12530 0 0

Che Guevara December 10, 2016

You can line the well with wood yourself.

A beautiful well on the site is always pleasing to the eye. Today, it has become fashionable to decorate a well with wood, decorate it with stone, and also build heads in different styles. I will tell you about the simplest and most affordable ways to equip your own source of drinking water.

How to build a canopy for a well

These designs have no restrictions. They can be round or rectangular, have one or more slopes. The canopy is installed directly on the house or in the ground, concrete, brick, or other foundations. So, in order to build such a superstructure, we will analyze in detail the following step-by-step master class:

- We are preparing the base. The pillars can be installed on a columnar, strip, or monolithic foundation. Since the upper part is light in weight, there are no strict requirements for the base, and two profile pipes or rounded logs are sufficient for support.

- After installing the supporting pillars and corrugated pipes in their upper part, you can install a finished metal roof and build a frame with your own hands. To do this, we attach the boards of the supporting frame to the vertical posts in the upper part.

- Let's start assembling the roof truss. It is better to assemble it on the ground and install it ready-made.

- After installation, we cover the truss with OSB boards.

- We cover the roof with metal tiles, corrugated sheets, and other materials.

- We sew up the gables with clapboard and plastic.

Cladding of the above-ground part of the log house

What we habitually call a well frame has, in fact, been made of concrete rings for a long time. The top ring protrudes from the ground and looks unpresentable

It is especially important to line it when an open type well is being built, since in closed ones the ring is hidden behind the walls of the house. But even in closed structures, successful design of the log house can give completeness to the entire structure

Wooden traditions

To give the house above the well a purely rustic look, a frame is laid around a concrete ring. It is not necessary to adhere to the traditional square shape - the log house is made both hexagonal and octagonal. It is brought above the level of the rings and covered with a wooden flooring, in which a hole is cut with a door for a bucket.

House for a well in the form of a log house

For a Russian-style estate, a log house made of round logs is the most suitable option. If the buildings follow the traditions of Scandinavia, then rectangular timber or clapboard cladding would be acceptable.

Lining the well with clapboard

Stonework - a journey to the land of the elves

The well with stonework carries a European flavor. It will look fabulous on a site with a small wooden house and a garden in the spirit of Provence or next to a brick cottage in the English style.

Covering a concrete ring with stones is not difficult; it requires diligence, cement mortar and the stone itself. You can use large cobblestones, pebbles, flagstone, and flagstone looks especially picturesque if it is laid flat. Along with stone, facing bricks and tiles imitating natural masonry are used.

Stonework in the design of a well

In open wells, it is necessary to line the upper edge of the ring and secure a wooden or metal lid (door) to it.

Metal, but not plastic

There is nothing that prevents the use of non-traditional materials in the design of the upper part of the log house, from metal profiles to plastic. And if plastic could be immediately rejected as a short-lived material that cannot withstand low temperatures, then metal sheets can lead to interesting ideas. Of course, it will be necessary to build a wooden frame under such cladding.

Lining the well with metal

Species diversity of wells

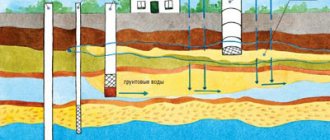

Currently, there are several main, most popular and popular types:

- ascending key;

- descending key;

- mine wooden;

- mine concrete;

- mine brick;

- mine stone;

- pipe structures;

- drilling or pipe structures.

A variety of materials can be used for arrangement, including:

- clay;

- wood;

- rubble stone;

- cobblestones and boulders;

- brick;

- flagstone;

- gravel or crushed stone;

- concrete solution;

- reinforced concrete.

Most often, wells or wells on a site are the best option for water production in the absence of centralized communications , so it is very important to determine what types of water supply sources are suitable for each specific site. When choosing, you will need to take into account the type of soil, the depth of the aquifer and other important factors.

When is a bottom filter needed?

To determine whether you need to make a bottom filter for a well with your own hands, you should, after a thorough inspection, determine the rock that forms the bottom of the structure. In addition, it does not hurt to find out the direction of the aquifer.

There are several possible options:

- The bottom is formed by dense clay, and springs flow from it. This rock does not dissolve or mix with water, so the well will be clean. This is one of the few cases when the filter can cause harm by blocking the outlet of the springs.

- At the bottom there is soft clay, which is actively washed away by water. In such a well, the water below will be cloudy. You can collect clean water from above, but the best option is to fill the bottom with crushed stone or pebbles. A layer of about 20 cm can prevent active erosion.

- If there is sand at the bottom and water seeps into the well and does not bubble up, then installing a bottom filter is a must. Otherwise, with any movement of water, the sand will be washed away and fill the bucket. The pump cannot be placed here either, since all its elements will quickly become clogged.

- At the bottom there may also be floating sand - sand that has become fluid due to saturation with groundwater. In such a well, it is most difficult to obtain truly clean water - you will need a bottom filter and additional protection in the form of a wooden shield.

Laying communications

Pipes running from the source to the cottage must be buried so deep that the water in them does not freeze. Therefore, you should know the depth of soil freezing; this information can be found in a construction company. When digging a trench, remember that at its bottom it is necessary to fill a layer of sand and gravel, the thickness of which is 10 cm.

Modern plumbing systems are not made from metal pipes. It is best to use products made from HDPE (polyethylene). The optimal pipe cross-section is 32 mm. You can easily find fittings for such products: fittings, tees, bends and adapters. Thanks to the use of fittings, installation work will be easy; you will not need to use additional devices.

