Efficient home heating is one of the most important tasks for every homeowner. An interesting solution to this problem could be a steam heating system, the operating principles and design of which differ from the usual water circuits.

This is not the easiest option, and has its own strengths and weaknesses. We will talk about the rules of design and organization, the features of the system with a vapor coolant. You will learn how to install steam heating in a private home and how to operate it correctly.

Principle of operation

When installing steam heating in a dacha, a stove or boiler is used as a heat source. With their help, water is heated to boiling point, then the evaporation process begins. The steam penetrates the batteries through the pipeline, gives off heat, and gradually condenses. The resulting water flows into the heat exchanger through the return pipe.

Steam boiler

When choosing a water heater, it is extremely important to pay attention to the performance of the unit. The larger the area of the heated premises, the more powerful the heating device should be.

In houses with steam heating, a solid fuel boiler is often used. A modern gas heat generator is comparatively more efficient. Using an electric device to heat a home is not economically profitable, which is associated with high costs for electricity.

Household steam boilers are used as a heat source for heating a house: they heat a container of water and drive the resulting steam into heating pipes Source eurosantehnik.ru

Bake

If the house has a stove, it can serve as a heat source when installing steam heating. This will save you from additional waste on dismantling the device and repairing the premises. It’s also worth remembering: coal and firewood are inexpensive fuels. When using it, there is no dependence on centralized electricity and gas supplies.

The steam generator is a heat exchanger; you can make it yourself or order it. The design itself is quite simple, consisting of interconnected metal pipes.

If you plan to use a wood stove as a heat source, you should immediately calculate and design a special heat exchanger Source 1-teplodom.ru

Outdoor games for two

- Above your feet - reminiscent of the modern challenge “The floor is lava.” While walking or communicating, you need to suddenly shout “Higher than your feet off the ground.” The participant must lift his feet off the ground in any way: sit on a bench, hang on a horizontal bar, climb a tree. The last one to find room to raise his feet and perform the action is considered the loser.

- Bowling - you will need a ball and plastic bottles that can be filled with a little water for stability. The task is to knock down as many bottles as possible with the ball.

- Quest - one person hides an object, the second, using notes with puzzles and riddles, looks for it.

Advantages and disadvantages

Equipped steam heating at the dacha has the following advantages:

- provides intensive heating of rooms;

- steam instantly reaches all areas of the heating system, regardless of its complexity or the size of the building;

- pipes never freeze;

- does not require large expenses for the device;

- can be used in buildings for seasonal residence, for heating several floors;

- maximum heat transfer coefficient;

- Can be used together with heated floors.

Flaws:

- circulating along the circuit, steam creates a lot of noise;

- pipes and batteries can heat up above 100°C, which creates a risk of burns upon contact;

- it is difficult to regulate the indoor air temperature;

- the system is susceptible to corrosion, so it does not last very long;

- in the event of a pipeline breakthrough, a dangerous emergency situation is created (the coolant temperature reaches high values).

Important! Steam heating can be used to heat a house with several floors. The steam rises independently to any height, cools, and returns as condensate. Moreover, the installation of expensive pumps is not required at all.

What games can you play together in the hospital?

- Rock, Paper, Scissors - Players must say the name of the game and count to three. The players' hands are clenched into fists. On the count of three, you need to draw one of the figures in the name. The stone beats the scissors, the scissors cut the paper, the paper wraps around the stone. Whoever has the stronger symbol wins.

- Lotto – you need cards and barrels with numbers. It is necessary to take the barrels out of the bag one by one and check whether the dropped number is on the card by marking it (covering it with a chip). Whoever closes the horizontal line (or all the numbers on the card) faster wins.

- Yes and no - the player makes a wish for an object, character or movie. The opponent’s task is to guess what the opponent has in mind by asking a minimum of questions that can be answered affirmatively or negatively.

Scheme

The heating system operates thanks to natural circulation. Therefore, the heat exchanger must be installed below the level of the radiators. The circulation pump ensures constant operation of the thermal circuit.

