences between collectors

To understand the differences between different collectors, let's see how it works. What you see in the next photo is a distribution control manifold from the Italian company FAR.

It consists of a cast body, which distributes the flow of water into branches and shut-off and control valves. Based on the type of valves used in the manifolds or the lack thereof, manifolds can be divided into three types:

Distribution . They are without valves.

Distribution regulating . They not only distribute the flow of water, but can also regulate the outgoing flows by turning the flywheel of the shut-off valve-axlebox.

Distribution shut-off valves . These devices are equipped with shut-off valves rather than control valves. Such valves must operate in two modes: fully open or closed.

The fundamental differences between types of collectors that are important for selection are listed.

Regulating manifolds allow you not only to completely open and close the water, but also to finely regulate the flow of water for each consumer. The adjustment knobs (they are round) allow you to control and adjust the water flow of the water supply without tools.

Distribution shut-off manifolds cannot be used to regulate effluent flows. For them, only open or closed modes are acceptable.

Most often, shut-off manifolds can be distinguished from control manifolds by the characteristic “flag” handles on the valves. The handles (flywheels) of the valve axleboxes of the regulating combs are always in the form of a barrel.

Here it is time to note that collectors are quite clearly divided into collectors for plumbing and for heating. The latter are used in warm water floor systems, sold in pairs (collector groups) and visually have a wider distance between outlets, not 36 mm, but 50 or 100 mm.

For the manifold heating system there are shut-off and regulating, shut-off and balancing, thermoregulating, shut-off and balancing with a flow meter. It is worth noting that some manufacturers allow the use of shut-off and control heating manifolds in water supply systems.

For example, FAR manifolds with protective metal caps. However, FAR manifolds with protective caps do not have adjustment knobs. The cap must be removed and adjustment must be made with a tool. This is not convenient and they are not installed on the water supply of apartments.

Kinds

Water collectors differ in material, design and other parameters. Before purchasing it, decide which model you need. Today combs are made from:

- Stainless steel. A material that does not rust and does not change its performance properties when exposed to high temperatures or fire. It is lightweight, so it is easy to install. Steel is harmless and does not change the chemical composition of water.

- Brass. Durable material, not subject to corrosion and high temperatures. Brass - expensive, but durable.

- Polypropylene. Inexpensive, not afraid of corrosion, lightweight. They are non-repairable and are used in places where the load on the water supply system is insignificant. They require a special approach to installation.

Collectors differ in the method of fastening. The most common is threaded. It comes with Eurocone, compression or solder fittings. Combinations are less common. Standard comb models include from 2 to 6 bends. If you do not use all the inlets, you can close them with plugs and open them in the future.

Select a manifold for your apartment's water supply by size

Any collector is selected according to the required number of branches. Next, let's look at its dimensions. The smaller the axial distance between the taps, the more compact the collector.

Please note that the taps of some collectors are made at an angle to the taps. This simplifies their maintenance in row installations in cramped conditions.

If there are a large number of branches, do not look for “long” collectors. Take two, for example 3+2 or 4+2 and combine them. This is provided by technology.

Peculiarities

The collector is a distribution comb. This is a pipe with bends at the same level and the same distance from each other. They have a right angle relative to the pipe. The inlet in the manifold is larger than the outlet. This way the water will be evenly distributed between consumers without loss of pressure.

The throughput capacity depends on the diameter of the inlet pipe. The use of such nozzles makes water consumption more comfortable, which is explained by the high cost. If finances allow you to equip a water supply system, be sure to take advantage of them.

The use of collectors allows you to connect consumers to one pipe. The set is ensured evenly along the consumption lines. Each pipe has fittings that stop the flow of water at any time. This is very convenient when repairing a specific consumption line and prevents leaks.