Experienced builders recommend buying polyethylene pipes, since they are budget-friendly and you can lay two lines from the source to the house. The first one will be the main one, the other one will be a backup one in case of an accident. By acting in this way, you will protect yourself from complex and expensive work in the future.

You should not place the pipeline directly on the ground; the pipes must be reliably protected. This function can be performed by large-diameter technical HDPE pipes, polymer corrugated pipes with or without insulation.

If the trench is deep enough and the main line is low and will not freeze, there is no need to insulate the pipes. But, before filling the trench with earth, it is recommended to lay a layer of polystyrene foam on top of the pipeline. This will prevent the system from freezing during the cold season.

Particular attention should be paid to the area where the pipes rise to the surface, pass through the basement or unheated basement. It is advisable to install heated lines or provide high-quality thermal insulation.

The pipe should be brought out through the walls of the well at the height where the main line passes. It is prohibited to place this unit in the area where the rings are joined. While drilling holes, a crack may develop along the edge of the ring and the structure will be damaged. The right solution is to make a threaded socket with a diameter of 1 inch in the hole.

The gap between it and the walls must be filled with a plastic sealant, for example waterproofing mastic with reinforcing fibers. Also, sealant must be applied to the walls of the ring outside and inside next to the hole. After this, you need to put on rubber gaskets and washers of suitable diameter on both sides, then you can secure the bend with nuts.

New place. Feedback from Yegor Konchalovsky about the installation of a septic tank:

On the threaded area of the outlet from the outside, you need to pack a fitting to which a plastic pipe laid to the source is attached. A tee should be installed on the fitting from inside the deck. A tap is mounted on its horizontal outlet, with which you can drain water from the water supply system for the winter in order to preserve the system. It is necessary to pack a fitting to the outlet of the tee, which is facing downwards; a vertical pipe will later be attached to it for drawing water from a source or for connecting to a submersible pump.

Peculiarities

The design of the well must meet certain requirements. Firstly, it must be in harmony with the surrounding landscape and the exterior style of a residential building, and secondly, if it is used for its intended purpose, as a source of water, it must be protected from possible ingress of sewage, sediment and other contaminants. Finishing can be done using stone, wood, brick, flowers. In the end, the well can simply be plastered or painted.

If the well is planned to be decorated with wood, then it is better to choose hard species that are not afraid of the negative influences of the environment. In any case, the selected material must be wear-resistant, insensitive to temperature changes and precipitation. If, upon completion of finishing, it is plastered or painted, its service life will increase and it will retain its attractive appearance longer. You can build a house over the well itself - this will further decorate it and protect it from precipitation.

Recommendations for finishing and video tutorials

Before lining the well, the surfaces need to be prepared.

To do this, all dirt and dust are removed. You can apply a primer. The main thing is that it is an antiseptic. Mold, mildew, and microorganisms will ruin not only the appearance of the well, but also the water if they get inside the shaft. It is better to think about how to line the well before the blind area is laid. Dismantling soft and pouring concrete will require additional costs. Those who veneer with wood should understand that within a few years the lining will have to be replaced. Paint doesn't last forever either. And lovers of sophistication should consider the option of lining with fresh flowers.

Design options

Once the base of the structure is made, it can be designed in various ways. As a result of the correct choice of the way in which this should be done, the well will acquire not only practical significance, but also aesthetic and design value.

Roof finishing

The roof can not only be made from neat, beautiful boards, but also decorated with carved wooden parts.

Unusual options for this part of the structure may also be used. One of these options involves a folding design made of thick glass. It is structurally made in the form of a cover over the well, which opens on door hinges mounted on the well frame.

You can provide a semicircular metal roof, decorated with curlicues made of metal.

Decorative finishing of a well with forged elementsSource dozor.spb.ru

It is possible to design this part of the well in the form of a hexagonal pointed structure.

Sometimes when choosing what to cover a well with, a soft roof can be a good choice.

Concrete ring frame

Using a stone around the concrete ring, create a beautiful stone wall that completely hides it. This can be done in various ways. For example, an imitation of a small door made of wood in a stone fence may look beautiful.

It is possible to use logs in the form of a log house in a folk style. Sometimes such a frame is made not quadrangular, but hexagonal.

An option can also be used when, using wooden planks coated with varnish, a design is made that resembles a wicker basket. To do this, they are laid out horizontally at each level so that they look like a polygon. In this case, at each next level above the corner there is a flat part of the board.

Decorative finishing - a well in the form of a basketSource stroim-dom.radiomoon.ru

Using an unusual gate shape

This part can be made, for example, in the form of a steering wheel of a sailing ship, or simply in the form of a wheel with spokes installed perpendicular to each other.

Clay castle

Clay has always been an excellent sealant and barrier to water

- The well is dug from the outside, freeing 3-4 rings or about the same number of meters, filled with clay, and compacted well.

- The clay should be free of sand and soil to prevent water from reaching the well.

- You can fill the recess with cement mortar, which is prepared in the following way.

- Tools and raw materials are being prepared. Mixing container, cement, sand, electric drill or shovel, water.

- One part of the cement is diluted in a container with water and thoroughly mixed until a homogeneous cement laitance is obtained. Add 3 parts of fine, dry sand to it and mix it just as well with a shovel or drill. If the waterproofing work was carried out correctly and in compliance with all recommendations, then the taste of drinking water will be excellent.

