The technology for constructing buildings using SIP panels came from Canada back in the second half of the last century.

The abbreviation “SIP” is translated from English as “Structural Thermal Insulation Panel”. This name fully corresponds to the characteristics of the material.

SIP panels are produced for any part of the building and allow you to build a thermally insulating and durable structure in a few weeks (depending on the complexity of the project and climatic conditions). And now from theory to practice - read about how to build a house from SIP panels yourself.

Advantages and disadvantages of houses made of sip panels

Sip panels are not a new material - they have been used abroad for a long time. But we became acquainted with it relatively recently on the domestic market, so before ordering such a house, it is recommended that you familiarize yourself with its strengths and weaknesses.

The advantages include the following:

- low heat loss - this characteristic can be further increased if the facade is also insulated;

- small panel width – allows you to save usable space;

- it warms up easily and retains heat - this point will be appreciated by those who are building their home in a sunny region, especially when the first heating bills arrive;

- low weight of the material (1 m² of wall weighs approximately 18-20 kg) - allows you to save on organizing the foundation (the number of floors of the building should be taken into account);

A pile foundation will cost significantly less than a strip concrete foundation Source stroy-sovet.com

- affordable price - this is due not only to a lightweight foundation, but also to the absence of the need to use specialized equipment;

- construction does not require much time - the simplest option can be implemented in literally 2-3 weeks, and completed “turnkey” in 2-3 months;

- excellent external characteristics - a flat surface simplifies finishing work;

- long service life - houses made of sip panels (subject to construction technology) can last for more than 60 years without additional repairs.

Canadian technology is the best option for the construction of ready-made buildings. If all modules are available, installation of the frame box of the house is very quick. If the construction company knows its business, then it will take specialists 2-3 days.

When building a house project from sip panels, you will not need heavy equipment Source 2we.ru

But as they say, every barrel has a fly in the ointment. This also applies to this material. It has a number of its disadvantages:

- low fire resistance - sip panels are compared with wood according to this characteristic, therefore electrical wiring is carried out according to the standards for a wooden house;

- the insides of the panels can be favored by rodents - but this is a problem in almost all private buildings;

- if the slab is damaged, it cannot be “glued” together - the element will have to be completely replaced with a new panel;

- without additional protection, at very low temperatures, the joint seams begin to freeze;

- The façade should be clad with lightweight materials, since sip panels are sensitive to additional load.

All of the above disadvantages can be called relative. For example, fire resistance can be increased thanks to a special coating that imparts fire-retardant properties. Or if we are talking about rodents, then you can use metal gaskets in the walls and floor. So, all these points can be called not so much disadvantages as the features of such a material as sip panel.

Working with SIP panels Source bankfs.ru

See also: Catalog of house projects made from SIP panels.

Houses made of sip panels: features and examples of layouts

The first step in building a house is selecting a suitable project. The most convenient solution is to contact a construction company. Firstly, all the work will be done by professionals, and secondly, they not only work with their catalogs, but can also draw up a project based on your plan. Projects of houses made from sip panels are very diverse, so there are no problems with the choice.

One-story houses made of sip panels

An example of the layout of a house project made from SIP panels Source bankfs.ru

As can be seen from the example, the house already has all the main premises, and if the customer wishes, the project can be supplemented with a garage, attic, veranda, summer kitchen or any other building. As for prices, approximately they look like this:

- country house up to 50 m² – from 675 thousand rubles;

- residential building up to 50 m² – up to 900 thousand rubles;

- residential building from 50 to 100 m² – from 1350 thousand rubles;

- residential building from 150 to 200 m² – from 2.25 million rubles.

This is an approximate cost. The final figure in each specific case will be calculated individually.

Two-story houses made of sip panels

This option for a house made from SIP panels is already more relevant for permanent residence. It will also have a large area (from approximately 120 m²), and therefore is perfect for families of 4 people or more.

One of the best options looks like this:

Layout option for a two-story house made of SIP panels for permanent residence Source 1drevo.ru

Often in two-story houses there is a demarcation of zones - the first floor for guests and the second for the family. In this case, it is better to equip another bathroom on the second floor.