Select a water supply manifold based on body material

Collectors are made of brass (sunny shade) or bronze (red, copper shade). Plain brass brands are not coated with anything (eg Tim). Bronze products are not coated with anything (for example, Oventrop). Some brass models are plated with nickel on the outside (for example STOUT). The best manifold models (FAR and UNI-FITT) are completely chrome plated.

Let me explain about chrome plating. According to European laws, nickel must not come into contact with drinking water. Hence the chrome plating and the higher price of the product. This doesn’t work for us, so the Russian Valtec makes manifolds from nickel-plated brass.

Making a comb with your own hands

Although economically this is not very justified, with the necessary tools and a lot of patience, you can make a polypropylene comb yourself. To do this you will need the following materials:

- hacksaw and soldering iron for polypropylene;

- pieces of polypropylene pipe with a diameter of 25 and 32 mm;

- tees 32x25x32;

- plugs for 32nd diameter;

- couplings with internal threads 32:1 inch and 25:34;

- couplings with external threads 25:34;

- sealant;

- Ball Valves;

- air extractor.

You can do without an air extractor. But be sure to leave space at both ends to connect additional devices to the water supply comb in the future. During welding, it is important to “by eye” check the quality of the seams in order to prevent completely welded elements.

Video on how to make and install a cold water distribution comb yourself:

Select a manifold for the water supply of an apartment or house by company

Let me immediately note that the brands of collectors listed below by country may differ from the place of their production; everything needs to be clarified when purchasing.

VALTEC Russia

The Russian company of engineer entrepreneur Pavel Eduardovich Melnikov has been known since 2002. Low price, good quality.

Italian company Far

FAR Rubinetterie SpA was founded in 1974 by Alberto Alessina and Guerino Alessina and Nicola Rovaletti. QAVR quality certificate, Green Valve brand.

Italian Tiemme

On the market since 1990. It is proud to carry out its entire production cycle in Italy to ensure the quality, safety and reliability of its products.

Italian Luxor

Luxor Minuterie Idrauliche was founded in 1960 in Carpenedolo. All products comply with ISO 9001:2015 certification, Certified in Russia.

UNI-FITT Italy

The Italian brand has 19 enterprises in Europe and 9 factories in Russia. On the Russian market since 2010. Externally very similar to FAR.

General fittings

GF collectors come from Italy. There are manifolds with shut-off ball valves and control valves. Large selection of types and sizes, material nickel-plated brass.

Calleffi

Another “Italian” from 12 companies and 5 representative offices. All 3 factories are located in Italy. There are no crafts.

Polish Solomon

Cheap Polish-Chinese brass miracle. You need to look in Russia.

STOUT

European brand with factories in Russia, Italy, Spain, Germany. Products in the mid-price range, with nice, unfolded white handles. More used for heated floors.

Tim

TIM company was founded in 1994. produces a wide range of manifolds for heating and plumbing. The TIM Group unites 6 factories in China and distributors throughout Europe, Russia and the USA.

German Rehau

A narrow range of brass distribution combs for sliding sleeves and nickel-plated distribution manifolds with continuously adjustable 4 outlets. Large selection of collector groups for heated floors.

Products on the market

Depending on the material, the cost of products ranges from 400 to 2500 rubles. Collector groups for 200-300 outputs can cost 10,000-40,000 rubles.

There are models from different manufacturers on the market, the popular ones include:

- Watts;

- Uponor;

- Giacomini;

- APC;

- Luxor;

- Fado;

- Caleffi;

- Valtec;

- Bianchi.

The stores offer not only combs, but also accessories. Products without taps are economical. They are used to install individual wiring and make it possible to select suitable parts. Purchasing a product with shut-off valves will make the installation process easier. When assembling the units, the need to install valves disappears.

To adapt the device to the home system, components are purchased. These include valves, valves, and pump groups. Mechanical drives, plugs and pipes are required.

Manifold cabinets are used for wall mounting and maintaining an aesthetic appearance.

