One of the design options could be to designate one of the walls common to the first and second floors as a view. Then the decoration of this view wall can be done more decoratively than all other walls. Another way to accentuate a view wall is to place a collection of paintings on it.

With all the variety of designs for vertical movement that surround us in public and private homes, there are not many options. Regardless of the device, they consist of the same elements:

The height of the fence on the site is higher than the railing. The march fencing is made at least 900 mm, and the platform fencing is 1100 mm.

Then 500 cm: 19st. = 26.32 cm – tread width.

The opening for the stairs to the second floor is determined based on the lift height, design option, area, angle of inclination and number of steps. In the case of a straight type of device, the angle of inclination is less than that of a rotary product.

Stair installation between floors of a building

Structure of the structure

The device includes:

- Support beams in the form of bowstrings or stringers.

- Support posts placed for screw structures.

- Steps.

- Railings including balusters and handrails.

If a large opening is selected for the stairs to the second floor, the bowstrings are placed on the sides. They cover the ends of the steps, which are inserted between the supports for further fastening. Treads with risers are recessed in the installation. If a stringer is installed, then the steps are laid on top of it. Bowstrings are created in the form of two designs, but no more. And the stringers, based on the width of the march.

Ladder installation between floors

The size of the opening for the stairs to the second floor provides for the installation of 1 to 4 stringers (load-bearing and additional). A tread is a horizontal part of a step, and a riser is a vertical part. The latter is optional. The railing acts as a support to provide safety properties.

There are 2 main groups of staircase structures:

- Curvilinear type. They are available in rotary and screw versions.

- Marching option. Straight with or without intermediate or rotary platforms.

Standard parameters: Steps

Calculation of the opening for the stairs to the second floor begins with determining the basic parameters. The gap between the finished floor level of the two floors acts as the height. When determining the number of vertical parts of the step, it is necessary to adhere to the recommended height of 15-18 cm.

Staircase for ascending to the upper floor

However, it is possible that a decrease to 12 cm or an increase to 20 cm is possible. When determining the number of steps, the result must be rounded. Calculations are made by dividing the total height by the riser size.

In order to correctly calculate the opening for the stairs to the second floor, it is important to remember that one flight includes 3 to 18 steps. As the quantity increases, it is divided into 2-3 flights, separated by flat and turning platforms.

The height and depth parameters of the steps must be equal in size within the same flight. This is required so that the user’s step does not go astray when the user moves up.

Staircase structure for internal placement

Height and depth

The standard size of the opening for the stairs to the second floor is 2 m in height. The depth of the steps is 23.5 to 35.5 cm, but the optimal parameter reaches up to 28-32 cm. To create accurate calculations, you will need a formula where the mandatory criterion is the sum of the height (h) and depth (b) of the steps in plan, equal to 47 cm.

Simply put, tread depth:

b = 47 – h.

The calculation results are accepted as a basis if they satisfy the specified parameters.

You can calculate the stairs to the second floor for a narrow opening. This is facilitated by a different height/width ratio of the steps:

b = 63 – 2a.

Ladder device for indoor installation

Installation length

To determine the parameters, the previously determined number of steps in the flight, minus one, is used. The resulting indicators are multiplied among themselves.

If the length is too long, a rotating structure of 90 or 180 degrees is created. It will be supplemented with intermediate sections or winder steps.

The vertical gap varies between 190-200 cm. This eliminates the possibility of injury when ascending or descending one person.

Important!

The recommended opening width for the stairs to the second floor varies from 900 to 1400 mm.

Calculation example

To create a project, the main dimensions are determined:

Ladder for installation in the house

Parameter calculations

Knowing the location of the installation in plan (for example, 500 cm) and the height of the room (300 cm), the number of steps can easily be found by dividing the height of the building by the height of the riser (15 cm): 300: 15 = 20 steps.

1 step is subtracted from 20 (the floor of the upper floor acts as a step) = 19 tbsp.

Then 500 cm: 19st. = 26.32 cm – tread width.

Then the previously given formula 2A+B = 56.32 cm is used, the rise is formed at an angle of 29.4°. The recommended parameter 60-64 cm does not correspond to the calculated data.