The following figures can be given for the cost of constructing a two-story house:

- residential building on 2 floors of 150 m² - from 2.25 million rubles;

- residential building with 2 floors of 150-200 m² - from 3.6 million rubles;

- residential building with 2 floors from 200 m² - from 4.8 million rubles.

See also: Catalog of companies that specialize in the construction of houses from SIP panels.

Houses made of sip panels with an attic

Attic is an attic space converted into a separate room. The main advantage of such a project is functionality, compared to a one-story house, and a more reasonable price, compared to a two-story house. But the main advantage is the presence of full two residential floors, so this option can be suitable for both a small and a large family of 4 people. It is very comfortable to equip a bedroom or a children's room in attics, since the windows here, thanks to a special design, provide much more light.

An example of the layout of a one-story house project for vulture panels with an attic Source bankfs.ru

The image shows how the attic space became two bedrooms thanks to the attic. But the first floor was completely ready for simple relaxation and receiving guests. If desired, you can build a house from sip panels on two floors and then the attic will become a kind of third floor.

Also, the attic room, provided that there is enough space for the whole family, can be converted into a gym, billiard room or any other recreation room.

To build a house from sip panels with such a layout can cost the following:

- one-story house with an attic up to 100 m² - from 1.8 million rubles;

- one-story house with an attic of 100-150 m² - from 2.55 million rubles;

- two-story house with an attic of 100-150 m² - from 3.15 million rubles;

- two-story house with an attic of 150-200 m² - from 3.75 million rubles.

High-tech house made from SIP panels Source stroy-fbk.ru

Questions related to the selection of a Canadian house project arise constantly. Here we will try to discuss the topic of design in order to make this important stage of preparation for construction easier for our clients.

Construction without a design at an organized construction site is not allowed. If a person takes on construction without a project, this indicates that he is not yet ready for such a responsible task. The result of construction without a project is always flawed and sometimes sad.

To build a house frame from SIP panels, you need an architectural and construction part of the project (AC). It contains detailed drawings of all house structures (foundation, floors, walls and roof) and their components. Professionals will not be contracted to build a house without speakers. Shabashniks and self-builders, out of economy or lack of necessary knowledge, often try to “cheat fate” and get involved in makeshift self-construction without a project.

Don't repeat other people's mistakes. The benefits from the construction of the project are enormous. Construction “on site” without a project for beginners is associated with endless climbing on structures with a tape measure, endless thinking about the way out of this or that difficult situation, dismantling already assembled structures, etc.

The architectural and construction part (AC) of the project includes an architectural solution (AP), containing a description of the building, floor plans, facades, sections, roof plan and 3D views. The AR is made by an architect, the rest of the AS is prepared by a designer with special knowledge and skills. You cannot build according to AR. This is the same construction without a project.

Houses made from SIP panels do not have any significant specific features at the preliminary design stage. Only at the stage of detailed design (cutting panels, design of components, etc.) are the features of SIP technology taken into account. This means that any project can be taken as a basis for construction using SIP panels.

A great variety of preliminary designs are presented on the Internet. Any of them can be easily adapted to SIP construction technology. This is purely technical work that is performed by the designer using modern computer-aided design programs.

If you plan to use the services of our company to build your house, then you need to choose (purchase) or draw a preliminary design in any form (picture, hand drawing, etc.), and the intricacies of SIP design are our problems. Send your project or a link to a project on the Internet by email to: This email address is being protected from spambots. You must have JavaScript enabled to view it. , and we will calculate how much it will cost to build your house with our team.

If you are going to build from SIP with your own hands, then you can try to do the project yourself. The popular weapon of a novice designer from SIP - the Google SketchUp program - will help many with this.

Competent design requires knowledge in the field of structural mechanics. Self-builders without special education need to prepare for design by studying the basics of construction science on thematic Internet resources or looking through technical literature. Most mistakes are made when designing SIP floors and roofs.

Design for SIP

There are two approaches to designing a house from SIP panels:

The first approach is to choose any project you like and convert it for construction from SIP panels.

Another approach is special (optimal) design for standard sizes of SIP panels.

