I design frame houses. Price of the Architectural and construction section (AR and KR) RUB 3,00

per m² floor area (). Current price, 2021.

If you are going to build it yourself, then at a minimum you need a constructive section: a 3D model, drawings of walls, ceilings, rafter system and calculation of boards and cladding slabs. To order a project from me, we divide the work into three stages:

- I’ll send you a file to fill out, we’ll coordinate the dimensions, materials, plans, type and slope of the roof, location of window and door openings;

- I make a 3D model of your frame house, make all the changes;

- I make drawings, count boards and cladding slabs.

The price of the architectural and construction section is 300 rubles per m²

floor area (individual design, 3D visualization of your home, components and pies of walls, ceilings, roofing).

My address is in the Contacts section. Write and I will send you a file with questions for design.

I have made several dozen projects of frame houses for different regions of Russia. You will find examples of my work in this section. All these are real houses that were built according to my designs. I do not use ready-made automatic design programs, so each building has its own characteristic feature. They have one thing in common - the building rules and techniques that are used in Canada and America. Therefore, all my projects have a characteristic Canadian (North American) style.

How are other technologies different?

Frame design has a number of differences from the residential buildings we are used to. First of all, this concerns interfloor ceilings and wall construction. In most cases, boards are used. A small percentage accounts for the use of I-beams and LVL beams as structural materials, which is usually associated with the need to cover spans and open spaces. There are no fundamental differences in the designs of the foundation, rafter system, communications and external decoration from stone or wooden buildings.

In principle, any low-rise building can be designed in the Canadian version. In our country this is usually what happens: the customer finds a layout he likes, but for foam concrete or timber. I can keep the layout and appearance, but I am changing the design of the house to a Canadian one. The main reason is very simple - this option is cheaper to construct and more profitable during operation, since an energy-efficient wall with equal thickness to a stone or wooden one turns out to be an order of magnitude warmer.

How to order?

The main problem that everyone usually faces is where to find a person who can fulfill such an order using floor plans and facade views from another building. There are 3 solutions here:

Companies

Firms usually offer a dozen options for ready-made solutions that can be adapted to your wishes, or offer the services of an in-house architect. Quite a good solution, but very often you may encounter the fact that a company provides such a service, assuming further construction. The management does not agree to distract the architect, especially at the height of the construction season, since the profit is small;

Design specialist

The drawings can be made by a specialist who does only this. Such work is usually carried out by architects or design bureaus who do not have a clear specialization in a specific technology, but can apply their knowledge in this area;

Design yourself

The basic principles can be mastered by you on your own. For this there is all the necessary literature in the section. However, the manuals are usually in English. In this option, you need to be able to work in one of the graphic programs and subsequently use drawings and printouts for construction.

If everything is done taking into account standard solutions tested on millions of North American homes, then it doesn’t matter who does the work: you yourself or an architectural bureau. Today, an official project with a seal is not required for construction and registration of ownership, since the rules have been simplified by the law on dacha amnesty.

Be prepared for the fact that even if you order this work from a specialist, you will have to check the quality of its performance. People are not robots and can make mistakes, but this is rare. but the real problem is designing a pseudo-frame house. In particular, timber is widely used, the pitch of the wall posts is not adapted to the external cladding with slabs, the width of the insulation slabs is not taken into account, large spans are covered with ordinary boards. If in doubt, ask to see a couple of drawings from previous work and ask a few questions. The point is that further construction on this project should be ordinary work, and not a feat of labor and a search for solutions on the spot.

If you need help designing a frame house in SketchUp. Individual design and construction of frame houses in the Moscow region. My contacts are in the Services section.

The main differences between individual construction and standard private house projects

Surely every reader has at least once seen brand new, identical to each other, small, cozy houses located along a suburban highway. These are cottage villages built according to standard, unified designs.

On the one hand, such houses are time-tested and universal. The implementation of such a project, provided that it is entrusted to professionals, will not take much time and will not hit your pocket hard. In addition, the standard project already includes a plan for the location of residential and technical premises, as well as the distribution of communications.