However, if we create 17 steps with a height of 17.65 cm and a width of 28 cm, the result is 63.29 cm, which suits us. The elevation angle is 32.2° and the length is 448 cm. This allows you to determine the type of construction. The distance between the step and the ceiling is 1.9–2 m. This parameter should not change along the entire length of the flight.

Standard Ladder Installation

The width of the march is equal to the width of the exit to the cell:

- Indoor structures are 90 - 100 cm.

- Buildings with an increased level of comfort 1.25–1.5 m.

- Garden houses are equipped with a march with a width of 70 - 80 cm.

A width of 80 cm is provided for auxiliary structures of simple shape. These include basement or attic installations. The width is determined between the railings or between the balusters and the wall.

Screw structures create a gap from the central support to the outermost part of the step. The optimal size is 110 cm. Between the marches placed in the opposite direction to each other, a gap of 10 cm is provided.

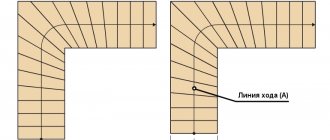

Using a similar technology, a staircase with winder steps with a 180° turn is created.

Classic wooden staircase

Types of installations

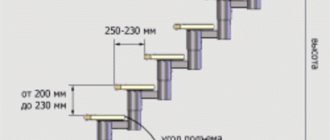

The optimal solution in choosing steps is a crossbar of 300 mm and a rise of 170 mm. These indicators are formed when the march is inclined at 30 - 40 degrees. In addition, there are a number of other important requirements

:

Classic staircase made of solid wood

Construction of the structure

The start of work is determined by measuring the distance between the openings and the opening parameters. Then a project is drawn up, where all the dimensions and type of structure are noted, the material for the stringer or bowstring, and the angle of elevation are indicated. The number of ordinary balusters and the size of the railings are calculated.

When preparing materials, a stringer marking is created on the inside of the product. The stringer of the device is cut down using a jigsaw.

The outer parts are milled. The milled parts of the stringer are finished with abrasive (sandpaper No. 8, then No. 4). LSM grinding is done with a grain size of 100, and then 180. An analogue of a LSM is a high-pressure grinder.

Calculation of step rise

The wall support of the left part of the structure is mounted.

A support column (temporary support bar) is placed and the external stringer of the 1st right part is installed. Both stringers are set according to level. Try on the staircase support with a groove for the stringer tenon.

The vertical part of the step is sawed down. The wall and outer parts of the stringer of the second segment of the wooden device are placed. The opening is finished off with wooden panels overnight. All connections are made using glue.

Cutting a hole in the ceiling is quite difficult, so it is worth considering the entire course of work in detail.

Cutting a hole in the ceiling is quite difficult, so it is worth considering the entire course of work in detail.

The design of the opening must correspond to the style of the interior of the room and be in harmony with the staircase structure.

The floor and ceiling in the staircase area should not stand out in any way from the design of the main covering.

The internal section can be finished with plaster and putty compounds, followed by painting.

It is possible to decorate the internal surface with overlay panels, but when cutting through the ceiling, it is necessary to take into account their thickness.

The cut surface must be smooth and free of roughness and other features that may interfere with safe movement.

You can decorate the opening to your liking

The stairwell guardrail is necessary to prevent falls; it is made of durable materials in accordance with the design of the room.

When we install a staircase, we take care of the visual appeal of the bowstring, stringers and other side and bottom elements of the staircase. Without finishing the ends of the floors, the staircase will look sloppy. But the builders also have to finish the work. Often on projects we come across unlined walls and raw edges of floors between floors, and we are asked to make the space around the stairs beautiful.

When we install a staircase, we take care of the visual appeal of the bowstring, stringers and other side and bottom elements of the staircase. Without finishing the ends of the floors, the staircase will look sloppy. But the builders also have to finish the work. Often on projects we come across unlined walls and raw edges of floors between floors, and we are asked to make the space around the stairs beautiful.

The cost of finishing the ends of the floors depends on the size of the working area, the base material, the selected type of cladding - the price of simple pine planks and carved oak will differ. An inexpensive option is to cover the protruding beams with veneered MDF boards and paint the boards in the color of the stairs. We also install decorative wooden moldings of the required shapes at the ends of the ceilings so that the staircase has a complete look.

