Low-rise country houses have occupied a serious niche in the construction market today. Various materials are used, such as brick, various types of blocks, but wood remains one of the most popular. In order for the house to be comfortable at any time of the year, it must be properly insulated. One of these materials is polystyrene foam, which is distinguished by its practicality and reliability. Insulating a wooden house with polystyrene will be the key to effective thermal insulation of the building. This will significantly reduce heating costs.

Types of expanded polystyrene

The material is a gas-filled polymer. Thanks to the technology, the insulation contains a low percentage of water, and the main part consists of foamed polystyrene with additives. It is this structure that gives it high performance, capable of retaining heat and sound.

Internal structure of polystyrene foam

Depending on the manufacturing method, polystyrene foam can be of several types. Its price, density and feasibility of use in a particular area depend on this.

*

- Pressless - consists of granules that are repeatedly dried and foamed. It is characterized by fragility and a high level of moisture absorption.

- Pressed - has a low heat transfer coefficient. Due to additional pressing, the granules and structure are closed. Additional work during production increases the cost of pressed polystyrene foam.

- Autoclave - production involves the use of an autoclave, so this type of material is rarely found on the building materials market. Using autoclaved polystyrene foam to insulate a wooden house is impractical.

- Extrusion – polymer material for household use (film, packaging, containers). Not intended as insulation.

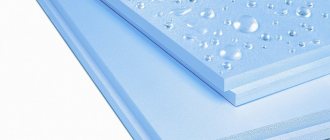

- Extruded is an ideal option for insulating a wooden house. It is non-pressed polystyrene foam, but the production technology uses an extruder. The pores of the insulation are as closed as possible and are small in size. These indicators create high thermal insulation properties. Extruded polystyrene foam is the most common and affordable type of insulation on the building materials market.

Features of insulating a wooden house with polystyrene

Expanded polystyrene is a lightweight, durable sheet of varying thickness. Thanks to its integral microstructure, it is resistant to mechanical stress and external natural factors.

Appearance of polystyrene foam

*

There are two ways to install insulation depending on the mounting location:

- Internal insulation - involves installing expanded polystyrene on the internal parts of the walls of the house. This method has many disadvantages, one of which is that the material does not absorb moisture and does not allow water vapor to pass through itself. Thus, the heat in the house will not pass to the wooden walls from the inside, and the counter flow of air and cold will act from the outside through the wall. In this case, the dew point will shift inside the house, which will lead to condensation between the wall and the insulation, and ultimately to rotting of the wood. This phenomenon causes the formation of mold, mildew and insects.

Insulation of a wooden house from the inside

- External insulation is the so-called ventilated facade. The advantage of this method is the use of waterproofing and the ability of the insulation to be ventilated. External installations are more expensive than insulation inside the house.

Insulation of a wooden house from the outside

Insulation of a wooden floor with polystyrene in a house is carried out between the wooden floor joists. This allows you to prevent the entry of cold air from the ground, as well as stabilize the temperature on the floors, preventing warm air from below from rising through the ceiling and oversaturating the floor of the heated upper floor. Insulation of floors is also effective if the rooms above are not used during the cold season and are not heated.

Insulation of a wooden floor with polystyrene

Application area

Taking into account the previously mentioned disadvantages, it is possible to choose the use of polystyrene foam without damaging the building. Polystyrene insulation of wooden buildings (if required) is better done from the inside than from the outside. This will protect the material from destruction and the building from defrosting. It makes more sense to use vapor-proof material in stone buildings (brick, concrete), but if absolutely necessary, wooden ones can also be insulated.

Stone and block buildings can and should be insulated from the outside. But it is not recommended to insulate wooden houses from the outside with polystyrene foam.

Insulation of floors

When used internally, the main area of application is the ceiling. Laying into a floor structure is also possible. But when carrying out work, the strength of the material should be taken into account.

- The first use case is common for concrete floors. In this case, the insulation is laid under a cement-sand screed. To prevent the foam from breaking through, the screed is made reinforced with a thickness of approximately 50 mm. For reinforcement, special meshes with reinforcement with a diameter of 3 to 6 mm are used.

- The second option is applicable for buildings with wooden and concrete floors. In the first case, the insulation is laid in the ceiling or floor between the beams. In the second case, you will have to make a wooden frame, with foam plastic mounted between the joists. In this case, the ceiling pie increases, eating up the useful height of the premises.