Cottage village

The advantages of standard construction include the following factors:

- affordable cost of project implementation;

- short deadlines for construction and finishing works;

- a wide range of ready-made projects, allowing you to save development time;

- the ability to refine and slightly adjust the finished project in accordance with the wishes of customers;

- changing the interior, interior decoration.

Individual construction

– this is an opportunity to realize even the most daring ideas, create a unique, original facade of the house, as well as arrange the interior spaces in accordance with the needs of each family member, with their taste preferences in interior design. In this case, planning an 8 by 8 house, like any other, will take a little longer.

As a rule, individual projects attract future owners of private houses due to their uniqueness - only one house is built according to such a project. In addition, at the project development stage, all customer wishes are taken into account, even the most daring ideas are realized, which allows us to avoid further redevelopment of residential premises, as could happen with a standard project. Every detail of a future private home can be thought out in advance in order to quickly turn a well-designed project into reality.

Foundation grillage for a frame house

The thickness of the grillage in my case is 250 x 250 mm. The width of 250 cm coincides with the diameter of the pillars. The height is determined by the depth of the snow cover in your region. In the Moscow region, at least 400 mm. The grillage should be 150 mm above the zero ground level. Thus, the height of the grillage is 400 - 150 = 250 mm. When designing, the outer boundary of the foundation coincides with the external dimensions of the frame house. We design a grillage strip under all load-bearing walls, lay supports under the fireplace, the boiler in the boiler room and platforms under the porch. After drawing the foundation, we combine it into a component or group for further ease of work and calculation. Assign a name to the first layer (for example, foundation). In the future, you can hide non-working layers to facilitate access to other components of the frame house when designing. Once again, to better understand design, you need to understand how to create a component, layer, extrude an object, etc. These are basic skills and dozens of manuals have been written about this;

Cost of work

The final cost of preparing this type of document is influenced by a number of factors. First of all, this is the quality and level of initial information provided by the customer. The amount of data that needs to be processed is also important. For large objects it will be significantly larger. The customer’s special requirements are also taken into account (for example, the need to meet a certain budget or use specific materials).

You can find out the preliminary price by calling +7 499 350–47–31 and +7 495 233–05–56. We are waiting for your calls!

Frame house foundation piles

Foundation piles are laid below the depth of soil freezing (150 mm in the Moscow region), so the base of the pile should be below this mark. Once you've drawn the first pillar, organize it as a component or group. Using the copy function, we first place the pillars at all angles and places where the grillage strips intersect. This way we will get up to 60% of all pillars, which you cannot do without. Next, we use a simple rule: the distance between the pillars cannot be more than 2 m. We measure the distance between the required pillars. For example, 3.4 m. Accordingly, you need 1 intermediate post.

To quickly distribute intermediate pillars, you can use a simple technique - first divide the distance between the outer pillars by 2. For example, 6.9 m / 2 = 3.45 m. Round up to 4 to get 1.725 m between the piles. We copy the pillar and move it to the extreme position at 6,900 mm. Enter /4 Enter. 3 intermediate piles appear at equal intervals.

In my case, the average distances between adjacent pillars are in the range of 1.6-1.8 m. As a result, we get 34 piles under the grillage. We put 7 additional posts for the front and back porch. Finally, we combine all the pillars into a separate layer. The foundation is ready. Already at this stage we can calculate the volume of concrete:

Piles: 1 pile 0.125 m3 x 41 = 5.125 m3

Grillage: 70 m x 0.25 m x 0.25 = 4.375 m3

Front porch: 3.5 x 1.7 x 0.15 = 0.9 m3

Rear porch: 2.3 x 0.9 x 0.15 = 0.31 m3

Total: 10.71 m3

There is an alternative option for volume calculation using built-in plugins. More on that later;

Private house: advantages compared to an apartment

Own, presentable, cozy and comfortable housing without annoying and noisy neighbors is the dream of any modern person. Each of us, after a tiring day at work, dreams of proper rest, which is almost impossible to get in an apartment panel building. The individual layout of a private house, on the contrary, allows you to zone the space and create your own recreation area for each family member.