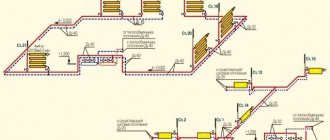

There are open and closed steam heating circuits: in the first case, the system is connected to the atmosphere (open), in the second, it is completely isolated from the effects of atmospheric pressure Source s-proms.ru

Steam heating in a house involves the installation of a one- or two-pipe heating system. The optimal choice of the latter depends on the area of the building that is planned to be heated.

Single-pipe

With single-line wiring, radiators are connected in series. The resulting steam passes through a pipeline from one battery to the next. As a result, the first radiator is always the hottest, the last one is almost cold. The single-pipe system is suitable only for small-sized rooms (no more than 80 m²).

Two-pipe

If the house has a huge area, a two-line heating option should be used. A constant supply of hot steam is carried out through the upper pipe. The cooled condensate returns to the heating unit through the lower pipeline. Regardless of the distance from the boiler, all heating batteries heat up evenly.

A single-pipe heating system is more suitable for heating a summer house or a small house; for a spacious cottage or two-story building, it is recommended to use a two-pipe system Source gubernia.media

Overhaul of heating systems in a private home

Major repairs of home heating systems, as a rule, involve their partial or complete reconstruction.

With proper preparation, such repairs can be done by yourself without damaging the interior of the home. Currently, the market offers modern, functional and high-quality press fittings that allow you to repair home heating systems without soldering and welding, which is very convenient in cases where major repairs of heating systems do not involve repairing the house itself. This is the most cost-effective solution for doing home heating system repairs yourself.

Major repairs of home heating systems may include the following work:

- boiler replacement;

- replacement of radiators;

- replacement of pipelines;

- replacement of individual sections of home heating systems;

- replacement of the entire heating system;

- other repair work related to the replacement of certain parts and assemblies.

Heating diagram for a two-story house.

Major repairs of home heating systems can be spontaneous or planned. Of course, the second option is more preferable, because involves the opportunity to thoroughly prepare for its implementation with your own hands, to purchase the necessary equipment and materials. All other things being equal, this is the most profitable solution. However, practice shows that another option is much more common. Often, a major overhaul of home heating systems is caused by an urgent need, when it is no longer possible to avoid it. Sometimes this entails eliminating many serious problems, because even the most experienced technician may not immediately understand a system unfamiliar to him, not to mention doing the repair himself.

The likelihood of such cases can be minimized. Timely measures taken make it possible to independently choose the time for major repairs and slowly do it yourself. It cannot be completely avoided, because any equipment has a limited service life and sooner or later it will be necessary, for example, to replace the boiler or lay new pipelines.

Materials and equipment

To properly equip steam heating, you need to prepare:

- heat exchanger;

- radiators;

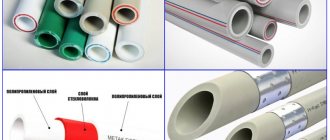

- pipes (preferably galvanized steel, copper);

- pressure reducing valve;

- brackets;

- valves;

- clamps, elbows, fasteners;

- welder;

- hydraulic valve;

- reduction-cooling device;

- pump;

- container for collecting condensed steam.

Advice! To minimize the cost of organizing steam heating, expensive equipment can be rented.

Radiators for steam heating are selected in accordance with the characteristics of the material from which they are made, taking into account the operating temperature Source otoplenieblog.ru

Heat exchanger

When building a brick stove, a heat exchange device will have to be ordered or made on your own. To do this you will need a welding machine and metal pipes. The thickness of the walls of the latter should be more than 2.5 mm. By welding they must be connected in the form of a coil. In addition, it is worth taking care of the tightness of the joints. It is important to take into account that 1 m2 of the surface of a curved spiral produces about 9 kW.

After creating the structure, it is important to check for permeability: fill it with kerosene, then outline the seams with chalk. Darkening of the latter will indicate penetration of a flammable liquid into the heat exchanger. Therefore, it is unacceptable to use such a device for heating with steam.

Self-manufacturing of a heat exchanger is only possible for people who have certain skills, tools and knowledge Source heatylab.com

Installation process

Steam heating in a private house from a stove should be installed in this way:

- When building a stove, place the heat exchanger in the combustion chamber. If the stove device is planned to be used for cooking, there should be no pipes left on top.