The absence of restrictions that the original design imposes in the first approach allows you to create more cost-effective projects when specially designing for SIP. Usually, when adapting a project developed for construction from other materials to SIP technology, it is possible to cover up to 50% of the wall area with whole panels. With special design, it is possible to cover entire panels and 80% of the area.

Therefore, when designing independently, many people take the second route. Almost always, independent design involves construction with cutting of panels on the construction site. The more uncut panels can be placed in the structure of the house, the less labor will be spent on assembly.

But there are pitfalls here. Most often they forget that it is necessary to ensure the load-bearing capacity of the structure in relation to the loads and impacts acting on the building (from its own weight, from wind, snow, operational). Laying entire panels anywhere is dangerous! Particularly large restrictions apply to the use of uncut panels in SIP floors and roofs. Moreover, in these structures, the cross-section of the joining beam of the panels should be determined by calculating strength and rigidity

In addition, if the design task is subordinated to the technical features of SIP technology, there is a danger of building a solid, warm “barrack” instead of a house. The desire to maximize the benefits of panel construction leads to the fact that “standard” Canadian houses acquire a characteristic appearance. Technology is displacing architecture from the project. Apparently, because of this, a judgment arose about the limitations of Canadian technology from an architectural point of view. In fact, this is not true. If we are building a house for ourselves, and not for sale, some excesses (from an economic point of view) are not only acceptable, but should be welcomed in every possible way.

The first design approach also allows for optimization for construction from SIP. The possibilities for this are slightly less than with the second approach, but the techniques are the same. Here are the most effective:

If we assume a floor-to-ceiling height of 2.8 m or 2.5 m, standard SIP panels do not have to be cut or extended in length. This condition is not at all burdensome (the attic is an exception). Therefore, when designing, the main dimension becomes the width of the standard panel of 1250 mm.

You can reduce the number of cuts and waste by choosing the appropriate sizes of window lintels. If the floor has a height of 2.8 meters, then the optimal window opening is, for example, 1250 mm wide and 1400 mm high. In this case, from one standard 1.25x2.8 m panel, two pairs of sill and above-window blocks will be obtained in three cuts without waste. Another option: by cutting the SIP panel longitudinally into two parts 900x2800 mm and 350x2800 mm, we get two blanks for sill and above-window blocks for window openings 155 cm high. By choosing the appropriate width of the window openings, these blanks can be cut without waste.

Very rational cutting, when with one cut of the SIP panel we get two parts. Example - two halves 625x2800 mm.

The optimal height for low attic walls is 1250 mm or 1400 mm.

By combining entire standard SIP panels and optimal parts, they create cost-effective projects.

When adapting a project you like to SIP technology, small changes are usually made to the project that do not significantly affect the architecture, but optimize the process of manufacturing and assembling SIP structures. The fewer SIP joints you get, the better for various reasons. However, under no circumstances should you become obsessed with not cutting the panels! It’s better to do this: if it’s possible to use an entire panel without compromising the architecture and strength, we use it; if something gets damaged, we definitely cut it. After all, cutting SIP panels even on a construction site is not that difficult.

You shouldn’t get too carried away with optimization for SIP. This takes a lot of time, and a significant effect can only be felt during mass production. Therefore, the complex task of minimizing the volume of construction and installation work (CEM), time for cutting panels and waste is solved only with standard design, when the house is “produced into series”.

Two more practical tips

When designing, keep the thickness of the panels in mind. In our case it is 174 mm. The walls of a 5 by 5 meter house cannot be built from whole panels. But 5.174 by 5.174 m or 5.348 m by 5 m is possible (installation gaps at the joints are not taken into account). Therefore, when drawing floor plans, panels should be drawn as rectangles, not as segments.

It is better to neglect the installation (dilatation) gap of ~3 mm at the junction of the panels when designing. The manufacturing accuracy of the panels themselves is within +-3 mm per meter. Cutting panels “eats” several millimeters.

Smart Design

Some tips for sustainable design:

The easiest way is to join SIP panels at an angle of 90° and 180° (diagrams of different joints are given on the official SIPA website in the technical information section). Therefore, we recommend sticking to right angles in your house design (even when designing bay windows). If you really want, you can make a SIP joint at any angle. But you'll have to tinker.

