The difference between steam and water heating

The operating principle of a steam heating system is as follows: water brought to a boil in a container is converted into steam, which then enters the heating radiators, heating them. There, the steam condenses, transforming into a liquid state, flows into the expansion tank through specialized outlets, and then goes back to the heat exchanger.

The difference between steam heat supply and water heat supply is considered to be, first of all, the circulation of different types of coolant. Secondly, the heat transfer is higher, and the rate of warming up the room is 3-4 times faster than that of a water heater. With similar costs for solid fuel, the efficiency of steam heating is greater than that of water.

To install steam heating, no large-sized equipment is required, which makes this heating system economical. If the system is inactive, pipes with water coolant may freeze over the winter. In contrast, a steam system can be started without much effort without such difficulties.

There are also certain disadvantages that a heating system with water coolant does not have:

- Heating radiators heat up over 100 degrees, which can be unsafe for those around.

- The heating system is very noisy

- Changing the temperature is difficult

- Inability to install a heated hydraulic floor system.

- Plastic pipes cannot be used for the system.

- An oven with a built-in steam heating system is difficult to use at the same time to cook food.

Features of low pressure systems

A common version of such a system is closed, using gravity return of condensate to the boiler, which does not completely fill the pipes, and an upper pipe distribution is used.

First, the system is filled with water to the required level, after which heating begins. The condensate flows down a common riser and, when a predetermined level is reached, is forced into the boiler.

In the same system with bottom distribution, it is recommended to install pipes with a slight slope in the direction of steam movement in order to reduce noise effects. At the point where the condensate is drained, a loop-shaped water seal is installed, which prevents the movement of steam onto the condensation line.

The steam velocity in such systems should be moderate, no more than 0.14 m/s. Otherwise, the steam will also capture particles of moisture accumulated on the walls. As a result, the system operates with more noise and increases the risk of water hammer.

Combined wiring, i.e. a combination of upper and lower wiring is used if pipes are laid under the floor of the upper or middle floor of the house. The lumen of the pipes through which water returns to the boiler will in this case be closed by condensate.

If the pressure in the system exceeds 0.02 MPa, it should be made open. The air is removed through a condensate storage tank, and to prevent steam from leaving the system, a condensate drain or water seal is installed. Water from the storage tank is pumped into the heat exchanger, which allows the storage tank to be installed below the level at which the heat exchanger is located.

The coolant for heating a private house with a boiler room is heated in a heat exchanger located in the boiler room. Upon reaching the operating temperature, the steam moves to a manifold that divides the flow into two circuits: for the main rooms and for the boiler room (+)

Do-it-yourself steam heat supply from a stove

In order not to install a heating boiler for the installation of a steam heating system and spend working capital on this, you can use the stove available in the house. It will act as a heat source with cheap solid fuel, moreover, it does not depend on the central gas and electricity supply. The steam generator is a heat exchanger, which can be made to order or in-house. The disadvantages of a stove-steam boiler are similar to those of a direct combustion stove or fireplace: the inability to accurately regulate the heating temperature, the lack of complete fire safety, and also the possibility of smoke in the room due to incorrect kindling. Similarly, a boiler stove has the same number of disadvantages as an ordinary one, but there are many more positive qualities.

Steam heat supply from the stove

Before steam heat is supplied from the stove, the heat exchanger should be analyzed for leaks. This can be done this way: kerosene is poured inside the device, and the seams are outlined with chalk. Places where the chalk has darkened indicate a leak, which means that this device cannot be used for a steam heating system.

To remove steam heat from the stove, the following components will be required:

- Heating batteries. Their number should be equal to the number of windows in the room.

- Heat exchanger

- Copper or tin pipes for condensate drainage and steam lines.

- Shut-off valves (air bleed valves, valves)

- Connecting fittings: elbows, pipe clamps, fittings.

- Spider fasteners for heating devices

- Hydraulic valve

- A reduction-cooling unit, thanks to which steam is converted into a liquid.

- A reducer to reduce the pressure from inside the system.

- Pump for circulation of forced type liquid.

