A gas boiler is often located in houses outside urban areas, in small businesses and shopping centers. Its task is to maintain the required air temperature in the room, and in some cases, to provide hot water supply. Smart automation in modern boilers turns on heating only if the temperature of the coolant (usually water) or the air in the room drops below a predetermined level. In this way, it is expected not only to save fuel, but also to reduce wear and tear on the device as a whole. In certain scenarios, so-called clocking may occur. Let's talk about him.

Features of a double-circuit gas boiler

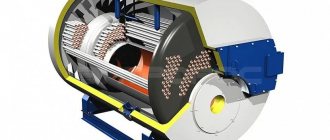

Knowledge of the features of its design will help you understand the principle of operation of a double-circuit gas boiler. It includes a number of components that promote heating of the coolant and are responsible for switching to the DHW circuit.

Uninterrupted operation of the unit is only possible if all component modules work harmoniously. General information about the main components will be enough to understand the operating principle of a double-circuit gas heating boiler.

Gas pipe in the kitchen - how to hide and decorate it? Photos of examples of ready-made solutions.

The kitchen is often the main place in the house where people spend most of their time - cooking, eating, meeting and socializing. That is why, when renovating it, you want to get the perfect result, create coziness and comfort.

Therefore, it is important at this stage to think through the entire ergonomics of the space. While making a sufficient number of sockets is not a problem, the communications in the kitchen in the form of various pipes create a number of problems when carrying out repairs.

If water or sewer pipes can be moved, hidden under a screed or in a wall, or hidden behind a curtain in the case of a heating pipe, then in most cases this will not work with a gas pipe.

According to existing standards, it is strictly forbidden to close a gas pipe “tightly.” Free access to it must be provided, otherwise during inspection you will be fined and forced to break the structures covering the pipe.

You cannot shorten the gas pipe in the kitchen yourself; you cannot move it to another place - approval and permission from gas services is required.

And in some cases this is simply not possible, for example, if the pipe runs throughout almost the entire kitchen area. But even if all the necessary permits for changes have been obtained, it will still not be possible to completely cut off the gas pipe in the kitchen.

This begs the question, what to do in this case, what to do so that the pipe does not spoil the appearance of the kitchen. Don't despair. There are a lot of options for hiding a gas pipe in the kitchen. Moreover, most of them will not require large expenses. Let's look at the main ones.

The easiest and cheapest way to hide a pipe in an existing interior is decoration. You can do it yourself, or use the services of a decorator. Available materials are used for decoration, and the result will impress you.

Construction device

The design of the device includes the following elements:

- Burner . It is the main module of the heating boiler. Its location is the combustion chamber. The burner's task is to heat the coolant and release thermal energy for the DHW circuit. To accurately maintain the required temperature, this element is equipped with an automatic combustion control system.

- The combustion chamber . Burner installation location. It can be open or closed. Closed structures are equipped with a fan that supplies air and removes smoke. Thanks to it, the effect of quiet noise is achieved when the equipment is operating.

- Circulation pump . Responsible for creating forced movement of coolant inside heating pipes and for the efficiency of hot water supply. Unlike a fan, there is almost no noise when the pump operates.

- Three-way valve . Thanks to this device, the boiler has the ability to switch to the water heating function for hot water supply.

- Main heat exchanger . The design of a wall-mounted double-circuit gas boiler involves its placement on top of the burner, inside the combustion chamber. This ensures the heating of water, which subsequently enters the heating pipes or the hot water system.

- Secondary heat exchanger . Responsible for heating water for domestic hot water supply.

- Automatic devices . Provide control over equipment operating parameters, monitoring the heating level of the coolant and water. This makes it possible to adjust the operation of the burner, control various components, maintain the flame, record problems that arise, etc.

The space at the bottom of the housing is intended for installation of switching taps for the heating circuit, hot and cold pipelines and gas supply. Some modifications of gas double-circuit boilers are equipped with twin heat exchangers: the operating principle of the double-circuit boiler does not change.

Prevention measures

Breakdowns of gas equipment happen to everyone; it is impossible to insure against this.

