- Functions of devices used for piping a gas boiler

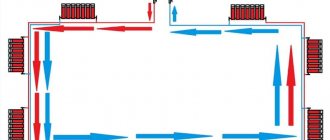

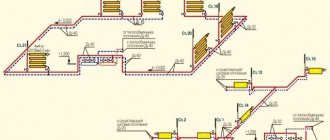

Two-pipe heating scheme for a house with a hydraulic arrow and collectors, designed for the ground floor and 1st floor

Advantages and limitations of gas heating systems

✍ Advantages of heating with gas:

- Affordable price;

- High efficiency. The efficiency of gas boilers ranges from 80% to 90%. Some manufacturers claim energy efficiency of 96-98% efficiency, but in reality this is manipulation of numbers;

- Small dimensions combined with equipment performance;

- Operation does not require frequent maintenance or special knowledge. Most products operate automatically;

- The gas boiler does not require loading with fuel and subsequent cleaning;

- Installing a double-circuit boiler will make it possible, in addition to heating the house, to use hot water.

✍ But this system has technical limitations:

- The operation of the equipment, especially if many automatic devices are installed, is carried out using a programmable microcontroller, which cannot operate without electricity;

- Power surges and power outages will cause a breakdown of the heating system; the control board, even with protection, can burn out;

- In the room where the gas boiler is installed, reliable ventilation must be installed; the room must have an area and volume that meets the standards;

- Before installing gas equipment, you must obtain special permits; the installation of the system must be carried out by specialists who have permission to do this work.

Required documents

To obtain technical conditions, the following documents must be attached to the application:

- passport of the gas boiler, which comes with it in packaging from the manufacturer;

- installation and operating instructions;

- quality certificate;

- a certificate stating that the boiler complies with the standards and requirements put forward by the state in relation to gas equipment.

For private houses, Raigas often offer to issue a technical certificate for the premises where the boiler will be placed. This document records the purpose of the room. That is, it is now either a boiler room or a furnace room. Separate buildings fit the definition of the first. For the second, premises built into the house or attached to it.

✍ Basic operational characteristics of gas boilers

Household gas boilers differ in several ways:

- Device installation method;

- Device power;

- Type of gas burner;

- Method of creating traction;

- Burner ignition method;

- Combustion chamber view;

- The material from which the heat exchanger is made;

- Number of circuits used.

✍ Device installation method

- Parapet. Low-power devices, in the range of 5-15 kW, are used for heating small houses. Mounted on the wall, it is permissible to install it under a window. At the installation site, a coaxial chimney is installed through the wall;

- Wall-mounted. They produce devices with power ranging from 10-35(40) kW. The boilers are small in size; you can find stylish models that can be placed in the kitchen, openly, without hiding it with a false panel. Well suited for one- and two-story buildings of medium size with good insulation of external walls;

- Floor-standing. The most powerful devices used in private homes are productive with great capabilities. Installation of a chimney pipe is required, sometimes a special room is required for installation.

✍ Number of circuits

- Devices with one circuit. Designed only for heating the coolant;

- Devices with two circuits. In addition to the heating function of the house, it serves to heat water. They can be with a built-in boiler or flow-through. Devices with a boiler are more economical, but more expensive and larger in size.

✍ Type of traction

A boiler requires a continuous supply of oxygen to operate; the method of supplying it is called draft.

Natural cravings. Fresh air comes naturally from indoors. Combustion products and water vapor are removed through a vertical chimney. These boilers have a simple design, and accordingly, the device costs less. They are non-volatile and operate quietly, but such boilers are affected by the gas pressure in the gas duct. When the pressure decreases, the burner flame goes inward, as a result the burner may burn out.

Forced draft. These devices have air supply fans. Combustion products are removed through a coaxial chimney.

These devices have advantages:

- Only air coming from the street is used;

- No expensive vertical chimney required;

- Works stably at any pressure;

- It is permissible to place it in any room; there is no need to make a separate boiler room.

Disadvantages of a forced draft boiler:

- During operation, the high-performance fan makes a lot of noise;

- It costs expensive;

- Depends on electricity.

✍ Heat exchanger material

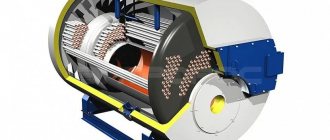

This is a boiler element that is subject to severe dynamic thermal loads.

They are made from materials such as:

Cast iron

Lasts up to 40 years, resistant to chemicals contained in the coolant. Due to the large mass, the coolant may continue to heat when the boiler is no longer burning. But it has disadvantages:

- Cast iron is fragile and can crack if handled carelessly;

- Hard water cannot be used as a coolant;

- A temperature difference between inlet and outlet is undesirable for the material. Stresses appear inside the metal due to non-uniform expansion.