Examples of decorative wells in the country

Some design examples:

- Wooden tower. The head is decorated with boards and metal hoops, which makes it look like a wooden barrel. A gable roof is installed on top on carved pillars. Additionally, you can decorate the composition with flowers in wooden vases, decorative figurines of gnomes or fairy-tale animals.

- Decorative crane. The traditional well design is without a canopy; a long lever is used to lift the water. Its support can be made from a tall wooden figurine of a bird or animal. The upper part of the well is designed in the form of a wicker basket.

- Sailing ship. The rotating lifting mechanism is equipped with a wheel stylized as a ship's steering wheel. The well itself and its top cover are finished with deck boards.

- Ceramic jug. The design is in the form of a jug, the surface of which is lined with ceramic tiles or natural stone. The hole for water intake is covered with a lid.

- In the style of minimalism. This fashionable style trend today involves the absence of decorative elements. The head of the well is trimmed with plastic panels. The supports are made of forged metal. The roof can be covered with colored polycarbonate.

The design of the well should be in harmony with the landscape of the site and the style of the house. If the building is covered with siding, then a well in the old Russian or medieval styles will look alien. In this case, it is better to choose plastic and metal for its design.

How to cover the seams in a well so that they do not leak

How to cover the seams in a well is a pressing question for its owner

If a well is built from reinforced concrete rings, sooner or later water begins to leak through the seams between them and cracks appear in the walls.

This can happen very quickly if workers did not pay enough attention to sealing joints during construction or if the soil on your site is very mobile. How to cover the seams in the well in this case and how to do it correctly?

Installation of open well finishing

Installation of the finishing of an open well with a lid begins with the manufacture of a canopy. Wooden beams, steel angles or metal pipes can be used as load-bearing elements of the canopy. To cover the canopy, you can use any available roofing material: boards, plywood, plastic, galvanized iron sheets.

When using large covering elements, for example, slate or tiles, the load on the rafter system and support posts of the well should be calculated taking into account the weight of snow in winter and the strength of the winds in the region.

After making the canopy, you need to install the stands. They can be made from wooden beams, logs or an H-shaped metal profile corresponding to the load of the section. The racks can be dug close to the concrete ring of the well and subsequently covered with some kind of decorative finish.

If the racks are made of wooden beams or logs and are themselves a decorative element, they can be installed on the outside of the decorative finish of the well pipe. The distance between the supports must correspond to the length of the canopy; this must be taken into account when designing and manufacturing it.

The lower part of the racks must be treated with moisture-proof and bactericidal compounds before being buried in the ground. The racks must be dug strictly vertically and plumb. After which the finished roof is installed on them and the gate is mounted.

The open-type country well is also equipped with a sealed lid. It can be made of metal, plastic, waterproof plywood. If the weight of the lid is large enough, then it can be divided into two sections (shutters) and equipped with handles for opening. The edges of the sections or covers can be attached to the support posts using metal permanent door hinges.

To decorate the walls of the well, materials such as:

- brick - facade decorative;

- stone - artificial or natural;

- siding panels;

- clapboard;

- tiles - ceramic or clinker;

- corrugated sheeting;

- large pebbles.

If desired, you can create a combination of different facing materials. The main thing is that the decoration of the well fits harmoniously into the overall line of landscape design.

What plants to plant near the well

Directly near the source of water supply, you can plant decorative foliage and beautifully flowering garden crops. An interesting solution would be to use a gabion or a budget alternative to factory mesh to form a mesh frame around the above-ground part of the well structure.

Further design depends on the surrounding landscape design. If a significant part of the garden area is represented by alpine slides and a recreation area, then the space between the base of the well and the mesh frame can be filled with decorative stones. If it is necessary to make the design more flowery and picturesque, then the mesh holding the stones is used as a support for the arrangement of climbing vegetation.

One of the most beautiful and popular ways of decorating a well structure among domestic homeowners is to surround the water source with densely growing plants. In this case, in autumn, the roof of the well is often used as flower beds, but it is allowed to place hanging flowerpots and containers with hanging plants at the ends of the well. Also, flower pots with plants can be placed around the entire perimeter.

Material selection

A variety of materials are used for cladding. The main requirement for them is to withstand temperature changes and be moisture resistant. Materials meet these requirements to varying degrees. Some require additional protection, others do without it.

Tree

For cladding, different types of wood are used: logs after rounding, edged boards, slabs, beams. The highest quality material is logs, but well-treated boards and beams will last no less. The most moisture-resistant are larch, cedar, birch, oak, aspen. Nevertheless, these rocks and others are treated with anti-rot and insecticides before installation.

The advantage of wooden structures is that it is not necessary to repeat the configuration of a round well. You can make a square or polygonal cladding. It harmoniously combines with elements of wood carving, which gives the design an expressive Russian style.

A well lined with wood.

Stone

Stone finishing is a spectacular but expensive option. For cladding, granite, sandstone, and pebbles are used, laid on cement mortar. If there is wild stone in the area, you can collect cobblestones. The best material is flat, medium in size (10 cm). Properly laid walls around a well will last for decades, because the stone is not afraid of heat or cold, rain and snow. Installation may seem difficult for masons without experience, so it is better to hire a professional.

Plaster

Concrete rings are plastered if the surface is of poor quality. After drying, finishing is carried out. This can be whitewashing, painting or decorative plaster. The disadvantage of this option is that it is not durable. After some time, defects will appear and you will have to update or redo it.