Modern house made of wooden beams

Why are private households so popular these days?

- The cost of building a private house is quite affordable:

thanks to the use of innovative technologies and modern materials, the price of a private house can easily compete with a city apartment, both in the secondary housing market and in new buildings. - Location:

the future homeowner can choose a site for development that will be located in a place that is as comfortable as possible for living and meets the needs of all family members. - Autonomy of communications:

heating and hot water in a private house, unlike those served by public utilities, will always be freely available and in the required volume. - Safety:

in the area adjacent to a private house, there is always a place where you can set up a children’s play area, set up a small garden, vegetable garden or flower bed, and also provide safe parking where the safety of the car will be guaranteed even in the absence of a garage.

We design the bottom trim of a frame house

For the bottom trim we use larch with a section of 38 x 150 x 4000 mm. Larch wood is heavier than pine and spruce, so it is difficult to work alone with 6-meter boards. So, let's create the first board in SketchUp. Select a fill. We create a component, assign a name and dimensions, in the future the Cut List plugin will count the number of components using this data. If you are working without components and groups, then leave 1 mm between elements. For convenience, you can hide the foundation layers (grillage and piles). The external boundaries of the lower frame coincide with the outer perimeter of the frame house and the projection of the internal walls of the frame house. For the convenience of leveling the horizontal level of the platform (in case of unevenness of the foundation plane), we design 2 strapping boards. This is completely optional and you can use 1 layer of boards. In this case, the cross-section of the grillage will be 250 x 288 mm, so that the plane of the first floor platform coincides with the height of all steps of the porch. To form the bottom trim, the functions of copying, dragging and rotating elements are used;

-+

We design the ceiling of the first floor

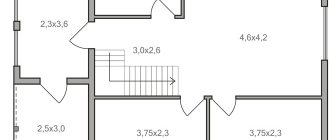

For my project, floors made of I-beams with a height of 200 mm were selected; accordingly, the outer perimeter, double-triple logs and spacers will be designed from boards with a section of 38 x 200 mm. If you cannot use boards (for example, when the height of I-beams or floor trusses is 350-400 mm), all these elements are designed from I-beams and frame trusses. But since for my project the maximum span does not exceed a length of 3.75 m, we will use the most affordable I-beams in combination with boards. We select the lag pitch to match the width of the platform’s outer skin sheet 1219 x 2438 mm, taking into account the recommended gap of 3-4 mm. To ensure that the first sheet covers the entire thickness of the outer board of the platform, we reduce the first step by half the thickness of the log 80/2 = 40 mm + 2 mm gap = 568.5 mm, then the standard log step is 610.5 mm.

This technique will be used when designing the walls of a frame house and roofing. Using a simple technique 610.5 Enter-*number of lags-Enter, we install lags with a given step in one operation. Using the same technique, you can install logs with a pitch of 407 mm or any other. Many materials in North America are manufactured with rapid frame house design and construction in mind. The directions of the lags are usually chosen in the direction of the shortest span of the rooms, the step is selected according to ready-made tables.

We install double boards in the projection of the internal walls. We also pay attention to the places where powerful load-bearing wall posts will rest. In these places we install additional blocks between the lags. This group of elements can be designed after the walls, focusing on the projection of the load-bearing posts. In the picture below I have marked these elements. The joists are created as components; after the design is completed, we combine all the floor elements into a layer. You can count the number of lags by hand or use the Cut List plugin;

Covering the first floor platform

The sheathing of the first floor floor platform will be made of osb/osp with a thickness of 18.3 mm tongue and groove. We draw the first sheet, save it as a component and then copy it along the horizontal axes with a step of 2442 mm and 1220 mm in a checkerboard pattern. We cut off the excess. The sheets are positioned with the long side perpendicular to the floor joists. As a result, for the 1st floor we will need 33 sheets of osb / pox with a thickness of 18.3 mm tongue and groove. In my case, the joists have different directions in the northern and southern halves of the house. We arrange the platform sheathing sheets in the same way;