There are also two ways to attach foam to the ceiling. With or without a frame. The choice of method depends on what material the ceiling is made of and technical capabilities.

Ceiling insulation with foam plastic

When insulating the ceiling, it is worth remembering about waterproofing and vapor barrier. Polystyrene balls are not afraid of water, but moisture can accumulate between them. Manufacturers are usually silent about this property. In this case, the ceiling should contain the following layers (they are listed from bottom to top, from the side of the warm room):

- the material with which the ceiling is sheathed;

- vapor barrier necessary to protect the insulation;

- insulation;

- floor design;

- waterproofing (sometimes mounted on top of the ceiling);

- floor of the next floor.

Insulating the ceiling of a house (attic floor)

If necessary, insulate the floor, vapor barrier is also laid below, and waterproofing on top. It is important to remember that the first is always located on the warm air side, and the second on the cold air side.

Wall insulation

Foam plastic is also actively used for thermal insulation of the walls of houses from the inside. In this case, steam and water protection is also required. When performing interior finishing, it is worth leaving a small gap between it and the heat insulator to eliminate settled steam.

But it is important to remember that polystyrene foam is not the best option for walls. It has extremely low breathability, so it can create a greenhouse effect indoors. In this case, you will have to take care of installing additional forced ventilation (which is expensive).

Based on all of the above, we can generalize: polystyrene foam is an inexpensive material to protect a home, with an impressive list of disadvantages. It makes more sense to use it for floors than for walls. In a wooden building, if possible, it is better to use vapor-permeable mineral wool.

Pros and cons of expanded polystyrene

It is necessary to understand that styrene, which is a by-product from the oil industry, is used to make the material. Therefore, it cannot be said to be an absolutely environmentally friendly material. It is produced only industrially; artisanal and home production of polystyrene foam boards is impossible.

However, extruded polystyrene has a number of significant advantages:

- low cost compared to other insulation materials;

- high thermal insulation rates due to the dense structure;

- low weight and good compression resistance;

- has excellent soundproofing qualities;

- moisture resistance;

- a wide choice depending on its characteristics: density, thickness, surface structure, end edges (straight or groove), color palette;

- able to interact with various adhesives, lime, gypsum, cement, salt, bleach, water-based paint;

- does not rot (decomposition of the material in the ground can exceed 10 years);

- fire resistant (fire temperature is 2 times higher than wood);

- durability (manufacturers guarantee a period of operation from 15 to 60 years);

- no need to use special tools for cutting and installation.

The material is created artificially and has no natural origin. It contains many chemical additives and compounds that are unknown to the average consumer, so in addition to its advantages, polystyrene foam has disadvantages:

- reacts negatively to ultraviolet radiation, from which the structure is destroyed over time and the original characteristics are lost;

- reacts negatively to gasoline, fuel oil and various types of solvents;

- susceptible to destruction by termites and rodents;

- in case of combustion, a gas is released, which is many times more dangerous than carbon dioxide (it is fatal for humans).

Important! When heated, polystyrene foam emits toxic fumes, so its use in baths, saunas and similar rooms is prohibited.

*

Why is it better to insulate with foam plastic?

There are a number of factors:

- Materials from the expanded polystyrene group are ideal for arranging floors, as they help solve two problems simultaneously: they provide thermal insulation and prevent the penetration of steam and moisture. Owners of residential and commercial premises located on the first floors are especially in dire need of vapor and waterproofing.

- Polystyrene foam and its extruded “brother” do not absorb ground moisture, which, being an ideal conductor, significantly reduces the insulating properties.

- A square meter of materials can hold a load of up to 350-400 kg without destroying the structure, which significantly exceeds the performance of most finishing floor coverings.

- This type of insulation is compatible with electrical and water equipment of “warm floor” systems.

- The structure and geometric parameters of materials do not change either from moisture, which causes swelling of most insulation materials, or from prolonged exposure to high temperature.

- Expanded polystyrene is resistant to negative factors of chemical and biological origin.

- Simple, non-labor-intensive installation. The slabs can be easily cut to create small segments; using polystyrene foam, you can insulate floors in rooms of any size or configuration.

And the main advantage is the affordable price, affordable for most who want to make repairs or build their own home and carry out effective floor insulation with foam plastic at budget rates.