Tires

An almost free method, the implementation of which will require used car or tractor tires. Tires with a larger diameter are difficult to find, so in most situations they are limited to a maximum size of 17″. This is enough for a well made of a narrow pipe.

Finishing the well with tires.

Ceramic tile

The original surface is created using ceramics. Mosaics are glued onto concrete rings; tiles can be used for rectangular wells. A variety of surfaces allows you to choose an acceptable option. The tiles can be smooth and corrugated, shiny and matte, with patterns, imitation of natural stone. It can decorate any surface.

Siding and plastic panels

Plastic materials are fixed to a frame made of metal profiles or wooden slats. Installation is simple, you just need to cut the material to size and connect it using the locks available at the ends. The elements are fastened to wooden sheathing with staples using a stapler, and to metal sheathing - with self-tapping screws. The option is inexpensive and installation takes little time. Installation with glue on a thoroughly leveled and primed surface is possible.

Lining

The lining looks good when finishing a well. Installation is no different from installing plastic panels. You will also need to build a frame and secure each element with screws. They are connected to each other by locks: the tenon is inserted into the groove.

The correct technology requires that before installation the lining is treated with anti-rot and anti-beetle agents and is varnished. If the last operation is performed after installation, the locks will remain unprotected on the inside, which will soon begin to deteriorate.

Choosing concrete rings for a well

To make a well water supply system with your own hands, many install concrete rings. The popularity of this solution is explained by the fact that this material has optimal characteristics. Concrete rings have sufficient strength because they are reinforced with steel rods. They will last for a long time and are not afraid of frost or high humidity.

There are several types of concrete rings on sale. The most commonly used are the following:

- Wall rings . Suitable for arranging the neck of a well, that is, the upper part of the trunk. Such rings can be used for all types of sources. The best option is reinforced concrete products.

- Additional ones . Such rings are suitable for cases where standard products cannot be installed. They have non-standard dimensions, due to this feature the area of their use is determined.

- Made of reinforced concrete . These rings are most often installed and are suitable for creating sewerage systems and drainage wells.

This is interesting!

Insulation of water supply with cable and heat-insulating materials Read more

There are different types of reinforced concrete rings on sale, for example with a bottom. However, almost all products are equipped with grooves at the factory. They are necessary to prevent the rings from moving after they are mounted.

You should buy rings based on the required size. Therefore, you first need to calculate the diameter of the product that will suit you. All rings are marked during production, most often indicating the size of the internal section, as well as the height. In addition, it is important to consider the width of the walls.

To make a well water supply in a country house, products with a diameter of 100 cm are suitable. Rings with a diameter of 1.5 m are not often used, but they are also popular. The diameter should be selected taking into account the depth of the aquifer.

Rings are available in different heights, the most popular option for dachas is 0.9 m. Such reinforced concrete products are convenient to install, since in this case a small number of seams are obtained.

When buying concrete rings, remember that you need to choose products of a certain brand of concrete. To find out this parameter, you should study the technical documentation. Experts do not advise buying rings if they are made of concrete grade below M200. It is best if the rings were steamed during manufacture.

Design options

There are several design options for a well house. Their shape depends on the original design of the well and the materials used. Based on their shape, all houses can be divided into several types:

The easiest to build is a roof house, which is represented only by a triangular gable roof.

A beautiful house for a well will add a touch of originality and style to your suburban area

More difficult to build are houses in the full sense of the word, which have the appearance of a quadrangular frame and a decorated roof. In the option where the well is made not of logs, but of concrete rings, the base can have a round shape.

A house for a well in the form of a quadrangular frame and a decorated roof

House for a well with carved decorative elements

House for an open well

Well house with a log-frame base

Beautiful house for a well, decorated with flowers

Even typical log cabins can look completely different thanks to different shaped roofs. They can be either gable (symmetrical or asymmetrical), or in the form of a pyramid with a different number of sides, or in the form of a cone.

House for a well with a gable roof

An oriental style roof looks very stylish

Spectacular house for a well with a roof in the form of a hexagonal pyramid

The drawing of the well house, as well as its further construction, will depend on the chosen configuration. The dimensions of the well house should always correspond to the structure of the well itself: a series of concrete rings or a log structure. A roof that is too small will not protect the water in the well from dust, debris and other unnecessary things, and a structure that is too large can make the well inconvenient to use.

If you design a house for a well, focusing on the other objects of the suburban area, you can achieve the creation of a holistic composition

The dimensions of the well house must always correspond to the structure of the well itself

Old-style well house

Various options are being considered as materials for houses:

A wooden well house is valued for its environmental friendliness, affordability, beauty and durability.

The most popular material for wells is wood

Beautiful wooden house for a well with carved elements

Houses for wells made of stone combine especially well with other similarly designed buildings on the site

Stone for wells can be natural or artificial

Stone wells take on a medieval look

Some well owners prefer to use galvanized steel to create a house. Such buildings are quite simple to carry out, but they are not always pleasing with their appearance. It should also be taken into account that a galvanized well house without additional insulation will not be able to protect water from freezing.

A well is not only a place to store water, but also a magnificent decoration of the site

A well house with a brick base will last a very long time

House for a well with a base of concrete rings

Any well is worthy of decoration in the form of carved elements on wooden products, ceramic sculptures on stone buildings, or an interesting design on galvanized structures.

House for a well in a rustic style

Well house with antique design

This is interesting: Examples of design of country wells - we look carefully

Decorative wells made of stone and brick

A well made of stone looks fundamental. Climbing plants are great for decorating a stone base.