- Welding inverter

Before starting work, a connection diagram and pipe installation are developed in advance. The drawing determines the location of the furnace-boiler, from which the wiring diagram with all the required connection elements is laid down. For heating an area of no more than 80 sq.m. A single-pipe connection diagram for heating devices is suitable. With this connection method, convector heaters heat up gradually, the first of them being stronger than the others. The two-pipe scheme is suitable for heating rooms larger than 80 sq.m. and two-story houses. The pipes are connected to the design radiators in parallel. If it is intended to install a system based on the principle of gravity circulation, the heat exchanger must be placed below all radiators and pipes at an inclined angle. In this case, it is necessary to install a pump for trouble-free circulation of the heating system.

After the scheme has been developed and all the structural details that are needed to assemble the heating system have been taken into account, you can make an estimate for the purchase of materials and begin to work.

After the scheme has been developed and all the structural details that are needed to assemble the heating system have been taken into account, you can make an estimate for the purchase of materials and begin to work.

Work methodology

It is worth considering that installing a steam heating system without dismantling the old stove is unrealistic. In order to build in a heat exchanger, you need to install it inside the combustion chamber at the furnace lining step.

Heating devices are installed under each window, to which inlet and outlet pipes are connected at a slight slope of 3mm. Each heating device is equipped with an air bleed valve.

Steam heat supply from the stove

To protect the system, shut-off valves are installed in front of each convector heater and in front of the entire system in general. A cooling reducer and pressure reducing valve are also installed at the beginning of the system. At the end of the system, a container is placed to collect condensate with a similar small slope as the pipes. From it, water flows into the heat exchanger. A pump is installed in front of the stove in a forced-type circulation system.

Work technology

If the house does not initially have a stove, then you first need to partially open the floors to place the foundation, lay the foundation, and cover it with roofing material.

The first row is laid on waterproofing. The following are placed in order, controlling the vertical with a level or plumb line. Fire-resistant wire is inserted at the door installation sites, tying the door contour.

The firebox is laid out according to the previously described technology.

The chimney is made of two layers. A metal pipe is installed as a base, and the outside is tied with thermal insulation. All that remains is to lay bricks around it, leaving space for the damper.

For safety, each connected radiator is equipped with shut-off valves and air release valves.

Mayevsky tap on the radiator

At the beginning of the heating system, a cooling reducer and pressure reducing valve are installed, and a condensate tank is mounted at a slight slope. The liquid from it will be directed to the heat exchanger. A circulation pump is installed in front of the furnace.

Adviсe

The chimney of a stove with an installed steam generator needs to be cleaned of soot more often. In order to ensure free flow of condensate to the lowest point, it is better to install the stove in the basement. Installing valves will help prevent dangerous situations from occurring, so it should not be neglected.

When installing a heating system in a wooden house, it is necessary to ensure fire safety measures by protecting wooden surfaces from overheating. To do this, the adjacent wall with the stove and the floor surface must be covered with heat-resistant material. A shutter valve for the combustion chamber and a blower must be installed at the stove. It is better to plan the placement of the stove-boiler not near the load-bearing wall for the convenience of the process of installing the smoke exhaust duct system.

The height of the smoke exhaust should not be less than 4 meters, otherwise the accumulated condensate will enter the combustion chamber. If the stove is located in a neighboring building (for example, a separate heat-generating unit), there is no need to dismantle and move it inside the house. In this case, it is necessary to properly insulate the pipe wire that connects this building with the stove and the house

In order to prevent the coolant from overheating more than 100 degrees, you can change the temperature if you completely close the vent and slightly open the furnace combustion chamber.

Manufacturing of grate

Steel reinforcement is the main material for this structural element. Experts say that the diameter of a 200-liter barrel is 57.15 cm, so the grate needs to be made smaller, since it will need to be installed inside the heating device. To secure it, you need to make projections from steel sheets between the ash pan and the firebox and weld them to the inner walls of the barrel. The grate must be installed on the received support pins.

Craftsmen recommend making wide doors to make it easier to clean the stove from the barrel, since during heating, burnt raw materials will fall into the ash pit. In addition, the optimal height of the ash pan is 10-13 cm.

Differences between steam and traditional heating

Steam heat supply operates according to the principle:

- First of all, water is heated in a container to a boil and turns into steam;

- steam passes through pipes to heating devices, giving off heat;

- in batteries, steam condenses, turning back into water;

- water flows through the outlets into the expansion tank and goes back to the heat exchanger.

Unlike a water heating system, a steam heating system provides greater heat output, heats the room three times faster, and is ergonomic. It requires small equipment, which, in fact, reduces the price of the system in general. Another plus: in an abandoned house, the pipes don’t freeze when it’s cold outside. Thanks to this, it is easy to start the steam heating supply by arriving at the dacha during winter, and when leaving, make sure that the fuel is completely burned out.