Basic formulas for calculating stairs.

Formulas for calculating stairs

...When calculating the stairs, the main dimensions of the flight of stairs are determined, which best correspond to the convenience and safety of movement. The best option is a wide and flat staircase. But in practice, in each specific case one has to proceed from the parameters of the space left for the stairs. Sometimes you wonder how you can push 18-20 steps into a given niche space.

The main parameters of the staircase include the height of the rise, the type of staircase, the plan area, the steepness, and the number of steps. All these parameters are not independent, that is, they cannot all be assigned. For a straight staircase, the height of the rise and the steepness determine the plan area and, conversely, the plan area and the height of the rise determine the steepness. When designing, you must immediately set the values of the defining parameters. After this, you can calculate the slope, which will determine the number of steps.

Basic formulas for calculating stairs.

- Average step formula (S), also known as Blondel's formula: S = a + h×2 (600 ≤ a + h×2 ≤ 640).

- Safety formula: a + h = 460 mm.

- Convenience formula: a – h = 120 mm.

Practitioners prefer the golden ratio, which duplicates the SP.

All the calculations and formulas given are the theory of relativity, plus or minus a kilometer. All calculations are made exclusively based on the existing situation. For the concept of convenience of treads and risers, there is a golden ratio - this is a 300 mm tread and from 150 to 170 mm, a riser, a step thickness from 40 mm to ease of processing. The height of the riser depends solely on the level of inclination of the stringer. The clearance depends on the height of the walker, individually. A dwarf will need a riser with a height of 120 mm and a clearance of 1000 mm.

Calculating the size of the opening for a spiral staircase will depend on its configuration. In most cases it has the shape of a circle. There are also square-shaped options. Typically, a spiral staircase is chosen in cases where the space for arranging the opening is limited. This is the most compact option.

Ideal angle parameters

For the sake of convenience and correct use of space, it is recommended to leave the span angle at 20-50 degrees. A more accurate value must be determined depending on the shape of the landing. If for flat and screw structures the slope will be smaller, then for strict marching and attached structures it will be many times greater (for more details, see the section above).

If possible and for aesthetic reasons, it is recommended to adhere to 45 degrees when erecting the structure. This parameter complies with GOST and safety regulations during movement.

Marching staircase with an optimal climbing angle

On a note! The width of the step plays a role when descending. If it is equal to foot size 45, then it will be convenient to move down. The owner will not have to worry about slipping.

Opening for a U-shaped staircase

Most often, openings for a U-shaped staircase with two flights are made in the shape of a square. The size of its side will correspond to the sum of the widths of the steps of both flights, that is, approximately 2.0 m.

Again, if the ceiling height is large, then with a normal slope of the stairs, the minimum distance from the steps of the lower flight to the interfloor ceiling must be taken into account. The norm is similar to the above - at least 1.9 m.

- main, connecting floors of residential premises;

- additional or auxiliary (lead up to the attic or down to the basement);

Features of designing a wooden march in a private house

The staircase design is usually done at the house planning stage. If such a decision is left to the last minute, the march will have to be adapted to the available space.

In the interfloor space of the residential second floor, stairs are installed, which are convenient for moving, carrying loads and evacuating in case of unforeseen situations. In auxiliary rooms, a less convenient design can be designed.

When making calculations, please note:

There are many programs that will make calculations, produce a drawing, a 3D image of the future structure based on your measurements - SolidWorks. ArchiCad, AutoCad and others. Staircase manufacturers also provide design services. From them you can not only order a drawing, but also the production of wooden elements for self-assembly of the march.

Spiral staircases to the second floor, examples of optimal sizes, calculation formulas

A promising view are spiral staircases to the second floor, in the form of a regular segment, a spiral-shaped hyperbola and curvilinear ones. They are classified according to the fastening of the steps into options:

- the wide end of the wedge-shaped steps rests on the wall, and the narrow end on the rod;

- on the central support with the stairs indented from the walls;

- to the string (stringer), turning into supports - railings (post and string or both strings - spirals). When making the string of such a ladder, the use of metal or wood is very expensive. Spiral concrete stairs have become a popular economical solution. They are durable, but visually light.