When selecting projects or when independently developing floor plans, it is desirable that the bathrooms of different floors are located strictly above each other, and the bathroom of the first floor is located next to the kitchen (has an adjacent wall with the kitchen). In this case, the costs of such utility networks as water supply, sewerage and ventilation are sharply reduced.

Complex roof structures are much more expensive than simple ones and less reliable. Complex roofs require periodic maintenance. It is necessary to clear leaves and other debris from the valleys. And walking on the roof increases the risk of leaks. In winter, complex roofs collect a lot of snow.

The fewer roof windows, smoke and ventilation passages through the roof, the cheaper and better.

You will have to pay for architectural “excesses” in the floor plan (bay window, etc.), including the forced complication of the roof.

The more your house differs from a cube, the more expensive square meters become both during construction and during operation (energy efficiency suffers).

An attic instead of a full floor is not the best solution from an economic point of view: the costs are the same, there is more work, and there is less usable space. But often an attic makes a house more attractive from an architectural point of view. In addition, according to Russian standards, the attic is not a floor. This allows, without breaking the law, to build two-story houses with an attic (i.e., actually three-story houses) from wood and SIP.

When designing the foundation, as well as when planning floors, it is advisable to avoid large (more than 4-5 meters) spans of future floors. Otherwise, the cost of floors will increase, or intermediate supports (columns) will have to be installed.

Large glass area, many exits to the street - high costs for windows and doors and, most unpleasantly, for heating.

If problems for the entire life of the house do not frighten you, you can make a balcony above the bay window. It's very beautiful and convenient. But it’s better to first talk to people who made such a decision. The topic of leaks when constructing a balcony over a bay window is discussed quite actively on the Internet. A maintained roof is a complex and expensive structure. Attempts to solve the issue using simple means lead to problems.

Rationalism is ruining architecture. Break these rules and build beautiful houses.

Project selection

The main value of the project is the development of the architectural part that determines the appearance and floor plan of the house. Independent creativity at this stage can lead to irreparable mistakes.

Often houses designed by the owners themselves, and not by architects, are immediately recognizable by their appearance. The fact is that many people design their house for reasons of convenience, but the architect solves another problem, namely, how to combine convenience with a beautiful form.

When planning floors yourself, the most common omissions are narrow and dark corridors, cramped staircase halls with very steep stairs.

The first approach mentioned above allows you to avoid mistakes when designing yourself, when you first select an architectural design you like, and then attempts are made to edit it to suit your requirements and the features of SIP technology. This approach is simpler and more suitable for DIY design.

The cost of individual design from scratch (architectural and construction part of the speaker system) depends on the qualifications of the contractor and amounts to 300-600 rubles. per m2 of total area. If purchasing a ready-made project or individual design services from professional architects is not suitable for some reason, then you can take the path of “creative processing” of published or already implemented projects. A lot of simple and easy-to-build projects have been published on the Internet. It will not be possible to simply borrow a project, because it is not the projects themselves that are published, but pictures without dimensions. You can't build a house from a picture. But you can start from the picture when designing yourself.

Copyright is required by law to be respected and observed. But simple projects, as a rule, are not burdened with copyrights and migrate from site to site under different names. Simple projects of individual houses, in principle, have a lot of doubles. An individual house is small, but there are millions of projects. Coincidences are inevitable when trying to design something optimal or rational. Even if you design your house entirely on your own, most likely you will basically repeat what has already been invented and implemented many times.

According to floor plans. It is better to look at the basic diagrams in numerous project catalogs, including on the Internet. There are not many reasonable or optimal options for placing several rooms in a small area.

Most likely, you will be able to find a preliminary design that suits you in all respects and you won’t have to rack your brains much. It is easy to make small changes to suit individual requirements. Most people do just that.

When choosing a project, you should remember that building a two-story house is cheaper than a one-story house of the same area, but part of the usable area in a two-story house is “eaten up” by the staircase hall.

In order for your spouse to approve the project, you need to pay serious attention to the kitchen. There will be much less controversy. If you are building a large house, then the kitchen-dining room should not be less than 20 m2. For a family with small children, it is advisable to combine the kitchen in a space with a dining room or living room. This makes it easier for the housewife to keep an eye on the child.

Understanding the technical details of the process of constructing houses from SIP allows you to choose from several projects you like the one that will be easier and cheaper to implement yourself. This mainly concerns the roof of the house, especially if it is assembled from SIP. The more slopes a roof has, the more difficult and expensive its construction will be.

When assembling architecturally complex houses with your own hands, a lot of waste is generated from cutting SIP panels. In the absence of special skills, installing a complex house will take a lot of time.

If the house is simple in architecture, then you can save on a contracting organization by choosing what is cheaper, or by hiring a team of guest workers. But here you need to understand the topic well and keep track of everything, otherwise it may happen as in the well-known saying.

If we ignore the architecture, financial restrictions in choosing a project mainly concern the total area of the future home. But the main thing when choosing a project is to understand what you like. If we find what we like, we determine what we can afford and, if necessary, eliminate architectural excesses, reduce or increase the area.

Over the years, we have observed a clear pattern: when there is a shortage of financial resources, people often strive to build a house as large as possible. As a result, there are not enough funds to quickly complete construction. As a result, many SIP houses stand for a long time without external finishing.

There is no point in chasing the maximum area of the house. A big house means big worries and maintenance costs. Less is more. The house should first of all be beautiful and comfortable. It is always possible to increase the area of a house made of SIP panels with an extension, especially if the main house is placed on a pile-screw foundation.

When studying catalogs of ready-made projects, you need to be careful. The total area of the house is calculated in different ways. Due to different counting rules, the result may differ by almost two times. Therefore, you should always carefully check the numbers indicated in the preliminary design.

How to decide based on financial considerations? If you build a turnkey project with your own hands, then you will need to budget about 10-12 thousand rubles for materials. per m2 of total (construction) area.

If you plan to hire builders, then it is better to focus on 20-25 thousand rubles. per m2 in a turnkey option (with work and materials). It is possible to build it cheaper, but most people are unlikely to be satisfied with such a budget option. For example, a floor made of 20 mm edged boards is acceptable only in a utility unit, but not in a turnkey house. And there are plenty of similar offers on the market for cheap houses. “Cheap” labor poses no less a danger. Real masters know their worth and are always busy.

Where to look for projects?

On numerous websites of architectural bureaus, in online stores of ready-made house designs. As a rule, on these resources projects are systematized by total area and purpose, which makes searching easier. There are many catalogs. Finding them is easy.

Plans.ru catalog is the most developed - about 4 thousand projects for every taste. There you will also meet “old acquaintances” - simple projects wandering under different names on the websites of construction companies. More than a thousand projects are presented on the website Homeplans.ru . Internet version of the catalog of projects of the magazine “Cottage Collection” - allhomes.ru . Printed project catalogs with DVDs are sold in kiosks, stores, gas stations, etc. Russian catalogs, unfortunately, are often similar like twins. The same projects are published in many catalogs.

To search for foreign house projects, you can use regional search engines Google and others. It is not necessary to know English or another foreign language. In the pictures with numbers everything is clear and so. You can use an on-line translator.

Polish house designs are very popular on the RuNet. Polish and other Slavic sites are good because you can read some things without knowing the language. Any Russian will guess that “podobne projekty” means “similar projects.”

Projects of excellent quality are presented, for example, on the website of the Polish architectural studio “Z500” (Russian translation). Many construction organizations “borrow” projects from this catalogue.

The most popular construction magazine in Poland “Murator” is published in Ukraine in Russian (catalog of projects).

American and Canadian catalogs are overwhelming in their scale. There are an order of magnitude more projects in them than in Russian catalogues. It is possible to select projects by style. For example, there are 26 thousand (!) projects in the homeplans.com .

We will help you adapt to SIP technologies and implement the project you like.

What's happened

All prices indicated are inclusive. That is, from the moment you purchase the project you like until you move into the finished building. The work of a construction company includes the following services:

- construction of a foundation (often a pile-screw type is used);

- building a house - framing, assembling the frame, creating a basement, erecting walls and partitions, interfloor and attic (or mansard) floors, roof);

- all consumables;

- roofing arrangement - rafter system, sheathing, counter-lattice, finishing coating;

- installation of windows and doors;

- creating a terrace or porch, if the house design provides for one;

- final finishing of the facade.

Features of designing houses from sip panels

Houses made from sip panels are classified as frame assemblies. In order to erect a box on a site, you will need an architectural and construction part of the project, which describes in detail all structural structures (walls, floors, floors, foundation, roof) and their components.

A SIP house project is not just a house layout Source novokazan.ru

The plan will also include:

- description of the entire building;

- facade;

- sections and 3D images;

- plan of each floor and roof.

In fact, a house project is not a one-sheet document.

Today there are two methods of designing houses:

- the client is provided with a catalog of designs for houses made of sip panels and chooses the option he likes;

- individual design.

As for the second method, it can be combined with the first - you can choose a specific project and it will be supplemented according to your wishes. Also, in addition to sip panels, other materials can be used in building a house.

When designing a house made of sip panels, you need to take into account many important nuances:

- features of the site, in particular the type of soil;

- how many rooms will there be in the house, and where will they be located;

- general layout of the house and delimitation of residential and utility rooms;

- the location of communications in the home itself and when approaching it.

Ceiling heights can be standard or tailored to the individual wishes of the customer. The location of windows and doors is selected in accordance with the current set of building codes and recommendations, but wishes can also be taken into account.

Necessary materials, equipment and tools

If you buy ready-made SIP panels and do not waste time making them yourself, then for work you need to have the following tools and materials :

- Screwdriver. The tool must have good power and a fully charged battery (if it is not powered), since you need to tighten a lot of fasteners.

- A drill or hammer drill (if the foundation is very strong) to drill holes for anchors.

- Wrenches - for completely tightening large bolts (if the diameter of their heads does not fit the largest bit for a screwdriver).

Stapler (construction) – for quickly joining waterproofing and vapor barrier materials.- Extension cords – for operating power tools.

- A mallet, sledgehammer or powerful hammer - for adjusting SIP panels in relation to each other.

- Stepladder, scaffolding – for working at heights.

- Guns for polyurethane foam.

- Level (regular, laser) – for level installation of panels along vertical and horizontal planes.

- Angle (construction square) - to check the evenness of the installation of panels at the corners.

- Pencil and tape measure - for making marks and markings.

- Hacksaw, jigsaw, electric saw - for cutting panels. Please note: if you purchase a ready-made set of SIP panels, the use of these tools will be reduced to a minimum, except perhaps only for trimming. But in the case of self-production of elements, these devices must be on site.

- Rollers, rollers, containers or sprayers - for treating wood with antiseptic and fire-fighting agents.

- PPE (helmet, headphones, gloves, goggles, respirator). When working with power tools, you need to take off your gloves so that threads or other small lint do not get caught in the rotating mechanism and this does not result in hand injury.

- Foam burner - used when cutting ready-made elements. If the parts are cut by the manufacturer according to a pre-calculated design, then there is no need for this tool.

- Cleaning equipment (garbage bags, brooms, brushes).

- SIP panels.

- Polyurethane foam.

- Fastening elements (bolts, anchors, screws, nails), if they are not supplied with the panels.

What is the construction technology?

There are two technologies in construction that are very often confused with each other. This is frame-panel and just frame.

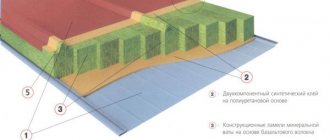

Since when attaching sip panels, wooden beams are used, which help create a rigid frame of the building, some are inclined to consider houses made from sip panels as frame houses. On the other hand, since the panels themselves are also load-bearing structural elements, houses made from sip panels are also often called panel houses. In fact, there is a combination of technologies here and SIP houses are officially called frame-panel houses.

A separate advantage of the technology is that the design features of the panels allow the material to easily withstand both transverse (for example, during a hurricane) and longitudinal (from the mass of the building itself) load. This type of frame connection in houses using Canadian technology helps increase strength by 5-8 times.