By the way, not only furnaces, but also boilers operating during mining can be used as a generator for steam heat supply. But in most cases, a system of this kind is installed in garages and utility rooms for environmental reasons.

Where is it used?

High efficiency indicators can only be achieved by installing special equipment in production where large volumes of steam are needed. Although, due to the danger, it was forbidden to equip public places and apartments with these types of devices, some large private country houses are quite successfully heated.

The solution is also perfect for implementing steam heating in a country house. But the purchase of components must be approached as seriously as possible; low-quality elements will easily burst at the slightest appearance of rust, since the walls will weaken somewhat.

Disadvantages of steam heating and ways to eliminate them

- heating devices from steam heat up above 100°C, due to which they pose a danger, especially for children and animals;

- the steam heating system does not stop working noisily;

- temperature control is difficult;

- impossibility of installing warm hydraulic floors.

The first disadvantage can be removed by protecting heating appliances and supply pipes with screens. There is a huge range of such decorative interior elements made of wood and plastic.

The noise in the system can be greatly reduced if you use anti-noise spider fasteners for heating devices when installing them, and install the steam generator itself in an individual room.

The 3rd point is hard to remove. But for the 4th, there is a solution - if you wish, warm hydraulic floors can be replaced with infrared film floors.

Attention! It is not advisable to designate a brick stove with a steam generator for heating and cooking at the same time, since it will still be unrealistic to use it in the summer months. Or, you will have to come up with an alternative option for the warm period. For example, perform a summer oven in clean air.

Also, plastic pipes cannot be used in the system; they will not withstand the temperature regime.

Advantages and disadvantages of a homemade barrel stove

Currently, there are many options for making your own stove for household needs. To assemble a potbelly stove, old gas cylinders and sheet iron are used. In the first case, it is quite difficult to get the necessary container. As for sheet iron, it is not cheap. However, there is a more accessible source material from which it is easiest to make a heating unit - a 200-liter metal barrel.

Using a metal barrel to construct a heating device has many advantages

Why is it recommended to use this volume? This is explained quite simply. When assembling a potbelly stove with your own hands, you need to make sure that it holds a large amount of fuel. This will maximize the time interval between loading new batches of firewood. In addition, the dimensions of such a container make it easy to allocate space for an ash pan.

Most often, these home-made structures are used for heating basements, garages, and workshops that do not have autonomous heating.

In order to answer the question of how to make a potbelly stove, you need to carefully study the instructions. Using a metal barrel to construct a heating device has other advantages. For example, the natural dimensions of the tank do not prevent the fire from burning freely. And also such a stove does not require the selection of special fuel.

Homemade structures are used for heating basements and garages that do not have autonomous heating

As with any other device, a homemade potbelly stove also has some disadvantages. During operation, the container body heats up to a very high temperature, since the metal sheet is small in thickness. Thus, while such a potbelly stove is operating, it is strictly forbidden to touch it. You can make a stove from a 200 liter barrel with your own hands quite quickly (in just a few hours).

Such stoves have low efficiency, which is explained by the peculiarities of their design. During operation, part of the thermal energy simply evaporates into the chimney. Experts do not recommend using coal as fuel for such barrels. It's all about its high combustion temperature, which thin walls may not withstand.

Installation diagram of steam heat supply from the furnace

- Natural and forced circulation system

A system operating on the principle of gravitational circulation requires placing the pipe coil below the level of the heating devices and all pipes at an angle. A forced system requires a pump to ensure uninterrupted circulation of the pipe coil.

Schemes also come in one- and two-pipe.

- Single-pipe steam heat supply scheme for a private house

This scheme operates on the principle of serial connection of heating devices. The coolant moves through the pipe, moving from one battery to another. As a result, the first heating device turns out to be the hottest, and the final one is almost cooled down. Due to this, it is best to use this scheme for rooms with a modest area - from 40 to 80 m2.

- Two-pipe scheme

This system is better suited for houses with large areas and two-story country houses. It is distinguished by the fact that the heating devices in it are connected in parallel, using two pipes: inlet and outlet (condenser). In this scheme, the coolant is supplied to all heating devices at the same temperature, since it does not have time to cool down.

Pipe classification

The construction of a steam pipeline requires the presence of 2 parts: a condensate pipeline and a steam pipeline.