However, there are a number of ways to reduce the risk of breakdowns:

- Scheduled diagnostics of gas equipment before the start of the heating season - a specialist will conduct an inspection, do a test run and tell you about all the nuances of this boiler.

- Selection of the correct operating mode of the boiler and pump.

- Periodic cleaning of all combustion chamber elements is carried out only by a specialist.

vote

Article rating

Similarities with other designs

Although the design of a double-circuit wall-mounted gas boiler is far from simple, upon closer examination of the operation of its components, everything turns out to be not so scary. Equipment of this type resembles a gas instantaneous water heater (especially the presence of a burner and heat exchanger). All other parts are borrowed from a single-circuit wall-mounted boiler. A significant positive role is played by the built-in piping, consisting of an expansion tank, a circulation pump and a safety group.

When studying the principle of operation of a gas double-circuit boiler, it is important to keep in mind that mixing water from the hot water system with the coolant should not be allowed under any circumstances. To pour liquid into the heating system there is a separate pipe, which is part of the circuit. To prepare hot water, a certain volume of coolant is used, which moves inside the secondary heat exchanger.

Defect or incorrect setting?

An unpleasant phenomenon is often viewed as a technical malfunction, but it is not. The temperature sensor is triggered by a change in temperature - the burner turns on - the boiler heats up. Everything works correctly and in accordance with the specified conditions. And the fact that the cycle irrationally uses the boiler resource is the problem of the user, not the underlying program.

Thus, clocking is not a defect, but the result of incorrectly adjusted temperature ranges or a poorly organized heating system. There are several most common reasons for the boiler to not operate correctly:

- Incorrectly installed thermometer.

- Small temperature ranges.

- Unregulated burner.

- Low heat capacity of the heating circuit.

It is these problems that are a frequent reason to call a specialist. Of course, you can do it on your own - just follow simple tips.

Principle of operation

Now you can take a closer look at the operating principle of a double-circuit boiler. Armed with knowledge of why individual elements and modules are needed and having understood the principle of operation of a gas boiler, it’s time to move on to studying the question of how a wall-mounted gas boiler works in general.

As you know, equipment of this type is designed for two modes:

- Heating.

- Heating water for the home.

It should immediately be noted that this type of equipment cannot operate simultaneously in two modes. This explains the presence in its design of a three-way valve that directs a certain part of the coolant to the hot water system.

Using non-freezing liquid as a coolant

Antifreeze

If you plan to use antifreeze liquid (ethylene glycol or propylene glycol) as a coolant, then you should find out whether this is allowed by the manufacturer.

In the event of a breakdown, you may be denied warranty repairs. My opinion here is that antifreeze can only be a necessary measure.

For example, at the dacha, where you don’t want to drain the system every time in the fall. In other cases, the best choice is prepared water.

Heating mode

The operation of a double-circuit boiler in heating mode is no different from the operation of a simple flow-through heater. The initial switching on of the burner is accompanied by a sufficiently long period of operation, which allows the temperature in the heating circuit to be raised to the required values. When the optimal mode is reached, the gas supply stops. If there is an air temperature sensor in the home, the automation itself will monitor its readings. The gas burner modes of a double-circuit boiler can be switched by special weather-dependent automation that monitors the temperature outside the house.

A working burner gradually increases the temperature of the coolant, the movement of which inside the pipeline is maintained by a circulation pump. Thanks to the operating principle of the three-way valve in a gas boiler, water is able to pass inside the main heat exchanger in normal mode. Removal of combustion products can be carried out spontaneously or with the help of a special fan (as a rule, it is equipped with the upper area of a dual-circuit apparatus). In this case, the DHW circuit is in an inactive state.

Proper system shutdown

There are many situations when the system still needs to be turned off. For example, before repair or maintenance. Or if the boiler is installed in a country house and there will be no need for heating for a long time. Some owners unknowingly simply pull the plug from the socket and that's it. It is not right. The shutdown rules depend on what automation is installed in the system. Let's look at the most common of them.

EuroSit 630

- Smoothly turn the temperature control knob to the right. The white star needs to be flush with the corresponding image on the panel.