We design frame walls

In this project, the load-bearing racks are made of boards with a section of 38 x 200 x 2'885 mm, together with the trim boards (1 lower and 2 upper 38 mm thick) this will form ceilings 3 m high. Typically, the design of load-bearing vertical racks for a frame house is carried out from a board with a cross section of 38 x 150 mm, taking into account the fact that we can then put a sheathing with a 50 x 50 mm block inside to form a cross frame. In this case, the thickness of the external walls will allow enough insulation to be installed to meet the thermal resistance requirements. But for this project, the finishing will be done by applying a “wet” facade, so it was decided to use a board with a larger width of 200 mm. The optimal pitch for racks with a cross section of 38 x 150 mm is 407 mm. The choice of racks with a cross-section of 38 x 200 mm made it possible to increase the pitch to 610.5 mm, taking into account the insulation of the inter-rack space of the external walls with mineral wool without cutting. So, we create the contours of future rooms by installing the bottom trim boards on the projection of these walls. For external 38 x 200 mm, for internal 38 x 150 mm. Internal walls are almost always made from 38 x 100 mm boards with 400 mm pitches, but for this project we chose 38 x 150 mm boards with 600 mm pitches for the interior walls.

The pitch of the external wall posts corresponds to the dimensions of the external cladding sheets. For this project, OSB will be used measuring 1219 x 2438 mm (4'x8′) with a recommended gap of 3-4 mm between sheets. As a result, the pitch of the osb sheets is 2442 mm, which means the pitch of the external racks will be 610.5 mm. The first post must be offset by 1/2 of its thickness (19 mm) for proper installation of the osb starter sheet. So, we install the outermost post, the next one is copied at a distance of ~592 mm (610.5-19 mm).

The next step is to copy the outer post component at 610.5mm increments. We will draw window and door openings and reinforced components later. We get a general wall frame that matches the dimensions of the sheathing sheets and insulation. In the future, this circumstance will allow the installation of sheathing and insulation to be carried out as quickly as possible with minimal trimming. If you choose cladding with sheets of 1250 x 2500 mm, then design the frame with a pitch of 626 mm or 417 mm. For internal walls, the step should correspond to the plasterboard dimension of 1200 mm, that is, 400 or 600 mm. For the first racks we also make an offset of 1/2 the thickness of the rack (19 mm).

After we have applied the frame mesh of the external and internal walls, we install window and door openings. To do this, you can use ready-made nodes of these elements, which are in every frame construction manual. I chose one of the schemes, but you need to understand that there are several alternative designs for window and door openings. It is better to create the opening components separately and then insert them into the frame wall structure. At the same time, we trim and remove excess posts. The basic rule is that the pitch we have chosen (610.5 mm and 400 mm for external and internal walls, respectively) should not be violated.

Please note that the height of the lower window sill should take into account the size of the radiator if you are planning this heating option. 90% of all windows in a frame house have common elements. The differences are only in the width of the horizontal elements. The choice of window opening sizes depends on your preferences. In the case of panoramic windows, the upper opening should be covered with a built-up beam made of boards. LVL beams are used for garage entrances. For doorways, you can ask the manufacturer of the entrance doors for the dimensions for a specific door model and design it with an accuracy of mm.

After completing the design of the first floor of the frame house, it is necessary to lay the jibs. To do this, take 1 board with a cross-section of 38 x 150 mm, turn it at an angle of 40-60 degrees and cut it into the outer posts of the frame house. In this case, the jib must “catch” at least one of the strapping boards. For internal walls, horizontal fire breaks are usually installed with a stand height of about 3 m or more.