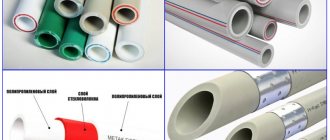

Pipes can be made of different materials.

- Steel. Such pipes are characterized by high strength and resistance to mechanical damage. However, they can become rusty if they are not first coated with an anti-corrosion solution. To install them, you must use a welding machine.

- Copper. This is a fairly strong, strong, durable material that can withstand high temperatures. The high-temperature soldering method is used to install copper pipes. The disadvantage of this material is its high cost.

- Galvanized and stainless steel. Such pipes are also not cheap. But at the same time, they have a long service life, are highly reliable, durable and resistant to corrosion.

- Cast iron. This is a classic version of pipes. Cast iron is characterized by special strength and availability. However, it weighs a lot, which is also worth considering.

Plastic and metal-plastic pipes are not used when installing steam heating, since these types of materials are not resistant to elevated temperatures.

How to arrange steam heat supply from a furnace with your own hands

Equipment and materials

For a steam heat supply device you will need:

- heating devices (under each window);

- heat exchanger - essentially a water tube boiler or steam generator;

- pipes for steam and condensate drainage - give preference to materials resistant to high temperatures: galvanized steel or copper;

- elbows, connectors, pipe clamps, spider fasteners for heating devices, shut-off valves: valves, air release valves;

- a hydraulic valve used to allow drying of the steam pipeline;

- pressure reducing valve to reduce pressure in the system;

- reduction-cooling unit;

- inverter device;

- container for collecting condensate;

- pump.

It is better to rent expensive equipment.

Heat exchanger

You will have to make a heat exchanger for a brick stove yourself or choose one. For this you will need metal pipes, a wall thickness of 2.5 mm and an inverter apparatus. You can combine them as in the picture or make them in the form of a coil. The main thing is to monitor the quality of the weld seams. The calculation is performed approximately like this: 1 m 2 of the coil surface delivers up to 9 kW.

After the design is made, you need to check it. To do this, you need to pour water into it and make sure there are no leaks. However, this method is not very informative, because welds may have slag inclusions, which will not be detected in the absence of excess pressure.

The best way to control the quality of seams is using the “kerosene on chalk” method. To do this, you need to chalk all the welds and pour kerosene inside the structure. If there is a tiny pore, the chalk will fade because kerosene will seep into it.

Sequence of work

The heat exchanger is built into the furnace at the stage of its laying directly into the combustion chamber

Next, according to the diagram, heating devices are installed under the windows. Inlet and outlet pipes are connected to them. For gravitational circulation - with a smaller slope of 3 mm per meter. Each convector heater should be equipped with an air release valve.

For safety, it would be a good idea to install shut-off valves in front of each heating device and one in front of the entire system. At the beginning it is also necessary to install a pressure reducing valve and a cooling unit.

At the end of the system, a tank is placed to collect condensate, from which water also flows downhill back into the heat exchanger. It would not be a good idea to use a membrane expander for this purpose, since it is designed for temperatures up to 85 ° C.

In a forced-type circulation system, a pump is installed in the return pipeline in front of the furnace.

How to heat a large house without extra costs

If you install a heat exchanger in the combustion chamber of an existing brick oven and create an external heating circuit, you can create stove heating with a water circuit. In this case, the register mounted in the firebox will serve as a solid fuel boiler. It turns out that two heating systems are concentrated in one place:

- oven;

- water circuit with register.

A water heater built into the firebox can be called a register, a coil or a heat exchanger, but the essence will not change. It serves to heat the coolant, which is supplied to the external heating circuit.

With this device, the brickwork is heated by heated air passing through the chimneys. At the same time, food and feed for livestock are prepared on the top plate of the combustion chamber. At this time, water is heated inside the firebox and sent to the circulation system. A circuit is created in the same way as when installing a conventional hot water solid fuel boiler. The chosen scheme is single-pipe. The peculiarity of circulation is that the entry into the register is significantly higher than usual. Therefore, the height difference in the circulation circuit must be taken into account.

The created combined scheme for heating a private house will allow one stove structure to heat up to 300 meters of living space, especially if a circulation pump is used in the scheme. However, then heating will depend on the operation of electrical networks. In the event of a power outage, the pump can be bypassed.