Selecting a manifold by diameter, thread and connection method

The most difficult moment of choice, which I will continue in the following articles. Some necessary information:

- The outlets of all control and shut-off manifolds have external threads (M).

- The diameter of inlets and outlets is indicated in inches (1/2.3/4.1″);

- Pass-through manifolds are threaded on both sides of the main flow. By type of thread they are designated: VR-BP (internal thread - internal thread) and NR-BP (external - internal);

- Bends with external metric thread M24x19 are designated as MR;

- Manifolds with flat seal outlets (FLAT-FACED) are additionally marked TP;

- Metric thread M24x19 is more reliable than simple pipe thread. It can be tightened by hand, for example, a flexible liner;

- The flat seal bends are connected to the gasket. They are used to connect manifolds and pipes (equipment) from different manufacturers;

- The Euroconus connection does not require sealing gaskets and works on an O-ring (collet connection). It withstands temperature changes well. Used to connect metal-plastic, PEX and copper pipes. To convert a Eurocone to a flat seal, there are special adapters.

How to install?

Before installing a water distribution unit for cold and hot water supply, give an accurate answer to the following questions and consider the following points:

- How many water consumers are there on site? The number of collector outlets should be the same or slightly greater than the number of consumers. Excess branches are closed with plugs.

- What type of pipes will be used to install the water supply? It is necessary to purchase devices designed specifically for pipes made of the selected material.

- Estimate in advance the position of all engineering elements in the space of the plumbing cabinet (you can make markings on the wall). Please note that a water meter and a water filter are installed in front of the distribution comb. The convenient location of all devices facilitates maintenance and repair work.

- Get reliable fastening - a poorly secured distribution unit can lead to depressurization of connections and damage to the pipeline.

- Before installation, make sure that you have all the necessary consumables on hand: sealing material, gaskets, adapters.

Installation of the water distribution unit occurs in the following sequence:

- Install the inlet shut-off valves on the water supply riser.

- Install the meter, filter and check valve.

- Connect the manifold and securely fix it to the wall

- Install a water supply to each consumer. Secure the pipes with fasteners.

This operating algorithm will allow you to avoid errors. Regardless of whether the collector is needed for water supply or heating, its installation is the same. Such wiring requires more time, skill and money, but pays off quickly and provides comfort in further use. Collectors are appropriate not only in cottages and large houses, but also in apartments.

Water distribution combs will effectively regulate its pressure

Every housewife has encountered such a problem as a decrease in pressure in the water supply system during the simultaneous operation of several points. This problem is solved using a distribution manifold. Among consumers, they are better known as water supply combs. This wiring scheme is considered the most effective and in demand these days. This engineering solution is quite complex, but has a number of advantages.

Flaws

Despite the wide control possibilities, manifold heating distribution has not become widespread. And there are good reasons for this:

- Increased consumption of main pipes compared to conventional heating schemes. The more complex the building geometry, the more material needs to be purchased. Increased installation costs are also one of the significant reasons for low consumer demand.

- Traditional systems can be easily mounted on the wall in open or hidden versions. It is possible to lay a lot of lines from the comb only under the floor. Otherwise, you will get a very depressing picture, where heat mains will dominate the interior. And the material consumption for wall mounting will increase significantly.

- A prerequisite for installing the liner inside a concrete screed is the absence of joints. Each connection point is potentially dangerous from the point of view of breakthroughs. The prospect of destroying the foundation in order to eliminate a coolant leak looks depressing and requires a considerable investment of money, labor and time.

- The hydraulic resistance of a system with a mass of pipelines increases significantly. Especially if the diameter of the lines is small. Therefore, no gravity heating systems can even be considered. Only forced circulation of heated water.

- If you plan to use several independent heating circuits, then a circulation pump must be installed for each of them. Otherwise, the scheme simply will not work. Hence another item of additional costs.

- In any case, the system turns out to be energy-dependent, since it will not be able to function without a heating pump. Again, it’s a nuisance if for some reason there is no electricity. Or you will have to take care of an autonomous power supply.