Optimal generally accepted parameters

An easy-to-use spiral staircase with dimensions in accordance with generally accepted parameters assumes the presence of:

- span, width from 800 mm;

- structures with a diameter of 2000 mm;

- lifting height 3000 mm;

- steps from 200 mm deep in the middle;

- D diameter of the support is 100mm, with D the location of the steps from the center is 150mm;

- D of the wide edge near the edge is 400 mm or less;

- D (total) of the entire staircase is not less than 1300 mm, but not more than 3300 mm;

- D – railings on the inside 1200-3200 mm;

- Opening in the ceiling D from 1300 to 3300 mm;

- march, width 530 mm - 1430 mm.

Existing types and types of stairs

Frame and support post

First, our user made a frame for the winder steps and a support post.

For the frame, YaRo used 40x50 mm timber. The dimensions of the support column are 100x100.

For the second support of the march, I screwed in the rest of the professional timber measuring 100x150. On the support pillar, the craftsman made cuts for the second, third and fourth winder steps.

First, I screwed the platform for the winder step to the post, and then secured the support to the floor through it.

Next, our participant varnished the stringer that will stand against the wall in two layers. This is so as not to waste time.

*The thickness of the overlap in this example is 205 mm; if the overlap is larger, then this project may not be suitable.

Types of stairs

By design, the following types of stairs are distinguished:

- Marching straight lines;

- Marching with a turn;

- Screw;

- Curvilinear.

Let's look at each type in more detail and find out their functional features.

Marching stairs

Diagram of the flight staircase

These stairs leading to the second floor are the most common and familiar in our opinion, however, they require the most usable space in the house. If during design the flight of stairs turns out to be too long, then the plan and the designation on it of the staircase are divided into several parts, and at the same time it is transformed into a turning one.

Turning stairs are divided into L-shaped and U-shaped. In the first case, the turn between the marches will be a right angle, and in the second case - 180 degrees. To make the staircase more compact, the space between the flights is equipped with a step, which slightly reduces comfort when moving. You should choose a specific option, taking into account the layout of the house and its design features.

The device of a spiral staircase

Such stairs are considered the most compact and can be made from both wood and metal.

Existing types and types of stairs

Spiral marches allow such stairs to be placed on literally a few square meters of the floor plan of a private house. In addition, the design of a spiral staircase looks very attractive and gives the interior a special look. Among the disadvantages, we can note some difficulties in operation due to the fact that the steps are winders.

When creating a plan for a spiral staircase, you should understand that it will be impossible to transport large cargo to the second floor along it, and also that the space under it cannot be arranged in a useful way.

In relation to residential private houses, the design of a spiral staircase is rarely used. Much more often it is erected as interior decoration or another place for transporting people to the upper level. It is also worth noting that with the help of a screw structure, two-story country houses and houses for temporary stay are equipped.

Ready-made metal spiral staircase project

The designation of a spiral staircase is somewhat different from the designation of other types of stairs, therefore, if the house plan is made with your own hands, you need to understand this issue by studying the relevant SNiP.

Curvilinear stairs

This type of staircase is a hybrid between a spiral staircase and a flight of stairs. By design, they, like a spiral staircase, provide winder steps, however, their turn is not so steep, which is more convenient when moving.

The designation of curved staircases occupies the house plan much less than marching ones, however, the complexity of their manufacture is higher. Such stairs look very attractive and allow you to give the interior a sophisticated look. In addition, the space under the structure can be used to a greater extent.

Let's calculate the exact number of steps on one flight:

Types of stair railings by material and method of execution and fastening

The staircase railing can be made of wood, plastic, or metal. The technological process of creating and installing the stairs depends on the selected material. Fastening and assembly methods will also differ. Recently, a combination of different components has been increasingly used in interiors. Wooden or metal stairs and vertical railings can easily be reinforced and decorated with plastic and glass parts in the form of infill.

Wooden

Manufacture of stair railings from wood has long been used by man. The natural material lends itself well to processing and has different textures and patterns. This has led to the widespread use of wood for the construction of stairs of any style and design. Railings can be painted, sanded and varnished, thereby extending their service life. Using wooden railings for stairs¸ you can decorate the room in any style - from classic to modern.

