Visiting a bathhouse is a useful pastime that many people enjoy. What could be more pleasant than a good steam bath and then enjoying hot tea in nature? Everyone wants to have a bathhouse on their plot, but many are faced with a problem - the territory of their plot of land is too small, which is why they cannot afford to build a building.

Even if you cannot boast of a spacious area, there is no need to deny yourself the pleasure of having your own bathhouse. The best option for areas with a small area is a 3x4 bathhouse project.

Description of the bath

According to old customs, the room consisted of two steam rooms, combined with a washroom and a dressing room, which was also a dressing room.

- Nowadays, a bathhouse can already be called a sauna. After all, it is divided into a steam room and a separate room for washing.

- The general name of a bathhouse implies one room with a boiler of water and a stove with stones.

- And washing the body takes a few minutes, like taking a shower, dousing from a tub or plunging into a vat of cold water.

All this introduced new standards in the distribution and number of rooms in a modern bathhouse. Clearly stated restrictions and rules for determining the optimal size of the bath. There are logical conclusions on the basis of which plans and calculations are made before construction begins.

What to build from

A 2x3 bathhouse project may involve the use of various types of building materials and technologies. Let us consider them comprehensively, taking into account their positive aspects and possible negative aspects.

Log sauna

It is impractical to build a bathhouse from logs in such dimensions. Firstly, to create the necessary thermal insulation parameters, the diameter of the logs must be at least 270 mm, and this takes into account the fact that at the junction this parameter will be about 140 - 160 mm. If the thermal insulation properties are insufficient, when installing individual elements, you will still have to allow a large number of cuts of long logs, and laying the corners “into a paw” or “into a bowl” will take a lot of effort and time.

The structure itself will be quite bulky, and the internal volume will be insufficient. The only option for using this technology in construction can be seen in the construction of a traditional black bathhouse. Which, by the way, is becoming increasingly popular in Finland. Such a bathhouse has a single-volume internal space, without division into a steam room and washing area. There is no dressing room or rest room in such buildings, so the lack of internal space is not acutely felt.

Bathhouse made of timber

It will not touch the rounded beam, but consider the elements of a classic rectangular section. Timber for the construction of a compact bathhouse seems to be a more preferable option than a full-fledged log. There are several reasons:

- You can use a smaller cross-section, about 150×150 mm, without loss of load-bearing and thermal insulation qualities;

- Such elements are more convenient to transport, store and install, which is very important in conditions of limited space in a small area;

- Sawing timber, laying it in corners and shaping it is incomparably easier than logs;

- The load on the base will be less, therefore, it can be made less massive;

- It is easier to maintain timber in the required sanitary condition than logs. It is more convenient to process, paint, and clean.

In terms of choosing a material, it will be useful to take a closer look at larch timber. The combination of high consumer qualities makes it unattainable for many competitors.

By the way! Profiled timber has even greater advantages, primarily in terms of installation. But its cost, relative to its ordinary counterpart, is higher.

Frame technologies

Perhaps the most acceptable option for a budget sauna of compact size is a design based on a frame set. Let's immediately note the advantages:

- Extremely low load on the foundation, which makes it possible to use original technologies, for example, based on car tires.

- Speed of construction. In addition, the assembly of the structure is quite simple technologically.

- Excellent thermal insulation qualities.

- A small amount of commercial timber, which is necessary for construction. The main requirements are for the quality of load-bearing elements only. Rough cladding can be done with boards of a lower grade.

- Ease of fitting window and door openings.

- The thin walls are thin, which allows for some gains in the volume of internal space.

- If desired, such a structure can be dismantled without much damage to its integrity.

Remember! All types of wooden buildings must be treated against damage by insects - pests and microorganisms. It would also be useful to use means to increase the fire resistance of wood.

Brick baths

They require a more thorough approach to organizing the foundation. In addition, such buildings take a little longer to erect, they require the use of mandatory measures for thermal insulation of the structure and, finally, one cannot do without finishing the interior of the steam room with wooden elements, like linden lining. In general, brick is a non-flammable, strong and durable material that does not require additional measures to protect the structure from adverse weather conditions.