Such a stove for a home with water heating must work in conjunction with a register, so even in summer the system must be filled with water or the stove heating must be abandoned. The pipes in the firebox will become unusable if water does not circulate through them. Do not forget that the circuit must have an expansion tank.

Invisible moments when operating steam heat supply from a furnace

Brick stoves with a heat exchanger produce more soot in the chimney than in most cases, and it must be cleaned more often.

With a gravity system, the furnace will have to be built in the basement so that the condensate flows freely to the lowest point.

Do not neglect the installation of valves - they are needed for safety and elimination of accidents. Since the pump requires electricity, it is necessary to take into account that if the power is turned off, it will be impossible to stop the operation of the furnace.

Steam heat supply in a wooden house is installed according to a similar principle as in a brick one. You just need to follow fire safety measures - protect wooden surfaces from overheating.

Modernization of the design

A barrel with an internal volume of 200 liters can provide a decent amount of heat. But the heat transfer efficiency will be small. Some of the thermal energy will completely fly away into the pipe. Therefore, the stove needs to be slightly modified. This is done in the following ways:

The steps we have given will help you make your barrel stove more efficient. If you don’t find a sample for 200 liters, you can take one for 150 liters - there will be a little less space in it, so you will have to add firewood more often.

- Brick walls are built to the right, left and behind the barrel - they will work as a kind of heat accumulators.

- The stove is scalded with round pipes of small diameter (for example, ¾ inch) - a convector is formed, which will cause air circulation in the room and effectively remove heat from the stove.

- By lengthening the horizontal part of the chimney - pass it through the entire room in order to take away maximum thermal energy from combustion products.

We will offer you a few more ideas for upgrading a stove made from a 200-liter barrel. For example, you can line its interior with fire bricks. To organize the hob, use the cast iron insert in the top cover. Try to make a stove with increased heat transfer - weld two barrels together in height. There are also modifications with horizontal barrels.

Steam home heating from a stove

Heating with a stove has been used since the moment people thought of building a stove in their homes. The first furnaces, naturally, were not steam - they used either specialized shafts - rough ones, or only the heat that came from the stove. Immediately after its appearance, steam heat supply began to use the furnace as the main heating element in the system.

Scheme for connecting the stove to the heating system

The principle is very simple: the fire heats the pipe wire passing through the furnace. Water moves throughout the system due to temperature differences.

Manufacturing Instructions

During operation of the stove, its body heats up strongly, so such a heating apparatus must be placed on a monolithic fire-resistant surface. This could be a layer of concrete, asphalt concrete, metal sheet, or just earth. The stove must have its own chimney; connecting the device to the chimney of other heating devices is prohibited.

There are two options for assembling such a furnace: with a horizontal and vertical arrangement of the barrel.

Vertical model

Vertical potbelly stove from a barrel

Scheme of a vertical potbelly stove made from a barrel

The manufacturing process of a vertical furnace model looks like this:

- Prepare an opening on the side surface of the barrel to allow loading of firewood;

- The door can be purchased in advance or a cut-out part of the wall can be adapted: hinges and a handle can be welded to it, making it convenient to close and open the combustion chamber;

- A little lower than the combustion door, cut another hole for mounting the blower door. To make the blower itself, a thick-walled pipe, cut lengthwise, is used. It should be able to move along the metal slats, but not be completely removed;

- At a height of 20 cm from the bottom of the container, install grate bars - a metal plate with holes or a welded cellular structure made of reinforcement. To fix them, use a regular steel corner.

Option 1 - mesh grid

Option 2 – fittings

- You need to weld metal legs at the bottom of the barrel or simply install the structure on bricks;

- The role of the hob will be played by steel wire, which can be welded to the top lid of the oven;

- Brick lining (optional)

To protect the walls of the container from burning, the inner surface of the firebox can be additionally lined with refractory bricks, giving it a semicircular shape using a grinder. Masonry should be carried out using a kiln mortar containing 1 part fatty clay and 2 parts sand. The mixture is made with a minimum amount of water and should have a thick consistency;

- Next we make a chimney (more details below).

A hole for a chimney with a diameter of at least 15 cm is cut out from the side of the container in its upper part (or side). The height of the pipe must be at least 4 m. When installing it, the following recommendations should be taken into account:

- It is advisable not to install the pipe strictly vertically; the presence of horizontal and inclined sections increases the amount of heat received, but the number of turns should not exceed 3 times;

- the bending angle should be 30 degrees, and only in exceptional cases reach 45 degrees;

- horizontally located chimney elements cannot be longer than 1 m;

- to prevent condensation, the part of the chimney facing the street should be insulated with basalt wool;

- To reduce the load on the device body, the chimney must be attached to the wall.

On the chimney of a potbelly stove, you can install a rotary valve or a valve that moves along guides. Using this element, you can adjust the intensity of heated smoke removal and completely block the chimney during the period when the stove is not heated.

Horizontal model

The efficiency of a potbelly stove made from a 200 liter barrel will be higher if it is made and placed horizontally.

Potbelly stove from a barrel - horizontal version

Scheme of a horizontal potbelly stove made from a barrel

The algorithm of actions for horizontal placement of the container will be as follows:

- Place the barrel on its side;

- To ensure stability of the structure at the bottom of the container, you need to weld legs from a steel angle or small diameter pipes;

- In the upper part, cut an opening for storing fuel the full width of the barrel to make it easier to remove the grille and reflector;

- Install a metal reflector inside the container, which will separate the combustion chamber from the chimney and the grate (you can make it yourself from reinforcement rods;

- Cut another opening lower to allow air flow into the firebox and clean the stove from ash, or make it a separate structure by welding the ash pan. As a result, the design will look like this:

Inside view

- Weld hinges on one side of each hole and install doors of the appropriate size. For tightness, it is recommended to cover them with asbestos-cement cord;

- In the back of the container, make a hole for the chimney and weld the pipe. Further installation of the chimney pipe is carried out in the same way as for the vertical model.

- You can also weld a sheet of metal on top of the barrel and use it as a hob.

Final design

Why the actual furnace steam heat supply

No one forces you to build a furnace in order to replace the boiler with it. However, if you already have a stove, then installing a boiler is somewhat impractical. There are several reasons for this at the same time:

- heating with wood or coal will not be very expensive than other types of fuel;

- demolition of the furnace can cause additional expenses for repairs, and in some cases even capital ones;

- steam heat supply control is manual, which means the risk of automation failure is completely eliminated;

- heating with wood is the best option for a private village house or a country house;

- if the gas can be turned off, then the stove stops working only if there is no firewood or coal, and this is on the owner’s conscience.

Logs from fruit trees

Fruit trees also have good properties needed for a hearth. They are used both for stoves and for barbecues and smokehouses. Fruit wood has a very good aroma.

When cutting down fruit trees, it is advisable to store this wood and then use it to light the stove. It will also be used for barbecue and smokehouse. Most often, this wood can be purchased by cutting down old orchards. The most common trees for kindling are cherry or apple. Cherry logs emit more soot, but light up very well. Apple logs do not produce much smoke, therefore they are considered the highest quality fuel.

What specifics might there be?

Like any other heating system, steam heat supply using a wood-burning stove has certain disadvantages. It would be correct to use even a word that is not given and change it to specifics that may seem inconvenient to some:

- Sometimes the stove is located in a neighboring building. This is not uncommon, but a solution has been found. It is only necessary to pay great attention to the proper thermal insulation of the pipeline, which will connect the house and the building with the stove. Otherwise, a lot of heat will be lost.

- The coolant in the system can heat up above 100 degrees. This is due to the fact that in a closed space the pressure becomes greater when heated and, based on this, the temperature increases. Stopping the supply of wood or coal does not solve the problem; putting out the stove is also not an option. It will be quite simple to slightly open the combustion chamber of the furnace and completely close the vent so that the temperature from inside the system stabilizes. This is inconvenient, but it is quite possible to learn how to determine the required amount of fuel for a one-time use.

- The lack of automation means the impossibility of independent work. To maintain the desired temperature, you will either need to accept that until the morning the pipes and heating devices cool almost completely, or add a new portion of fuel in the middle of the night. This is also uncomfortable, although not critical.

- The risk of smoke in the room where the stove is located is quite high. Low atmospheric pressure, dirty chimney, damp firewood, poor quality coal - these moments can bring their own share of troubles.

Diagram of the wood stove and heating system

Main components

The key component of the system is the boiler. Its main purpose is to convert water into steam. Later it goes into the pipeline.

The boiler must be powerful enough to pull two floors at the same time

The design elements here are:

- pipe system;

- collectors;

- drum.

A container of water is also required. It is called the body of water. There is a special means of evaporation here, which plays the role of a separating element.