The most important advantage of wood is that, even without much carpentry experience, you can build a staircase to your house with your own hands by choosing a material with a suitable texture. For work, you need to give preference to hardwoods such as beech or oak. Of the coniferous trees, pine lends itself well to processing, but its fibers are very soft. Spruce is more difficult to process - it is even more pliable and knotty.

To make various parts of the future staircase, different types of wood are used. Balusters that bear the main load should be made of hard wood: beech, ash, oak. The cut of these trees is beautiful and original in itself. Softwoods do not last long, dry out and crack, and very soon require replacement. The optimal wood moisture content when making balusters should be 12–18%.

Glass railings for modern interiors

The use of glass to decorate and fill fences has taken interior design to new levels. In the generally accepted understanding, glass as a material is fragile, short-lived and unreliable. However, modern technologies make it possible to widely use laminated glass for interior stairs. This material is glued with a polymer, which does not affect its transparency and significantly increases its strength. In a critical situation, such glass, unable to withstand the loads, will not shatter into small fragments, but will be fixed on the film. When talking about glass railings, two types should be distinguished:

- railings without a frame, consisting exclusively of glass;

- glass is a filling component.

The use of glass as filling makes the structure light and airy. You can make drawings like stained glass. With this type of work, the filling is continuous, and therefore safe. The tempered glass used for such railings is made differently than ordinary glass. During production, the material is “heated”. It is heated at high temperature and then brought to its original temperature state. The material is unusually strong, can withstand heavy shock loads and, when broken, disintegrates into non-sharp, safe edges. To build stair railings, you can use tinted and multi-colored glass, achieving an ideal combination with the interior. Duplex and triplex with a thickness of 10 mm can be used to make a structure made of solid glass, which is inappropriate for homes where there are children. Despite the strength of the material, you should still avoid beating it.

Plastic in handrails for stairs

The use of PVC (polyvinyl chloride) for the construction of fences allows you to significantly save on the purchase of materials for building stairs. This is a practical and budget material. Railings made of plastic will last a long time and will not lose their appearance for a long time. They do not require any special care. The option of creating balusters from plastic involves the introduction of a metal core, which will take on the entire load. In this case, the plastic plays a decorative role, decorating the supports. PVC is not natural, but over the years it does not deteriorate, rot or lose its shape.

Metal railings

Metal is the strongest basis for the manufacture of staircases. This is a typical staircase fencing used in the construction of multi-storey residential areas. Durability and ease of maintenance, the ability to give the railings a stylish look, this is just a short list of the advantages of metal. When constructing stair railings, many metals can be used.

Some cottage owners, in pursuit of style, prefer aluminum for its lightness, elegance and brilliant appearance. At trade counters, entire aluminum kits are sold for those interested, which owners can assemble at home without much effort. This is a huge advantage of aluminum railings. But at the same time, the metal does not tolerate shock loads, bends and quickly loses its shape. Over time, scratches form on the surface of the railings and they are affected by corrosion.

Chrome-plated railings also look good, which can also be purchased at retail outlets as an assembled structure. The elegant appearance and stylish shine negates one big disadvantage - they wear out quickly.

There are three ways to manufacture metal fences: welding, forging, assembly (fittings and pipes).

Welded metal

Metal railings made by welding are considered the most economical.

For the manufacture of railings using welded technology, a metal beam of 10x10 mm is used, for the posts - a profile pipe of 15x15 mm (or 20x20 mm). A 40x4 mm strip is suitable for the handrail. During assembly, electric arc welding is used with further cleaning. Welded structures are widely used for equipping administrative buildings, office premises, private cottages and summer cottages.

Forged

It is quite difficult to make forged railings with your own hands, especially if hot forging is planned. But the forging process can also be done cold. There are special bending machines that are available for rental. Using such equipment, you can prepare a variety of twisted and bent elements for your stairs. When working, you have the opportunity to choose various metals and rolled products. The material itself is quite expensive, which is a significant obstacle for “home” craftsmen.

The design of the railings during forging can consist of:

- round or square rod;

- profile pipes (round, square, rectangular).

For manufacturing, simple structural steel can be used, which is subsequently painted in any color that matches the interior.