- Close the tap on the gas pipeline inlet.

MiniSit 710

- Smoothly turn the temperature control knob to the right until it stops. After that, click the "Off" button.

- Close the tap on the gas pipeline inlet.

- Turn the temperature control knob to the left until it stops.

- Close the tap on the gas pipeline inlet.

Sit 820 NOVA mv

- Turn the knob to the right to the “Off” position (star icon). The main burner will go out, but the pilot torch will continue to operate.

- To stop gas flow completely, turn the knob to the "Closed" position (small white dot).

Hot water supply

The hot water supply system turns on only when you directly turn the water tap valve. The occurrence of a flow provokes the operation of a three-way valve: this way the heating system is started. At the same time, a flame appears in the gas burner if it was still turned off. As a rule, it takes a few seconds for hot water to appear from the tap.

It is also important to understand how a double-circuit boiler heats water. As stated above, when it is turned on, the heating system is turned off. The regulation of this entire procedure is carried out thanks to a three-way valve, which redirects a certain volume of heated water inside the secondary heat exchanger (there is no flame on the secondary at all). The incoming coolant begins to heat the water circulating in the heat exchanger. Despite some complexity of the circuit due to the small circulation circle of the coolant, double-circuit gas boilers with separate heat exchangers are easy to maintain and repair. OGV boilers are also popular, allowing efficient supply of hot water.

What to do when a malfunction occurs?

Gas consumers should understand that they do not have the right, but the obligation, to repair their home or apartment equipment. Moreover, in a timely manner and with high quality.

And since frequent shutdown of the boiler is potentially a malfunction, this legal requirement cannot be ignored. Since for this, according to Art. 9.23 of the Administrative Code faces a fine.

Repairing any gas equipment is a responsible procedure, as it significantly affects safety. Therefore, you should not overestimate your capabilities or try to save money, risking the lives and health of people nearby, including relatives and friends.

The size is 1-2 thousand rubles. And, if suddenly the situation, through the fault of the user, becomes dangerous to the life and health of people or an accident occurs, then you will have to part with 10-30 thousand rubles (Article 9.23 of the Administrative Code).

It is easier and more reliable to contact the gas company with which the contract has been signed. And all the risks will fall on their shoulders. As well as responsibility for the timeliness and quality of repairs. And for violations the company will be held liable in accordance with Art. 9.23 Code of Administrative Offences. Where is it said that penalties can reach an impressive 200 thousand rubles

You should also remember that you should not take responsibility for yourself by trying to eliminate the cause of switching on/off yourself. Especially against the backdrop of the fact that problems with equipment inoperability must be resolved by specialists from companies with which the gas consumer has signed an agreement. And for ignoring such a rule, additional sanctions in the amount of 1-2 thousand rubles are threatened - this is also stated in Art. 9.23 Code of Administrative Offences.

Any repeated violation of the above norms will be the reason for punishment in the form of a fine, the amount of which will be 2-5 thousand. The basis for this is the corresponding norm in the above article of the Code of Administrative Offenses.

Characteristics of combined type heat exchangers

Combined heat exchangers provide boiler equipment with the following advantages:

- High efficiency in the DHW system.

- Simplicity of the internal structure.

At the same time, the likelihood of scale formation increases. However, separate heat exchangers still have more advantages, which explains their high popularity. Due to the complexity of the design, almost complete disappearance of scale is achieved. While the hot water supply is running, the circulation of coolant inside the heating pipes stops. If this process drags on for a long time, it can lead to an imbalance in the heat balance in the house. In this case, a double-circuit gas boiler operates, as in the summer, when there is no need for heating.

After tightening the valve, the three-way valve is activated, after which the double-circuit boiler goes into standby mode. In some models, the cooled coolant begins to heat up immediately. The operation of a double-circuit boiler for heating only will continue until the next time the tap is opened. The productivity level of individual modifications can reach 15-17 l/min: this is directly affected by the power of the boiler equipment.