After completing the stage, we combine all the elements of the frame walls into a separate layer. Additionally, you can divide all the walls into groups, which will further facilitate the preparation of drawings for construction;

Projects for year-round living of various sizes

The dimensions of the frame house, just like the material to be chosen, are absolutely free for your imagination. And in this case, frame builders win again, since the technology involves the construction of completely different parameters.

Up to 50 sq. m

Very compact, made as 6X6 or 6X8. Features: low price and speed of construction. There are usually no more than 2 rooms inside.

From 50 to 100 sq. m

This is an economical option for a family of 4-5 people. Most often these are one-story buildings that are equipped with an attic.

From 100 to 150 sq. m

More spacious, often two-story. Additionally there may be: a built-in garage, a balcony, a terrace, a ground floor. A strip foundation is usually offered for this building.

From 150 to 200 sq. m

A large country cottage of this size may include several bathrooms, an additional summer kitchen, a greenhouse or a gym. There is often a fireplace inside.

From 200 sq. m

Luxury villas feature a full range of rooms. Typically these are two-story buildings with an additional attic and basement space. The foundation is strip or monolithic.

6X6 m

Miniature Finnish houses often look like this. On the upper semi-attic floor there is a bedroom, and below there is a kitchen, a combined bathroom and a hallway. Relevant for a summer residence.

In the article, we described how frame house projects are developed with the calculation of materials, and also showed what they are like. To complete the topic, watch the video:

Source: youtube channel Andrey Chance - construction of houses using USHP

This information is not an official recommendation and is taken from open sources. The material in the article is not a guide to the legal rules for registering land, property, erecting and finishing walls, or conducting construction. The manufacturer is not responsible for legal advice, as well as for defects in the structure or its elements that arise during or after completion of construction work based on this information. To carry out such work, use the services of certified specialists in the field of law and construction.

We design interfloor ceilings

When designing the interfloor floors of a frame house, a simple rule must be taken into account: the racks and joists must be located on a single vertical axis. If it is not possible to follow this principle, then it is necessary to add frame racks to avoid weakening the supporting structure. We also additionally lay reinforced beams to support the walls of the upper floor. To do this, the racks are doubled or stacked depending on the load. The common dimensions of the external wall and platform slabs and the uniform spacing of the posts and joists make the design task easier. It also makes sense not to draw all the joists again, but to copy the ceiling of the first floor in increments of the height of the rooms. Most of the floor elements of the 1st and 2nd floors will continue to coincide. When planning the direction of the joists, it is necessary to take into account not only the length of the overlapped spans, but also the location of intra-house communications. For example, ventilation and sewer pipes have a diameter of 100 mm or more, so it is advisable to take into account their route when choosing the direction of the lag, so that in the future you do not have to lower the ceiling by 100-200 mm;

Designing the walls of the upper floor

The rule for placing frame wall posts on the same vertical axis should be observed when designing the walls of the second floor. Notice the vertical red lines - they show how this rule works. It is almost impossible to observe this principle for all racks, since, for example, internal walls have a pitch of 400 or 600 mm. To do this, a double strap is installed along the upper belt of the racks, which creates a belt for supporting the racks or joists. In Scandinavian countries, the technique of cutting into the crossbar racks is often used; this creates additional support for the racks of the upper floor. As with floors, the easiest way is to copy the walls of the first floor to the second level and then make changes. Each wall can be combined into a group for the convenience of preparing working drawings in the future. The presence of ready-made elements such as window openings allows you to copy them to the second floor level. For the appearance of a frame house, the presence of uniform elements reduces the feeling of chaos during design and will make the construction process easier for you in the future;

Modern private house: what materials to use for construction?

Modern technologies and materials for the construction of private houses are quite extensive: today, in the construction of houses, not only the usual brick and concrete are used, but also lighter materials that simplify the construction process, as well as ensuring a presentable exterior, a high level of heat and sound insulation of the building.

Note: The use of modern building materials allows the future homeowner to benefit not only in the cost of building a private house, but also in the speed of construction.