Cast fences and railings

The main difference between this type of railing is the manufacturing feature. The technological components of the process are:

- pouring mold;

- molten metal to fill the mold.

For the production of such railings, brass, bronze and cast iron are usually used. Forms are developed according to customer sketches in accordance with the interior being created. Cooled products can have various configurations. The railings are distinguished by high strength of element joints and long service life. Significant disadvantages are the high cost and complexity of the manufacturing process. Molded railings are a great option for installing outdoor stairs in an open space to decorate the exterior.

Combined stair railings

Combined fencing is a combination of metal, plastic, wood and other materials. In such fences, crossbars and glass are used for filling. The possibility of improvisation when using railings of this type allows you to decorate any type of interior with them - from classic to ultra-modern. Internal fences of the combined type are beautiful, original and safe. Their use is acceptable in both private cottages and administrative buildings.

Stainless steel is the main option for railings, which goes well with other materials. When creating this structural element, tempered glass and triplex are used. Such glass, like stainless steel, is resistant to temperature changes and can withstand shock loads. Handrails can be made of hard wood, impregnated with a special composition against dampness and temperature loads. Another option is PVC handrails, which do not fade or collapse for a long time.

When constructing combined fences, simple black steel can be used, which is painted to protect it from external factors. It is also possible to introduce decorative elements made of bronze and copper.

Calculation of system elements

The layout of the straight and rotary march structure is carried out according to the general principle. To calculate the stairs to the second floor, you need to measure:

- height (H) from the floor of the first floor to the floor of the second floor. If the finished floor is not finished, add the thickness of the screed, underlay, or floor covering to the resulting number;

- the length of the opening is from the end of the ceiling to the outer wall. Double-check from different angles. If the values are different, take the smaller one;

- opening width - the distance between the right and left walls. We double-check again on both sides and take the minimum size.

Let's calculate the angle of inclination

The slope depends on the area of the house and the height of its ceilings. A staircase with a slope of 30-36 degrees will be compact, but it will be difficult to go down it. For a slope of 40-45 degrees, you need a large room, since such a wooden staircase is quite bulky. The lower the inclination, the more dangerous it is to move along the march; the higher it is, the more space the structure takes up.

Correct calculation of the width and height of the step will ensure ease of movement up and down. The average human step is 63 cm, the step height is 2 times less (31.5 cm). The standard value is 30 and 15 cm, respectively.

We calculate the slope using the formula:

- 2x + y, where

- X - riser height;

- Y - tread width.

If the size of the steps is less than 14.5 cm, X does not need to be doubled. The lower the step, the wider it should be.

Ratio of inclination angle (in degrees) / tread size (w/h, cm):

- 30/ 28/16

- 33/ 26/17

- 37/ 24/18

- 41/ 22/19

- 45/ 20/20.

How to correctly calculate the slope in a simple way:

On a piece of paper, draw a right triangle in which:

- horizontal leg - horizontal projection of the base of the future staircase;

- vertical - height from floor to floor between floors;

- hypotenuse - the length of the march.

The acute angle at the bottom of the projection is the elevation angle. If its value is within the norms, you can begin to calculate the steps.

Let's count the steps

The slope of the march is 40-45º. Let's calculate the number of steps using the formula:

- 2A + B=60-64 cm, where

- A - riser height;

- B - tread width;

- 60-64 is the average human step.

Let's say A=14-17. We calculate the width of the tread B:

- 60-15x2 or 64-15x2 = 30 or 34 cm.

The lack of width can be compensated for by a protrusion.

We calculate the number of elements in a march:

height H/step height (riser) = quantity

The optimal riser height, recommended by SNiP, is 15-19 cm. If the result is a fraction, round to the nearest whole.

Let's assume H=280 cm. Let's calculate:

- 280/15 =18, 6

- 280/16= 17,5

- 280/17=16,4

- 280/18=15,5

- 280/19=14,7

In a march you can do from 14 to 19 steps (a larger value is rounded up, a smaller value - rounded down).