The slight effect of neglect gives the building a special charm.

There is an option to use plastic “under the stone”. The advantage is its light weight and mobility.

The composition around the well must be designed in a certain style. In this case, a forest spring.

Beautiful masonry and equipped area around. What more could you want on a hot afternoon!

Brick wells look a little simpler, but they perform a decorative function perfectly.

Design features

The finishing of the structure is selected depending on the style of the entire site and should be combined with the exterior of the main building. It can be made from the following materials: savage stone, wood, concrete, plastic, brick, plaster, using other raw materials. The main thing is that the building material is wear-resistant and does not deteriorate due to temperature changes.

When considering the design of the structure, you should pay attention to the need for periodic maintenance of the well, namely cleaning and disinfection. Accordingly, access to the head should be made free, and decorative elements should not interfere with the implementation of auxiliary work

Ordinary facing materials can look rather dull, so wells are often painted with multi-colored paints, decorative painting is done, which you can freely do yourself, even if you have no painting talents, just use stencils. In addition to painting, you can use floristry and create a composition of flowers around it.

If practical application is being considered, then it is necessary to protect it from the entry of sewage, for this purpose the head is made higher, a blind area is poured around it, it is covered or a roof is installed.

We build a well ourselves: stages of a long journey

If you have decided that it is necessary to build a well on your site, before you begin directly laying it, you need to do a number of fundamentally important actions, in military terms, to carry out reconnaissance on the ground.

Reconnaissance and survey of the local population

The art of finding a water vein using a grapevine slingshot has been well known since ancient times.

At this stage, you will have to become district inspector Aniskin for some time and carry out a number of urgent operational measures:

- Carefully survey local residents about the availability of water and its quality in the immediate vicinity of your site.

- Visit your local geological exploration office and review geological maps for the depth, abundance and quality of local waters, again as applied to your site.

- Independently inspect the area for the presence of plants on it that indicate the proximity of groundwater. These are Norway willow, black alder, large burdock, common plantain and others.

- You can also localize a good place to lay a well if you systematically place a cast-iron frying pan upside down overnight in the area during the summer. Abundant condensation inside early in the morning can serve as a positive signal.

- For additional research, you can contact dowsing specialists or frame framers, who certainly have a positive reputation.

Willow is a time-tested, reliable neighbor to an underground water source.

And a young guy went to the mine: shaft sinking

The work of a digger can be entirely manual

At this stage, you will have to experience all the delights of the hard work of a Stakhanovite shock worker in the domestic mine construction industry.

And almost completely mechanized

The process itself consists of several stages:

- Estuary marking. Do not forget that the mouth should have a diameter of +50% of the cross-section of the main body of the trunk. At the finishing stage, this volume will be filled with clay for waterproofing and covered with reinforced concrete screed.

- Preparing the site for transshipment of supplied soil. Take into account the required loosening coefficient; for clay it is 1.5. That is, when excavating a pillar with a volume of 20 cubic meters. at the transshipment site for loading and removal you will have 30 cubic meters. do not place the dumping area directly next to the trunk of the future well. In order to minimize the pressure of the excavated soil on the walls, place it at a distance of at least 5-7 meters from the work area.

- Take care to ensure ventilation and drainage as work deepens. This is especially true at depths below the horizon of the maximum occurrence of perched water, which is 12-15 meters. Local ventilation can be provided by an axial high-speed fan with an impeller diameter of about 400 mm, and drainage by a low-capacity drainage pump.

- The provision of tools is as follows. To loosen the soil, you need a bayonet shovel, a short hoe, and a cleaver, which is a wide ax mounted vertically on a long handle. To excavate a stone, you need a pair of crowbars of sufficient length to handle the work. For loading, a shovel with a straight and conical edge and a scoop are required. As a universal tool, an American-style shovel.

- Lifting and transferring soil. To facilitate lifting, it is necessary to arrange a simple or double block on a metal or wooden frame. The use of such a system simplifies and facilitates lifting compared to direct manual lifting. Constantly monitor the integrity of the rope and the reliability of fastening the lifting vessel in order to prevent its accidental fall into the face of the shaft.

- Carrying out surveying work related to constant quality control of the vertical axis and diameter. These requirements can be met by using a plumb line and a diameter template, which can be used to carry out constant measurements of the quality of the work performed.

We prepare rings, but not wedding rings

Since the casing of the body of the trunk of the future well in our case will be done using concrete rings, their selection should be taken care of in advance.

With a fairly wide range of concrete rings on the market, finding a quality product in all respects is not at all easy

Important! Recently, plastic rings for lining the walls of wells have appeared on the market. Since there is no experience in the long-term operation of such products in the country, it seems premature to talk about such materials as a full-fledged alternative to traditional ones.

Making well rings from concrete is, if not complicated, then in any case a very responsible procedure. Therefore, take the choice of manufacturer and product quality very seriously.

- The basic, or rather generally accepted, diameter of a concrete ring of this type is 900 mm. It is this diameter that determines the normal operation and subsequent repair of a well made of concrete rings. In addition, the cost of such a product meets the optimal ratio for such an important criterion as price.

- It is worth paying attention to the quality of the ring body, the presence of locking elements, the tightness of the fit, the diameter of the mounting loops and other things.

- It would be useful to make sure of the positive reputation of the ring manufacturer, based on the systematic quality of products and a reasonable pricing policy.