Baths made of building blocks

Much like constructing a small sauna from a log, building it from building blocks is also not a rational option for a number of reasons:

- As a rule, the minimum thickness of a full-length block is 200 mm. Taking into account the thickness of the layer of thermal insulation material - 50 mm and the internal finishing layer - 35 - 40 mm, the useful internal space is reduced quite noticeably;

- Block, more than brick, is demanding on the quality of foundation waterproofing;

- Finding a high-quality block is more difficult than brick, because, unlike brick, the production of which is concentrated at large industrial enterprises, the production of blocks is carried out by many small manufacturers, for whom compliance with mandatory technological requirements is far from an axiom.

A word from Experienced! The load on the foundation can be somewhat reduced and the quality of thermal insulation can be improved by using blocks based on cellular concrete. The most important thing is to find high-quality material, otherwise after a while the elements will simply begin to collapse.

Types of baths

Based on the time of use, baths are divided into seasonal and permanent. In seasonal or summer cottages, they steam in the summer, coinciding with the gardening period. Permanent or year-round are used regularly at any time of the year.

Seasonal buildings usually do not need to be built large. They are needed for 4-5 months. In some cases, if there is a large family or regular guests who are ready to use the steam room, a larger bathhouse may be needed.

The average size of country baths depends on the size of the land plot and usually does not exceed 3x3 meters.

A year-round sauna is built thoroughly, often with all the amenities: running water, sewerage, relaxation rooms, a terrace. Not only do they steam and wash there, but large groups also relax there.

Important points

Before starting all construction work, the design of a 3x4 frame bathhouse (and any other as well) must contain a number of technological and construction solutions.

- Thermal insulation. High-quality measures for sealing and insulating the bath will guarantee good air exchange. For these works, fiberglass or mineral wool is most often used, because they have excellent characteristics;

- Vapor barrier. The main disadvantage of frame construction is the appearance of condensation. This is explained by the fact that moisture penetrates into the frame through cracks during rains and snowfalls. Therefore, in order to avoid such a phenomenon, you need to carry out this stage of work well.

A good solution would be to use a vapor barrier film or glassine; they are placed between the layer of inner cladding and insulation. Experts do not recommend using roofing material, since when heated it emits an unpleasant odor;

- Choosing the right wood. Only good dried boards are suitable for construction work. Aspen, larch and linden are ideal for these tasks.

They have a low thermal conductivity and are almost not deformed. The lining itself must be without flaws and of the highest quality.

Foiled mineral wool

Number of rooms in the bathhouse

The total number of rooms in the building depends on the following factors.

- How much space is allocated for the bathhouse?

- How many people will use the steam room?

- How much does the owner want to invest in the business?

The most basic budget building contains two rooms, a steam room, which is the base, and a dressing room. However, if desired and financially possible, a real modern bathhouse consists of a steam room, a dressing room, a shower or washing room, a relaxation room,

If two or three people prefer to regularly take a bath procedure, paying attention only to the bath process, then two rooms are enough: a steam room and a changing room.

Construction budget restrictions also play a role. However, if there is enough space for construction and enough money, then you can build as many rooms as your heart desires.

If there are more than three people in a family, and the owners are used to receiving guests, then there is no need to limit yourself to two rooms in the bathhouse. Complete rest is possible if you have free space. In this case, in addition to the steam room and dressing room, a full-fledged sauna with a relaxation room, shower, toilet, swimming pool, terrace or open veranda is built.

Floor installation

The floor is formed with 5x5 bars, which are secured to the joists with self-tapping screws. Subfloor boards are laid on top. Then install waterproofing in the form of a film or roofing material and insulation - mineral wool. The thickness of the thermal insulation is at least 10 cm. Waterproofing in the form of glassine is also placed under the final finishing so as not to spoil the mineral wool.

Features of installing the floor in the washing room:

- Remove soil around the perimeter of the floor to a depth of 50 cm.

- Fill the pit with sand and gravel 10 cm thick. This will avoid creating a pit.

- The logs are formed from asbestos pipes, which are filled with concrete when forming the foundation. This prevents possible movement of the joists.

- Form a subfloor. A gap of 5-7 mm is left between the boards to install rubber gaskets.

- Next, hydro- and thermal insulation with the formation of a fine finish after installing the walls.

Construction according to this option allows the floor in the washing room to dry faster. This extends the life of the wood.

Steam room area

The size of the room where the main process takes place depends on several reasons.

- Steam room heating options. If the stove is brick, then we start from its size. If it's electric, it won't take up much space.

- The number of people who will steam at the same time.

- The height of the tallest family member.

The minimum size of the steam room is 2 sq.m. It’s convenient to steam there for one person, or less often for two. An area of 3 square meters or 1.5x2 meters around the perimeter is suitable for three or four people.

If the size of the plot and the family budget allow, then the size of the steam rooms in the bathhouse is determined based on the power and speed of heating the room. the long wall for the shelves should be less than 2 m, the short one at least 1.5 m.

The height of the ceiling in the steam room affects the speed at which the air in it warms up to the desired temperature. As a standard, ceilings should not be lower than 210cm. then, when swinging a broom, nothing will interfere with this bath procedure. If there are tall people in the family, then the ceilings are made 230 cm. The maximum ceiling height in the steam room reaches 250cm.

The size of the shelf depends on how the owners are used to steaming. If you are sitting, then there is no need to make them long. A length of 150cm and a width of 45cm will be sufficient. In a lying position, you will need a shelf from 1.6 to 2 meters in length and a width of 65 cm.

The windows in the steam room are located at a height of 120 cm from the floor. Window size 35 x 35 cm.

Peculiarities

When building a compact bathhouse, use standard lumber - planed timber with a length of each product of 6 m. Manufacturers produce wooden products processed on four sides of this particular molding. When erecting walls 3 m wide, the timber will only need to be cut in half, which will speed up the construction process and make the work easier.

Important!

To comply with fire and sanitary safety, ensure the recommended distance from the facility to the adjacent territory and buildings. There must be at least 1 m between the fence and the bathhouse, and at least 15 m from neighboring buildings.

Before starting construction work and design, check out the photos of finished baths measuring 3 by 4 to choose the option that suits you. After choosing a building model, the design and construction stages will not be difficult. Due to the compactness of the bathhouse complex, carefully consider the layout of the premises, the location of the heating stove, window openings, and entrance groups.

Waiting room

The dressing room is made with a minimum area of 1.3 sq.m. This size is enough to take off clothes and hang them on hangers.

In a large bathhouse, space for a dressing room can be separated by calculating the number of people who will be there at the same time. Typically the area is from 6 sq.m.

In front of the dressing room, you can make an additional corridor that traps cold air in winter.

Construction stages

To build a bathhouse on your own site, you will need to perform the following steps:

- foundation equipment;

- walling;

- roof installation;

- finishing walls using insulation;

- construction of a stove and chimney;

- performing finishing works;

- installation of plumbing;

- placement of furniture.

Foundation

Having decided on the project and location of the bathhouse, they begin to build the foundation.

For a bathhouse, a support-column foundation is used.

Before making the foundation, it is necessary to carefully level the surface.

Then pillars are made from brick, the space is filled with crushed stone and filled with screed.

You can also build on a strip foundation. It is used quite often. Such a foundation can withstand any load from the walls.

To carry it out, a trench is dug, a reinforced mesh is installed and a mixture of cement, sand and water is poured.

Formwork can be used to raise the foundation above the soil level.

Walls

For them it is necessary to choose high-quality and reliable materials. You can use wooden beams, bricks, cinder blocks.

The choice of solution directly depends on the material used.

Wooden beams allow you to install a prefabricated bathhouse.

Be sure to level all surfaces. When building walls, do not forget to make door and window openings.

Often, interior finishing is done using lining. Various materials can be used for external walls.

Roof

You should not choose a roof design that is too complex. The simplest option is enough.

To complete the roof, rafters are installed, a layer of waterproofing is laid, and then the roofing is laid.

The roof can be made single-pitch or gable.

Installation of the first option is simpler and less expensive. However, a gable roof is more often used.

Doors and windows

It is preferable to choose wooden windows and doors

When installing them, it is important to carefully seal all cracks to avoid heat loss.

You should not choose plastic, as it quickly becomes unusable when exposed to high temperatures.

Sometimes doors are made of glass.

Floor

It must be thoroughly insulated. For a more comfortable stay in the bathhouse, you can install a heated floor.

It is worth considering the following nuances:

- the foundation is covered with waterproofing and insulation;

- water supply pipes and sewerage are located in the washing room floor;

- boards are most often laid on top of this.

Finishing

The decoration of the room plays an important role. Wall insulation will help ensure good heat retention. For this, mineral wool or polystyrene foam is often used.

Insulation of internal walls and ceilings is carried out in the following sequence:

- fix the waterproofing layer;

- attach wooden sheathing;

- fix vapor barrier and mineral wool;

- surfaces are finished using lining.

The outer surface is painted and lined with bricks or boards.

Arrangement of the bathhouse

In addition to all of the above, it is necessary to supply electricity, water and sewer pipes. Keep in mind that the steam room and washing room have high humidity, so you need to take this into account when installing electrical wiring.

Finally, the necessary furniture is installed.

After reading this article, it becomes clear that building a bathhouse yourself is quite simple. To do this, it is imperative to take into account all the requirements for its construction and choose high-quality materials.

Numerous photos of the inside of the bathhouse will help you decide on the design and layout. If all requirements are met, the bathhouse will serve you for many years. This will be a great place for family holidays and receiving guests.

Sink or shower

After the steam room you usually want to freshen up. It’s good if there is a vat of cool water next to the bathhouse. Previously, natural reservoirs were used for this.

Now you can make a separate section in the bathhouse for taking a shower. Or pouring water from a bucket.

- The size of the shower according to the standards is 1x1m or 1.3x1.3m.

- This size is enough to take a shower.

- If desired, the shower room can be enlarged.

Making walls

Before installing walls, you need to decide on the location of doors and windows. In a small bathhouse, racks are formed at the corners of the building. On the front and rear walls, which are longer, additional racks are installed in the middle. But they can be displaced due to the way windows and doors are installed.

Step-by-step procedure for constructing walls:

- Install corner posts. In a vertical position, they are first fixed temporarily with slats, but strictly according to the level.

- Place vertical racks on the sides. The lower parts of the side posts are secured with metal corners. Then this is the procedure for the front and back walls.

- Additional reinforcing elements are installed in the form of beams. Boxes for windows and doors are formed according to size. There is only one door. There are one or two windows for the locker room. Small in size to prevent heat loss. The purpose of windows is ventilation.

- All connections are reinforced with metal corners. It is recommended to use self-tapping screws instead of nails - it’s more reliable.

- In the same way, the bases of the walls inside the bathhouse are formed according to their availability.

- After the frame of the walls is formed, they are sheathed. Lining or OSB boards are suitable as cladding.

After covering the external walls, insulation is installed. To form the frame, a 10x10 cm beam is usually used, so the insulation should not be thinner. How to build a frame bathhouse with good insulation is to use mineral wool. Inexpensive material that is easy to seal cracks. They must be carefully closed; there should be no gaps. If you miss some connection without insulation, this will lead to a rapid loss of temperature inside the bath.

The vapor barrier is made of foil. The minimum thickness is 40 microns. The foil joints are connected with tape. The order of installation is from top to bottom in stripes. A stapler is used to secure it to the wood, but glue can also be used.

The template will make it easier to install the rafters. It is made of light boards and placed next to the installation site of each rafter. It is easy to avoid mistakes with such a system.

Instructions for forming the roof:

- Assembly is carried out on the ground for ease of operation and manufacturing accuracy. Then the finished structure is raised.

- Each part is installed in its own place above the central beam. Places must be marked in advance with a bright pencil.

- The roof must have ventilation holes. A sheathing is installed between the rafters and the counter-batten.

- It is easier to cover the gables with OSB boards - this will form a solid element.

Slate is the best roof covering. Roofing felt is not recommended because it tears quickly and easily. You can use metal tiles, it’s more aesthetically pleasing. But when it rains, metallic tapping will be heard.

Restroom

In each bathhouse, the dimensions of the relaxation room are individual and are calculated depending on the owner’s requests. One is large enough to accommodate a table and bench. Others prefer to install there, in addition to the dining group, a billiard table, a sofa, and a TV.

Everyone's vacation habits and wallets are different. Therefore, there are no standards for the size of the rest room.

Important. All doors in the bathhouse open outward according to fire safety standards.

In addition to the main premises, there are options for a bathhouse with a swimming pool, a terrace, and two-story buildings.

More projects

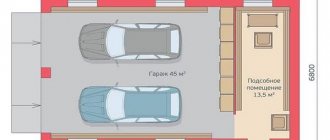

Project "A"

Here we note the following nuances:

Project "B"

The features of this project immediately catch your eye:

Here the 3x4 bathhouse diagram clearly makes it clear that the structure is being created mainly for the sake of a washing room - the ventilation in the steam room betrays the author, but this is also an option (project “B”)

Project "C"

A simple project of a familiar, native Russian bathhouse. Here:

And this is an ideal and recommended option, one might say the traditional layout of 3x4 baths (project “C”)

Project "D"

Here, perhaps, everything can be considered ideal:

Standard sizes

A bathhouse is often built from timber or logs. Wooden construction is limited by the standard length of wooden blanks. Common general dimensions of a seasonal bath are 2x3m, 3x3, 3x4 meters. Large year-round structures will have a log frame of 4x6, or 6x6 meters.

The bathhouse remains one of the favorite types of recreation in Russia. Not only do you steam and wash there, but you also meet with friends and relatives. Correctly chosen dimensions for a bathhouse will help improve your relaxation after working days and make it more comfortable.

Foundation options for different soils

Increased strength from the base is not needed due to the light weight of the frame structure. But the foundation must be of high quality and match the type of soil underneath it.

You cannot make a shallow foundation on soft soil - this will lead to inevitable shrinkage. Therefore, it is important to choose the right type of base.

Wooden or timber type

Solid soil and a light bathhouse design measuring 3x4 allow the construction of a structure on a wooden foundation. This type is ideal for clay soil, which does not suffer from excess moisture, but has seasonal mobility.

For the foundation, hard wood is used, preferably oak. It is treated with an antiseptic or covered with dust and moisture-proof materials: resin or oil with wax.

The wood should be as dry as possible before installation. After installation, the beams are secured on the sides with stakes.

Light sauna on a block foundation

A small bathhouse, when installed inside a heavy stove, can be placed on a base made of blocks. But this type of foundation is effective only with a shallow layer of soil freezing in winter.

To form the foundation, you need to install gas silicate blocks around the perimeter of the walls and secure them with soil. In this case, the blocks are set strictly according to level. Deviations are excluded.

Columnar option

Suitable for soil with an uneven structure and high groundwater levels, where a foundation of increased depth is being built. For reliable fastening, pipes are driven into the ground, on which the building is placed. No equipment is needed for the work. The tools you will need are: mound, cement, plastic or asbestos pipes.

Construction order:

- Level the ground and mark the installation points for the pillars.

- Drill holes up to 50 cm deep. Waterproof the bottom with polyethylene.

- Pour concrete and install the pipe at a depth of about 30 cm.

- Wait until it hardens and fill the pipe with concrete to the end.

A grillage is formed on top of pillars made of hard wood or metal. An economical and effective option for a frame bath on soft soil.

Pile-screw frame

When building a frame bathhouse with your own hands, its massive structure when built on deeply frozen soil requires the formation of a pile-screw foundation. Piles are driven below the freezing depth - to solid ground. The tying of the piles, as with the columnar type, is done with wood or metal.

Tape base

The heaving and reliable soil allows you to form a strip foundation for construction. It's easy and quick to build. The main thing is to complete the entire pouring of concrete at once to form a monolith.

Procedure:

- Forming a trench with a perimeter the size of the walls, 40 cm wide and 50 cm deep.

- Fill the bottom of the trench with 15-20 cm of soil. For better compaction, moisten it with water.

- Install formwork 50 cm high and 30 cm wide.

- Reinforce the foundation base. The reinforcement is tied together rather than welded together.

- Pour concrete.

To prevent concrete from deteriorating under the influence of moisture, it must be protected. Waterproofing is done with roofing felt or thick film. But it’s better to first add a waterproofing agent to the solution - it’s more reliable.

Photo of a bathhouse with optimal sizes

Spacious living room 5 by 6 meters

When placing a sofa against a wall, a great trick you can use is to hang a wide mirror or a large painting of a bright landscape above it. If the choice falls on the picture, then it could be a modular design. If the entire design is made in a classic style, then the picture can be framed in a baguette, but this will only make it heavier. Using canvas paintings on a stretcher is an ideal solution for minimalism and hi-tech.

Walls

It is better to decorate the walls or background of the room in light colors: white, beige, pastel yellow, light blue. Such colors, coupled with bright lighting, will visually expand the boundaries of the room and create lightness in the space. The color of the walls can be alternated and different shades of the same color can be used on the same wall. For example, the entire wall is light beige, but the area around the TV and above the bedside table can be painted light brown or dark yellow. Such decorative techniques will add additional details to the interior.

Ceiling

The ceilings in the living room can be made of glossy stretch ceilings. This is an elegant and inexpensive solution. If the ceiling surface is uneven, then using tension elements is an ideal option. They are installed quickly and are not expensive. The glossy surface of such a ceiling will visually expand the boundaries of the room.