If there is an interfloor staircase with a landing, we plan a landing for the entire width of the opening, 1 m long, and place it on the drawing. Let's calculate the exact number of steps on one flight:

shaft length minus platform length / tread width

In our example it turns out:

200/25 (tread width according to SNiP) = 8

Given the existing dimensions, there are 8 steps each on the lower and upper flight and the ninth is a platform, which is considered as a step. In total, the staircase consists of 17 steps.

Let's calculate the step using the formula:

interfloor height (H) / number of steps = step height (riser)

Let's calculate using our example - 280/17 = 16.47. Round to 16.5 cm.

We got a comfortable staircase of 17 steps, with a step height of 16.5 cm and a tread 25 cm wide.

Since we rounded fractions during the calculations, we need to put the deviations somewhere. For example, an error of 0.03 cm in the height of the riser will go to the bottom step, which we will make shorter than the others by 5.1 mm (17x0.3).

We check the correctness of the calculations on the spot - we draw a projection of the steps with the given dimensions on the wall with a pencil. You will be able to find out if a window, door, or radiator is bothering you and adjust the calculations.

In the process of designing a staircase, an important step is also the calculation of the staircase opening. The opening for the stairs is a hole made in the ceiling, which is necessary to install the structure. In order to avoid any difficulties when installing a flight of stairs, and to ensure that the descent to the stairs is convenient and safe, it is necessary to make all calculations as accurately as possible. We will look at how to make a staircase opening, as well as what its optimal parameters are, in this article.

For those who don't like cleaning: 6 life hacks for organizing a kitchen that will hide dirt

IVD. Repair and finishing

No registered user is viewing this page.

Are you a professional architect or designer?

Purely IMHO. Iron or wooden frame, laid on a brick on three sides, and on the fourth, fixed to the wall. And on the frame - an ordinary wooden or iron door with welded hinges. I don’t know about you, but in Moscow there are countless of them in garbage dumps.

senya-ice wrote: Funds are limited. We are thinking about roller shutters or lyada. Which is better, which is warmer?

Thank you, of course, but if you put a door into a cottage from a garbage dump, then God bless you! By the way, the option of a door was considered. There is an opening there of 3.46x0.9 m. It will be a very weighty door.

Why make a hatch? It will be very difficult to lift it. Make an insulated box of foam or aerated concrete to cover the opening, and a regular door into it. Vertical. The space above the hatch cannot be used anyway. And this way all the hemorrhoids will be removed.

And this size is already more interesting, I thought for your standard door “190 By analogy with my basement. If the task is not to tightly insulate the basement, then you can use a couple of panels placed on ball bearings and moving one relative to the other like glass in a bookshelf. And if there is a solid sealing, if it is necessary to maintain the size of the opening, then a roller shutter. True, in this case you will have to make a fence so as not to catch the “brown cat with big ears.”

As experience shows, the issue of design of a staircase opening cannot be called extremely relevant, since few people are interested in the visible part of the end of the ceiling. The corner staircase adjacent to the wall becomes a segment of a single staircase block. If the opening is made in the center of the room, then the visible part of the end of the ceiling is plastered and then painted in the shades of the window slope. In the case of a wooden floor, it is recommended to cover the hole with wood.

Typically, in a wooden house, the dimensions of the opening for the stairs are determined by the width of the flight. If it is intended to install a single-flight structure, then the opening is calculated in this way: the gaps necessary for attaching the fences are added to the width of the stairs. In the case of a two-flight option, all measurements obtained are multiplied by 2. The length of the holes is determined by the slope of the flight of stairs. It is required that a person of average height standing on any step does not hit his head on the ceiling.

The lighting problem also needs to be addressed. It is optimal when the staircase opening is filled with the comfortable light of stylish chandeliers located in the space between the flights. This way you can create a single composition.

Making a staircase

- Having calculated the basic parameters of the future staircase and opening, draw up a detailed project. Put all the available values on it. When designing the width of the staircase opening, do not forget to add to the width of the steps the distance required for installing the railings.

- Draw a contour with the dimensions of the staircase opening on the ceiling. Remove the floor covering within the existing markings.

- Next, part of the beams is dismantled. They are removed by connecting the remaining elements together. Be sure to strengthen the structure by adding cross beams that have the same cross-section as the main ones. Fasten them to metal corners along the entire length of the opening.

- Securely fix the installed bars on all sides.