Floor insulation with foam plastic - cheap, effective

How to insulate insulation

Environmental influences, moisture, temperature changes, cold have a certain effect on any materials. Areas where access is restricted require special attention. To protect wooden walls and house structures when insulating with polystyrene foam, it is necessary to pay attention to waterproofing and vapor barrier. For this purpose, special roll materials are used.

Vapor barrier film

During the insulation process, the waterproofing material must be fastened on the cold air side (street, ground, concrete base). The vapor barrier is installed on the side of the warm air flow (inside the room). An alternative vapor barrier option can be polyethylene film used to cover garden greenhouses.

Gate protection

Many people are faced with the problem of seasonal “walking” of the pillars (the base of the gate), which is why they do not close.

The best solution is to protect the base (posts) from freezing when installing the gate. If you have already installed ordinary iron gates, then they must also be thermally insulated from the inside. If it is possible to attach the sheets with dowels to the material from which the gate is made, it is worth doing so.

If not, the usual glue method will do. The already glued insulation is covered first with a vapor barrier film, then with outer skin. To enhance thermal protection, you can use foiled polyethylene.

Thus, the correct choice of thermal insulation material makes insulating a garage a fairly simple process that anyone can do.

Hello, reader of the site about DIY repairs BabyRemont.ru.

One way to insulate your home is to insulate the walls outside the house. For this, extruded polystyrene foam or foam is used. The installation of these panels is identical.

For insulation of brick and reinforced concrete walls, extruded polystyrene foam is used without a vapor barrier. But, if you are going to insulate aerated concrete (foam concrete) walls from the outside, you must additionally make a vapor barrier on the warm side.

The thickness of insulation panels for external walls should be, on average, 5 cm. But this directly depends on the wall being insulated and the climate zone. Before purchasing extruded polystyrene foam or polystyrene foam, to select the correct thickness, first consult with specialists or the seller (perhaps he is also a specialist).

Extruded polystyrene foam, like polystyrene foam, protects from both cold and heat.

Thanks to this, comfortable living conditions are created. Before thermal insulation from the outside, level the surface of the walls using plaster solutions. Do not install insulation on an uneven surface!

Attach thermal insulation boards to the walls only after the plaster solution has hardened.

Installation of expanded polystyrene

To insulate floors and walls with polystyrene foam in a wooden house, different technologies, features and recommendations are used. Laying on the floor is usually done using wooden joists. To do this, you need to make a base from the bottom. You can use 2 methods, one of which is to fasten boards or other material at the bottom of the joist, as a base for insulation.

The second option is to install slats on the left and right sides of the joists, onto which the base for the insulation is subsequently mounted.

The bars are fixed to the side of the lag, and a board is laid on top

Before installing the insulation, it is necessary to lay waterproofing in the base, which will prevent the penetration of moisture from the ground or concrete (in the case of a monolithic slab foundation). Next, the polystyrene foam boards are laid. It is recommended to install the material in several layers (minimum 150 mm in height in 50 mm slabs). The layers must be laid so that the seams between the material are covered by the next layer. The principle of chess order.

It is imperative to leave a ventilation gap of about 20 mm between the top edge of the joist and the insulation. If the polystyrene foam is flush or higher, then you need to additionally raise the height over the entire area using lathing.

A layer of vapor barrier is laid on top to prevent the penetration of steam from the heated house. Next, you can begin installing the subfloor, where floorboards, plywood or OSB boards are used.

How to attach polystyrene foam to wooden walls of a house

Insulation of the facade of a wooden house is carried out using frame technology. It consists of the construction of a frame into which the insulation is placed. All work is carried out in stages.

An example of a frame system for insulating a house

*

Principles of installation work

Regardless of the choice of type of thermal insulation, it is necessary to follow the sequence of work performed for proper insulation. If we consider the structure from bottom to top, it will look like this:

- waterproofing layer;

- thermal insulation layer;

- vapor barrier layer;

- design for floor installation;

- floor.

Compliance with this order of work guarantees the maintenance of normal temperature conditions in the room and protection of the structure from freezing and rotting.

The easiest way to insulate the bottom is through joists. They are beams measuring 5x10 cm or more, on which the floor is subsequently laid.