- Install radiators and connect the pipeline to them. To ensure natural circulation in the future, it is necessary to maintain a slope (3 mm per 1 m).

- All converters must be equipped with valves designed to remove air.

- For safety reasons, install a shut-off valve in front of each battery or one for the entire system.

- At the beginning of the circuit, install a cooling device, a pressure reducing valve.

- Connect a container to collect condensate. From it, water will flow at an angle back into the heat exchanger. It is not advisable to use a membrane expander: it is not designed for temperatures exceeding 85°C.

- When using forced circulation, install a pump directly in front of the stove (in the return circuit).

Important! Heating systems with natural circulation of steam do not require the installation of a tank or pumping equipment. Therefore, their work does not depend on the presence or absence of electricity.

If heating is planned to be done with solid fuel (for example, wood), then metal pipes must be used to install the system Source 1poteply.ru

Do-it-yourself solutions to common heating problems

Typical heating problems in a private home can be solved with your own hands. Prepare the necessary tools for this:

- Drill.

- Gas and adjustable wrenches.

- Hammer.

- Screwdriver.

Diagram of a heating boiler for a private house.

Depending on each specific situation, you may need other tools, but you definitely won’t be able to cope without the above.

If one or several batteries heat poorly or do not heat at all, then first of all you need to check whether there is air in them using air vents. If water flows from the drains, but the battery still does not heat, make sure that both taps of this radiator are open. The next step is to check the radiator for clogging. To do this, other heating radiators that heat normally and are located on the same branch as the faulty one must be shut off so that all the water flows through this battery. If it starts to warm up, it means it is not clogged. In this case, it is necessary to perform hydraulic leveling of the branch, i.e. cover the remaining batteries on the branch so that more goes to the non-working one.

Be prepared for the fact that leveling will take quite a long time, because the heating system can respond very slowly to changes in its settings.

If the taps in front of the battery are completely open and it is cold, then it is clogged (which is extremely unlikely). Basically, the last batteries on the branch may not heat up. However, this can always be corrected by hydraulic leveling. If suddenly someone tells you that “it just doesn’t pump there” or “the pump power is not enough,” do not rush to believe and touch the pipes or pump. In order to “not pump too much”, it is necessary to make many mistakes when installing the heating system, the probability of which is negligible.

Another fairly common problem is a drop in pressure in the heating system. Once again, we need to remind you that after starting the heating system you need to let it work for several days or even weeks. Air is dissolved in the heating system, which comes out during manual deaeration and automatic air vents, but it does this gradually. This leads to a decrease in pressure in the system. At first, frequent replenishment of the heating system is quite commonplace. If the heating has been running for more than a month and the pressure is still dropping, you can check the next version.

If the volume of the expansion tank is incorrectly calculated, pressure surges in the heating system may occur, as a result of which the safety valve may operate (discharge water). As a result, when cooling there will be a drop in pressure. If everything is fine with this, then the problem is a leak in the system and you will have to find a leak.

Another fairly common problem is pressure surges in the heating system. The expansion tank is responsible for compensating for changes in the volume of the heating system. Consequently, if the pressure changes over a wide range when the temperature changes, then the reason is precisely in the expansion tank: it is either broken or its required volume was calculated incorrectly. This usually leads to the safety valve tripping or even stopping the boiler due to insufficient pressure in the system. To resolve this problem, it is better to contact specialists.

Useful tips

When selecting equipment for creating a steam heating system, during its installation it is advisable to take into account the following recommendations:

- You cannot use used heating radiators. They are highly likely to have hidden damage, which will subsequently cause the system to depressurize.

- It is not advisable to use cast iron batteries. Under the influence of large temperature changes, they begin to collapse.

- Installation of the circuit must be carried out by workers with certain knowledge and skills. Otherwise, the created design may be ineffective.

- If you install a steam generator in a conventional wood-burning stove, you can significantly save usable space. In addition, home heating costs will be minimal.

- When using natural circulation, it is recommended to install the stove in the basement of the house. This will ensure that condensation quickly drains to the lowest point.

- For safety reasons and to prevent emergency situations, you cannot refuse to install valves.

The installation of steam boilers in a central heating system is prohibited by law. In private homes, this type of autonomous heating can function for decades without requiring replacement of the main structural elements.