Steam space

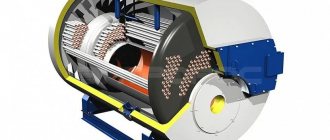

Additional equipment can be installed here. It can be useful if steam separation is required. Intensive exchange between steam and water is the basis of boiler operation. Heating devices are divided into water- and fire-tube. In the latter case, heated gases move in pipe channels arranged in a container of water.

Water tube modifications work on a slightly different principle. Here water moves through channels built inside a chamber with gases. First it heats up, after which it begins to boil. Water moves naturally inside the boiler.

In all types of boilers, the same rule for converting water into steam applies. First, the liquid is carried into a reservoir located in the upper zone of the device. It then flows into the collector and rises into the drum located at the top, moving through the heating area. Steam is formed inside the pipe and goes up. It can move through a separator where it is separated from the liquid. Then it goes into the steam pipeline.

Heating can be easily installed with your own hands

The boiler can use various fuel options. In accordance with these features, the design can be modified. Changes may also affect the type of operation of the combustion chamber. Let's say a grate is required for those cases where solid fuel is used. At the same time, special burners will be needed if the fuel is gaseous or liquid. Mixed options are more convenient and practical.

Radiators and pipe system

Temperature indicators in the steam system are within +100…+130°C. Compared to water ones, they are much taller. That is why it is not recommended to use similar equipment for arranging systems. This applies to pipes made of polypropylene and metal-plastic. The maximum performance indicators of these materials are within +90…+100°C; their use is strictly prohibited.

For the main pipeline, 3 types of pipes are allowed. Steel ones are considered the cheapest products. They manage to withstand temperatures of +130°C.

Condensation formed inside the parts leads to rapid destruction of the pipe material. We must not forget that steel is not resistant to corrosion. The aggressive coolant environment enhances this disadvantage. The connection requires welding, which requires a lot of time and labor. It is better to take galvanized steel pipes. These products withstand elevated temperatures and require the use of a threaded connection method. This approach greatly simplifies the workflow. The only thing that can serve as an obstacle to purchasing such products is their high price.

Another ideal option is copper pipes. The material is plastic, not afraid of thermal influences, durable, and not subject to corrosion. Soldering is used to connect copper components. Copper piping is durable, but expensive.

It turns out that in terms of the combination of price and quality, preference should be given to steel pipes that have a galvanized or anti-corrosion coating.

If you do everything on your own

Furnace steam heat supply can be done independently. Certain knowledge and, very importantly, tools are needed, but acquiring them is not a big problem:

- The stove should be located in a place where it will not be a hindrance to residents. And the point is not that she will ask for free space for herself. Adding firewood or adding coal - sometimes smoke escapes, and then the risk of absorbing a “smoky smell” is very high.

- If you need to choose between a steel and plastic pipe, then it is better to go with the first option. Iron wire pipes for air heating are the most suitable, since the economy in this case cannot be compared if gas or liquid fuel were used. Thanks to this, it is possible to make the pipeline diameter larger, thus increasing the volume of the coolant. But the area of the metal from which heat will emanate also increases. So it makes sense to think about this.

- The stove is made of metal or fireclay brick. Two options worked well. But there are differences, and for some they are fundamental. For example, a metal stove cools down much faster after the last batch of wood or coal has burned out. Brick retains heat longer: even if the stove goes out in the evenings, in the morning you will feel a temperature of about 30-40 degrees on the surface of the brick. For steam heating, this will not play a special role, but if the stove heats a separate room, then it is better to look in the direction of brick.

Water heating system circuits installed in the furnace

Steam heat supply using a furnace is an affordable option, although with characteristic features. However, this option has been tested over time and has proven itself very successfully. So you shouldn’t discard it outright.

Choosing the best option

It will be difficult to install a massive brick stove in an already built house. In this case, water heating is best organized on the basis of a metal potbelly stove, which can be placed on a reinforced wooden floor without pouring the foundation.

However, if it is possible to make the foundation as it should be, then preference should be given to a more reliable brick stove structure.

The water circuit around the house for a wood-burning stove is best made from thick steel pipes and with natural circulation of coolant

Installing a circulation pump and/or accumulator in the heating circuit in question is a waste of money and zero additional benefit. They will only complicate the installation of the system. And if the lights go out, these devices will create problems. Whereas the heating option without them will continue to calmly heat the house if there are problems in the electrical network.