Installation with a manipulator greatly simplifies work in all respects

- Calculate the possibilities of transporting and unloading products at the most reasonable price, and this can be provided by an on-board vehicle with sufficient carrying capacity, equipped with a crane-manipulator unit. Among other things, if such a CMU, in addition to a hydraulic boom drive, is equipped with a winch, then in addition to unloading, you can organize the installation of casing rings directly from the side.

Although manual labor flourishes wildly in the vastness of the country

Montage, how much is in this word

The actual installation of casing elements, when a do-it-yourself well made of concrete rings is at stake, can be done using two technologies. These are direct casing and blast casing. Let's look at them in more detail.

Direct casing is carried out along the finished trunk, starting from bottom to top. In this option, it is possible to greatly facilitate and reduce the cost of installing a well made of reinforced concrete rings by using a manipulative installation and combine delivery, unloading and installation into one complete operation.

However, this technology is possible if the well is driven through stable rocks that do not require fastening, or you can get by with a simple temporary structure supporting the support.

When mounting according to the bottom-up scheme, it is necessary to securely and without distortions place the main ring on the sole, since it ensures the reliability and alignment of the entire barrel set

If the excavation is carried out on unstable, sandy soils, prone to crumbling, quicksand, then casing the walls of the shaft is possible only by casing with blasting. What is it?

As the face advances, the rings are simultaneously lowered, or as experts say, rings move towards it. The rock removed from under the edge of the ring causes its independent movement from top to bottom following the face under its own weight at the initial stage, and under the weight of other rings at subsequent stages of work.

In this case, for the convenience and safety of work, a frame with a block is needed, which will ensure the forward and correct movement of the ring to fit onto the previous one.

The use of stationary block structures greatly simplifies installation and increases work safety

A word from Experienced. When installing rings with undermining, rings with a lock are required. Since the side rocks are unstable, closing the rings will prevent displacement and rotation of the rings, and will preserve the integrity and alignment of the structure, and a well made of reinforced concrete rings will serve faithfully for many years. If there is no locking element, the locking effect can be achieved by welding the mounting hinges and additional embedded plates using electric arc welding. It would be useful to recall the provision of local ventilation and other safety rules when carrying out hot work at depth.

When you are constructing a well from concrete rings, a kind of folk instruction written with sweat and blood categorically recommends cutting the seams where the rings meet each other.

There are several ways:

- This is a clay castle for a well made of concrete rings. It is ensured by laying a clay mortar of enriched fatty high-quality clay along the entire perimeter of the joint.

- Laying a polymer or rubber gasket along the diameter of the ring.

- Using a special waterproofing sealant.

Important! When using polymer, rubber tapes, or sealant for a well made of concrete rings, be sure to ensure that they are chemically inert and safe when in contact with water.

The process of creating a straight filter with a wooden shield

The sequence of manufacturing a well bottom filter is as follows:

- A shield is made with a diameter corresponding to the size of the well. The shield will require durable boards in which holes are specially drilled to ensure water circulation.

- At the bottom of the shield, a 5 cm high beam is attached - these will be the “legs”.

- The finished shield should be lowered to the bottom of the well, and a layer of large stones should be placed on top of it. This is how the shield is secured.

- For the first layer of the filter, river pebbles or gravel are used, for the second - pebbles, but of a smaller size, for the third - quartz sand, and for the fourth - shungite. The optimal thickness of each layer is about 150 mm, but the upper layers can be smaller, up to 5 cm. Thus, the bottom filter will take about half a meter of the entire well depth.

It is quite possible to make such a filter for a quicksand well with your own hands. Do not forget that the bottom filter requires cleaning and rinsing every 6 years. As for the shield, it is necessary in cases where there are quicksand below or the speed of water inflow is very high. It is recommended to make it from wood with antibacterial properties - for example, juniper, oak is also suitable, but you can also use a metal mesh with cells no larger than 2 * 2 mm.

Well care rules

Do not forget about the hygiene of well water supply. Since you use the extracted water for drinking, proper care of the source is important. Follow the guidelines below to keep your well free of contamination:

- If any item is found at the source, it should be removed immediately. To do this, use a long rope with a hook at the end.

- When you have small children in your family, it is important to protect them from falling into the well. Forbid them to run near it, lock the lid.

- Animals often fall into wells. Be sure to pull it out, and then pump out the water and disinfect the source. Then it can be refilled with water. To prevent the animal from falling, create a fence.

- It is necessary to carefully inspect the source annually, and ideally twice or thrice a year, to detect contamination on the walls. To inspect, you will need a bright flashlight; you need to lower it into the well and inspect the walls.

- To prevent particles of dust, leaves and other contaminants from getting into the well and to keep the water clean, always cover the source. To do this, you need to equip a wooden or plastic cover. The optimal solution is to build a special house with a mini-door yourself.

When you plan to go down into the well, be sure to take an assistant with you to help you at the top. To go down at 11:00 you will need a strong ladder or rope.

Before going down, make sure that no toxic gas has accumulated in the well. To do this, light a candle and lower it on a rope. If the candle flame below has not changed, then everything is in order. But when the candle goes out, it means that the gas concentration exceeds the permissible values. Do not go down into the well under any circumstances, this can lead to death!

How to remove gas accumulated in a well? To do this, use a home vacuum cleaner. You can also use a potbelly stove, but the effectiveness of this method will be lower. It is placed next to the well, a pipe is inserted into the ash pit and lowered to the water's edge. Then you need to heat the stove strongly, then the gas will come to the top.