The chimney of a stove with a built-in heat exchanger gets dirty faster than a conventional stove, so it needs to be cleaned more often Source roof-tops.ru

Reducing clearance in old heating pipes

Lime deposits and rust reduce the internal diameter of a metal pipe by more than half

In old “Khrushchev” buildings, problems in the heating system are obvious and predictable. There, the service life of the pipelines has long expired, and therefore they cause not only a decrease in heat, but also accidents. Over many decades, the pipes become so clogged with sediment that they are unable to provide normal circulation. The decision must be drastic - replace all the pipes.

In addition, a decrease in pressure in the system is caused by the formation of scale on the heat exchanger of the heating boiler. Using too hard water leads to such consequences. To prevent a similar problem with heating devices, special water softening agents are added to the system.

How does steam heating differ from water heating?

In a water heating system, the coolant is often water. It moves inside the pipeline and gradually cools there. In the case of steam heating, the liquid being poured evaporates and hot steam moves through the pipes. After cooling, it condenses and then flows through the return pipeline back to the heating unit.

When the coolant is steam, the thermal output of heating devices is significantly higher, rooms heat up three times faster. Such a system starts up quickly even after a long break in use.

Additionally, it is worth noting the lower cost of materials for steam heating devices. This is explained by the use of compact and ergonomic equipment during installation (for example, pipes of relatively small diameter).

Unlike water heating, steam heating gives greater heat transfer and warms up the room three times faster Source pechiexpert.ru

Construction of an installation without a project

Repairing a heating system is often more difficult than building a new home from the very beginning. Therefore, if you decide to make changes, it is worth making a project. Moreover, the house and the need for heat could have changed significantly over the years - the walls were insulated, the windows were replaced, and so on. Carrying out calculations and re-adjusting the boiler and radiators can bring significant savings - at the investment stage, if we do not buy an unreasonably large boiler and radiators, and during operation, since an incorrectly selected boiler will operate with less efficiency.

In addition, there are many elements in the system, the parameters of which must be selected by a specialist based on calculations; sometimes it turns out that switching two radiators in the same room helps to balance them hydraulically, without significant damping of flows using valves.

And such intensive damping means, for example, a higher load on the circulation pump, higher energy consumption and unpleasant squeaks and noise from the system.

Appliances operating on liquefied gas are placed indoors below ground level

Liquid gas, i.e. Liquefied gas has a higher density than air, so in case of a leak it accumulates on the floor of the room. This is contrary to natural gas, which, lighter than air, rises to the ceiling, where it is removed by ventilation (exhaust grilles are installed at a distance of at least 15 cm from the ceiling).

Due to this property of liquefied gas, the equipment supplied with it should not be installed in rooms whose floor is below ground level - in the event of a leak, liquid may accumulate in them.

Boiler room is too small

This problem applies mainly to solid fuel boiler houses, since their cubic capacity must be at least 30 m3 - with a room height of about 2.6 m, which means a surface area of about 12 m2.

In addition, there is a second condition - a minimum of 4 m3 per 1 kW of the rated power of the boiler, so a boiler with a power of only 7.5 kW can be installed up to 30 m3!

If you are switching to a boiler that runs on liquefied gas, this can become a serious problem, since the minimum volume of the room with a gas boiler is 8 m3 if it has an open combustion chamber and 6.5 m3 if it has a closed chamber (it takes air directly outside).

Hydraulic tests

Pressure testing is carried out within 2 - 3 days at elevated pressure.

Hydraulic tests of the heating system (pressure testing) are planned and control measures designed to check the reliability of heat exchange equipment. This action is carried out in order to detect components, equipment and communication sections that are potentially dangerous in terms of leaks. Hydraulic tests should be performed before the start of the heating season, after completion of planned or major repairs of the system.

During the inspection process, water is pumped into the pipes and air is released. Then, using a pump with a pressure gauge, a pressure of 2-6 atm is created in the circuit, which is higher than the nominal one. Signs of a malfunction are leaks and drops of water at the joints. After eliminating the defects, the test is repeated. A prerequisite is the use of hot water, the temperature of which is equal to or higher than the calculated one. The thermal test shows the true readiness of the circuit for operation.