Steel

They last up to 25 years; steel heat exchangers resist mechanical deformation and high temperatures well, but they are susceptible to corrosion, which can occur if used incorrectly.

Copper

The highest quality and most durable material used in the manufacture of heat exchangers. Although they are expensive, they do not lose popularity thanks to:

- The thermodynamic qualities of copper improve the heating of the coolant; it occurs evenly without creating an overheating zone;

- Copper resists corrosion well and does not develop sediment or scale;

- The walls of the heat exchanger can be made thin, which reduces the weight of the product.

✍ Ignition method

In gas boilers, 2 types of ignition are used:

- Semi-automatic or manual. The gas is ignited with a piezoelectric element or a simple match. A small burning wick appears in the boiler, and with its help the burners are ignited. In this case, the injector consumes a lot of gas throughout the year;

- Auto. This method significantly saves gas consumption, while at the same time increasing the safety of boiler operation. The big disadvantage is that the operation of the equipment is completely dependent on the availability of electricity.

✍ Type of gas burner

Gas boilers use 2 types of burners:

- Atmospheric - the oxygen required for combustion is supplied by natural draft. Used in devices with power up to 70 kW. They create almost no noise, but their efficiency is low;

- Ventilation – air enters the burner under pressure, which makes it possible to use different modes of operation of the device. Allows you to maintain the specified coolant temperature and has high efficiency.

✍ Power

Gas boilers are divided by power into one- and two-stage devices.

Single-stage devices are budget boilers with low automation. This equipment is operated manually;

Two-stage – make it possible to change the performance of the equipment. This is called the transition to winter and summer mode.

Using equipment in different modes allows you to:

- Gas costs change, which allows you to save a lot;

- The number of on and off cycles is reduced, which seriously reduces the load on the equipment allowing it to work longer.

Functions of mechanisms installed when piping a gas boiler:

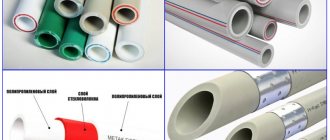

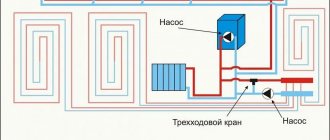

- Expansion tank. In systems with gravitational circulation, it is permissible to use a non-sealed tank; in closed systems with forced circulation, a membrane tank is used. It is designed to compensate for the thermal expansion of the heated coolant;

- Circulation pump. Serves to move coolant through the system and regulates its speed;

- Comb. A device used to uniformly distribute the coolant supplied to the system throughout all existing circuits of the heating system. It is equipped with metering and control sensors and shut-off valves;

- Safety group - devices mounted on a special comb, connected to the boiler piping. Among them are a pressure gauge, a safety valve;

- Mud trap - a coarse filter embedded in the water supply pipe;

- A hydraulic arrow is a vertically located closed container to which the return and heating circuit are connected.

A boiler with a circulation pump consumes a lot of electricity. To guarantee uninterrupted power supply, you need to purchase a diesel generator.

Recommendations for choosing a boiler

When choosing a gas boiler for your home, you will have to choose between a wall-mounted and floor-standing model. It’s difficult to make a choice here, each of them has pros and cons, you need to take into account the conditions under which the device will operate.

✍ Double-circuit and single-circuit models

This applies to wall-mounted appliances; if you live in a small house with a kitchen and one bathroom, then buy a double-circuit boiler - it will provide you with hot water.

If there are several bathrooms in the house, then install a single-circuit device together with an indirect heating boiler.

✍ Gas consumption

When choosing, you are guaranteed to ask the seller: “how much gas will the boiler consume to heat my house.” One seller will name the figure 5-6 cubic meters per day, and another 7-8 cubic meters. Of course, you will buy the one that uses less gas.

The mistake is that you asked this. No one can say exactly what gas consumption will be. This does not depend on the boiler, but on the heat loss of the building. All houses will have their own!

✍ Boiler efficiency

It's rare that a manufacturer will tell the truth about the efficiency of their products. It is important to know that wall-mounted products always have higher efficiency than floor-standing models. The ceiling of this parameter has long been reached, and the real efficiency can differ only in hundredths of percent.

✍ Heat exchanger made of copper or aluminum?

Aggressive advertising convinced us that there could be nothing better than copper. Of course, this is true, at the same time, the efficiency of a boiler with an aluminum heat exchanger decreases by no more than 1% over time. But by installing an aluminum heat exchanger, the manufacturer is actually trying to save money.

✍ 106% for condensing boilers

You can find condensing models in the store, as they claim to have very high efficiency.