The use of special reinforced concrete blocks when constructing a well shaft on their own forces summer residents to think about how to lower the rings into the well without a tap. Following the builders' recommendations while observing safety requirements will allow you to complete the procedure yourself.

Loading concrete rings into the well.

Choosing a site for construction

First you need to decide on your place of work.

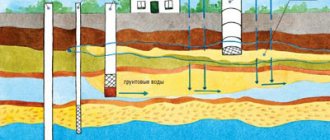

A number of factors are taken into account. Thus, construction near sources of large pollution is prohibited, otherwise water, passing through the upper layers of the earth, will absorb harmful substances. These may be garbage pits or wastewater collection points. Building a well is not always profitable. In this case, the hydrological factor is taken into account. In swampy areas, well water cannot be used.

Before starting work on arranging a well, you should decide on a place on the site

In addition, it is important to pay attention to the topography and type of soil. So, on a slope, getting to the water will be problematic. The location should be as close as possible to the place of consumption

In addition, this will reduce the cost of water supply. But placing the source close to home is also not recommended. An interval of 5 m should be observed. The choice of time to dig a well requires special attention:

The location should be as close as possible to the place of consumption. In addition, this will reduce the cost of water supply. But placing the source close to home is also not recommended. An interval of 5 m should be observed. The choice of time to dig a well requires special attention:

- Spring. Time of active snow melting. It is not recommended to dig at such a time, because you can make mistakes when choosing the depth. It all depends on the increase in the height of groundwater passage. The depth will be insufficient, and the well will dry up in the cold season.

- Winter. It is considered the best time to carry out such work. More precisely, the end of winter. At this time, the water level is lowest. But in cold weather it is difficult to carry out work. But only in winter can you dig a well in places passing through the floating pond.

- When setting up deep mines, a lot of temporary resources are required. And work should be carried out without interruptions. This is why you will need to manage your time correctly.

Construction will require at least three workers. One works in the mine with a shovel, filling containers with earth. The second worker pulls out and carries the buckets. The third one replaces the tired one. The main thing is to do everything quickly.

Recommendations and safety precautions

It is recommended to begin arranging a well by preparing tools and special devices to facilitate the procedure. To work, you will need a shovel with a shortened handle and a lifting mechanism to move the rings.

First, a pyramid-shaped construction tower is installed above the mine. You can make your own tripod from timber or wooden rods fastened at the top. The device is designed to secure the winch. Some craftsmen use homemade welded devices with a collar to lift and lower concrete products. The mechanism is also used to extract the excavated rock from the well shaft to the surface.

To control the vertical position of reinforced concrete blocks, a laser level, plumb line or spirit level is used. You will need a special tub or bucket to lift the excavated soil.

Don't dig too wide a pit. A large excess of the diameter of the well over the size of the ring will lead to displacement of the structure under the influence of external factors. The risk of pit walls collapsing increases.

For the safety of working personnel, the following measures are taken:

- Craftsmen without personal protective equipment are not allowed to work inside a well shaft. At depth you will need a helmet, gloves, safety belt and rubber boots.

- Workers are prohibited from standing under suspended loads. If there is no reliable shelter when lifting and lowering the rings, workers are required to leave the pit.

- The time workers spend at the bottom of the well should be limited. If signs of poor health appear, the assistant should help the master get out.

To comply with safety regulations, it is necessary to provide a safety margin for the construction tower or tripod. It is recommended to equip the lifting mechanism with a metal cable.

To excavate rock to the surface, only whole buckets or tubs are used. Holes and crevices in soil lifting containers increase the risk of injury to personnel by increasing the risk of soil fragments falling on workers' heads.

Comparison of wells made of plastic and concrete rings

Concrete as a material for wells has both advantages and disadvantages. The main advantage is that concrete and reinforced concrete rings for wells have a lower cost compared to analogues made of polypropylene, polyvinyl chloride and polyethylene.

The disadvantages that significantly limit the use of concrete rings include the complexity of installation. There is no way to do this without a crane and heavy special equipment. In addition, concrete rings are produced in standard sizes, which significantly limits their use. Here you can see the weight of the concrete ring for the well.

Now let’s list the advantages of plastic rings:

- Their main advantage is their low weight. Replacing a ring weighing 40 kg can be done by two normal men. Therefore, if the agenda is to build a well in your dacha or in your yard without involving a large number of people and equipment, then plastic rings are the only right solution.

- Due to the low weight, there is a second advantage - the ability to deliver the rings by your own transport to any place in your personal plot.

- Polymers are plastic materials. If, for example, water in a concrete well constantly freezes and thaws, then, in the end, this will render it unusable. Plastic wells are not sensitive to rapid changes in temperature, as well as increased soil vibration. So in some places (near the highway, working mechanisms) plastic rings are an alternative that will allow the well to go without repair for a long time.

- The ease of installing plastic cannot be compared with installing concrete rings. Polymers can be cut, sawed, sanded and bent. Therefore, each well made of plastic rings is customized to the specific needs of the customer.

- Thanks to the threaded connections, the plastic rings are tightly screwed onto each other. Special impregnations and mastics complete the 100% tightness.

The variety of polymer wells knows no bounds. In addition, you can always order an individual project, which will not cost much more than a standard one. The ease of working with plastic and the relative cheapness of its production allows us to talk about a new era in building materials.

Prefabricated plastic rings have a guarantee of 50 years. But even if something happens and one of the rings of the sewer, drainage or drinking well is damaged, it can always be replaced. Screw connections make dismantling and installing new elements much easier.

Types of plastic wells

Sewer. If there is no centralized sewage system at the dacha or there is no desire to install a storage septic tank, then a plastic sewer well will always help out. Install special kinets at the bottom through which the liquid will flow into the soil. Drainage or absorption. This is a type of sewer well. You can do without a chute, but you need to put a bed of gravel and sand on the bottom. Classic drinking. Here, plastic can be used not only at the initial stage of constructing your own water source. With the help of prefabricated plastic rings, you can “reanimate” an old concrete structure. Leaks at the joints of reinforced concrete rings, unpleasant odors from the depths of the well, clogging of the aquifer and other problems can be solved by restoration. This process is also called “rehabilitation.” To do this, take plastic rings of a smaller diameter than the former well and sequentially screw one on top of the other. A cushion of sand and cement is poured between the concrete walls and plastic rings. A filter of fine-grained gravel and sand is poured onto the bottom. As a result, there is no need to dig a new well, which saves tens of thousands of rubles. Cumulative. This type of well is adapted for collecting rainwater and using it for irrigation.

It is important to ensure the tightness and reliability of the butt joints, because the water here will be above the aquifer. The strength characteristics of plastic rings for wells allow them to withstand significant pressure and mechanical loads in any direction

Observations. They are designed for monitoring and repairing sewer systems. They are equipped with ladders, handrails and other devices for the convenience of operating personnel.

How to prepare

Preparation begins with choosing a method. In order to perform the work efficiently and obtain the planned result, it is necessary:

- Study the composition of the soil below the bottom of the excavation. To do this, it is advisable to carry out auger drilling in order to determine from the extracted samples to what depth the well shaft needs to be increased and to obtain the required water level.

- Based on the obtained soil samples, on the advice of experts, decide which immersion method to use. It is important that under the bottom of the excavation there is no quicksand (a layer of silt, sand and clay mixed with water), which can complicate the task and sometimes influence the decision to stop exploiting the source.

- Go down and examine the condition of the reinforced concrete products, possible cracks, depressurization of the joints between the rings.

- Determine the condition and capacity of the soil at the bottom of the excavation, and prevent the concrete structure from sinking during deepening.

- Having decided on the method of increasing the bottom, prepare the necessary materials, tools and equipment.

Preparation is the most important stage of work, which ensures the consistent implementation of the step-by-step plan and the successful implementation of the project.

Typical sizes of reinforced concrete rings

If for some reason you cannot use ready-made products, then the owner of a country or summer cottage should think about options for making them yourself.

To do this, you need to make a mold from available materials, install a reinforcing mesh into it, and then pour in a concrete solution mixed in strictly defined proportions.

Factories producing reinforced concrete products and structures use special product markings. Well rings of standard size have the same height, equal to 900 mm. The thickness of the cylinder wall and its diameter may vary. The wall thickness varies from 70 mm to 140, and the diameter - from a meter to two.

The main dimensional parameters of a reinforced concrete ring for a well: Dв - internal diameter, Dн - external diameter, H - height

With an increase in the diameter of the ring and the thickness of its walls, the consumption of concrete increases. The weight of the product also depends on these dimensions. To reduce the mass of the finished product, they try to reduce only the height of the reinforced concrete ring, and make the walls as thick as possible. On sale you can see products with a height of 350, 450 or 500 mm. They are also called additional rings and are installed upon completion of work, when a product of standard sizes no longer fits entirely into the dug well.

Another way to “legally” reduce the weight of a well ring is through the mandatory use of reinforcing mesh. In this case, the wall thickness can be 6-8 cm, which does not impair the strength characteristics of the product. Therefore, it is better to make reinforced concrete rings with your own hands for building a well on the site.

It is necessary to reduce the weight of the well ring in order to avoid the use of lifting equipment during installation work

This is important for summer residents and gardeners who decide not only to make products with their own hands, but also to move them around the site without the use of special equipment

Image gallery Photos from Hand-made concrete rings are most often used for the construction of water intake wells

They are very advantageous to use in the construction of inspection and rotary wells of storm and drainage sewer systems

Self-produced concrete rings guarantee cost reduction in organizing autonomous sewage systems

Short concrete rings look great as elements of landscape design of the area

Concrete rings for well construction

Rotary sewer well made of reinforced concrete ring

Construction of a septic tank made of concrete rings

Concrete rings in site arrangement

What are concrete rings for?

Most often, concrete rings are needed to construct a well, but they are also used to construct an autonomous sewer system - to make septic tanks or filtration wells. Another area of application is inspection wells when installing stormwater and drainage systems. Even cellars are made from concrete rings. Moreover, there are different options - vertical, horizontal. In general, the scope of application is wide.

Concrete rings are used for the construction of various structures

There are rings of different sizes to suit different needs, they also have different wall thicknesses, and can be with or without reinforcement. Despite such an abundance of choice, many people think about making reinforced concrete rings with their own hands. The thing is that when arranging a site you may need more than one ring, or even ten. Some people spend more than a dozen just on a well. The cost of manufacturing reinforced concrete products is much lower than their retail price. Even taking into account the fact that you will have to make molds for concrete rings. And if you also take into account the cost of delivery, the savings turn out to be very significant.

Description of the septic tank

This model is supplied by a domestic manufacturer that has proven itself well in our market. A septic tank is a voluminous storage tank with thick, durable walls (up to 1.5 cm) and stiffening ribs.

The kit includes a neck for mounting the hatch, a cover and a special biological filter that provides maximum filtration of wastewater. Neck diameter 50 centimeters. Depending on the model, the device is equipped with one or two working chambers connected to each other using overflow pipes.

Septic tanks have a cylindrical shape, which ensures reliable fixation in the ground and high resistance to soil pressure. Filters are also made in the shape of a cylinder and consist of polymer fibers. A separate filter is necessarily included in large-volume products (from 4 cubic meters). This filter can be easily removed from the working chamber and washed with a stream of water. Cleaning is carried out regularly as contamination occurs - not only small, but also quite large organic residues settle on the filter fibers, which over time undergo natural rotting and disintegration into small fractions.

Options for how to deepen with your own hands

Work can begin only after assessing the reasons for the disappearance of water. Each of the methods for reviving an excavation is used in a specific case, depending on the condition of the soil and the flow rate of the aquifer.

It is more convenient to deepen wells at the end of August, beginning of September or in winter, when the level of the aquifer is minimal.

Settling a concrete column

This method is applicable in a shaft of up to 10 links, operating for no more than a year, if there are new rings in it.

Settlement of a concrete source shaft that has been in operation for more than two years, with old reinforced concrete products and compacted soil around the column, can lead to deformation of the structure.

- We prepare for work: shovels, buckets, cable, block on a tripod device; rope ladder, safety belt with rope; canvas clothes, rubber boots and a helmet with an LED flashlight. To pump out water we use a deep pump;

- We remove the protective house, gate (device for raising water). We clear the bottom of silt, crushed stone and sand, check the barrel for displacement of the rings, the presence of cracks and wear on the inner surface;

- the work of removing soil from the bottom is carried out by two workers with practical experience and knowledgeable about safety precautions. The worker below is wearing a safety belt with a rope. We remove the earth from the bottom by digging under the lower ring, using buckets, a cable and a block on a tripod;

- Having removed the soil under the shaft to the height of the reinforced concrete element, use a load and an excavator to press on the upper link, and lower the structure into the shaft to the excavated depth;

- We repeat the process, immersing ourselves to a new layer of water, but no more than three meters. We place new rings on top of the column, securing them to the trunk with plates with anchor bolts and brackets. We insulate the joints between reinforced concrete products with a solution of cement and liquid glass;

- Having lowered the structure to the required depth, we leave the last ring above the surface of the earth. We lower a layer of filter crushed stone into the shaft and pump out the cloudy liquid until it appears clear. We install a protective house.

The advantages of the method of settling a concrete shaft when deepening the source include the integrity of the column (without violating verticality) and maintaining the tightness of the seams between the rings.

Disadvantages - the risk of damage to the trunk links when the structure is pressed in due to the density of their contact with the ground, the limited depth of use of the method. The need to waterproof all connecting seams between the crowns after the column is settled.

Concrete rings of smaller diameter

To increase the flow rate, this method is used.

Preparatory work and removal of soil from the mine are similar to the previous method, with the exception of digging under the lower link of the shaft.

To lower the rings, we use an electric winch with a lifting capacity of up to 1 ton and a metal structure on which it is suspended above the well.

- We increase the output flush with the inner wall of the column. We carry out the work until signs of collapse of the walls of the funnel appear;

- a worker rises from the excavation and the ladder is removed. A ring with an outer diameter smaller than the inner one in the column by 4-6 cm is suspended from the winch cable and smoothly lowered;

- When it reaches the bottom, the descending worker installs it in the center, vertically to the trunk of the source. Then the next link is lowered and connected to the previous one with plates and anchors;

- the rings are lowered until the top link appears in the old mine shaft. As soon as the result is obtained, we stop installing the crowns. If there are no keys, it is necessary to further deepen the well, digging under the lower concrete circle of the new trunk;

- Having installed the column, we waterproof the seams and fill the space between the links of the old and new trunk with a solution of cement and sand.

The positive thing about this option is the use of standard products in dense soil conditions.

Disadvantages include the large weight of the structures, labor-intensive work, and the need to seal seams.

This method is used if it is enough to increase production by a meter to increase the flow rate of the source.

For the filter we use a perforated plastic pipe. The procedure is the same as when installing crowns of smaller diameter, but instead of concrete links, a one and a half meter PVC pipe is used. Its diameter is 4-6 cm less than that of the column links.

- We make holes in it (20 mm) for perforation over the entire area. We cover the pipe with a stainless steel mesh with a fine mesh. The created filter protects against sand ingress;

- To deepen the excavation with the diameter of the rings in the column less than 800 mm, we use a bailer. We remove soil from the bottom of the well by a meter until there is an active influx of water;

- We install a plastic pipe with a mesh on the bottom, sealing the space between the barrel and the link. To prevent it from floating up, we fix it to the concrete column with anchors at the junction.

Square well

The easiest way in suburban conditions is to assemble a square formwork for a well using wood. Of course, a round well looks much more beautiful, but it is very difficult to assemble a shape for it due to the location of the fittings. For beginners, this is the most promising option. The materials you should not use are plywood sheets for square formwork. Firstly, it can be severely warped while the concrete hardens, which will greatly affect the future well. Secondly, if you take plywood, then only with a good moisture-repellent layer, and this is an expense. It is better to take non-dried boards that have lain for about a year in a covered, ventilated area. Such wood has natural moisture, so it should not in any way affect the shape of the structure during the concrete pouring process.

Recommended dimensions of one prefabricated section: 0.8 m - height, 1 m - width and 0.1 m - wall thickness. Thus, we get the following parameters:

- external formwork - 1.2 m by 1.24, panels 0.8 m high;

- internal formwork - 0.96 m by 0.96 m with a height of 0.8 m.

Each section consists of boards of selected thickness knocked together, in this case 20 mm. One section is located above the second, then the structure is completely assembled. If you want a removable option, then for more convenient assembly you can stuff metal corners on the outside of the structure in the corners. For a solid one, you can use rivets.

Afterwards, in the future well you need to place reinforcing mesh and wire every 30 cm, this will be the main condition for the rigidity of the structure. After assembling the reinforcing mesh, concrete can be poured.

The peculiarity of this method is that it is not necessary to use a vibration installation for better quality of the concrete product, since the mixture is compacted well under its own weight. After a week and a half, you can check the result. This is the simplest, but also the most unreliable way to form a well on your site.

Unusual design examples

In addition to traditional installations, there are original options that will become the accent of the site. For example, a well in an oriental style: it looks like a pagoda - with a characteristic bell roof or a 4-6 pitched canopy.

Another option is a hut. From a distance the structure looks like a small house. A window or door is used as a hatch to collect water.

Another idea is nautical style. Instead of a curved handle, a steering wheel is attached to the thread, the chain is replaced with a cable, and the body itself is made in the form of a ship's bow.

Production of reinforced concrete structures

Reinforced concrete products are used to construct wells of various types: gas, inspection, sewer and water supply. Rigid concrete is used to make rings. There are several known technologies for the production of reinforced concrete rings for wells:

- Volumetric vibrocompression. The creation of the structure is carried out by volumetric vibrocompression of concrete products. Processing takes place in special metal forms that have the function of immediate removal of formwork. The use of a brick press increases the speed of manufacturing rings for wells. Vibrocompression significantly saves space for performing the necessary processes. The use of such an installation reduces the need for a large number of maintenance personnel. For high-quality production you will need only 2-3 people.

- Molding creation. Outdated production technology. In this case, the birth of reinforced concrete structures is carried out using metal formwork. A special form, called metal-plastic, has two cylindrical surfaces: an outer and an inner part. A concrete mixture is laid between them. When the concrete has hardened thoroughly, the metal formwork is removed. The use of injection molding technology is only possible if there are large premises, since space will be needed not only for creating products, but also for their drying and subsequent storage. Production volumes depend on the number of metal molds.

https://youtube.com/watch?v=NPLgo_RSpXw

Types of products

The round reinforced concrete structure serves as a reliable assistant during the installation of utilities. Rings are conventionally divided into several main types:

- water intake;

- collectors;

- rings intended for installation of underground cable electrical networks;

- sewer and gas pipeline concrete structures.

Also on the modern market you can find the following products:

- Overlapping rings.

- Device with a lock or with a bottom.

- Auxiliary. Made to order. With non-standard sizes. They are used in emergency situations when conventional rings are not suitable for forming a well depth shaft.

- Wall. Suitable for constructing any type of well. They participate in the formation of the neck of the created structure.

- Reinforced concrete. Actively used during installation of system communications. They will be useful during the construction of a water supply, network, gas, drainage or sewer well.

Concrete structures with different parameters are available in modern construction stores. The standard, maximum dimensions of this product are as follows: height - 100 cm, internal diameter is about 200 cm. Specific weight no more than 300 kg. The maximum wall thickness is 120 mm.

Advantages and disadvantages

Ready-made structures, like any existing building material, have their pros and cons. The strengths and weaknesses of reinforced concrete rings should be noted. Each of the advantages improves the performance of the well. Reinforced concrete products have the following positive qualities:

- Rigidity. Thanks to its rigidity, the ring can be used even on unstable ground.

- Availability of a rich and wide range of sizes.

- Concrete adapts well to any environment, so structures have a long service life. Products can perform their functions without interruption for 100 years.

- They speed up and facilitate the process of installing a sewer or water supply system.

- High quality and reasonable price.

- High level of tightness. The seams fit tightly together. This eliminates the possibility of groundwater getting inside the product.

However, reinforced concrete products have their drawbacks. So, the main disadvantages of these small structures are:

- Lack of mobility. It is almost impossible to move the created water supply structure.

- The weight and dimensions of the product are also considered a disadvantage. To install reinforced concrete devices you will need special equipment. Its use requires additional material costs.

Necessary professional equipment

It is almost impossible to make well rings yourself. It would be more reasonable to purchase their ready-made version, made in production using special equipment.

To fulfill orders, hydraulic equipment is used - a press or a vibroform. Oversized industrial equipment of this type occupies at most 200 square meters and can be mastered even by a person without advanced technical skills.

The technological process is structured approximately as follows:

- A concrete solution is poured into a special tank;

- Under the influence of vibration forms, the raw material shrinks and excess air escapes;

- Concrete is compacted as much as possible in the form;

- The product is delivered to the conveyor where final drying occurs.

Concrete rings should be made from high-quality cement.

The advantage of products purchased from the market is almost 100% protection against defects. It is almost impossible to achieve such a result without specific equipment.

Purchasing a vibrating press for one use is also considered unprofitable. Such equipment is quite expensive and pays for itself only after 5-10 cycles of regular use.

A well and its subsequent care are not cheap, so the owner must be prepared for possible expenses. You certainly shouldn’t skimp on the quality of concrete rings, because remaking an already finished structure will probably cost an order of magnitude more.

Types of well rings

Types of rings

Well rings can be made of two materials:

- Concrete.

- Polymer

Peculiarities:

- Both have excellent properties and characteristics. They are widely used for the construction of water supply wells.

- With them, the process of constructing a structure is quite simple and all actions are completed very quickly.

Types of concrete rings

The ring for a concrete well is made from:

- Concrete mortar.

- Fittings.

- Various additives that increase its strength and environmental friendliness.

GOST 8020 90 well rings come in several brands:

- KFK - rings that are used to equip a sewer well.

- KLK - rings for arranging storm sewers.

- KDK - for organizing in-channel networks - transition wells with various equipment or special transition pipes.

- KLV - these rings are universal, as they can be used for water supply and storm wells.

- KVG - designed for the construction of gas and water supply wells and networks.

According to their characteristics, reinforced concrete rings can be:

- KO - support rings.

- KD - additional ones.

- KS - wall.

- KPN - ring with a bottom.

- There are also rings with a quarter and floor slabs: Gearbox, K 10 10.

More details:

- Support rings for wells are needed if a hatch will be constructed in the future. They are installed in front of the floor slab and can ensure reliable fastening of the hatch.

- Wall rings for wells are ordinary reinforced concrete rings, which are installed on top of each other during the construction of the well. All joints must be filled with concrete mortar to ensure their reliable fastening.

Additional rings

- Castle wells are very similar to ordinary concrete wells. Their main difference is that they have a special lock. They are also called tongue-and-groove. In addition to the lock on the upper part, there are special ridges on the lower part. The design, which is assembled from this type of rings, is distinguished by its strength.

- There are also certain holes that are filled with concrete during installation. All of them, when securely fastened, are not capable of horizontal shifts. Reinforcement also takes part in their production, which gives them greater strength.

- Rings with a bottom are not particularly complex in their design, since they are made like wall rings, only they are additionally equipped with a bottom. Accordingly, during construction they are laid on the bottom of the structure and serve as a support for it.

- There are also adjustment rings for wells. They are used to increase the depth of the well in the range of 50 cm. This allows you to obtain cleaner water. They are made of reinforced concrete or PVC.

Polymer rings for wells

These rings are also manufactured in accordance with GOST.

They:

- More practical.

- They are light in weight.

- They can be of similar types as concrete ones.

- They are most often used for the construction of sewer wells, as they are easily assembled into ready-made polymer structures with a bottom.

How much does a well ring of this type cost:

- The price of polymer rings is lower than that of concrete ones.

- This is due to the versatility of the plastic used for their manufacture.

- You can easily lift the rings with your own hands and do not use special equipment, as when installing reinforced concrete rings.

Ring sizes:

- Inner diameter - 50-60-70-80 cm.

- Height - 10-70 cm.

Types of polymer rings:

- Additional ones.

- Wall.

- Supporting.

- With a bottom.

- With floor slab.

- With or without a lid.

Only in this case, the rings with the bottom are more airtight than reinforced concrete structures of the same type. Many professionals recommend replacing the old method of constructing a well with reinforced concrete rings, with a newer one using polymer rings.

How to lower rings into a well without a tap: options for immersion and nuances of performing the work

The use of special reinforced concrete blocks when constructing a well shaft on their own forces summer residents to think about how to lower the rings into the well without a tap. Following the builders' recommendations while observing safety requirements will allow you to complete the procedure yourself.

Loading concrete rings into the well.

Features of using plastic rings for wells

Separate plastic rings are used to assemble a single well shaft structure. They allow installation work to be completed in the shortest possible time, while reducing overall labor costs by at least half.

In addition, home owners are given the opportunity, with the help of such plastic components, to equip the necessary hydraulic structures in rather difficult climatic conditions, as well as in wet soils, which are subject to deep freezing in winter in regions with low temperatures. Such conditions negatively affect other design options, especially in cases where they are assembled from reinforced concrete rings. Even not very strong movements in the soil layers can contribute to their shift, which can lead not only to damage to the walls and violation of the tightness of the shaft, but also to the failure of expensive equipment installed in the well.

The modern trend in the quick and high-quality construction of various wells is assembly from plastic rings

Depressurization of the walls of a well used as a source of water creates a high probability of its rapid contamination and deterioration, necessitating frequent disinfection. The use of high-quality rings made of plastic solves this problem, since there are reliable ways to connect individual sections into a single sealed structure.

A two-chamber septic tank made of plastic rings - with a sealed container for accumulation and sedimentation of wastewater, and with a perforated one - for removing purified water into the drainage.

Plastic rings are used to equip well shafts intended for the following needs:

- For the construction of a conventional water well, a source of water. Not all ring models are suitable for this purpose.

- For the construction of chambers for local treatment facilities - cesspools and septic tanks.

- For storage wells of storm sewer systems.

Arranging a caisson for a well using plastic rings

- For inspection (inspection) wells at junctions of streams, turns, elevation changes, on straight sections at certain distances, etc.

- Caissons above the well for installing automatic pumping equipment in them, protecting the well from atmospheric pollution.

As you can see, the scope of application is very wide, covering, perhaps, the entire variety of hydraulic structures in a private house.

Tips for repairing wells

In village and summer cottage areas, wells are often built to supply water to the house. The material is wood, stone or concrete. But even the most wonderful and well-constructed well sooner or later requires repair. Wooden structures are susceptible to rotting, and cracks and displacement of rings and stones form in concrete and stone walls. Violation of the integrity and tightness of the well walls leads to a decrease in water quality associated with the penetration of upper contaminated water and soil inside. These processes intensify in the spring during heavy rainfall and intense snow melting.

Restoration and repair work cannot be postponed, because... water becomes unfit for consumption and can cause dangerous diseases. In addition, contaminated liquid leads to disruptions in the operation of pumping systems and filters installed in the well.

Features of repair of wooden wells.

The main reason for the deterioration of the condition of wooden wells is the rotting of wooden structures. It is necessary to identify the damaged area, remove it and restore the seal with new material. To do this, you need to make a platform from boards of sufficient thickness of such a size that a repair worker can freely sit on it, and it can freely move up and down inside the well shaft. The platform is secured with cables to a beam laid on the head so that it can be easily lowered and raised manually or by means of a gate.

Sequence of work.

1. Strengthening (hanging) the part of the frame that is located above the rotten area. To do this, you need to install “goats” on both sides of the well head. On them, on each side of the well, place 4 logs of shorter length, to which nail 2 reliable boards. Secure the crowns of the log house onto these strong boards with long nails.

2. Removal of damaged sections of the log house. Thanks to the preliminary suspension of the upper sections when removing rotten boards, the structure will not collapse.

3. Replacement of removed logs. The removed damaged area will serve as a template for making a “patch.” New logs are prepared according to its dimensions and driven in to replace the removed ones. When installing the patch, make sure it completely covers the exposed area. New logs are hammered with a wooden hammer and wedged. If the defective area is located in the underwater part of the well, then it is necessary to first pump out the water and replace it, preferably with a concrete part.

Type and structure

If you have decided on the location, all that remains is to choose what kind of mine you will make your mine. You can only dig a mine well, and you can drill an Abyssinian well. The technology here is completely different, so what follows will be about the mine well.

Well shaft type

The most common one today is a well made of concrete rings. Common - because it's the easiest way. But it has serious drawbacks: the joints are not at all airtight and through them rain and melt water enters the water, and with it what is dissolved in it and what has drowned.

Disadvantage of a well made of rings and logs

Of course, they try to seal the joints of the rings, but the methods that will be effective cannot be used: the water must be suitable at least for irrigation. But simply covering the connections with a solution is very short-lived and ineffective. The cracks are constantly increasing, and then through them not only rain or melt water enters, but also animals, insects, worms, etc.

There are rings with a lock. Between them, they say, you can lay rubber gaskets that will ensure tightness. There are rings with locks, but they are more expensive. But gaskets are practically never found, as are wells with them.

The log mine also suffers from the same “disease,” only there are even more cracks. Yes, that's what our grandfathers did. But, firstly, they had no other way, and secondly, they didn’t use so much chemicals in the fields.

From this point of view, a mine made of monolithic concrete is better. It is cast right on site using removable formwork. They poured out the ring, buried it, put up the formwork again, stuck in reinforcement, and poured another one. We waited until the concrete “set”, removed the formwork again, and started digging.

Removable formwork for a monolithic concrete well

The process is going very slowly. This is the main drawback. Otherwise there are only positives. Firstly, it turns out very cheap. The costs are only for two galvanized sheets, and then for cement, sand, water (proportions 1: 3: 0.6). It's much cheaper than rings. Secondly, it is hermetically sealed. No seams. Filling occurs approximately once a day and due to the uneven upper edge the result is almost a monolith. Just before pouring the next ring, scrape off the surface of the raised and almost set cement laitance (a gray dense film).

How to identify an aquifer

According to the technology, the soil is removed inside the ring and under it. As a result, under its own weight, it settles. This is the soil that you take out and will serve as a guide.

As a rule, water lies between two waterproof layers. Most often it is clay or limestone. The aquifer is usually sand. It can be small, like seaweed, or large interspersed with small pebbles. Often there are several such layers. As the sand goes, it means water will appear soon. Once it appears at the bottom, you need to dig for some more time, removing the already wet soil. If the water is coming actively, you can stop there. The aquifer may not be very large, so there is a risk of going through it. Then you'll have to dig until the next one. The deeper the water will be cleaner, but how much deeper is unknown.

Next, the well is pumped - a submersible pump is inserted and the water is pumped out. This cleans it, deepening it a little, and also determines its flow rate. If the rate at which the water rises suits you, you can stop there. If it’s not enough, you need to quickly go through this layer. With the pump running, they continue to remove soil until they pass through this layer. Then they dig until the next water carrier.

Bottom filter in a well

Bottom filter device for a well

If you are satisfied with the speed of incoming water and its quality, you can make a bottom filter. These are three layers of cameos of different fractions, which are laid on the bottom. They are needed to ensure that as little silt and sand gets into the water as possible. In order for the bottom filter for a well to work, the stones must be laid out correctly:

- Large stones are placed at the very bottom. These should be quite large cobblestones. But in order not to greatly reduce the height of the water column, use a flatter shape. Lay them out in at least two rows, and do not try to have them stand close together, but with gaps.

- The middle fraction is poured in a layer of 10-20 cm. The dimensions are such that stones or pebbles do not fall into the gaps between the lower layer.

- The top, smallest layer. Pebbles or small stones in a layer of 10-15 cm. Sand will settle in them.

With this arrangement of fractions, the water will be cleaner: first, the largest inclusions settle on large stones, then, as you move up, smaller and smaller ones.

Dig a well in Lyubertsy and Lyubertsy region, prices for digging wells

Digging wells in the Lyubertsy region is carried out using classical technology, which includes five stages: choosing a location, preparing the area, creating a shaft, installing rings and installing a well house.

Each process has its own characteristics and nuances, which should be known to anyone who decides to take on such work on their own. The choice of location for a well in Lyubertsy should be carried out according to the following principles:

- sufficient distance from objects that can pollute groundwater - garbage heaps, cesspools, factories, toilets;

- the distance to any structure is at least 5 m;

- elevated areas with the highest humidity.

But it would not be amiss to carry out reconnaissance work that will show the most accurate data regarding the occurrence of groundwater. As a rule, Lyubertsy is no different from other areas of the Moscow region. The depth here ranges from 4-9.6 m, so a well in Lyubertsy requires from 5 to 12 reinforced concrete rings.

The process of digging the structure is carried out manually and it continues until water begins to appear on the walls of the pit.

As soon as the first drops appear, it is necessary to begin lowering the reinforced concrete rings. This will prevent the ground from collapsing. After this, the digging of the well in Lyubertsy continues. Digging stops only when an aquifer appears.

At the final stage, waterproofing of the seams between the reinforced concrete rings is carried out. Basically, ordinary cement mortar is used for this. A gravel filter is placed at the bottom of the well. Sometimes this procedure is postponed for a year to allow the first cloudy water to clear. After this time, you need to make a clay castle. During this period, the shrinkage of the well will be completed and the structure will not be destroyed.

Well houses

Installation of the well house is the final stage. Such designs perform not only a decorative, but also a practical function. They:

- prevent dirt and various debris from entering the well;

- close the main opening and prevent people or animals from falling; protect from rainwater;

- allow you to safely lift buckets of water to the surface by equipping them with special manual mechanisms.

It is recommended to use a level when installing. The structure should also be securely fixed to the base. After this, the well is completely ready for use.

Prices for digging wells in Lyubertsy

Meterage Number of rings Cost of rings Cost of work Total cost

| 0.8 | 1 | 2 000 | 2 000 | 4 000 |

| 1.6 | 2 | 4 000 | 4 000 | 8 000 |

| 2.4 | 3 | 6 000 | 6 000 | 12 000 |

| 3.2 | 4 | 8 000 | 8 000 | 16 000 |

| 4.0 | 5 | 10 000 | 10 000 | 20 000 |

| 4.8 | 6 | 12 000 | 12 000 | 24 000 |

| 5.6 | 7 | 14 000 | 14 000 | 28 000 |

| 6.4 | 8 | 16 000 | 16 000 | 32 000 |

| 7.2 | 9 | 18 000 | 18 000 | 36 000 |

| 8.0 | 10 | 20 000 | 20 000 | 40 000 |

| 8.8 | 11 | 22 000 | 22 250 | 44 250 |

| 9.6 | 12 | 24 000 | 24 500 | 48 500 |

| 10.4 | 13 | 26 000 | 26 750 | 52 750 |

| 11.2 | 14 | 28 000 | 29 000 | 57 000 |

| 12.0 | 15 | 30 000 | 31 250 | 61 250 |

| 12.8 | 16 | 32 000 | 33 750 | 65 750 |

| 13.6 | 17 | Great Dane | Great Dane | Great Dane |

| 14.4 | 18 | Great Dane | Great Dane | Great Dane |

| 15.2 | 19 | Great Dane | Great Dane | Great Dane |

| 16.0 | 20 | Great Dane | Great Dane | Great Dane |

Production technology

Making reinforced concrete rings is a labor-intensive process that requires certain skills and knowledge. Therefore, for the construction of a small well, it is more advisable to purchase ready-made concrete products. You should know that the formwork for the rings is quite complex in its structural design. Casting work requires precision and accuracy. Compliance with the rules will avoid unevenness, loss of strength and the formation of voids in concrete. The main stages of ring production are described below.

Preparation of materials and tools

Required materials for formwork: two barrels and window awnings.

For formwork you will need:

- two steel barrels of different sizes;

- door or window awnings;

- fastening fittings;

- “pencil” for metal;

- grinder, cutting disc.

To prepare the solution:

- ready-made dry mortar or individual ingredients for mortar;

- concrete mixer;

- a bucket with which to measure the required volume;

- vibration compactor.

Basic requirements for the production process

- It is necessary to ensure sufficient strength of the collapsible form for the concrete rings.

- High-grade mixture not lower than M500.

- Fine aggregate - crushed stone with a grain size of 0.5-1 cm, washed sand.

- High-quality vibration compaction.

- Heating during operation at temperatures up to 5 0C.

Construction of formwork and frame

The outside of a cylindrical barrel is marked with two longitudinal “pencil” lines across the metal in half. Two door or window awnings are attached to the marked lines. Their bends must coincide with the drawn line. The same marking is applied from the inside of the cylinder, along which an incision is made with a grinder. This allows you to make the formwork drop-down. Fastening fittings are used to connect the halves.

The second cylindrical barrel should be smaller than the first. The same marks are made on it as on the first one with a distance between the lines of 1/3 from each other along the circumference. Canopies and spindles are also attached. The cylinder is cut along one line. The hinged parts must be assembled so that the inside of the structure is 5-10 cm higher than the external formwork.

The cylinders should open: the top one - outward, the inner one - inward. A reinforcing frame made of steel reinforcement or metal mesh is poured with concrete in the support ring, forming a strong reinforced concrete layer.

Filling with composition

To prepare the pour, you can use a ready-made concrete mixture or make it yourself. In the latter case, it is customary to take the ratio of cement to crushed stone and sand equal to 1: 1: 3. The volume of water is determined visually so that the solution is evenly distributed inside. The liquid is added in parts with thorough mixing.

The finished concrete solution is poured in portions. Each layer is carefully compacted. To do this, it is better to use a special vibration device. The large weight requires installation by a crane, so four mounting loops with a cross-section of 8-10 mm are installed in the reinforced concrete rings at the molding stage. The ends of the wire are bent and buried in concrete at a distance of 40-50 cm.

Seal

The entire volume is qualitatively compacted to remove air, which increases the strength of the finished product. Bayoneting or tamping with a rod partially solves the problem. In the absence of a vibrating platform, the use of a conventional hammer drill is allowed. To do this, instead of a peak, a reinforcement with a metal plate welded to its end is clamped.

Dismantling

The bolts of the external formwork are loosened. To make the mold easier to separate, the walls are tapped with a hammer. The inner part will be easier to remove if you first place two square pipes in it. After the concrete has thickened and hardened, these parts are simply knocked out of the concrete mold.

Pouring concrete mixture into a mold

When all the preparatory work is completed, they begin to manufacture the well ring.

Work order:

- Preparing the base . A sheet of iron or a wooden shield is laid on a flat surface.

- Form assembly . The blanks are installed (one inside the other), and the parts of the formwork are carefully secured.

- Form reinforcement . A reinforcing frame is lowered between the outer and inner walls of the formwork, fixing its position with wedges.

- Pouring the structure . Thick concrete mortar (W/C = 0.5) is placed in the interannual space in small layers (about 100 mm) and compacted using a steel pin with a diameter of 20 mm. The creamy solution (W/C = 0.7) is immediately poured into the mold to the brim, and then the mixture is compacted with a pin.

- Aligning the rings . After filling the entire form, they begin to level the end of the concrete ring, using a trowel to add mortar where it is missing. The product is covered with polyethylene or thick fabric.

- Removing formwork . Stripping begins after 3-4 days (if the concrete was thick), after 5-7 days (if the solution was liquid), leaving a ring on a metal sheet or wooden panel.

- Maturing of concrete . The reinforced concrete ring is wrapped with packaging film so that the composition ripens evenly over 2-3 weeks, gaining final strength.

It is recommended to wet the product with water every 4-5 days while the concrete is maturing.

The same technology is used to make rings for a cesspool. Detailed information about the classification and methods of manufacturing concrete rings for sewerage can be found in this article.

How and from what to make molds for concrete rings

Factory molds are made of sheet metal and reinforced with stiffeners. Metal thickness is 3-8 mm depending on the dimensions of the ring.

Molds for well rings are most often made of metal

From thick-walled barrels

At home, bending sheet metal with the required radius of curvature is not at all easy. It is much easier to find two thick-walled barrels with different diameters. The diameters should differ by 14-16 mm. In this case, the wall thickness will be 7-8 mm. For a well ring with reinforcement, this is what is required.

To make it easier to work with the mold for reinforced concrete rings, you can fasten the two halves together with door hinges

The bottom of the barrels is cut off, the inside is made higher by about 10 cm - this is more convenient. To be able to remove the formwork from the finished ring, the barrels are sawn lengthwise into two parts. The halves must be connected securely. You can do this in different ways:

- Having welded the corners with drilled holes, tighten them with bolts;

- make “ears” into which to drive wedges.

To prevent the inner part from leading, several spacers must be welded to each half, which will keep the walls from bending.

Having inserted one part of the formwork into another, they are placed at the same distance from one another (measuring the gap in a circle). Holes are drilled in several places for the studs with which they will be secured. Studs are pieces of rod with threads on both sides. The holes are placed one opposite the other so that parts of the formwork can be securely fixed.

Studs are inserted into the drilled holes and tightened with nuts. If the walls of the mold for concrete rings are not very thick, you will most likely have to place large washers or metal plates with holes cut out of metal under the nuts so that the mold does not bend when pouring concrete.

Sheet metal

If desired, you can make forms for concrete rings from a strip of sheet metal and wooden blocks, which will give rigidity to the formwork. Cut the strip to the required length - along the circumference + 10 cm for the connection. The width of the strip is equal to the height of the ring + 10 cm. Bend the sides 5 cm at the bottom and top, and make the same side along the edge of the strip. Drill holes in the side panel for the tightening bolts. Cut the top side every 20-25 cm (less if the diameter of the ring is small). Now the strip can be bent to create a ring. But it is very unstable - it “plays”. Rigidity can be added using a wooden frame.

Molds for concrete rings can be made from sheet steel

From the bar, cut pieces 20-25 cm long. Attach them under the side, drill a hole in the metal, screw sections of bars onto self-tapping screws. With a length of bars of 20-25 cm, the shape will not be round, but multifaceted. If this is critical for you, you can make cuts more often and cut the bars shorter. The height also needs to be strengthened. Bars are also used for this. They need to be fastened more often so that the walls do not sag.

If you know how to use welding, you can go the other way. In addition to sheet metal, you will need a profiled square pipe. 15*15 mm or 20*20 mm will do. First you need to bend four identical half-arcs from a profile pipe. Four large ones are for external formwork and four smaller ones are for internal formwork. Weld cut strips of metal to the arcs.

How to use arches from a profile pipe as a basis

Materials, tools and equipment

To ensure an increase in the mine, certain materials will be required for each of the options used:

- for settling the structure - concrete rings, cement, sand, liquid glass, metal plates with anchor bolts;

- arrangement of the excavated recess with reinforced concrete rings - concrete links with a smaller diameter than the internal ones at the crowns of the column, by 4-6 cm;

- increasing the depth with a plastic pipe and filter - PVC pipe is 4-6 cm smaller than the inner diameter of the concrete column, fine-mesh stainless steel mesh, sealant, anchor bolts, fastening clamps;

- deepening with a well and increasing flow rate through quicksand - casing plastic and metal pipe with a diameter of 25 mm, a tip with perforation;

- deep well pump for continuous operation.

To perform the work, the following tools, equipment and devices are required:

- Shovels, crowbar, buckets, rope; waterproof overalls, rubber boots.

- A device for lifting a bucket from a mine, a cargo concrete block, an electric extension cord.

- Electric winch, electric drill, grinder, well pump.

- When settling the structure, it is necessary to use an excavator.

Cleaning the mine after work

Upon completion of the increase in production, cleanup measures are carried out for further operation of the source:

- the walls of the column are cleaned of moss, dust deposits and clay deposits using a metal brush;

- the seams are insulated with a mixture of cement and liquid glass;

- for disinfection, treat with a solution of bleach;

- pump out the accumulated water and lay a drainage layer of crushed stone on the bottom;

- Keep the source closed for a day and pump out the water again.

After filling with water, the mine can be operated.

We begin to independently increase production after studying the safety rules for working in a mine, the experience of craftsmen who talk in video materials about the methods of immersing wells, and participating in work with professionals.

The header is beautiful and functional

The final stage of the construction of any well will be the installation of the head - a beautiful and functional part. The head is based on a primitive lifting mechanism, but is also designed to protect the source from contamination. If beautifully executed, it can become an excellent decorative element on the site. Also, at the construction stage, it is advisable to think about organizing the water supply to the outdoor shower, if there is one on your site.

The well head is designed at the discretion of the site owner

To organize the head of the well, the upper ring of the well should protrude 60-80 cm above the surface. But in the first year after construction, it is not recommended to arrange the site, since the ground may still subside a little. A temporary lift with a good roof is being built. You can make a head or house for a well yourself or purchase a ready-made one. As a rule, they are sold disassembled, but assembling all the parts is not much more complicated than a children's construction set.

What rules must be followed when servicing a septic tank?

There are simple rules that support the high-quality operation of the system.

- Cleaning. Twice a year, in addition to cleaning the drains, the septic tank must be inspected and the pipelines cleaned. Once every 5 years (or better yet, every 2-3 years) the bottom heavy fats are removed. The volume of sludge should not exceed 25% of the tank volume. When cleaning, part of the sludge is left to restore the microflora.

- Quality of work. The wastewater leaving the system must be 70% purified. Analysis of wastewater in the laboratory will determine the acidity indicator, which will allow you to find out the quality of the drainage system.

- Security measures:

- Work inside the septic tank is allowed only after intensive ventilation and using a safety belt (gases formed inside can be dangerous to human life).

- Increased safety measures are required when working with power tools (humid environments).

A septic tank made of concrete rings makes private housing more autonomous and, despite its shortcomings, it is one of the most reliable and durable options for treatment facilities for suburban real estate.

How to make formwork for a reinforced concrete ring

To make such formwork, you can use Tips from Maksimych, or you can also use your ingenuity. For those who don’t have enough time for this, I offer my proven option, which turned out to be the most convenient for me. Whether it suits you - decide for yourself.

According to the diameter of the future ring you have chosen, select two metal barrels. Extruded stiffening ribs on the walls of the barrels will not affect the ring manufacturing process.

You can find the required diameter of air ducts or pipes. You can also assemble formwork cylinders by connecting individual sheets to each other. Formworks made from plastic barrels show good results.

To deepen or not to deepen?

Drilling a dry well with your own hands is a very difficult and costly task, both in time and money. That is why it is extremely important to determine the feasibility of a future event.

First of all, you need to answer a few questions:

- A decrease in the amount of water in the well cannot be associated with the weather: prolonged frosts or prolonged drought.

- The water remaining in the well retained its quality. It has no foreign odors, is tasty and clean. If this is not the case, the bottom filter may become silted. The problem can be solved by proper cleaning.

- The water level in nearby wells has not changed.

If the answer to all questions is positive, it is quite possible that the problem is in your well, and it needs to be deepened. But there is still no need to rush to start work.

To begin with, it makes sense to carry out the following activities:

- conduct geological exploration by interviewing neighbors - owners of wells or wells;

- accurately determine the daily water flow;

- find out from the meteorological service or from the owners of exploited water sources at what depth their aquifer is opened;

- determine the ability of the soil to “hold” the walls of the mine without settlement.

Such labor-intensive preparatory work is due to the fact that all types of soil have their own characteristics and are characterized by certain nuances during work. Violation of technology and incompetence of the employee can lead to the blocking of the aquifer, or even destruction of the trunk when it gets into quicksand.

Quicksand is soil consisting of a water-saturated mixture of sand, organic matter and silt, which under certain conditions begins to move, which is dangerous not only for the well, but also for nearby buildings.

Mistakes in deepening a well shaft can be costly, both in terms of labor and money. The procedure can be carried out only once and if it fails, the only thing left to do is fill up the well.

At the same time, the cost of a new well dug nearby in some cases may turn out to be less than deepening the old one, and no one can guarantee success.

Experts recommend deepening the mine if several conditions exist:

- There is no quicksand at the bottom of the trunk.

- The well shaft is very deep, at least 10 rings. Otherwise, building a new structure will cost less.

- Good quality of water at the source.

- No deformation of concrete rings inside the trunk. If there are displacements, their value does not exceed 40 mm.

- The daily water flow is less than one ring.

The well will have to be deepened to the second aquifer. This is at least 5 meters, and there are no guarantees that the water in it is suitable for drinking.

Reasons for water leaving the well

The water level in the well may not be constant. It depends on a combination of many factors beyond the control of the owner of the structure.

The hydrogeological conditions of the area come first. Prolonged drought in summer and severe frosts in winter can lead to complete drying out of the well. This is a completely normal phenomenon and does not require any human intervention.

Practice shows that after some time the water will return. Most often, those who dug their wells at the beginning of summer suffer from the consequences of this phenomenon.

At this time there is a peak in the rise of high water, which causes the work to be mistakenly stopped before reaching the real aquifer. Therefore, experts strongly recommend digging a new well during a dry period or late autumn, and even better - in March, before the snow begins to melt.

It often happens that a limited-size aquifer gradually runs out. Moreover, if it does not have regular replenishment, and the operation was quite active. In this case, the question arises, which is better: to deepen the old well or build a new source. In most cases, deepening is more rational as it is the least expensive measure.

The same is done in the event of a sharp drop in the groundwater level in a given area. This occurs when the aquifer or lens cannot be recharged by infiltration of precipitation. In addition, the bottom of the well can become silted, making it impassable for water and forcing it to find other ways to escape.

It also happens that the precipitation level is normal, but there is still no water in the well. In this case, the reason may be the appearance in the immediate vicinity of a new well or borehole with impressive water abundance, which can temporarily “take away” water.

In this case, you need to wait four to five weeks; if the water level has not recovered, you will have to deepen the well shaft.

Deepening a well with your own hands: a review of the best methods to “get to the bottom” of the aquifer

Wells have been used by mankind since ancient times. The technology of their construction has been perfected over centuries and remains almost unchanged. The problems faced by the owners of such structures remain unchanged. One of the most common is reducing the amount of water.

Often the only solution is to deepen the wells to the next aquifer. We will tell you how and in what way the water intake excavation is deepened. You will find out what you will need to stock up on to carry out the work.