Having an idea of the operation of gas double-circuit boilers, it is easy to understand the purpose of its individual components. In some cases, this makes it possible to independently carry out repair and maintenance activities. Due to the high saturation of the internal layout, the developers were able to create very efficient heating equipment. The compactness of boilers of this type eliminates the need to equip a separate boiler room.

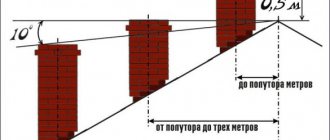

Norms for the location and rules for moving gas pipes in the kitchen

Most of the goodies on the tables appear with the help of a natural gift - gas. Naturally, the owners of the house want blue fuel to enter the kitchen unnoticed, without destroying the harmony, integrity of design and style, which has been thought out for months. Meanwhile, utility networks are not a toy, you cannot joke with them, because in the pursuit of beauty you can lose the main thing - life. So, how and where should a gas pipe be installed in the kitchen: norms and rules for handling the system.

General standards

First, it’s worth finding out under what circumstances gas pipes are used in the kitchen. The use of blue fuel in such a room most often means installing a stove. It's time to familiarize yourself with the terms of use. So, remember the main postulates:

- gas stoves are allowed to be installed in kitchens with a height of 2.2 meters (if the ceiling in the room is sloped, then to install the stove you should choose a place where it reaches the established norm);

- the kitchen should be equipped with a window with a window so that during the day repair work can be carried out without artificial lighting, ventilating the room (the presence of a functioning ventilation duct is welcome);

- between the slab and the opposite wall there must certainly be a passage with a width of 1 meter;

- ceilings and walls made of materials prone to combustion, according to standards, must be covered with plaster;

- The stove can be used in kitchens separated from the corridor by a secure wall/partition and door;

- The installation of gas pipes in the kitchen should be done so that the distance between the walls and the stove is at least 7 centimeters;

- branching to the slab is allowed only at the level of the connecting fitting;

- the shut-off valve should be installed at a level of 1.5 meters from the floor and at a distance of 20 centimeters from the side of the stove;

- To install the stove, it is permissible to use a special (heat-resistant - from 120 degrees) flexible hose and do not forget to change it, based on the recommendations specified in the product data sheet.

Other reasons

We can say that all cases when the radiator does not heat are unique in their own way. For example, the radiator, which is the last one in the system, does not heat. This means that the coolant simply does not reach it or the heat is “lost” along the way to it. If the latter, then the system is incorrectly calculated or the diameter of the pipes is incorrectly selected and, accordingly, the ratio of the amount of water/circulation intensity is incorrectly selected.

An expansion tank can help solve many problems. For example, airing can be removed by pumping coolant through the entire system. To do this, some install a valve in the lower part of the heating system, to which a tap and fitting are connected. After putting on the hose, you can pump water until air comes out through the expansion tank.

But this approach is quite risky - excess water, and there will be a lot of it, will fill the tank and flow out of it. In this case, work with an assistant who will monitor the water level in the expansion tank.

How to move a gas pipe in an apartment: transfer rules and location tips

The installation of gas communications in an apartment is subject to certain requirements, therefore, independent installation and connection of equipment, as well as moving the gas pipe to another place, is strictly prohibited.

All issues regarding the laying of internal and external gas pipelines are resolved by the gas service, without whose permission it is only possible to move the stove a limited distance.

We will tell you how to obtain approval for replacing a gas pipeline, and also describe the technology for moving an intra-apartment pipeline. The proposed instructions are not a guide to action; all work must be carried out by a representative of the gas service.

Reasons for moving gas pipes in the kitchen

All work on moving and replacing metal pipes, especially those requiring welding, is carried out by representatives of Gorgaz or another authorized organization. Having received an application from residents, they are always interested in the reasons for the planned transformations.

Most often, it is necessary to change the piping in the kitchen without changing the layout or moving equipment to other rooms.

The reasons may be different:

- replacing old equipment - purchasing a gas water heater, stove or boiler - which requires a little more space;

- major renovation in the kitchen;

- moving the gas stove from the window 0.5-2 m towards the sink;

- changing the installation location of the gas meter;

- moving a horizontal pipe from a great height under a table top, etc.

Often, the relocation of pipes is required in new buildings, where the original location of significant kitchen objects defies logic and explanation: suppose, if in a 15-meter kitchen the gas stove is located near the window, the sink is in the opposite corner, and the hood is on the other side, above the entrance to the kitchen.

We have to correct the design mistakes and move the stove closer to the sink so that food can be cooked in comfortable conditions.

The most common reason is the purchase of a new kitchen set with built-in equipment (oven and hob). In this case, the pipes need to be either shortened or lengthened, depending on the planned installation location of the devices.

If you want to find out how best to move a gas pipe in an apartment with redevelopment, we recommend contacting a design organization to draw up a transfer plan.

The fact is that in typical city apartments it is prohibited to reinstall risers, pipes, as well as any gas equipment in living rooms, and even to combine a kitchen and a room, permission is also required.

Obtaining approval for gas pipeline replacement

Whether a transfer is possible or not can only be decided by authorized bodies, that is, the gas service of your city (district). Only a qualified specialist has the right to carry out any dismantling and installation work. Of course, pipes cannot be moved without approval.

The permit is issued in the following sequence:

- Find out the contact details of the gas service at the place of registration, contact specialists, explain the situation, and consult.

- You draw up an application (using a standard form) that will “launch” the approval process.

- Based on your application, a gas service representative will arrive at your home. The time will be confirmed in advance.

- The specialist performs an inspection, listens to wishes, and answers questions. Often at this stage it is necessary to change plans, since the desired transfer does not meet safety requirements (a preliminary study of the gas pipeline installation standards will eliminate this unpleasant moment).

- Approval of the final transfer scheme, drawing up an estimate. All documents are prepared by the organization providing the services. No work will be carried out without the consent of the property owner.

- If the transfer conditions are met, pay for the service using a receipt and agree on the start time of the work.

The approval procedure usually takes several days; it can drag on for a long period for only one reason: if the property owners and representatives of the gas service have not found a compromise solution.

Any factors that violate the installation standards for gas stoves (boilers, meters, water heaters) may cause refusal to move pipes.

General requirements and standards

To ensure that the approval process goes smoothly, it is better to familiarize yourself in advance with the basic provisions for installing a gas system in residential premises. As a cheat sheet, you can use the regulatory document - SNiP 2.04.08-87* (current version).

If the walls and ceiling consist of flammable materials (wood), they must be plastered or lined with metal sheets.

Gas pipes are used to transport fuel to consumers - stoves, ovens, columns, so the location of the equipment is no less important than the pipe layout.

How to connect a room thermostat?

Almost all Baxi gas boilers have the ability to connect a room thermostat. If the temperature in the room drops, the device will send a signal to the heating equipment and the boiler will automatically start working.

All indicators depend on the balance and type of heating system. Thanks to the programmable thermostat, you can set the desired temperature during the day. If the temperature in the room is reduced by 1 degree, then you can save about 5% of gas in a year.

In Europe, it is mandatory to install a room thermostat for the energy efficiency of the heating system.

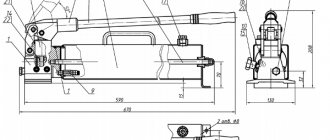

The main components of a wall-mounted boiler with a closed combustion chamber.

Figure 4 1 Safety relief valve (3 bar) 2 Gas valve 3 Primary filter 4 Ignition transformer 5 Injection burner 6 Temperature sensor (NTC) 7 Ignition electrodes 8 Combustion chamber 9 Primary heat exchanger 10 Sealed vacuum chamber 11 Differential combustion products flow relay 12 Fan 13 Coaxial air inlet-removal system for combustion products 14 Expansion tank 15 Ionization electrode 16 Temperature sensor OL (NTC) 17 Automatic air vent valve 18 Pump 19 Pressure sensor 20 Bypass with adjustable bypass valve 21 Three-way priority valve 22 Plate heat exchanger 23 Cold flow sensor water 24 Cold water filter 25 Charge valve 26 Drain tap A Supply line (FL) B Hot water outlet C Gas inlet D Cold water inlet E Return line (RL) F Drain pipe