How to make a reinforced staircase opening in a concrete floor, watch the video.

Useful tips

Any type of staircase located in the house must be provided with the necessary care. The most “capricious” in this regard is wooden. The owners who use protective compounds to treat the structure do not know that this is far from sufficient to ensure the beauty and reliability of the staircase. After the coating has dried, the following layers can be applied:

- dye. For indoor painting, only outdoor paint is suitable. The main thing is that, without disturbing the design of the site, you can choose the required color;

- wood oil You should only choose special oil for terraces. It does not create a protective layer, but penetrates deep into the material and provides protection inside, which does not need to be removed when re-applied. The oil is expensive, but the effect is good;

- varnish Applied to existing protective coatings.

The use of grinding is allowed as a last resort if partial damage has occurred over time.

Requirements for fencing

Since fencing has a leading practical function in preserving life and health, their design and manufacture is subject to the strict requirements of GOST and SNiP standards.

General technical requirements are determined by sanitary and fire safety standards :

- If there are more than 3 steps on the staircase, then there must be a balustrade.

- The height of internal staircase railings is at least 90 cm .

- Handrails are required to be installed in any conditions.

- Complete absence of sharp corners and sharp protrusions.

- Indispensable fireproof treatment of the entire structure.

- A balustrade is required along the entire length of the staircase.

Separate requirements are established for guardrails on stairs in institutions where children are located. They define the following safety and security parameters:

- The height of additional handrails is 50 cm.

- Mandatory absence of crossbars!

- The use of glass for filling is prohibited.

- The narrowest gap between balusters and posts is no more than 10 cm.

- It is important to install vertical fences to a height of up to 1.2 m. If there are children with mental disorders in the building, then the protection should reach 1.8 m.

For disabled people, the ramp must be surrounded by railings. They must certainly be rounded, be continuous and protrude in front of the steps by at least 30 cm.

This is due to the creation of the necessary conditions for the safe passage of a flight of stairs by a person with disabilities.

Regulatory regulation of these requirements is carried out:

- GOST 25772-83, 23120-78, 30247-94, 51261-99;

- SNiP 2.08.01-89, 2.08.02-89, 2.01.07-85, 35-01-2001;

- SP 31-102-99.

Detailed information about what they are, how they differ and how to make glass stair railings can be found here.

If you are interested in how to make a wrought iron porch railing with your own hands, check out this article.

Here you will find a description of the production, types and installation of Euro fences.

Fencing components

The design of the fence is far from monolithic. It consists of a complex of different parts that provide the necessary strength and stability.

Components of the system:

- Balusters.

- Handrails.

- Filling.

Let's look at each detail in more detail to understand its purpose and importance.

Balusters

They are vertical or inclined supports for the entire fence. More often they are attached to mortgages on the march. A special sliding method is also used.

In some cases, balusters serve as additional fastening for the entire staircase structure. These elements are necessarily durable and reliable, since they create the necessary stiffeners.

Handrails

This detail serves as a support for people. Made in the form of a horizontal or inclined plane. It can be fixed on balusters using fasteners or welded, in the case of a metal version. The handrails always have a smooth surface and a pleasant texture, since they are in direct contact with the skin of the hands.

Filling

This element mainly performs a decorative function. Available in vertical, horizontal, slanted or solid pieces that add attractiveness and uniqueness to a railing, it also reduces the space between balusters, thereby reducing the risk of getting stuck or falling down stairs through voids.

General Design Guidelines

Design is an important process. It is the basis on which the staircase in a residential building will be built. In order to create a project yourself, you will need “graph paper” - a special paper on which there are markings in millimeters.

Now on the sheet you need to draw a right triangle, which will serve as the basis of the diagram, using a scale of 1:10. The first leg will be equal to the distance that the flight of stairs will occupy. It is written in centimeters. The second represents the distance taken between the floor on the first floor and the floor on the second floor. The hypotenuse is the side that characterizes the length of the structure.

When specifying the parameters of steps and stairs, take into account the fact: the steeper the structure, the narrower and higher the rise will be.

On a note! When designing a flight of stairs at home, you can slope slightly inward to prevent your foot from slipping when going up and down. Staircases for emergency situations are compiled with similar GOST standards.