Scheme of floor insulation using joists Source nehomesdeaf.org

Surface preparation

An important step before starting to insulate a wooden house is preparing the foundation. The reason for this is wood, which is very capricious to many factors. Old houses and new buildings are insulated. It is necessary that the surface is dry, the wood must be dried. If the house has been painted, then all paint must be removed. The joints between logs or beams must be well caulked. If additional caulking is necessary, this must be done before insulation. You should also fill up all potholes and remove any remaining bark if present.

As soon as the surface is ready, it is treated with antiseptic agents. The choice of composition is a responsible step, because in the future the contact between polystyrene foam and wood will not be visible. It is necessary to create such conditions so that the walls of a wooden house do not end up in conditions that expose them to rot and further destruction. It is recommended to read the instructions for use before purchasing.

Installation of sheathing

To install insulation, you need a frame that securely holds the material, does not allow it to slide down over time, and allows the material to be ventilated. It is necessary to use only dried wood, otherwise the bars may twist after installation. Expanded polystyrene suffers from this, gaps form (cold bridges), and the finishing and façade material may also be damaged. Before installation, it is recommended to treat the bars with an antifungal and antiseptic agent.

The bars are attached to wooden walls with self-tapping screws vertically and horizontally. To do this, the bars are sawn through at the junction points and a groove is made for the connection.

Connecting bars into half a tree

The distance between the bars should be approximately 5 mm less than the width of the insulation. This will allow the polystyrene foam to fit tightly into place, eliminating any gaps. If several layers are to be laid, the seams of the subsequent layer should overlap the seams of the previous one.

It is easy to insulate wooden houses made of timber, but log houses are more difficult. The surface is not flat, so special attention must be paid to its preparation. You can use spray foam or seam sealant to repair potholes and small uneven areas.

Waterproofing and installation of polystyrene foam

After installing the sheathing, a vapor barrier is laid out, and expanded polystyrene slabs are mounted on top of it. To secure the material, you can use special nails with a large washer. In the future, this will prevent the sheets from moving away from the wall over time.

The wide washer allows you to firmly hold the insulation boards

Then the polystyrene foam is attached to the wooden wall. A vapor barrier in the form of a diffuse membrane is laid on top. One type of waterproofing material is isospan.

The entire insulated area is covered with a vapor barrier

It is important to look at the instructions for use supplied with the vapor barrier. The sides are different in composition and purpose, therefore, in order for the material to perform its function, it must be laid on the desired side. The waterproofing is attached to the wall with a furniture stapler, and at the joints it is taped with construction tape. The film is overlapped over each other by approximately 10-15 cm.

How to stick polystyrene foam on a wall

It is possible to attach the insulation to wood using a special adhesive or polyurethane foam. Both options are expensive, making it costly when compared to using sheathing. It is better to use an adhesive composition, because it comes in the same containers as foam, but has more yield as a result.

Glue or foam must be applied to ensure a secure bond to the wood surface.

The technology consists of preparing the base, removing any coatings, protrusions, or potholes. Ideal for houses made of timber and completely inappropriate for insulating log houses. In the latter case, the points of contact of the material are small and the difference in the logs will not make it possible to create a flat surface.

Expanded polystyrene is laid over the entire surface after applying glue or foam to it. The problem lies in further finishing, because with the lathing the fastening process is clear. If glued, the house can be plastered, which is not ideal for a wooden structure. The second option could be the construction of an additional structure in the form of a frame for the construction of the facade.

Finishing after insulation

Thanks to polystyrene foam, an entire “thermos” is created, which retains heat inside and prevents cold air from penetrating inside. This significantly reduces the heat loss of the building, saving money on heating. The final stage is finishing the facade.

Finishing the facade after insulation with polystyrene allows you to realize any ideas

For this purpose, wooden products are used - lining, imitation timber, block house, as well as various types of siding. Depending on the type of finishing material and its method of fastening, a second frame is built on top of the sheathing with insulation. It is on this that the finishing material is installed.

Advantages of using foam plastic in thermal insulation of floors

The color of the material does not in any way affect the quality characteristics and features of working with insulation.

The key advantages of using foam boards for thermal insulation include:

- The insulator has excellent ability to retain heat indoors;

- Subject to certain operating conditions, PPS is absolutely safe from an environmental point of view;

- Polyfoam also has excellent hydro and sound insulating properties;

- PPS can also be praised for its durability in operation.

Foam plastic is resistant to negative external factors. That is why the material is considered one of the best types of thermal insulators.

Details about the properties of the material can be studied in the video: