Cottages made using frame-panel technology have become one of the best options for suburban housing. They have many advantages typical of two-story wooden houses:

- Durable. If they are cared for promptly and correctly, their service life can exceed 50 years or more.

- Comfortable. In the winter cold, the rooms quickly warm up to the desired temperature, which is maintained for a long time. In summer, heat from the street does not penetrate into living spaces.

- Reliability. Its technical properties are not inferior to other materials used for house construction

- Possibility to build a cottage intended for both permanent and summer residence

- Reasonable price with high quality construction

Offers you the opportunity to build frame houses with an attic. We manufacture components with subsequent assembly at the client’s site. It is also possible to carry out turnkey interior and exterior finishing. After the work is completed, you receive a completely finished home, all that remains is to celebrate the housewarming. The warranty on “frameworks” will be up to 15 years.

How it all began

Introductory:

- The plot is 6 acres, rectangular, slight slope (about 0.5 m).

- Geodesy - a layer of black soil, 1 m thick, 30-35 m of clay, then clay with sand, aquiferous sand at a depth of 40-45 m, no high water.

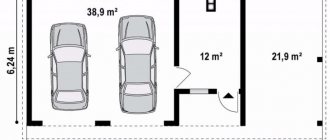

- The house is permanent, for permanent residence, one and a half floors (attic), 7.8x8.4 m, ceiling height 2.6 m.

- The foundation is an insulated Swedish slab according to the standard scheme for light houses.

- Construction - classic platform, thickness of external walls 150 mm, internal 150 mm, pitch of external racks 625 mm, internal 100 mm, external cladding of OSB. Wooden floor with joists, 50×200 mm, pitch 500 mm, span length 3.7 m, rafters 50×200 mm, metal tiles.

- Insulation – stone wool, 150-200 mm, between double racks, crossbars and trims inter-crown insulation (tow).

- The facade is imitation timber.

Layouts.

Design project.

Frame.

General form.

Calculation.

Construction stages

A house with an attic is being built using the following technology:

- Site preparation. The territory is leveled, plant and household waste is removed.

- Pouring the foundation.

- Installation of the supporting frame.

- Installation of walls, flooring, including interfloor ceilings.

- Roof finishing.

- Preparation of window and door openings.

- Laying thermal insulation. The material is used for year-round use of the house.

- Laying of engineering systems. Water drainage, sewerage, electrical networks.

- Finishing.

The frame structure does not shrink, therefore it is suitable for living immediately after the object is put into use.

Foundation

The insulated Swedish stove in 2015 also just began to spread in the central regions, and in the Southern Federal District, specifically in Taganrog, adenart became a pioneer.

adenartFORUMHOUSE Member

According to the USP technology, the black soil had to be completely replaced, but this would not be very cost-effective. After consulting here on the forum with experienced comrades, I decided to make a pillow without removing the entire black soil layer. I removed only 30-40 cm of the root-forming layer. This decision was agreed exclusively for a light house; I would not risk a heavier one.

Implementation according to all USHP rules.

- The bottom of the pit was compacted and covered with geotextile with a density of 160 g/m².

- I filled it with the first layer of crushed stone (one KAMAZ, 5-7 cm), compacted it, the subsequent layers required two unloadings, pouring, careful compaction, and with the last layer I brought the plane to the horizon.

- I filled it with sand, after compacting the 10 cm layer was compacted to 7 cm.

- I marked out the contours of the walls in the sand, assembled a sewer system for fitting, according to a previously drawn up diagram, dug trenches with a slope, laid pipes, backfilled them, compacted them.

- The water supply was introduced using a PP32 pipe with a thick wall, led towards the future well at a depth of 1 m, and insulated.

- I laid EPS with foaming of the joints, additionally fixed them with disc-shaped dowels, foaming the hole before driving in the fungus.

- The ribs were reinforced in two rods with a diameter of 12 mm, on top of a 3x150 mm mesh for attaching the contour of the heated floor, after laying the main line, on top of the pipes there was a 5x150 mm mesh and two more reinforcement rods in the ribs, on stands.

- For the warm floor, I immediately assembled and installed a manifold cabinet and a manifold; I specially took a larger one in order to later install a mixing unit in it, which will be needed to reheat the attic with radiators. The cabinet is located between the technical room and the bathroom, the partition will be assembled from a 50x150 mm board, between the bathroom and the kitchen there will be the same wide partition, inside of which there will be a drain riser and ventilation. The underfloor heating pipes were laid using a combined method: a snake above the external walls in increments of 15 cm and a snail inside in increments of 30 cm, secured with clamps. In the area of connection to the collector, the pipes were covered with thermal insulation; the length of the circuit is about 300 m.

- The electrical distribution panel was placed in the area of the future wall between the technical room and the vestibule, and from this point the cable was routed to the internal walls of the rooms. Wiring in HDPE pipe (20 mm), two cables in one, cable VVG NG ls, in the bedroom, cross-section 3×2.5 mm, in the kitchen two such cables, in corridors and bathrooms with cross-section 3×1.5 mm, similar threw it at the VOC and the well.

- Distribution of the water supply with the same pipe as the TP (Compipe 16×2.0 mm PE-RT/EVOH), because it was left after laying the circuits. From the entrance to the technical room there is a separate pipe for each consumer, a collector for cold water with six outlets, for hot water with four (bathtub and sink in the bathroom, kitchen sink, sink in the bathroom in the attic). I immediately laid the pipes for the attic, leaving about 5 m in reserve. Next, I pressurized the TP system before pouring.

- I assembled the formwork from a 50x150 mm board in order to use it later on the frame, covered it with film, supports and pegs from an inch that was taken on the roof sheathing. All leads and the manifold cabinet were covered with film from EPS packaging so that they would not become clogged when pouring. The lighthouses were assembled from a 28x27 mm profile, on studs; the structure turned out to be flimsy, but when this became clear, it was too late to change it.

- I ordered 9 m³ of concrete at the factory, with the estimated 8 m³, it took approximately 8.5 m³, concrete M300 P4, it began to grab in the middle of the pour, which is why they accelerated and it was not possible to get a perfectly flat surface, but no critical errors occurred. I didn’t do any grounding in the slab, I threw it onto the well casing pipe.

The budget for the USHP foundation with an area of 65.5 m² was 236,850 rubles, approximately 3,616 rubles per 1 m². He hired assistants only for pouring, paying 5,000 rubles for the work. I spent almost 60 thousand more on tools and consumables.

Why choose a frame house with an attic?

The attic design adds aesthetics to the house, providing the opportunity to choose an unusual roof option due to its complexity. The presence of planes of different shapes distinguishes an attic house from single-story frame buildings.

Also a plus is the illumination of the room - windows at an angle let in more light , opening up opportunities for variability in design.

As a rule, it is difficult to live in such a room due to low ceilings, so the attic is used for other needs. For example, arranging a children's playroom, library or office would be perfect.

Frame assembly

While the slab was standing, I took care of the fence, and at the same time poured crushed stone over geotextile on the entrance area in the entrance (entrance) area from the gate and gate to the house. The fence had to be abandoned at the stage of assembling the formwork in order to complete the warm contour before winter; the first two walls were assembled and raised in almost one day, another day was spent on assembling and lifting the third.

Assembly was complicated by the disgusting quality of the lumber - due to the curvature of the boards, the corners had to be tightened with bolts, the nails could not cope. The quick-release and screw clamps purchased ahead of time were very useful.

Not everything went as in Larry Hohn's films; if it was level at the bottom, a lot of effort had to be made to level the top, but things worked out, the box grew. I finally leveled the walls with the help of a winch and a tow rope, cut corner jibs into the corners, the region is windy, it’s not superfluous to insure OSB for your own peace of mind. At the same time, I made an insulated blind area.

There were no difficulties with the overlap - joists with a pitch of 488 mm, bridges (lintels) every 1220 mm, for laying OSB 1220x2440 mm, plus I added a lintel on the walls between the joists. Even without slab cladding, there is no trampoline effect with a span of 3.7 m.

But how to tighten the OSB to the top in one, I had to rack my brains, but even then everything worked out.

adenartFORUMHOUSE Member

I threw 4 50x150 mm 6-meter boards from the ceiling to the ground, near the stack of OSB, fastened them with an inch at the bottom in two places and made a support so that they would not sag. I nailed another board on top, about a meter from the ground, to support the sheet. He pulled the sheet from the stack onto the boards, pushed it a little and rested it on this board, then hooked two clamps on top of the sheet and a cable to them, and pulled it up from the ceiling by the cable. The most difficult thing was to drag the first sheet, or rather, it was more scary, because I had to drag it and step back along the joists, then it was calmer on the OSB.

I couldn’t find any rough nails on sale, so I fastened the sheathing with self-tapping screws (5 and 56 mm), with sizing using “liquid nails” from the middle price category. I twisted the screws “like in a book”, along the edge of the sheet along the edges of the walls after 10 cm, along the edges of the sheet inside the house after 15 cm, inside the sheets after 30 cm.

I covered the first floor with OSB sheets, horizontally, with staggered seams, assembled and raised the outer walls of the attic, gables and internal supporting walls. Raising a ridge made of double boards 50x20 mm, 8.4 m long with a gable height of 4.3 m alone is another puzzle. The decision is risky, but the winners are not judged.

adenartFORUMHOUSE Member

And I lifted the skate, although I didn’t make the scaffolding - I lifted it with a winch as I originally wanted, in one piece. To be honest, it was scary when a 100 kg fool was hanging on a rope above you. And then I had to climb onto a wall 100 mm wide and, standing on it, having no other supports, lift the ridge with my hands and push it into the opening on the pediment. Somehow I was able to lift one side and put it in place, and lifted the other side with a winch, but then I couldn’t do much with my hands, but then the neighbor with whom we raised all the walls looked in, and together we finally defeated him !

The quality of the lumber had an effect here too, even the boards that seemed even were bent, and the ridge tilted a little to the side, but further loading should correct it. I installed supports, the spans along the edges are 2 m, the central one is 3.5 m, there is no deflection.

Before assembling the rafter system, I worked out all the controversial areas (strengthening the ridge, fastening the rafters, friezes, etc.) in a graphic editor, and after the approval of the collective mind, I assembled all the elements.

I laid the membrane, filled the sheathing, laid the metal tiles in the color “moss green”.

I covered the attic with OSB, installed energy-saving windows, as usual, having first carefully studied the theory and consulted with forum members. During installation, I was guided not only by other people’s experience and advice, but also by the current GOST for the installation seam.

I installed a metal front door, I wanted a Finnish one, but the budget didn’t stretch it, so I had to make do with a more affordable option in the first place.

Important points

Having decided to use the attic space to your advantage, you will have to come to terms with the reduction in space due to sloping walls. To make a room comfortable and functional, you need to properly plan the arrangement of furniture.

Windows in the attic are also very specific - they differ from ordinary ones in size and, most importantly, in price. Their cost is higher than classic double-glazed windows for installation in walls.

It is important to take care of thermal insulation and choose the right roof. Without this, the attic will not be able to provide the required level of comfort for living.

Interior decoration

The insulation was laid flat, without trimming, although in a compressed state the thermal conductivity increases, but I didn’t waste time on trimming, the difference in the coefficients “per circle” is not so critical. The attic floor was insulated with 200 mm stone wool slabs, plus another 50 mm of glass wool underneath from the ceiling of the first floor, for sound insulation. I considered the vapor barrier purchased for the whole house to be a bit sticky and laid it in two layers in the attic, and on the first floor I used 200 micron film.

Next, I installed the electrical panel, carried out ventilation and closed the box with a membrane.

I taped the windows and made counter-insulation on the first floor.

The rough cladding of the walls is standard for frame frames - gypsum plasterboard, first I did the first floor.

I decided to make the staircase “solid”, a wooden frame with a niche, covered with plasterboard, and in the niche there was a couch and a house for a cat. The wooden base platform, stringers 60x300 mm, even in the rough version, the design really helped when I had to haul 90 sheets of gypsum board up.

At the same time, I connected a treatment station so that water could be used.

Before laying the tiles, I coated the base around the wet areas (bathroom, sink) with waterproofing mastic, and treated the remaining surfaces with a regular primer.

At this stage, construction costs amounted to about 1.25 million, which included all expenses:

- USHP – 260 thousand rubles.

- VOC – 70 thousand rubles.

- Well – 100 thousand rubles.

- Tools – 70 thousand rubles.

Condition of the house: closed circuit, ready for finishing of the first floor with floors (tiles, linoleum), interior doors, plumbing, simple kitchen and boiler room (electric boiler, boiler, etc.). The second floor is only covered with plasterboard. Both finances and time ran out, and the family decided to move. What remains to be purchased and completed:

- Putty, fiberglass and paint - on both floors.

- Floor coverings are on the second floor.

- Doors to the second floor.

- Facade.

- Fence.

Construction started in the early summer of 2015, almost single-handedly adenart built a one-and-a-half-story house, hired an engineer, practically finished the first floor, and moved in with his family in early March 2016.

Facade, finishing touches, fence

Work continued with cladding the façade with imitation timber, which the craftsman still preferred to “all kinds of siding.” As fasteners I used galvanized nails 2.5×5 mm, in a tenon at an angle of 45˚. Before installation, the boards were treated with colorless fire-bioprotectant, and on the façade they will already be coated with a tinted antiseptic – red-brown “Teak”.

At the same time, interior finishing was carried out.

adenartFORUMHOUSE Member

On the advice of a friend, I do this:

- I putty the joints/screws with starting putty;

- I go through a primer with the addition of glue;

- I glue fiberglass;

- I putty the entire surface with finishing putty;

- Cleaning up;

- I paint it with white interior paint in 2-3 layers.

Living room on the first floor.

Entrance hall and corridor.

As the heating season has shown, it is still impossible to do without radiators on the second floor, since the temperature difference is noticeable. But the stove, as intended, turned out to be an excellent heat accumulator and maintains heat after the heating system is turned off, although the boiler is set to 40˚C and is turned on only at night.

A staircase with automatic illumination of the steps; I made the controller myself, since a ready-made one is twice as expensive. The backlight is dynamic - the room darkens, the first and last steps light up at a third of the brightness. When someone goes up or down, the remaining steps gradually light up along the way and go out behind them.

Children's rooms are on the second floor.

Using leftover drywall, adenart made an imitation of old brickwork in the office; everyone liked it, especially considering the “zero cost.”

The office table is also homemade - edged board 50x150 mm, but in fact, 45x140-45, which after processing became even narrower and thinner. The frame was planed and sanded, the lid was only sanded, everything was varnished.

We also got around to the fence - a wooden picket fence on a metal frame. Initially, a chess game was planned, but the live appearance was not impressive.

Conclusion

adenart was not afraid of difficulties and lives in a house built with his own hands for his family, which is what he wishes for everyone. And its topic can be used practically as a visual aid for anyone who is just about to build or is already in the process, but is running out of energy.

If you have doubts about your own abilities, the advice and experience of other self-builders is most welcome. If you also have a frame structure in your plans, find out how not to build the RSK its most unsuccessful version. The video is about a frame house based on a Scandinavian design, on an old foundation.

Subscribe to our Telegram channelExclusive posts every week