Provide an open terrace at the project stage, rejoice at how beautiful and original it is. For a couple of years you will suffer from the inability to use it one hundred percent due to rain, wind and snow. Glaze the terrace. It takes a long time to get rid of the thought that such a beautiful room is empty most of the year - but you can receive guests there, have dinner, drink coffee and generally do something functional. Insulate the terrace.

Familiar algorithm, right? We have collected several terraces from FORUMHOUSE, which were open in a previous life and offer you to look at their before and after photos.

DIY frameless glazing

For the first time, frameless glazing appeared in Finnish homes. The purpose of such an unusual arrangement of glass on a glazed balcony was simple: to increase the amount of light and fresh air. Gradually, frameless glazing technology took root and spread beyond the country. Nowadays, frameless glazing is not uncommon; it attracts consumers with its light, even airy appearance, ease of installation and the large amount of light that enters the room due to the absence of frames. Frameless glazing began to be used not only on balconies, but also to create terraces and verandas in summer cottages.

We arrange the interior

When the installation is completed, you can safely move on to organizing the interior space of the gazebo or veranda. Install cozy sofas and armchairs, buy soft pillows and a bright blanket - then this place on the site will become your favorite. An example of a cozy veranda interior is shown in the photo below. Notice how harmoniously the interior furnishings combine with the panoramic view.

Photo: from the veranda there is a beautiful view of the site

Thus, if you have always dreamed of a stylish and modern gazebo or veranda, frameless glazing is what you need. We hope that the photos and videos presented in our material helped you decide whether you can do this type of glazing yourself or whether you will have to turn to professionals for help.

Pros and cons of frameless glazing

The advantages of frameless glazing include the following factors:

- Maximum light entering the room. During ventilation, most of the glazed space opens, allowing fresh air to freely enter the home.

- A unique panoramic view that will take your breath away.

- Frameless glazing looks rich and respectable. The glass is transparent, does not weigh down the interior, and fits into any room design.

- Frameless glazing uses impact-resistant tempered glass, making the design reliable and durable.

- Glass reliably protects the room from wind and precipitation, and is easy to maintain and use.

But there are also disadvantages to frameless glazing. Among them:

- Lack of tightness of connections, as is done in plastic windows.

- For a person with a fear of open spaces, going out onto the balcony will be a big challenge.

- It is not possible to install a mosquito net.

- To install frameless glazing, choose a high-quality profile, otherwise, after a few years, the fastening will become loose and the glass will begin to rattle during gusts of wind.

Features of the technology

In modern construction, several methods of glazing gazebos are used, but the frameless version occupies a special place. The glass is perfectly flat and there are no optical distortions. In addition, frameless structures are characterized by increased strength and safety, since tempered glass 6-10 mm thick is used for their manufacture. It is extremely difficult to break it, but if it does happen, nothing threatens the health and lives of those around you. The glass shatters into small pieces with rounded edges, eliminating the risk of cuts and other injuries.

Users often search for:

- Wooden windows for gazebos

- Methods of glazing verandas, terraces and gazebos

Such structures are vertical strips of glass from 50 to 70 cm wide, which are fixed only at the top and bottom.

Frameless glazing is combined with different materials, be it wood, brick or metal. The photo below shows a gazebo made of wood, stone and glass, which are in perfect harmony with each other.

Photo: gazebo made of combined materials with frameless glazing

Types of frameless glazing

The design features of opening the glass sheet lie in the classification of frameless glazing. There are three main types of opening glass sashes:

- Opening according to the book principle, when the doors move to the side, positioned one after another, gathering into an accordion book. Depending on the project, the sashes can move in one direction or in two opposite directions. The most common system, it provides reliable protection from dust, wind and cold.

- Moving the doors apart in different directions, following the example of doors in a wardrobe. The use of technology is typical for terraces and gazebos, however, it is not suitable for radius doors.

- Rotation of the sash around its vertical axis.

Maintenance of sliding structures

To ensure that the installed system lasts for many years and does not lose its newly purchased appearance, it is recommended to study and take note of a number of maintenance rules:

- Once every 2-3 years, it is necessary to disassemble the sashes and clean them with a damp cloth or vacuum cleaner from accumulations of dust and dirt.

- If you have a “cold” aluminum structure, you need to thoroughly clean the gap seals every year, since a lot of dust accumulates there.

- The mechanism must be lubricated to ensure good operation.

- Handle the sashes extremely carefully, especially if a lift-and-slide system is installed.

- During severe frosts, the doors often freeze and it is simply impossible to open them, but the use of brute force is strictly prohibited. Instead, you should keep a special product on hand - a glass defroster. If purchasing it is not possible, you can use a hairdryer to heat the required area.

There are very few rules, but following them you can significantly save money and time on calling technicians and repairing broken mechanisms.

DIY frameless glazing

Before starting installation work, it is necessary to properly prepare the materials. Selecting glass for frameless glazing is the most important step. The thickness of the glass depends on the number of floors of the balcony and the height of the opening. The higher the balcony is located, the stronger the wind load. If the opening for glass also exceeds 2 m, the glass itself should be no thinner than 8 mm. On the lower floors, 6 mm thickness is sufficient. Inspect the glass and profiles before starting installation: the glass must be free of holes and chips, the profiles must be free of nicks and irregularities.

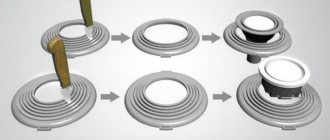

Step-by-step instructions for installing frameless glazing consist of several stages.

- Dismantling old glazing, frame, window sill, profile. Once the old window elements are removed, work on the base. Remove stones and uneven surfaces from previous window installations. To do this you will need a hammer and a grinder. On the contrary, fill the resulting cracks with putty.

- When installing frameless glazing, start with the top profiles. Install the profile at the upper end of the opening, secure it with bolts, and install the corners along the side ends of the opening. Check the horizontal profile using a building level.

- Fasten the corner strips near the bottom end, install the bottom profile, fix and check the horizontal position.

- Hang the glass by first inserting the top part into place, then install the bottom part. Check the joints between the glasses for leaks.

It is not difficult to do frameless glazing yourself, however, it is important to remember that manufacturers provide a guarantee on system elements only when the glazing is installed by a professional team. In other cases, you take on the risks of premature failure.

Which double glazed window to choose

Single-chamber and double-chamber double-glazed windows are in greatest demand. One chamber means that the window structure consists of two glasses, between which there is an air gap. It prevents the penetration of cold air. Single-chamber glass can be installed in a gazebo that will not be used in winter.

If you plan to create a year-round gazebo, then it is best to use double-chamber glazing. Such canvases include three glasses, between which there are two air spaces. It is this design that will provide the best protection from the cold.

Such a gazebo with sliding windows will be functional and comfortable.

Gazebo made of plastic windows

A gazebo with plastic windows may involve the use of such windows as a frame. This means that the structure will not have classic support pillars. All its walls will be represented exclusively by plastic windows. Sliding windows into this type of gazebo are also possible.

- Such buildings have certain features that need to be specified in more detail:

- Plastic gazebos need a foundation. After all, plastic windows themselves with a PVC or aluminum profile cannot serve as support for the entire structure. They cannot simply be installed on the ground or secured in any other way;

- The configuration of gazebos with glazing can be any - rectangular, square, with six corners, and so on. But creating a round gazebo will not work, since the profiles will inevitably create many angles. But outwardly such a design will be very similar to a round one;

- Plastic windows must be installed on a solid foundation. For this you can use a wooden beam. Such logs are laid directly on the foundation. They are strong enough to support the weight of the structure;

- When constructing such gazebos, it is necessary to make the foundation correctly. The durability of the building and its stability will depend on its strength.

You need to know that the base for the gazebo must be larger than its boundaries. That is, the dimensions of the base should exceed the dimensions of the gazebo by 50 cm on each side. At the same time, gazebos made of plastic windows are very beautiful. They let in a lot of light and leave room for decorating the interior space with decorative elements. At the same time, a gazebo with sliding plastic windows retains heat perfectly. If you build a hearth or stove inside, the building can be used in any weather.

Installation of windows in a polycarbonate gazebo

The glazing can be continuous. In this sense, the use of polycarbonate should be noted. This material can simultaneously act as glazing and as the walls of the gazebo.

The construction principle will be standard. It is necessary to attach polycarbonate fragments that were made in advance to the support pillars.

Such gazebos have a number of significant differences. They need to be described in more detail:

The important elements will be the floor and foundation. To construct the foundation, you must use columnar technology. They consist of erecting low brick columns, on which wooden logs are subsequently laid

The columns should be raised above the ground level by 30 - 40 cm; In addition to the foundation, serious attention should be paid to the construction of the floor. The basis will be horizontally laid timber logs

Boards and moisture-resistant plywood are laid on the indicated logs; Supports for fastening polycarbonate are attached to horizontal joists using angles and brackets.

Installation of windows taking into account the roof

Since plastic windows or aluminum profiles cannot withstand high pressure, heavy roofing materials should not be used. It is not recommended to use metal tiles or natural tiles.

Polycarbonate or soft roofing is ideal. If you plan to install natural tiles, you should make a strong top trim from timber. It will be able to withstand the load of a heavy roof and protect the frame made of plastic windows from damage.

In this case, glazing can be combined with wooden fencing. It can reach one and a half meters in height. An aluminum profile or plastic windows are installed on this fence as a frame.

Windows are installed using construction foam. This is a universal option for such designs.

Evolution of an open terrace into a closed one: glazing and insulation

Provide an open terrace at the project stage, rejoice at how beautiful and original it is. For a couple of years you will suffer from the inability to use it one hundred percent due to rain, wind and snow. Glaze the terrace. It takes a long time to get rid of the thought that such a beautiful room is empty most of the year - but you can receive guests there, have dinner, drink coffee and generally do something functional. Insulate the terrace.

Familiar algorithm, right? We have collected several terraces from FORUMHOUSE, which were open in a previous life and offer you to look at their before and after photos.

Open-closed terrace. First stage of evolution

It happens that family members cannot agree on one decision, and then a compromise has to be sought. A member of our portal with the nickname Pavel Again lived in an old house with an old veranda, the lower part of which was covered with boards, and the upper part consisted of frames with many pieces of glass of different shapes.

When they started modernizing the terrace, some family members insisted on an open version, while others dreamed of a closed one. We agreed on removable windows. Here is the technology used:

We screw threaded rods into the wall and hang sheets of transparent plexiglass on them from the floor to the roof (this is about 2.5 meters).

This is how this terrace lives: in autumn and winter it is closed.

And in the summer it is open.

Unheated terrace. Second stage of evolution

The next stage in the evolution of the terrace is a glazed unheated terrace. At this stage, terrace owners often have doubts about why they should cut off an unscorched terrace at all. But it usually turns out that there is a sense in this, and a considerable one.

A member of our portal with the nickname igestor built a beautiful house with a large open terrace, and in the very first winters he encountered all the disadvantages of such a structure on a hill and in an open place. This room, open to all winds, was uncomfortable even in summer.

But I am mainly tormented by the question of the feasibility of solid glazing of the terrace.

Like all owners of unheated terraces, our user was afraid of condensation and the fact that the double-glazed windows would not withstand frost. But he still decided on glazing: in the far side opening it is solid, and in the rest, including the door, sliding frameless.

Our other participant with the nickname Vit070476 came to the same decision, and after the very first winter.

The result exceeded expectations; we essentially got a gazebo, but without the snow and dirt.

His advice: be sure to provide opening doors, otherwise in the heat it will simply be unbearable to stay in such a room.

I was advised to do this at the construction stage, but I’m the smartest. In the end I did it and I’m very happy about it.

The double-glazed window serves without incident, there are no distortions, no condensation forms - apparently, the room is cooled evenly. In winter, the terrace is 10 degrees warmer than outside.

Here is a version of a member of our portal with the nickname Sintetik. The experience of operating an open terrace quickly showed that it is impossible to live like this any longer, it needs to be glazed.

The unheated terrace will be used only in warm weather; the rest of the time it is just a vestibule in front of the entrance to the house, protection from bad weather.

The terrace area is small, 16 meters, so instead of a simple double door that would eat up space, they decided to install sliding structures.

Aluminum profile with one glass. All three glasses move, height 2.8, width 60-85 cm, paired rollers, 4 rollers per sash.

Materials used

Unlike an open or semi-closed canopy, a closed garden gazebo can be used at any time of the year. Such buildings combine the functions of a summer kitchen and a platform for relaxation and pleasant time with the family, so the choice of glazing of the building plays an important role.

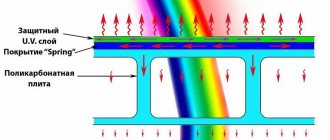

Polycarbonate sheets are a synthetic thermoplastic polymer that is produced by the organic synthesis of carbonic acid. Polycarbonate is not hazardous to the environment. Due to its safety and environmental friendliness, polymer plastic is used in the construction industry, the national economy, instrument making and medicine.

There are two types of polymer plastic: monolithic and cellular.

When choosing window material, do not forget about the conditions of the location where you live

Monolithic polycarbonate is a solid material, the main technical characteristics of which are high impact resistance, resistance to temperature changes and maximum light transmittance.

Honeycomb, or cellular polymer plastic consists of two panels connected by perpendicular jumpers. The degree of flexibility of the material, its strength and endurance is determined by the number of internal ribs.

When choosing a glazing material, it is recommended to take into account its technical characteristics and features. So, for regions with severe frosts and gusty winds, a monolithic fabric is suitable. Cellular polycarbonate retains heat better and has high noise insulation properties.

In this video you will learn how to install polycarbonate windows:

Converting a summer terrace into a dining terrace with transparent walls. Third stage of evolution

Our forum member with the nickname crystalik has a 6x6 meter bath house at his dacha near Novosibirsk, but the third part of this room is an open terrace.

This distribution of space seemed non-functional to him, and he decided to expand it into a larger space, which would include a kitchen, a dining room and a solid fuel boiler. The following project was born:

The terrace stands on 5 thick-walled stilts. The frame from the side of the house was attached to the protruding heads of the piles on which it stands. From the side of the house, the frame was placed on the heads of the piles on which the house stands, and in two places I additionally screwed in the beam fasteners.

The craftsman covered the closed part of the terrace (where the boiler is planned) with OSB sheets. I installed large windows “warm, not country.”

To avoid condensation on the windows with such a glazing area, low radiators are planned along the perimeter.

To avoid large heat losses, the owner of the house insulated the ceiling well.

We arrived at two o'clock in the afternoon. It was -24 on the veranda after a cold night. They turned on a two-kilowatt convector. The next morning at 11 o’clock it was +12 there, and -10 outside. We warmed up to +22 with a fan heater in an hour, drank tea and relaxed in the warmth.

Summarizing

Any homeowner can convert an open terrace that is not used in the winter into a closed one, if only they have the desire. To do this, you need to properly insulate it from the inside or outside, think about glazing and heating devices.

The impossibility of heating a terrace with panoramic glazing on a budget is refuted by many examples on our portal . Here is the veranda of our participant with the nickname Selshio, which is always warm.

Veranda 6x3, panoramic glazing height 2.8m, SP 1-chamber 36mm, underfloor heating. It’s -30 outside, +19 on the veranda, as it gets warmer outside, it’s hot on the veranda.

Glazing types

Depending on the installation method, the materials and glass units used, as well as the desired effect, it is possible to use several suitable types of glazing, each of which has its own advantages and disadvantages. The choice of a specific method for carrying out glazing work on the veranda and terrace depends on the individual case, the design of the cottage, adjacent and adjacent premises and the funds allocated for creating windows on the terrace.

Cold and warm

To create the required microclimate on an attached wooden terrace or veranda under the roof, two types of glazing can be used - warm and cold. The difference between the finishes lies in the thermal insulation, the materials of the glass frames and profiles, and the ability to retain heat.

With the cold type of frame glazing of the veranda and terrace, an aluminum profile is used without separate double-glazed windows, which makes replacing the glass in the frame more difficult compared to a classic warm frame made of wood or metal-plastic. Plastic casement windows and doors for the veranda are a more common proposal than the use of frameless systems.

The low cost can be counted in favor of the cold glazing option. Warm frameless and frame glazing is more expensive, but casement windows retain heat better. Frames and double-glazed windows of warm glazing are quite easy to maintain.

Partial and complete

To create an atmosphere on the veranda at the dacha or in a private cottage, two types of glazing are used - partial or continuous. Their main difference is the area of the double-glazed windows.

When using partial glazing of a veranda or terrace, there may be two or three blank walls and only one open wall with glass. In the panoramic glazing option, only the veranda wall adjacent to the permanent structure remains blank, and all others will be replaced with double-glazed windows.

The advantage of partial glazing is easier installation and maintenance, as well as the cost of casement glazing for windows and frame installation work. The disadvantages of such glazing are limited visibility and the merging of a wooden veranda with a private house.

The panoramic option of glazing the veranda to the house in a circle with double-glazed windows will cost more than simple, but thanks to it you can immerse yourself in nature. However, with continuous glazing, you will need more double-glazed windows, they will be more expensive to install, and if there are neighbors nearby, the open space may create some discomfort.

Frameless

Unlike the classic frame type, continuous frameless glazing allows you to achieve an impressive visual effect, which is achieved by using large glass rather than standard height glass.

Such frameless double-glazed windows for a wooden veranda attached to a house will cost much more, since the absence of a frame and frame complicates the work and maintenance of all constituent elements of the structure.

A frameless or frameless terrace glazing system is characterized by higher heat losses, which leads to an increase in the power of the heating system of the room.

Sliding windows

Another design option for the system is sliding casement windows for the veranda. Thanks to the high quality of the double-glazed windows, which ensures smooth sliding of all sliding structural elements and their tight fit to each other, sliding double-glazed windows are a good solution to the issue of saving free space on the attached terrace.

Sash frames with aluminum profiles are a good suggestion for regulating the temperature inside the room; they are easy to open and close when necessary. With proper care and proper work, plastic frames and double-glazed windows will retain their strength and appearance for a long time.

Portals

Portal systems are a good alternative to sliding sash structures made from frames for a terrace or veranda, since, like them, with a large glazing area and a high load on the frames, they allow you to open and close windows without affecting the internal space of the terrace.

The disadvantages include the high cost and complexity of installing double-glazed windows with this profile. The performance qualities of double-glazed windows and plastic frames will depend on the correct performance of the work and the location of the window mechanisms.

Like and subscribe to the channel so you don't miss new publications.

Polycarbonate windows

For wooden, brick or siding-lined terraces, simple, inexpensive and easy-to-maintain polycarbonate windows are suitable. You can use different types of this practical and modern material. Cellular polycarbonate has excellent heat and sound insulation properties, it is very durable, not susceptible to weather changes, and can withstand low temperatures well. An additional advantage is the affordable price. Monolithic polycarbonate is rigid and requires greater care when cutting. The material is not highly transparent; finished windows will create a slight darkening on the terrace. This option is suitable for buildings facing the sunny side.

Sheet polycarbonate resembles ordinary glass. It is absolutely transparent, flexible, suitable for creating fancy windows with small sashes. There are different shades on sale, which significantly expands the designer’s capabilities. The disadvantage of this type of material is its rather high price.