If after checking it turns out that there is no gas in the shaft, start cleaning the well. To do this, you need to go down and use an iron brush to remove moss and dirt from the walls. After this, use a fine mesh to collect debris from the bottom. After this, you need to wash the walls with water. At the bottom of the well there is a sand and gravel filter layer. It needs to be replaced, or you can take out the old filter, wash it and lower it to the bottom again. The final stage is disinfection and removal of water. The liquid may have to be pumped out 2-3 times before the well can be used.

Periodically, the water in the source stagnates. This happens when the well is not used actively enough. This water is not suitable for drinking. To clean the source, the stagnant liquid should be pumped out. To prevent this from happening, a ventilation pipe with a cross-section of 0.2 m is lowered into the shaft. It is important that its lower end does not reach 15 cm from the water, while the top of the pipe should exceed the edge of the well by 1–1.5 m. To prevent debris from entering into the pipe, the upper edge should be covered with a mesh.

Remember that it is important to regularly take your water for laboratory analysis. Even if the liquid at first glance seems clean and does not smell of anything, its chemical composition may be far from ideal.

;

Water supply

Did you find this article helpful? Share it with your friends:

How to make a water supply mechanism

There are 2 types of structures that can be used to manually raise water. It is worth highlighting the following:

- "crane";

- "gate".

You can make a “crane” for your own well, but it will require a lot of space. It is quite difficult to install, so it is rarely used. But to install the “gate” you will need 2 pillars; they need to be dug into the ground immediately after the well is brought to the surface. In order to prevent rotting, it is useful to coat a wooden post with a special compound. It can be replaced with resin.

First, the pillars are coated 2 times with a liquid composition, and then 1 layer of thick resin is applied. The pillars should be made of coniferous trees, then they will not require repairs for a long time. This material is less susceptible to rotting.

It is quite easy to make a concrete head with your own hands and equip it with a wooden roof. If the well shaft is made of brick or monolithic structures were used in construction, then they may contain embedded parts. For example, a sewer can be made of concrete rings with factory-installed embedded parts. They can be used to securely fix supports. The step-by-step instructions are as follows:

- It is necessary to measure the stand welded to the embedded reinforcement. The plate must be bent to its size.

- Using long self-tapping screws, the timber must be attached to the plate. Self-tapping screws can be replaced with nails. If there is no plate, then instead you should put a piece of pipe with a square cross-section. It is selected taking into account the size of the timber.

- In order to install pillars for a well with your own hands, you need to dig holes. Their diameter depends on the diameter of the pillar. The depth of the pit is 1.3 m. Before installing the pillars, you need to prepare the bottom of the pit. First you should pour sand, forming a pillow. It is enough to make a layer 20 cm thick; it needs to be compacted well. Then the bottom must be covered with a piece of roofing material, overlapping the walls. It is necessary to pour a 30 cm layer of concrete at the bottom of the hole. Ruberoid is required so that water does not escape from the concrete into the sand.

- The pillars must be completely covered with antiseptic impregnation. When it dries, the end is wrapped with waterproofing material. You can replace it with roofing felt. The pole is placed in the hole, and the vertical installation is adjusted using a plumb line. Then it is fixed with spacers and the hole is filled with concrete mortar. Allow 2 days for the foundation to dry, then proceed to further work.

The well gate is made of smooth logs and is a rotating drum. It is best made from hard wood. Ash is perfect, but you can use beech or more expensive oak. To remove friction, the drum needs to be made 40 mm less than the distance between the supports.

Making a gate for a well with your own hands is quite simple. You need to find a central point at the end of the drum and make a hole 50 mm deep. The hole must be drilled on the other side as well. Through holes of the same diameter should be made in the gate posts. They need to be strengthened; for this you can use steel bushings. After this, a handle is attached to the collar. Since high-quality drilling is quite difficult to do, it is easier to order the gate from a workshop.

At the last stage of arranging the head, it is sheathed. If the log house is made of calibrated logs, then it already has an excellent appearance. It is enough to make a roof, equip the source with a mechanism for raising water, and hang a door. If desired, the structure can be decorated with carvings.

The head of the manhole does not require decoration; the space around the shaft can be filled with concrete mortar.

Drinking water well heads made of other materials require additional finishing. The easiest way is to sheathe the surface with a board; you can use clapboard or material that imitates timber.

First you need to make a frame by purchasing a beam with a section of 50x100 mm. The structure, made for the well with your own hands, should be attached to the gate posts; it can be fixed to the concrete wall of the shaft. Next, the frame needs to be sheathed and the missing elements attached to the gate posts. The casing can completely cover the head, imitating a well house. The door will be on the roof.

https://youtube.com/watch?v=e7-qcjc0ZiA

If you wish and have free time, you can cover the head with a well house in the form of a mill. There are a lot of design options, so it’s worth choosing a drawing in advance

It is important to take into account the landscape design of the site and the style of other buildings

The head of a concrete well can be lined with ceramic mosaic. A house made of natural stone looks impressive.

Wood cladding

Today, finishing a well with wood and other lumber has become widespread. This is a simple and high-quality method. For the external decorative finishing of wells, various lumber is used:

- Edged board.

- Gorbyl.

- Logs that have undergone rounding

- Profiled timber.

No matter how the option for facing work is chosen, the final result is influenced by the imagination of the owners or workers. Today, cladding that uses profiled timber is considered very popular.

