Construction of houses from laminated veneer lumber > Houses and cottages from laminated veneer lumber > Houses from laminated veneer lumber

The design and construction of country houses from laminated veneer lumber are very popular in the modern housing construction market. In addition to their aesthetic appearance, houses made of laminated veneer lumber have high performance qualities.

Filters

- House made of laminated veneer lumber according to the Austria v2 project 480.94 m2 102

- House made of laminated veneer lumber according to the Era project 458 m2 15

- House made of laminated veneer lumber according to the Queenstown project 302.83 m2 38

- House made of laminated veneer lumber according to the Palmerston project 556.59 m2 81

- Country residence “Hunting Club” 2560 m2 33

- House made of laminated veneer lumber according to the project “Bear Corner” 421.2 m2 40

- House made of laminated veneer lumber according to the Corvette project 286.6 m2 103

- House made of laminated veneer lumber according to the Volga project 756.8 m2 22

- House made of laminated veneer lumber according to the Antoni project 760.3 m2 28

- House made of laminated veneer lumber according to the project “Austria v1” 466.44 m2 27

- House made of laminated veneer lumber according to the Belfast project. 271.24 m2 31

- House made of laminated veneer lumber according to the Weimar project 223 m2 115

- House made of laminated veneer lumber according to the Seattle project 664.74 m2 79

- House made of laminated veneer lumber according to the Viljandi project 224.31 m2 2

- House made of laminated veneer lumber according to the Manchester project 211.7 m2 32

- House made of laminated veneer lumber according to the Cardiff project 818.98 m2 20

- House made of laminated veneer lumber according to the Tartu project 233 m2 53

- Cottage community made of laminated timber Mikhalkovo Park 5100.92 m2 0

- House made of laminated veneer lumber according to the Montelimar project 412.2 m2 9

- House made of laminated veneer lumber according to the Portofino project 304.4 m2 61

- House made of laminated veneer lumber according to the Karlstad project 266.62 m2 16

- House made of laminated timber according to the Oxford project 276.6 m2 20

- House made of laminated veneer lumber according to the Bergen project 392.1 m2 14

- House made of laminated veneer lumber according to the project “Sosnovy Bereg” 201 m2 107

- House made of laminated veneer lumber according to the Wellington project 205.96 m2 15

- House made of laminated veneer lumber according to the Pitsunda project 324.99 m2 11

- House made of laminated veneer lumber according to the Dublin project 238.37 m2 55

- House made of laminated veneer lumber according to the Denver project 1331 m2 5

- House made of laminated veneer lumber according to the Ladoga project 231.2 m2 63

- House made of laminated veneer lumber according to the Tampere project 282 m2 16

- House made of laminated veneer lumber according to the Scandi project 281.4 m2 9

- House made of laminated veneer lumber according to the Stockholm v2 project 157.43 m2 23

- House made of laminated veneer lumber according to the Sokol project 618 m2 12

- House made of laminated veneer lumber according to the “Venice” project 612 m2 13

- House made of laminated veneer lumber according to the Riverhouse project 226.8 m2 38

- House made of laminated veneer lumber according to the Avignon project 137.2 m2 81

- House made of laminated veneer lumber according to the Alicante project 170 m2 61

- House made of laminated veneer lumber according to the Annecy project 271.7 m2 11

- House made of laminated veneer lumber according to the Antwerp project 197.3 m2 18

- House made of laminated veneer lumber according to the Belfort project 182.5 m2 23

- House made of laminated veneer lumber according to the Bergamo project 415.6 m2 9

- House made of laminated veneer lumber according to the Bordeaux project 321.7 m2 11

- House made of laminated veneer lumber according to the Verdun project 996.7 m2 9

- House made of laminated veneer lumber according to the Valencia project 279.6 m2 24

- House made of laminated veneer lumber according to the Verona project 223 m2 17

- House made of laminated veneer lumber according to the Versailles project 313.9 m2 17

- House made of laminated veneer lumber according to the Austin project 332.24 m2 0

- House made of laminated veneer lumber according to the Cologne project 228.5 m2 48

- House made of laminated veneer lumber according to the Lahti project 604.9 m2 5

- House made of laminated veneer lumber according to the Lausanne project 418.5 m2 3

- House made of laminated veneer lumber according to the Marmand project 262.4 m2 17

- House made of laminated veneer lumber according to the “Marseille” project 224.9 m2 20

- House made of laminated veneer lumber according to the Metropol project 196 m2 28

- House made of laminated veneer lumber according to the Modena project 239.3 m2 8

- House made of laminated veneer lumber according to the Montluçon project 210 m2 30

- House made of laminated veneer lumber according to the Oldenburg project 424.7 m2 11

- House made of laminated veneer lumber according to the Prague project 200 m2 126

- House made of laminated veneer lumber according to the project “Prague v2” 259.2 m2 4

- House made of laminated veneer lumber according to the Prague-mini project 175.7 m2 117

- House made of laminated veneer lumber according to the Ystad project 72.04 m2 13 9 597 110 RUR

- House made of laminated veneer lumber according to the “Provence” project 263.2 m2 9

- House made of laminated veneer lumber according to the Rochefort project 357.1 m2 7

- House made of laminated veneer lumber according to the Reykjavik project 127.8 m2 63

- House made of laminated veneer lumber according to the “Seoul” project 163.7 m2 35

- House made of laminated veneer lumber according to the Stockholm project 171.5 m2 19

- House made of laminated veneer lumber according to the Strasbourg project 340.1 m2 9

- House made of laminated veneer lumber according to the Toulouse project 255.5 m2 21

- House made of laminated veneer lumber according to the Turin project 174.2 m2 24

- House made of laminated veneer lumber according to the Turku project 129.2 m2 40

- House made of laminated veneer lumber according to the Finlandia project 541.2 m2 6

- Hall made of laminated veneer lumber according to the Leicester project 4

- House made of laminated veneer lumber according to the Helsingborg project 230.72 m2 39

- House made of laminated veneer lumber according to the Zurich project 314.8 m2 17

- House made of laminated veneer lumber according to the Akranes project 123.42 m2 5

- House made of laminated veneer lumber according to the Hannover project 365.99 m2 4

- House made of laminated veneer lumber according to the Oulu project 377.40 m2 3

Popular articles

January 11, 2021

The best materials for building a private country house: tips for choosing materials from Holz-House

April 5, 2021

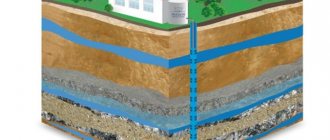

Basement floor in a private house, projects of houses with a basement floor from Holz House

August 18, 2021

Alpine-style laminated timber house: construction, interior design, choice of materials – Holz House

View all articles

Advantages of houses made of laminated veneer lumber

Form stability

The unique technology for manufacturing laminated veneer lumber has made it possible to improve the natural properties of wood, increasing its thermal insulation and strength characteristics. Glued laminated timber does not undergo deformation over time and retains its shape and size. This is due to the peculiarities of production: tight gluing of the lamellas avoids warping of the material and the appearance of cracks. A house made of laminated veneer lumber gives minimal shrinkage - 1-2%.

Reliability

Profiled laminated veneer lumber is made from high-quality wood using a unique technology and has high strength and density, not inferior to reinforced concrete structures.

Fire resistance and biological resistance

Due to the low thermal conductivity of wood and the high density of products, laminated veneer lumber is poorly susceptible to fire. Special “fire retardant” compounds applied to the surface layer increase the fire resistance of the material and the wooden structures themselves. Therefore, houses made of laminated veneer lumber are considered fireproof.

Durability

With proper adherence to the manufacturing technology of laminated veneer lumber, a high-quality building material is obtained that will last for many years without changing its performance characteristics.

Professional construction with guarantees

Leave a request or call us directly to discuss order details. Competent and responsible managers of the Vyatsky Dom Group promptly respond to every request. Clients are provided with information about the projects we have built, as well as possible options for their individualization. We serve not only Moscow and the Moscow region, but also other regions of the Russian Federation with a personal approach to clients.

High quality, reliability and durability are not empty promises, but hundreds of implemented high-quality projects, supported by the guarantee obligations of our company, which we provide for all types of construction work. Waiting for you!

Projects of houses made of laminated veneer lumber

Standard project

By choosing one of the standard designs of houses made of laminated veneer lumber, you save time. The construction company offers a large number of ready-made projects for country cottages and houses in different architectural styles. In addition, if a building was erected according to the chosen project, then you have the opportunity to see the finished house and evaluate the result.

Changes to the standard project

At the request of the customer, changes can always be made to the standard project he has chosen from the catalogue: increase the area of the house, change the layout, add a garage, terrace or basement, and so on.

Individual design

An individual house project is created taking into account all the requirements and wishes of the customer. Its development may take some time, but the result will be a completely exclusive house project. You can apply styles and architectural solutions that are not proposed in standard projects.

Constructive options for combined houses

Despite the variety of facade decor, the construction of combined houses must comply with the main principle: 1st floor is stone, 2nd floor is wood. It provides the building with the necessary strength and creates conditions for comfortable living on the second floor. Another problem solved by the combination of materials is reducing the labor intensity and cost of construction.

Anyone who does not want to spend extra money on exterior decoration is doing the right thing. The combination of stone and wood is optimal not only for structural reasons, but also from an aesthetic standpoint. Therefore, do not hide behind the finishing what looks perfect in itself.

An example is a mansion built in a deliberately rough combination of natural stone and logs. It fully complies with the canons of country style.

The chalet-style house, invented by Alpine shepherds, has its origins in the harsh mountainous terrain. It also used the idea of combining durable stone and warm wood.

Life in the mountains requires maximum reliability and functionality. Therefore, the first level of the chalet is always built from durable rock that is not afraid of snow debris, rockfalls and water. The second floor is designed to create comfort and coziness. For these purposes, you cannot find a better material than natural wood.

The “ancestral sign” of all buildings built in the chalet style is wide roof overhangs that protect the walls from heavy rains and melting snowdrifts.

Modern combined houses made of stone and wood are extremely diverse, since the choice of wall materials is very wide. If you are not satisfied with torn stone or flat limestone “flagstone”, then build the first floor from foam blocks. They are quite durable and at the same time as warm as natural wood.

When preparing for construction, do not forget that houses made of foam blocks and wood require a reliable connection between the first and second floors. Cellular concrete is a rather fragile material. Therefore, it will not hold the steel anchors securing the second level support beam.

A competent solution for such a structure is to pour a monolithic reinforced concrete belt over the foam block walls. It increases the spatial rigidity of the building and allows you to securely fix the anchor bolts.

The appearance of a foam block wall is not very expressive. Therefore, it is better to cover it with blockhouse or siding, laying a vapor barrier and a layer of mineral wool insulation behind the façade cladding.

For the combined construction of a cottage, you can use wood concrete blocks. They are stronger than foam concrete, not as fragile and very warm. Finishing arbolite walls is not labor-intensive, since any decorative plaster adheres well to them.

The second floor can be built from planed timber. This material retains heat well in a residential floor and does not require finishing cladding.

If you need a three-level combined house made of brick and timber, then build it according to this scheme: the ground technical floor is monolithic reinforced concrete, the first level is brick, the second is a frame or log house.

Speaking about the frame version of the walls of the second floor, we note that it will not only save your money, but will also allow you to flexibly change the internal layout, adapting it to family needs.

You can hide the frame of the second floor behind the finishing. Another interesting option is to specifically highlight it, turning it into an element of facade decor. For this purpose, half-timbering is best suited - an ancient frame system in which posts, beams and cross braces face the facade.

A serious problem with all cottages is dampness on the ground floor. A combined house solves it simply and functionally. The lower floor is reserved for utility rooms. Here you can equip a boiler room, a bathhouse, a workshop and a garage. Bedrooms, bathrooms, dressing rooms, playrooms and a kitchen are located on the second, drier floor.

Pros and cons of the combination idea

Having noted the main advantages of combined buildings: efficiency, planning flexibility, aesthetics and functionality, we will point out the disadvantages of such buildings.

The main one is the different “lifetime” of stone and wood . In rocks it reaches 150 years. At best, the tree will last half a century. For light frames and panel walls this period will be even shorter. Therefore, a moment will inevitably come when the first stone floor is still quite strong and reliable, and the walls of the second floor already require repairs.

Since combined country houses in Russia are still quite young, there is no negative experience of different rates of aging of wall materials. Therefore, reviews from their owners are mostly positive.

To summarize, we advise everyone who has decided to build a combined cottage not to forget about the different service life of the first and second floors. To extend the life of the walls, buy well-dried and antiseptic wood, and trust the assembly of the frame to experienced professionals, not hackers.

A wooden frame requires a properly assembled drainage system to prevent moisture from entering the wood. In addition, during the construction stage, constant quality control of the sealing of all cross sections of wooden posts and beams is required.

No. 13. Project "Estate"

If you want to build a spacious house for a large family that often receives guests, then this project is definitely worth considering. The central part of the first floor is dedicated to a large living room. The author of the project decided to allocate a separate room for the kitchen and dining area, but if desired, the dining room can also be arranged in the living room. From the living room you can enter the steam room with a dressing room and shower. The rest of the first floor is occupied by two bedrooms with one shared bathroom.

Above the living room on the second floor there are two more bedrooms, one of which has access to a balcony. The house captivates with the presence of a terrace, a combination of lightness and solidity. Total area – 235 m2.

Features of timber manufacturing

Before you start building from timber, it is advisable to study all its features and production technology:

- Initially, wood arrives at the plant and is sawn into lamellas. Parts with defects are removed from production. High-quality sawn samples undergo thorough drying using special equipment. This process takes about a week.

- As soon as the lamellas are dried, they are sent for planing. The essence of this procedure is to remove all irregularities from the surface. Only after this the lamellas are fastened together and placed under a press. The heavy load allows the beam to finally form. The final step will be to perform additional planing. After this, the workpiece is sent to the machine, which creates the required profile.

- Some customers are alarmed by the fact that when creating laminated veneer lumber, glue is used as a binder. However, it is water-based and does not have harmful toxins, which suggests that the material is safe.

- When producing the material, it is worth paying attention to such a stage as antiseptic treatment. Special bioprotection of the material reduces the likelihood of fire and protects the surface from various pests. Antiseptic treatment carried out in the factory involves applying a solution to all sides of the timber. This provides the maximum level of material protection.