All shortcomings ultimately come down to additional material costs. We can safely say that the collector wiring option cannot be classified as a budget solution.

Installation rules

You can do the wiring of the water supply network with the installation of the collector yourself. It is assembled according to this scheme: the main pipe is connected to the comb directly, without any branches. Pipes supplying water to each plumbing fixture are connected to it. The devices are conveniently installed behind the toilet flush cistern. But other versions are also acceptable.

To choose a location for the comb, take into account:

- accessibility for repair and installation;

- humidity (moderate);

- the presence of a load-bearing wall on which the device is fixed;

- the ability to work in case of an accident at any time of the day thanks to additional lighting.

Sometimes the device is installed in a separate room or closet. To secure the collector, special clamps are used.

Combs are installed for both hot and cold water supply. For ease of use and to avoid confusion, manufacturers produce collectors in two shades: red and blue.

Cranes and other components

When choosing a collector for water supply, professionals will always help you determine which is best from the existing range. Specialists will take into account the allocated budget and the material of the pipes from which the wiring in the house will be created. In addition, simultaneously with the comb, all components are selected to create a full-fledged distribution unit of the water supply system:

- valves;

- pressure gauges;

- pumps;

- valves;

- fasteners;

- plugs;

- couplings;

- filters;

- counters;

- fittings.

Manufacturers also produce manifold cabinets. They are built into the wall or mounted on its surface. Their use allows you to improve the distribution unit and provide free access to it.

Combs are produced with and without taps. When using the latter option, you still have to install shut-off valves, but they can always be replaced when a breakdown occurs. If you choose a collector with built-in taps, you will have to completely change the distribution element of the water supply system.

Manifold-comb without taps on taps Source komsis.su

Briefly about the main thing

The equipment of the collector block must meet the requirements for the functionality of the system. The collector device ensures uniform heating of the heating elements and a constant temperature in the room. Made from the following materials: polypropylene, brass and steel.

The manifold consists of a system to which threaded elements, fittings or control valves are connected. The collector is installed in a special cabinet or brackets are used.

Along with it, a mixing unit is used.

The durability of combs directly depends on the material and workmanship. You can purchase a ready-made distribution block or assemble it yourself from individual elements.

| Additionally The exhibition of houses “Low-Rise Country” expresses sincere gratitude to the specialists for their assistance in creating the material. – supplier of water supply and heat supply systems for any facilities, from the world's leading brands. The company also develops and installs automated metering systems for energy consumption. If you need more detailed advice, you can use the following contacts: website: www.makipa.ru email: phone: +7 (495) 134-48-01 |

Ratings 0

Read later

Famous brands

Valtec is an Italian manufacturer of a line of products for constructing water supply systems. A full range of products for metal-plastic, polypropylene water supply and stainless steel systems is always on sale. In Russia, representative offices are located in 6 cities, including Moscow, St. Petersburg, and Krasnodar.

Rehau is a German manufacturer with a history dating back to 1948. Products undergo multi-stage quality control.

Far (FAR) is another Italian company. In addition to shut-off and distribution valves, the line includes metal-plastic, polypropylene, copper and steel pipes.

Collector water supply system in the apartment

The collector distribution of water supply pipes in an apartment is the most beneficial from a hydraulic point of view, in contrast to a tee (where everything is more complicated with this). Quality, reliability and the absence of any unpleasant surprises in the form of temperature changes, etc., so here we will consider the use of collector wiring for a water supply system.

If you came to this page and want to see a cheap and “good” version of the water supply on tees made of polypropylene pipes running on top of the tiles in the bathroom, then you don’t have to read further. You will be very disappointed in what a high-quality water supply system in an apartment should be.

The collector system involves the use of the collector itself.

From it all water collection points are routed directly, i.e. without any intermediate connections. This justifies one of the advantages - the absence of hidden connections.