Decorative finishing with this material occurs as follows:

- We remove soil and vegetation along the perimeter of the ring. Length – 1-1.15 m.

- We create formwork from boards.

- We cover it with a reinforcing mesh made of thin rods.

- We create the composition: cement - 3 shares, sand - 5 shares, fine crushed stone - 4 shares.

- We fill and level the formwork. The height of the base should exceed the ground surface by 15-20 cm.

- We are preparing the material for the bottom trim. We give it a square shape. We use two whole timber and one half timber.

- The side of the beams that will be in contact with concrete is covered with bitumen mastic in one layer.

- First we put in half material. The placement of the halves in relation to each other is parallel.

- We have a whole range of options for them. From their corners we determine the connecting bowl to be half a tree. This results in an angular mounting into the paw:

- We attach such connections to the concrete base using wooden dowels. For this task, we make a through hole in the timber that goes into the concrete.

- We make dowels from the beams using the planing method. The dowels are twice the thickness of the timber. We drive them with a sledgehammer into the pre-made holes. We remove excess wood flush with the plane of the beam.

- The second line accommodates entire variants with designated corner mounting.

- In the first and second lines we connect the timber with dowels. The pins of the second line are slightly shifted in relation to the pins of the first line.

- When we bring the timber up to the plane of the ring, we create a frame from the boards. We attach a hatch to it. This is a defense against debris entering the mine.

- The stone is fastened on any surface that is flat and also well prepared.

- To do this, there are certain instructions according to which a number of works are performed.

Selection of finishing materials

The work can be done using different building materials. Each of the selected options has its positive and negative qualities. In order not to make mistakes and make the right decision, it is necessary to evaluate the components used.

Tree

Wood can be called a classic material; it is suitable both for finishing mines and as a basis for the head, well pillars, and roofing. With its help, decorative finishing is performed, for example, carving, painting, complemented by a pattern or image.

Wood cladding has its own characteristics:

- The material is inexpensive. It can be found at the market, in construction stores, and at sawmills.

- Raw materials are amenable to processing. Allows you to create beautiful structures that will harmoniously fit into the overall style of the dacha. A tool for the job can be found in almost every home.

- For landscaping, you can use ready-made finishing products, for example, imitation timber (false), lining, blockhouse. Such components can significantly reduce the time spent on work and get excellent results.

- The design can be additionally decorated with original carved elements.

- It is better to install a roof over the shaft, which will protect the recess from precipitation, leaves, and other foreign objects. In addition, it is an excellent decorative element.

Decorating a treasure trove with wood is an excellent option. However, the building material has two important drawbacks - poor resistance to humid environments and is a good food source for pests. Therefore, before using raw materials for cladding, it must be treated with special varnishes and antiseptics.

Brick and its varieties

There are several types of such building materials - silicate, ceramic, raw. The building can be finished with any of the above. For example, red brick will give the object a bright color and will look good on a summer cottage. A universal material is the version made of baked clay. You can either cover the finished head with it or completely build it.

To build a brick well or its cladding, you must adhere to certain rules:

- The arrangement is made only from raw materials that have a solid structure.

- The material absorbs moisture, so the surface must be periodically treated with water-resistant varnishes. Apply a layer of plaster, when it dries, additionally rub in cement.

- For work, it is advisable to use the same building material that covers the outside of the house.

- The masonry is made in both round and square shapes. The first option uses less raw materials.

- The width of the masonry should not exceed the size of two bricks (25 cm).

Stone

Stone structures are popular. Decorating a building with such material costs much more than the options considered. But the result is worth it. The result is a stylish structure with increased wear resistance.

The main characteristics of such cladding are as follows:

- For work, you can use both natural and artificial stone.

- Small rounded stones and large cobblestones are used for decoration.

- The material is used to finish the shaft and head.

- If the work is done efficiently, the building will last for decades.

- To emphasize the structure, you can lay a path to it from the same building material, and install a roof covered with metal tiles on top.

Finishing materials and their combination methods

In addition to the options listed, you can use plastic or siding. Registration is completed quite quickly. Porcelain or ceramic tiles look good. It can be smooth or rough, matte or glazed, antique. Separately, we can distinguish clinker tiles, consisting of burnt slate clay. Over the years, this material does not change its external structure, is resistant to moisture, and resembles brickwork.

If you choose the option of conventional painting and plastering of the structure, then you do not need to use wood, brick or stone for cladding. It is enough to clean the surface of the concrete ring, plaster it, cover it with a layer of primer, and paint it. Also, plaster is often used for brick buildings, and painting in its pure form is often used for wooden ones.

Metal and forged elements are mainly used for posts and roofing. Often combined designs are made, for example, barrel heads made of wooden slats, tied with metal rings.

Features and application in design

A well in landscape design can perform several functions, so it is used not only for decorating the area. This design is most often a source of clean fresh water. To hide wells or mines that are drilled in a summer cottage, they are improved by constructing a well frame, allowing not only to give a spectacular appearance, but also to protect drinking water from clogging.

In addition, the structure can be erected to disguise some technical elements on the territory, for example, sewer hatches, storm drains, water barrels. An excellent reason for construction is the need to store equipment for maintaining the site or to hide numerous hoses for watering.

Did you know? In Ancient Rus', wells were made in the shape of a bottle, because they accumulated water very well. But over time, it was decided to build a high above-ground part, because if a person fell into a well of the original type, it was impossible to get out of it.