More details about the technology, what are the pros and cons of sip panel houses, myths about the construction of frame, prefabricated houses:

Connecting panels to each other and to other structural elements

High-quality SIP fastening means the absence of cold bridges, ease of assembly of individual parts, and the strength of their connection. Each of the main structural units has its own characteristics.

Fastening panels to the foundation

To install wall SIPs to the foundation, waterproofing (roofing felt) is first laid on it, and trim boards are secured.

After this, the floor panels are laid. They are fixed to the base using anchors. The distance between fasteners should not exceed 2 m.

Installation of this type of SIP panels occurs as follows:

- Self-tapping screws with a diameter of 4.8 mm and a length of 95 mm connect the ceiling to the trim boards.

- Using 3.1x50 mm self-tapping screws, fix the wall panel to the DO. The distance between fasteners should not exceed 150 mm.

During the installation process, check the evenness of the SIP fastening using a building level.

Corner connection of wall elements

In the outer and inner corners (90°) the panels are joined together using wooden dowels. Typically these are boards 50 mm thick and 150 mm wide. An alternative for building a house is I-beams.

Useful: Frame attic

Please note: the joints of individual elements are first foamed with polyurethane foam.

The dowel is attached to one of the walls using self-tapping screws 4.8 mm in diameter. The distance between them should not exceed 200 mm.

The panel of the other wall is fixed to the dowel with 3.5 mm screws, maintaining a pitch of no more than 150 mm. The protruding part of the OSB board is fixed to the end of the wall panel in the same way.

Joining wall and floor panels

This is a complex SIP connection unit at home, which requires the use of a large number of fasteners.

- The floor slab is fixed to the lower wall using self-tapping screws, the diameter and length of which are 6.3 and 240 mm, respectively. The distance between them should not exceed 300 mm.

- A trim board is mounted on top of the ceiling. To do this, use 4.8x95 mm self-tapping screws, screwing them in increments of 100-200 mm.

- Using 3.5x51 mm self-tapping screws, fix the panels of the upper wall to the trim board. The distance between them should not exceed 150 mm.

- OSB on the floor trim board is also secured with 3.5 mm self-tapping screws. However, a step of 300 mm is acceptable.

When assembling a house, all installation joints are pre-foamed with an appropriate composition.

Angle of connection between roof and wall

To connect the roof and wall, perform the following steps:

- A mauerlat is fixed to the wall panel - a support for the lower level of the rafter system. To do this, use 4.8x95 mm self-tapping screws in increments of up to 200 mm.

- A strapping board is attached to the end side of the SIP roofing. Self-tapping screws with a diameter of 3.5 mm are installed at least 150 mm apart from each other.

- The roofing elements are connected to the Mauerlat with 6.3x240 mm self-tapping screws. The distance between them should not exceed 300 mm.

Please note : fasteners with a diameter of 6.3 mm are also used to secure roofing panels to the ridge beam.

Exterior design options for a house made from sip panels

Despite the many advantages of sip panels, they will quickly lose their strength from constant exposure to wind, moisture and sun. Therefore, such a house must be lined with additional external finishing.

Sip panels interact well with many materials. Even at the design stage, the customer can express his wishes for the external design. For such purposes you can use:

- decorative plaster;

- thermal panels;

- clinker tiles;

- block house made of oak, linden or ash;

- painting;

- lining;

- facade panels made of plastic, metal, stone or wood.

Depending on your financial capabilities, you can choose both cheaper and more expensive finishing options. Also, each design can also have its own classification. In general, the customer has plenty to choose from.

An example of finishing a house with stone and brick panels Source siding-cena.ru

Pros and cons of self-assembly

The advantage of self-assembly is that you can save on the work of professional builders . This is probably where the positives end.

Do-it-yourself production of panels requires additional equipment and tools. And when the owner builds the walls himself, he needs to be very careful to cut the material correctly to size, observe the spacing of the slabs and make the required degree of angles at the junctions of the wall and roof slabs.

Even experienced professionals can make mistakes. Moreover, non-professionals need to be very careful at every stage of work.