Wooden log houses, which are close to the Russian soul, have not lost their position, the houses of which are cozy and warm even in severe frosts. In addition, wooden houses do not require serious financial and time investments in finishing - facade and interior. A log house is built from high-quality rounded logs of the same diameter.

In order for such a house to last for decades, the wood must be properly dried and treated with special pest control agents. Modern construction involves the use of cheaper laminated veneer lumber, which in terms of quality is not inferior to a solid log and retains all its positive characteristics.

We design the roof and rafter system of a frame house

The roof truss system is essentially a frame wall at an angle to the horizontal. The upper end rests against the ridge beam, the lower end is attached to the harness. In this project, the third floor forms an attic space for non-permanent residence, so there will be no permanent staircase. The height of the attic ceiling should be sufficient for an adult (at least 2 m). We take a calculator and calculate the possible angles of inclination of the roof. In our case, 270 makes it possible to create an attic room with a given ceiling height and use 6 m of boards as rafters without extensions. To hold the ridge beam, we put 3 intermediate support posts into the project + in one place we attach the ridge beam to the ventilation shaft. Rafter pitch 610 mm. A rafter system made from boards 150 x 38 mm, taking into account the installation of sheathing under osb from boards 100 x 50 mm, gives a total of 200 m. The roof overhangs are about 0.5 m. It turns out that a 6-meter board forms rafters 5.5 m long, without an intermediate the supports will not withstand the snow load. Therefore, we place a support wall in the middle, which will form the side walls of the attic. The pier supports must coincide with the projection of the rafters. We form the ceiling of the future masarda with puffs.

A lathing made of boards 50 x 100 mm with a pitch of 407 mm for continuous OSB sheathing will form the basis for the installation of soft tiles. Similar to the main roof, we design cuckoos (in English they are designated dormer. For this project, 2 cuckoos allow us to get away from the barn-type gable roof and make the front facade of the house more attractive. Please note that the rafter system, the ceiling of the 2nd floor and the frame wall posts are aligned in a single vertical axis This allows you to design the frame as reliable as possible.

Modern private home: how to express individuality in the era of eclecticism

In accessible language, we live in a time when our society has not yet formed its own, individual style that corresponds to the general spirit of the era. Today, the layout of a one-story house cannot be done without referring to the historical architectural heritage, without mixing elements of various styles and trends from all times. The house plan with an attic, popular today, is direct evidence of this.

Classic private house

Of course, not every customer is sufficiently knowledgeable in the field of architectural trends, so there are often situations where the general style chosen by the customer is strict classicism, and the interior decoration is done in the Baroque style - the interior includes heavy wooden furniture, massive facades, luxurious decorative elements. This combination of styles in the project will certainly surprise the customer who sees the sketches for the first time.

Important! To ensure that the layout of a 10 by 12 house does not confuse customers with its clumsiness, the dialogue between future homeowners and the authors of the project should be conducted in a language that is understandable to both parties.

We design the external cladding of a frame house

To design the external cladding of a frame house, we use osb / pox with a thickness of 12.5 mm (1/2") in imperial dimensions of 1219 x 2439 mm (2′ x 4′), leaving a deformation gap of 3 mm. If the pitch of 610.5 mm or 407 mm is correctly observed, the short edges of the slabs will always fall on construction sites, joists and rafters. This will greatly help during construction to avoid wasted time and unnecessary cutting of material.

Using the example of my frame house project, I showed how to design it in the free Google SketchUp program. Additional functions of the program allow you to convert drawings from 3D to 2D and print them immediately before construction. You can also install the free Component Report or CutList plugins to count elements. It is not difficult to master the SketchUp program to the extent necessary for designing a frame house.

Standard solutions

The diagrams below show typical solutions. These schemes are not the only ones; there are possible options that can be found in the Download books section. But even they will help you avoid mistakes

Bearing wall

Please note the presence of double trim at the top of the wall. This allows you to distribute the overlying load onto the frame elements. A very common mistake is the lack of a stand to support the top lintel. This applies to doors and window openings. Usually the lower part of the strapping is done with 1 board.

Curtain wall

A non-load-bearing wall is somewhat “fragile” compared to the load-bearing version. The arrangement of the openings is simpler; it is possible to use a single strapping on top.

Rack locations

Corner designs

Particular attention to the design of corners. For some reason, this is where the largest number of mistakes are made. Corner joints are based on 3 principles: 1) it is necessary to insulate the corner; 2) create a strong supporting structure; 3) attach the outer and inner lining. The pitch of the racks is selected based on the number of floors and the thickness of the wall.

Window hole

The number of support posts and boards in the window lintel is calculated according to the tables. It all depends on the width of the opening in the wall. The lintel must have a minimum of 2 boards, but their number can increase to 3. Sometimes for large openings it is necessary to use LVL beams.

Internal walls and floor joists

1. The cut at the end of the joist cannot exceed 1/4 of the joist width

2. The hole in the joists cannot be located closer than 50 mm from the top or bottom edge, the diameter of the hole is no more than 1/3 of the width of the joists

3. The notch on the top edge of the joist cannot be more than 1/6 of the width of the board and cannot be located in the middle third of the joist.

4. Holes cannot be located in the middle third of the joists

5. Holes or cuts in the studs of non-load-bearing walls no more than 40% of the width of the board

6. Holes with diameters up to 60% of the rack width are allowed if these racks are doubled

7. The hole cannot be closer than 13mm from the edge of the stand

Opening in the ceiling

Openings for stairs or attic windows are also made using ready-made solutions. Double elements are actively used, as well as MetIz - metal hangers for boards.

1. To form openings, sections of composite beams are used, which are determined by the size of the opening.

2. If the opening width is less than 1.2 m, then you can use 1 board

3. The opening assembly, which is shown in the figure above, can be used if the opening is located no further than 900 mm from the supporting wall

4. If the size of the opening is more than 1.2 m, then the number of boards around the opening is doubled

5. Steel hangers can be used to fasten the opening boards

6. Logs adjacent to the openings, with a length of more than 3.6 m, are secured using steel hangers

Overlapping device

1. When the height from the ground is less than 450 mm, boards impregnated with fire and bioprotection or wood from oak or larch are used

2. A composite beam-transom, which is located closer than 300 mm to the ground, must be impregnated with an antiseptic or rot-resistant wood must be used

3. Bottom trim boards located on a concrete foundation, closer than 200 mm from the ground, are treated with solutions that protect against rotting

4. External finishing made of boards located closer than 150 mm from the ground is treated with protective solutions against rotting

The contact points between the bottom trim and the floor joists are subject to the destructive action of moisture. For these units, boards impregnated under pressure with antiseptic solutions are often used.

1. The diameter of the embedded studs is at least 12 mm

2. The bottom trim board is secured with at least two embedded pins, the distance between them is no more than 1.8 m

3. The bottom frame for a wall less than 600 mm long can be attached with 1 embedded stud to the foundation in the middle third

4. From the edge of the board to the embedded pin no more than 300 mm

1. The joists rest at least 40 mm on wood and at least 80 mm on concrete

2. The section and pitch of the lag are determined by the length of the overlap and the pitch of the lag. The length of the “overlap” of the logs is at least 75 mm, knocked down with 3 nails 90 mm

3. When installing the logs at the end, steel hangers or a support bar 50 x 50 mm are used

5. For log cross-sections from 250 x 50 mm, blocks must be used (any of three options)

Typical situations

- In general, you are satisfied with the proposed ready-made solution. You just want to make small changes, for example, replacing the garage with a sauna or swimming pool, or adding another guest room. After all, standard models may contain options you don’t need (for example, insulating the attic or having a garage that is too spacious). Or you have unusual ideas for correcting the project - tell us about them, and we will bring them to life.

- You want to create your own project focused solely on your needs.

All these tasks are within the capabilities of our employees. They will slightly transform the standard model or make it completely unique, and will help you plan every corner for maximum convenience and comfort for all members of your family.